Used ASML 5000 / 55 #9049734 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

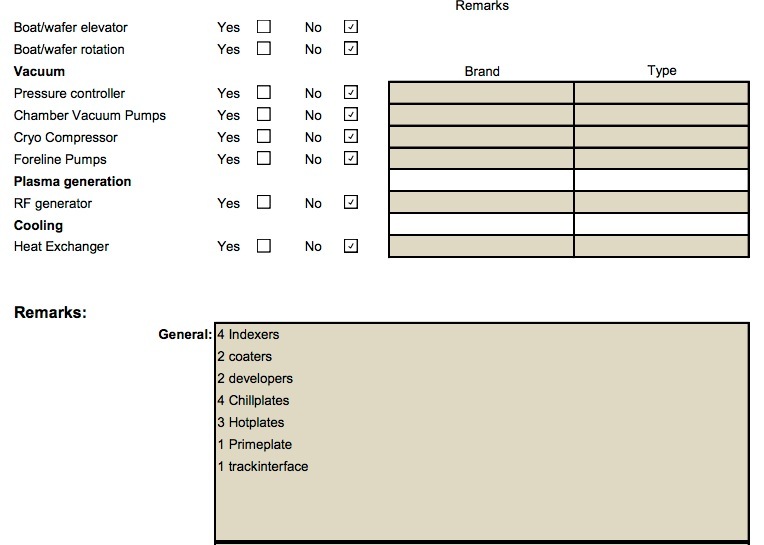

ASML 5000 / 55 is a wafer stepper that is used in the production of semiconductor products. It is a highly advanced, lithography-based tool that is capable of imaging tiny features onto a substrate. ASML 5000/55 is an electron beam (e-beam) lithography equipment that utilizes a scanning electron column and two stages of optics to image patterns onto a wafer or chip. The e-beam column utilizes a high voltage beam to focus and deflect electrons onto a surface, where it creates an image. The optics stages magnify and focus the beam to create an image with extremely fine resolution. 5000 / 55 is capable of imaging feature sizes as small as 4nm, which is essential for developing ever-smaller and faster microprocessors. It is designed for high-volume production and can handle up to 6" wafers with a cycle time of as little as 5 seconds per wafer. The system is composed of several individual components, including the electron column, optics stages, beam blankers and optics shutters, vacuum systems, and a wafer transport unit. The electron column is a precision mechanism of high voltage electronics, electromagnets, and components used to create and direct the electron beam. The optics stages utilize a variety of elements to ensure that the beam is manipulated in such a way that it creates the desired features on the substrate. The beam blankers and optics shutters are used to limit the point of interaction between the beam and substrate, while the vacuum machine creates a low-pressure environment ideal for imaging. Lastly, the wafer transport tool, in conjunction with the optics shutters, ensures that the substrate is securely held in place during the imaging process. 5000/55 has a footprint of less than 6 square meters and is considered relatively compact for a asset of its capabilities. It is easy to install and operate, but the complex mechanics and engineering required to create the necessary vacuum environment and maintain the high voltage within the column requires some technical expertise.

There are no reviews yet