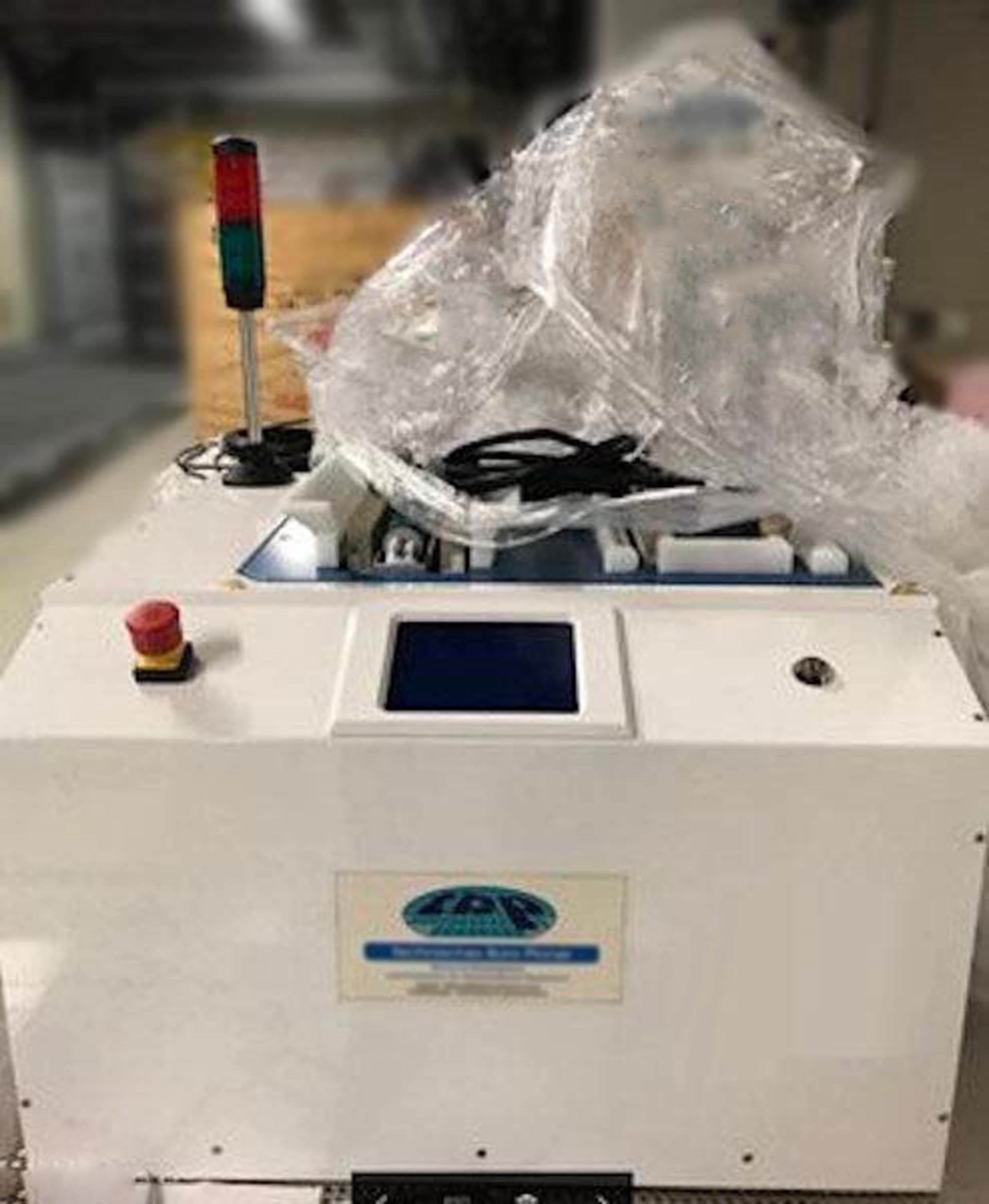

Used TB-PIONEER QBL 150 #9180969 for sale

URL successfully copied!

