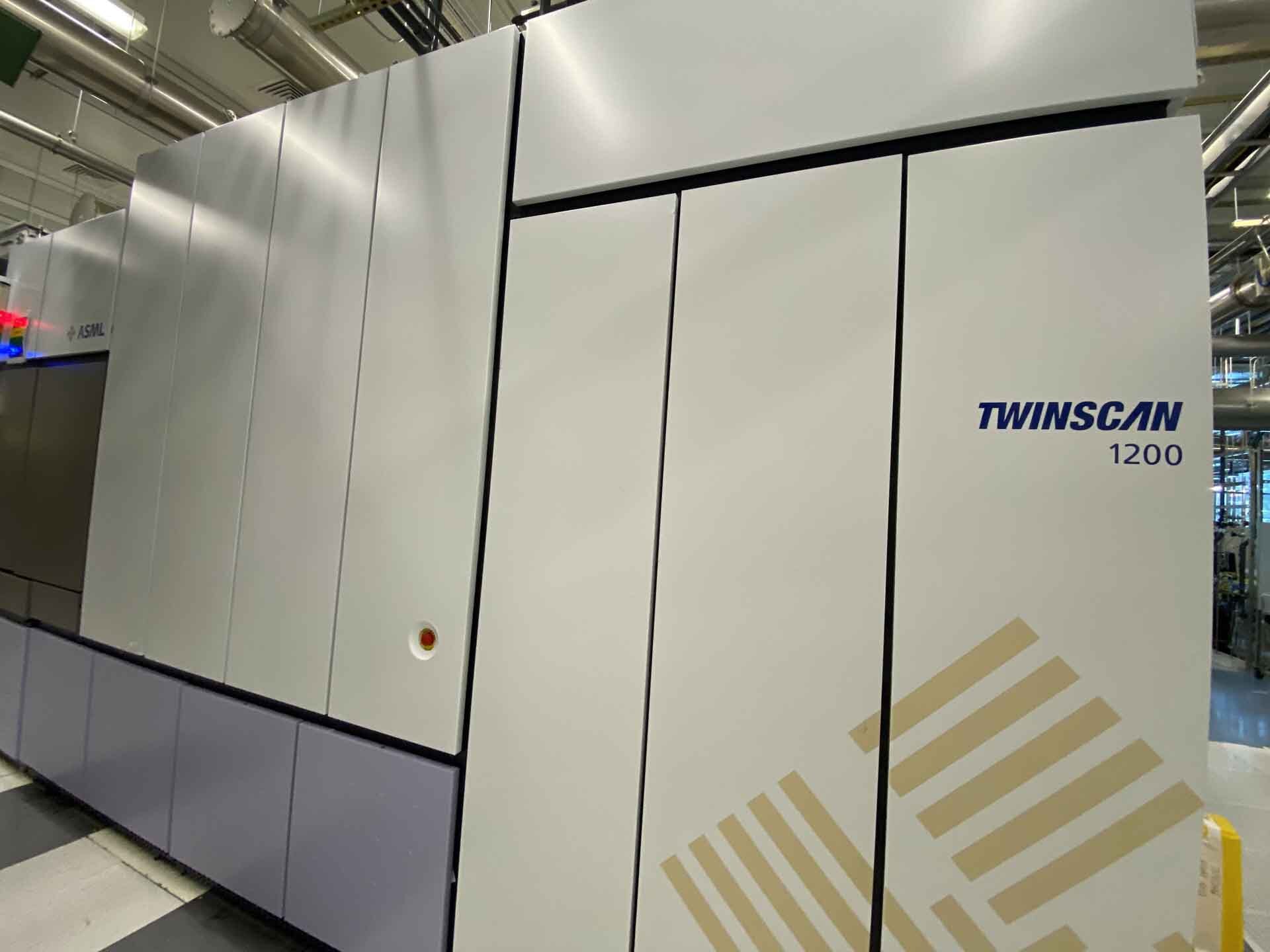

Used ASML AT 1200B #293602555 for sale

URL successfully copied!

