Used YASKAWA XU-F3000-CN04 #293614933 for sale

URL successfully copied!

Tap to zoom

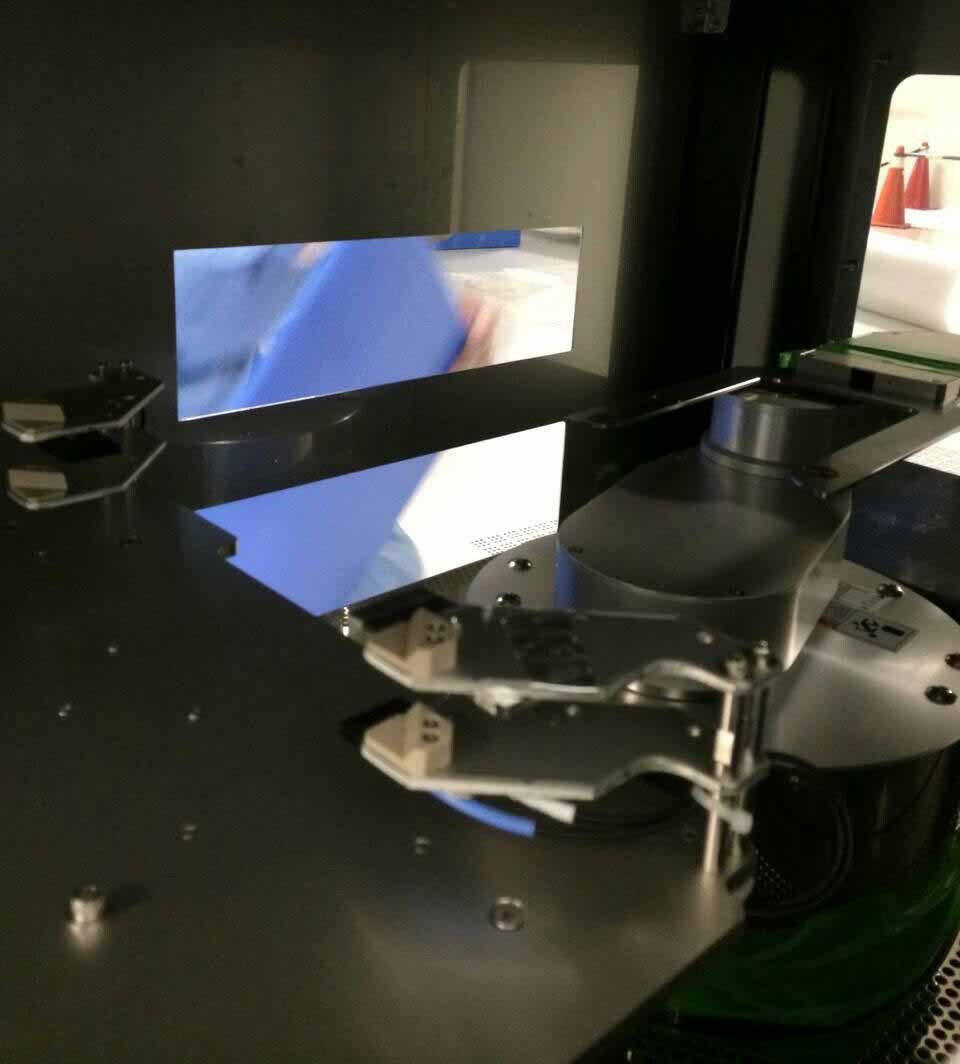

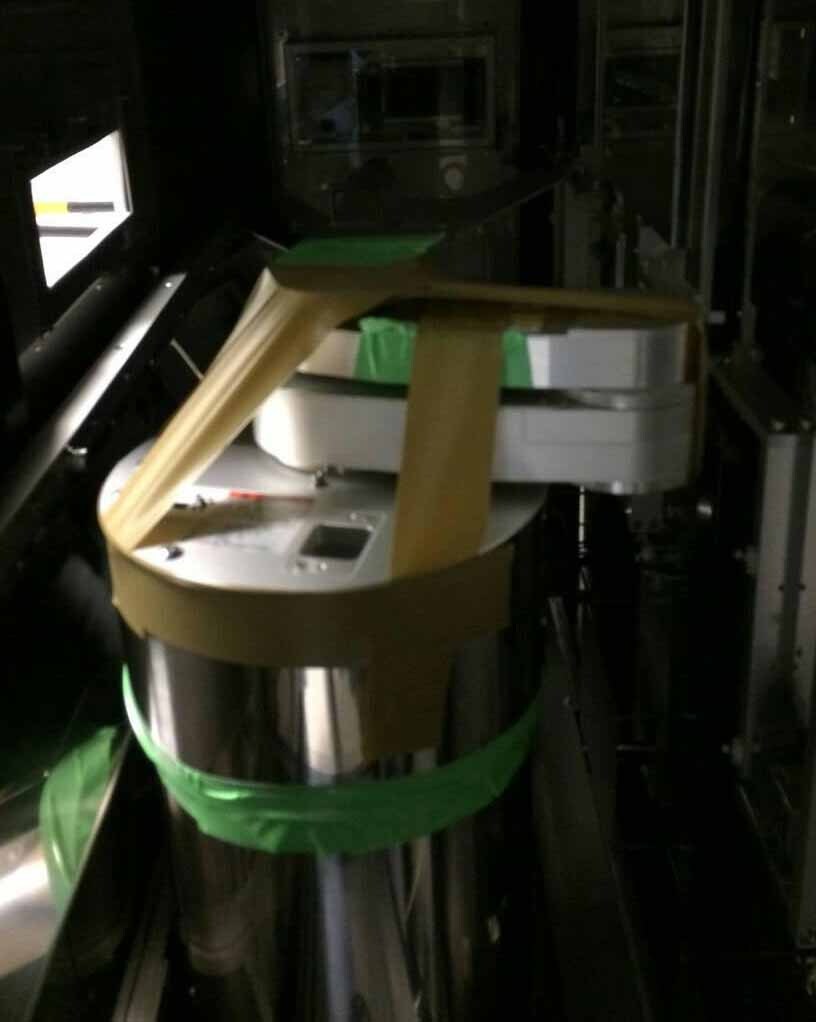

YASKAWA XU-F3000-CN04 is a digital wafer handling equipment designed to meet the needs of production fabs and research labs. The system's small footprint allows for the use of a number of other modules and components on the same production line. XU-F3000-CN04 is equipped with an advanced feedback control unit that helps ensure precise, repeatable operation and does not require any programming or setup. The machine boasts a four-axis drive, which eliminates the need for manual positioning and ensures precise wafer movement. Each of the four axes is equipped with its own drive motor and independent encoders, making it highly modular and adaptable to a wide range of applications. Additionally, its robust mechanical design is capable of handling a load capacity of up to 250lbs, making it suitable for a wide variety of wafer-handling processes. The pre-programmed control tool provides precise motion profiles so that wafers are not damaged or significantly misled during wafer transfer. The asset's unique motion control is based on linear interpolation, enabling it to accurately position wafers within an accuracy of five microns. To ensure accuracy, repeatable results and high throughput, the model utilizes a variety of sensors and feedback devices. YASKAWA XU-F3000-CN04 also offers a range of safety features designed to protect wafers and personnel working on the line. The dual gate door interlock equipment ensures that both gates are securely closed before production can begin, reducing the potential risk of injury. Additionally, the system comes with an automatic shutoff feature that halts the unit if the sensors detect any anomalies, reducing the risk of accidents or equipment malfunction. Overall, XU-F3000-CN04 is a highly capable and reliable wafer handling machine that is suitable for a variety of applications. Its advanced feedback control tool and dual gate interlock asset ensure accurate, repeatable motion and protect personnel and wafers from potential risks. In addition, its highly modular design allows for the integration of additional modules and components on the production line, making it an ideal choice for persisting in the development of semiconductor production.

There are no reviews yet