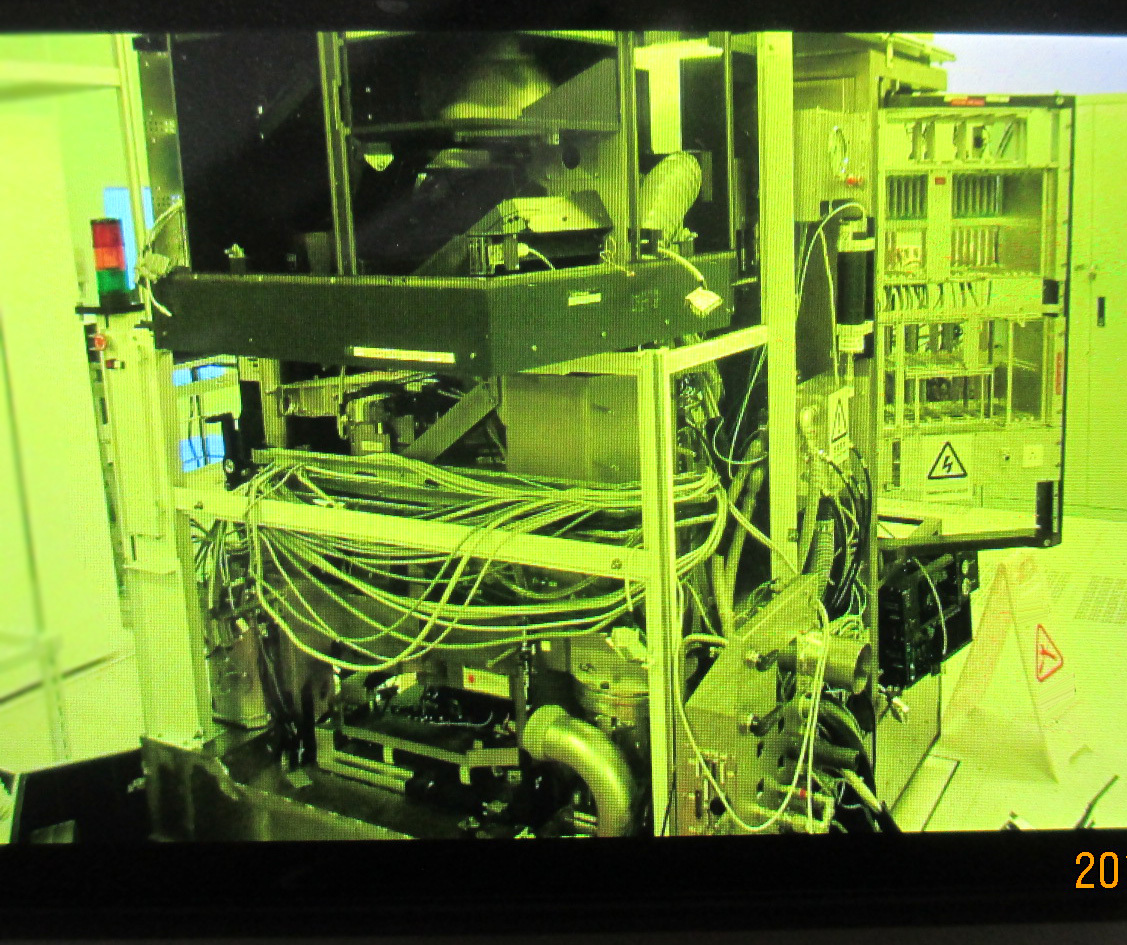

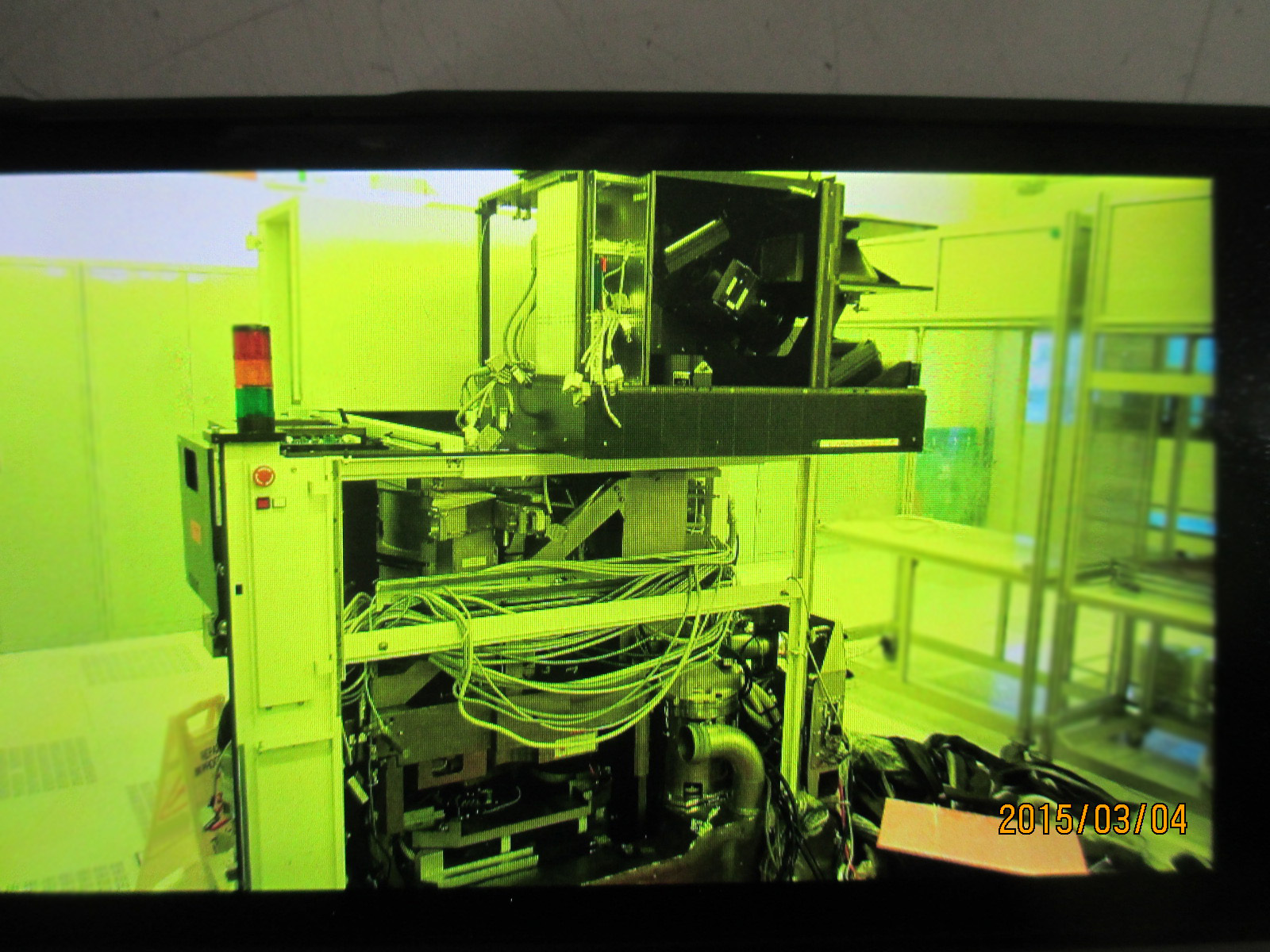

Used ASML 5500 / 60 #9092942 for sale

URL successfully copied!

Tap to zoom

ID: 9092942

Vintage: 1992

Stepper

Parts machine

Existing spare parts:

Main frame

Projection lens

Lamp house (lost shutter motor,some lens)

Level sensor

RMS

Wafer Prealignment system frame

Currently stored in a cleanroom

1992 vintage.

ASML 5500 / 60 is a wafer stepper used for photolithography in semiconductor production. It is a highly precise, automated imaging apparatus used to shape integrated circuits and other microscopic features on the surface of semiconductor chips. The machine is essentially a large microscope employed to accurately expose circuits and other patterns onto the wafer substrates. Photomasks are aligned and focused over the subject wafer and selectively exposed with a light source through a quartz optical window. The precision required to produce such patterns requires intricate alignment and tremendous accuracy, and 5500 / 60 is equipped with an array of technologies to achieve this. ASML 5500 / 60 is equipped with piezoelectric rectilinear stage mechanisms, providing smooth linear motion with micron-level resolution. Several compensation methods and sensors make precision movement possible, including encoder-assisted stage controllers, interferometric-level stepping, and optoelectronic focus detection, all of which enable the machine to accurately transfer patterns onto the wafer. The system is also equipped with automatic alignment in which the mask is compared to the wafer to ensure accurate placement. For processing, 5500 / 60 features a variety of light sources, numerical apertures, and exposure times which can be easily configured and adjusted. The machine is further equipped with a specialized laminar stage that moves parallel to the substrate surface, increasing levelness and allowing the optics to pass through different depths for variable overhangs. ASML 5500 / 60 is also equipped with robust safety features, such as emergency shut-off systems and an auto-retrieval feature that can quickly bring the subject wafer back to the start position should anything interfere with the wafer transport. Other features include a graphic user interface, built-in insulation and environmental controls, active vibration reduction, and post-exposure image analysis for enhanced quality control. In conclusion, 5500 / 60 is a versatile and precise wafer stepper used to shape integrated circuits and other microscopic features on the surface of semiconductor chips. The machine is equipped with an array of sophisticated motion, alignment, and safety features, all of which allow for a highly efficient and collaborative lithography process.

There are no reviews yet