Tap to zoom

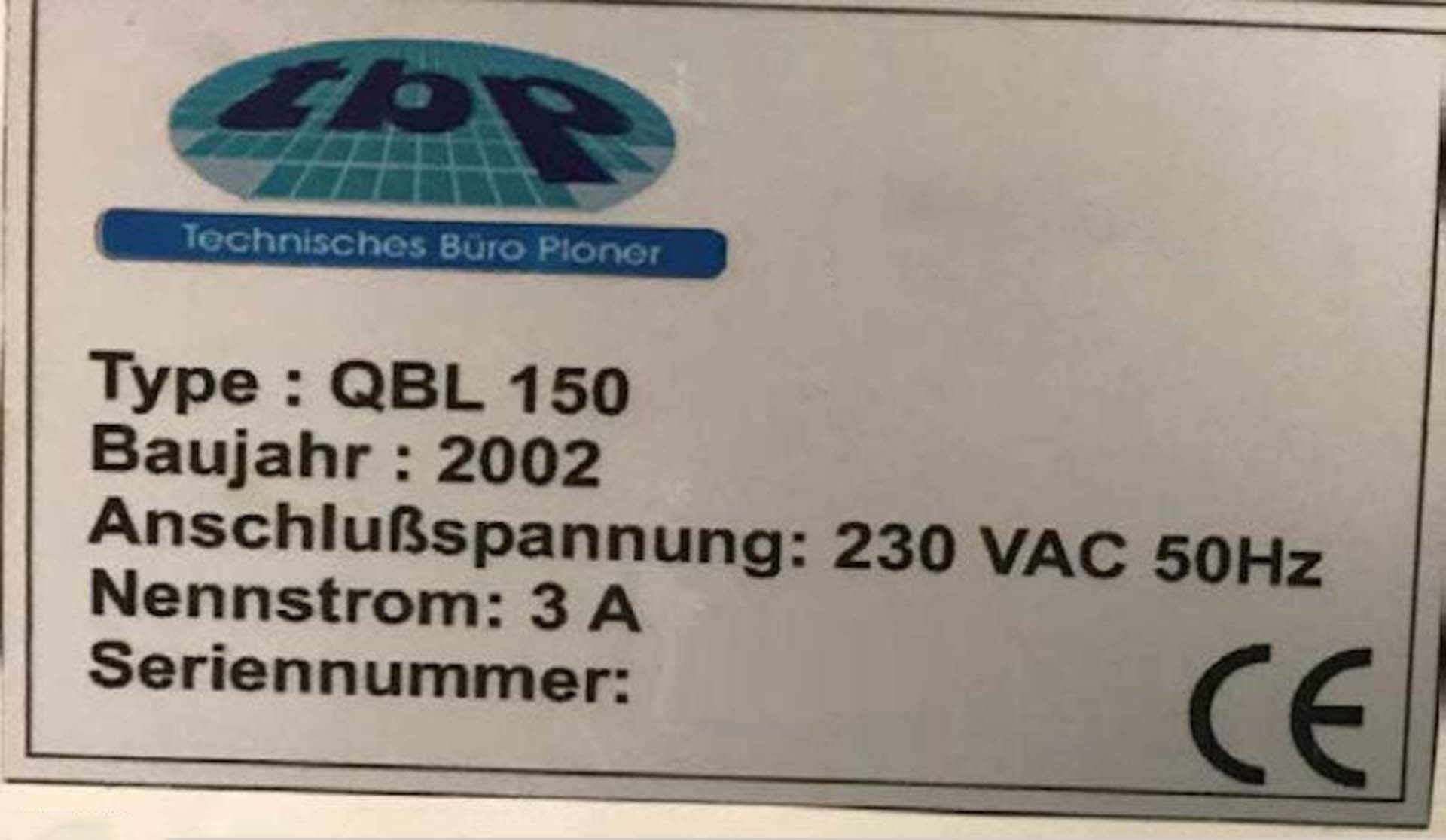

ID: 9180969

Wafer Size: 6"

Vintage: 2002

Quartz boat loader, 6"

Capable of wafer transfer: Plastic to quartz

Cassette to quartz

(2) Cassette stations:

Mechanical wafer notch / Flat aligner

Gripper mechanism

2002 vintage.

TB-PIONEER QBL 150 is a powerful and reliable automated wafer handler designed for use in a wide variety of semiconductor manufacturing applications. The device can be used to transport and handle wafers of up to 8-inch diameter and 0.3mm thickness. It has a 200mm x 200mm x 40mm routing slot that allows for efficient handling of wafer lots, providing increased productivity. Additionally, the device integrates an innovative vacuum clamping equipment, which ensures that the wafers are always firmly secured during transport and handling. QBL 150 integrates a robust and efficient motor drive system, featuring an AC main motor along with an optional stepper motor and servo drive. It also features a precise linear motion platform with a stable, synchronized movement to ensure accurate and consistent wafer transport. The device has a wide range of adjustable parameters, allowing for greater flexibility when dealing with a range of wafer lots. Additionally, the device is equipped with an advanced, easy-to-use software package, providing quick access to all programmable parameters. TB-PIONEER QBL 150 is engineered for reliability and durability in demanding production environments. It is constructed with top-grade materials for superior performance and is designed for easy maintenance, providing hassle-free operation. The device also features advanced safety features to protect against damages or losses caused by human errors. Furthermore, the device can be integrated with a wide variety of other systems, including optics, lasers, gas supply systems, temperature regulation systems, etc., allowing for precise control and unit-level automation. In conclusion, QBL 150 is an advanced and reliable automated wafer handler that can deliver consistent performance in a variety of production environments. It provides fast and efficient wafer handling with a wide range of adjustable parameters, precise linear motion platform and innovative vacuum clamping machine. The device is designed for easy maintenance and integrates a variety of safety features. Additionally, it can be integrated with a wide variety of other systems, providing the user with full tool-level automation.

There are no reviews yet