Tap to zoom

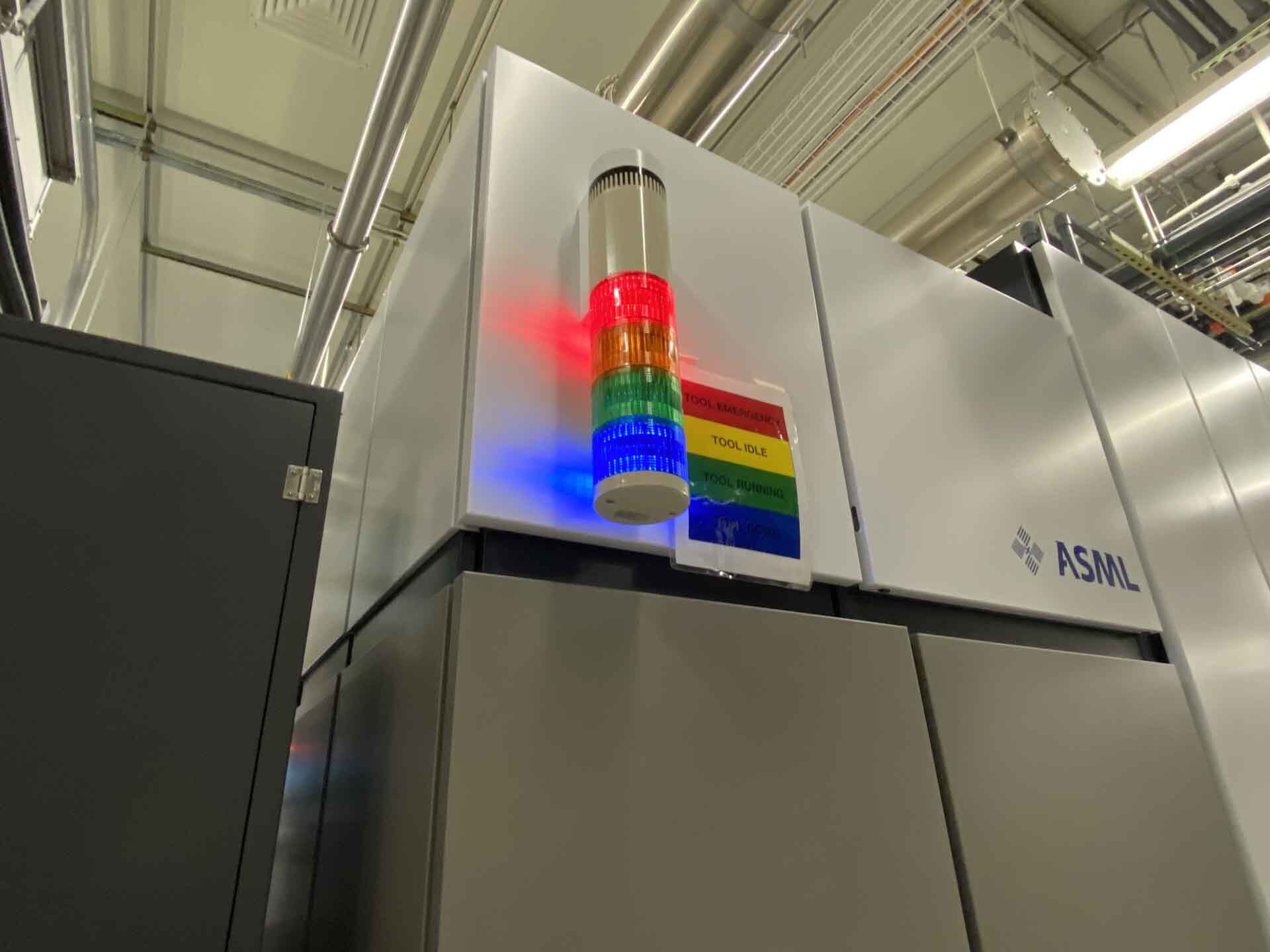

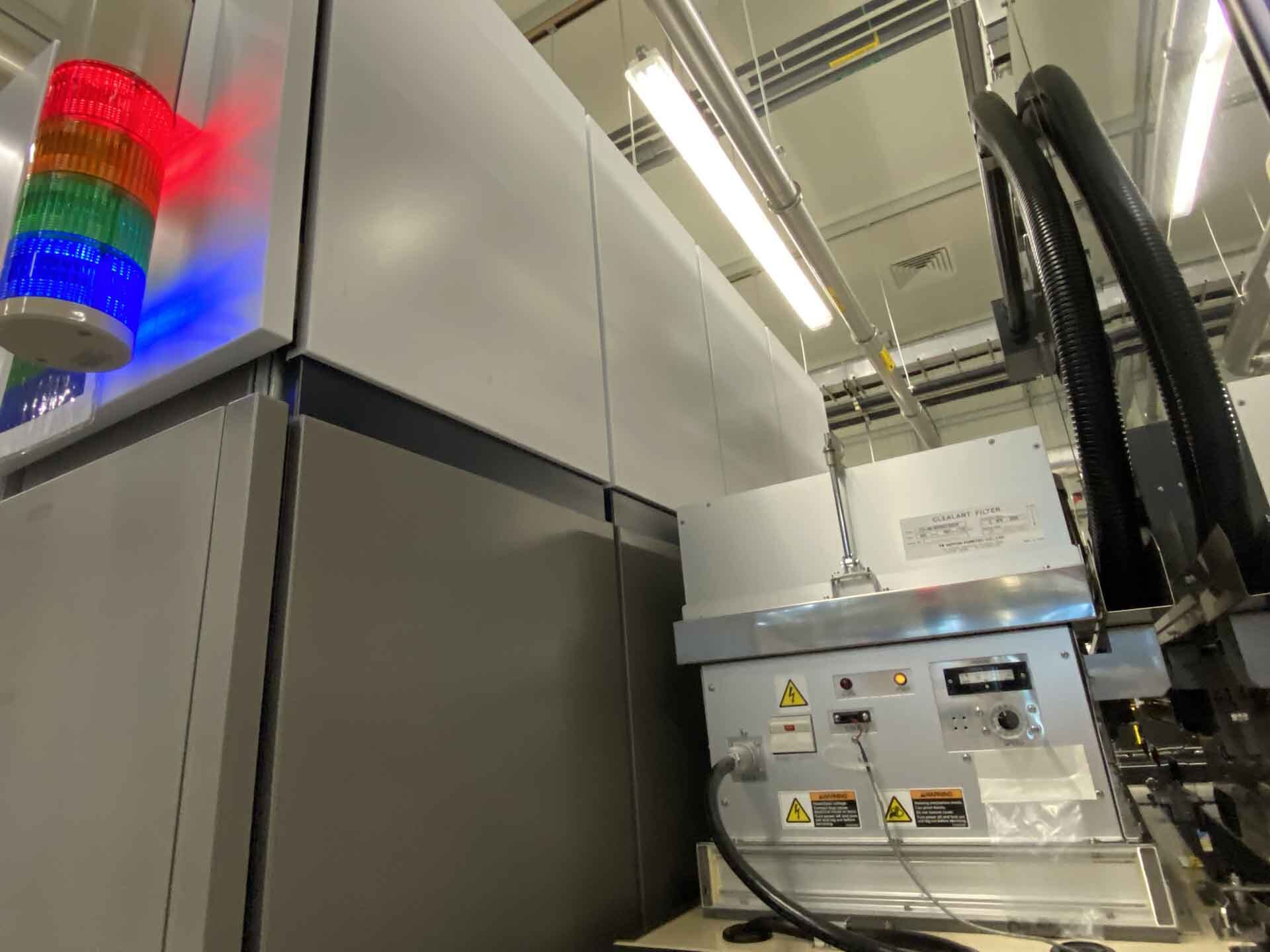

ASML AT 1200B is a state-of-the-art wafer stepper used for lithography in semiconductor manufacturing. It provides a high level of accuracy and reproducibility, which is essential for patterning the nanoscale structures on modern ICs. The wafer stepper is made up of a few distinct parts. Its optics module contains several different lenses, including the reticle objective lens, which focuses the imaging light onto the photoresist coated wafer. The reticle is held in a reticle holder and scanned in a precise pattern over the wafer. A wafer stage is used to translate and rotate the wafer under the imaging optics. The stepper also has an illumination system with a movable xenon lamp, allowing for precise adjustment of the UV light energy used to expose the photoresist. A camera system is also included for automatic alignment and monitoring of the patterning process. The stepper is operated by a computerized controller module, which includes a user-friendly graphical interface for setting up and managing the stepper's process parameters. This allows for a high level of precision, repeatability, and flexibility in adapting to new fabrics or process settings. The stepper also includes multiple built-in safety features to ensure that it operates properly and prevents any damage to critical components or exposures. In addition to its accuracy and repeatability, the stepper's modular design allows for easy installation and maintenance as well as separate electrical and mechanical components for faster and more effective repairs. The stepper is ideal for production settings due to its advanced imaging algorithm technology and ability to quickly and reliably pattern wafers. Overall, ASML AT-1200B is a highly accurate and sophisticated wafer stepper built to achieve the highest level of lithography performance. It is capable of producing extremely precise nanoscale patterns and provides a high level of speed, accuracy, and repeatability for modern IC production processes.

There are no reviews yet