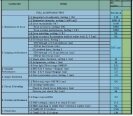

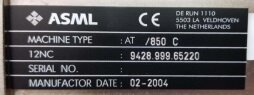

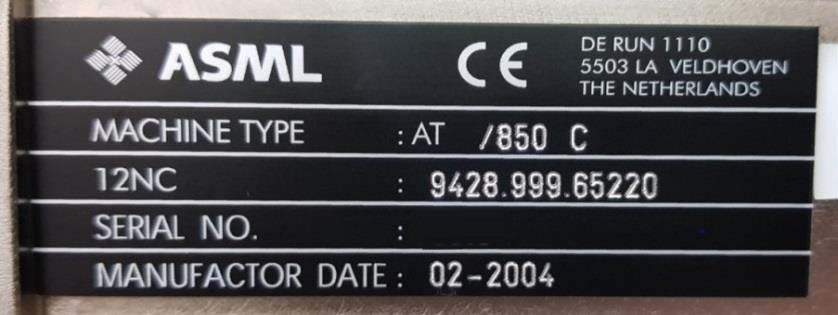

Used ASML AT-850C #9269680 for sale

URL successfully copied!

Tap to zoom

ID: 9269680

Stepper, 12"

SMIF

SECE I / II

Reticle size: 6"

Wafer type: Notch

Left inline flow

FOUP Left type: WH

MK V Type: RH Library

PPD Type: PPD2 + IRL

BMU Type: Standard

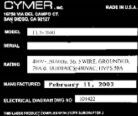

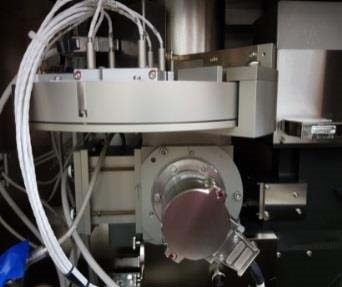

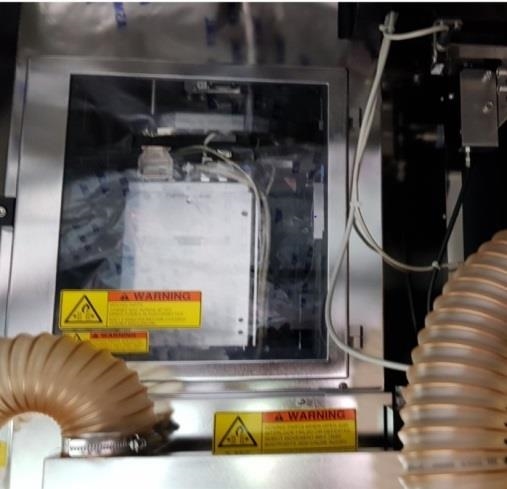

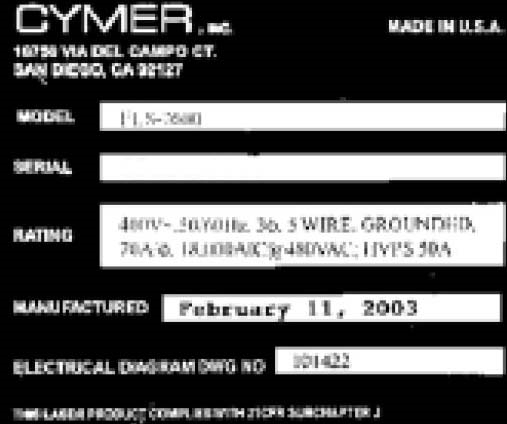

Light source: CYMER

Scan speed: 320 mm/sec

Chuck

2004 vintage.

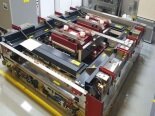

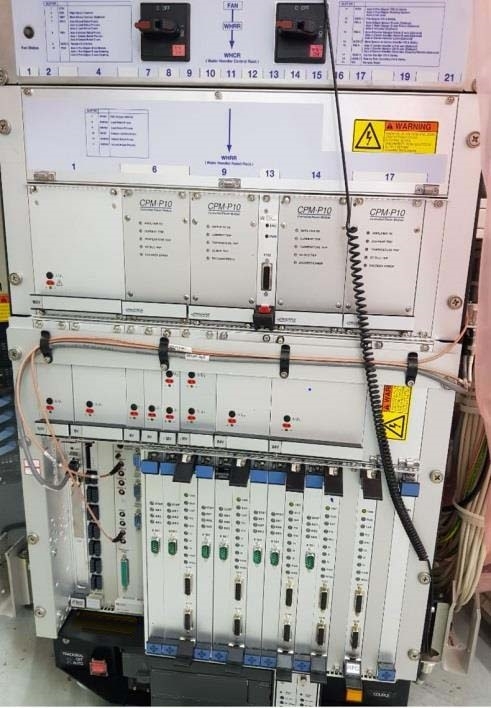

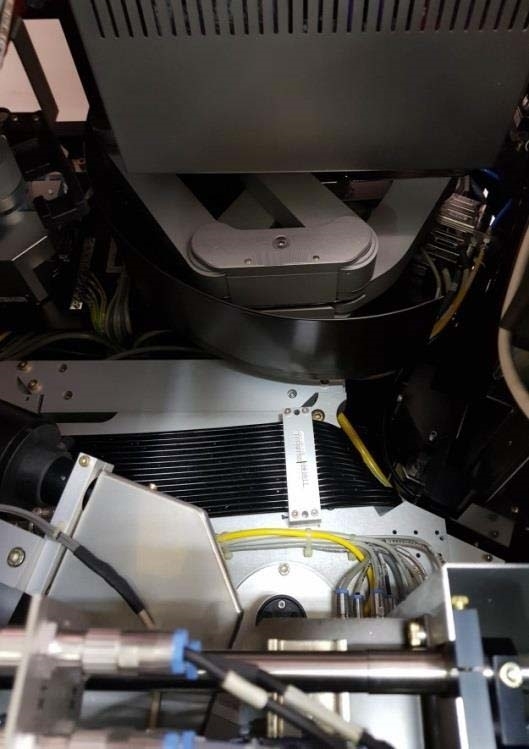

ASML AT-850C is an advanced wafer stepper designed to accurately and precisely define microscopic patterns on the semiconductor industry's latest generation of semiconductor wafers. By projecting light onto thin layers of photoresist deposited on the wafer, it is possible to create precise patterns that form the basis of silicate components used in integrated circuits. ASML AT850C is a fully automated scanner, which scans the entire wafer field in one rotation, allowing the image to be projected on the full surface area of the wafer in one shot. This allows for efficient and consistent photolithography. This system possesses a stage size of 350mm, which allows for a number of different wafers to be placed onto its stage at one time, enabling multiple processing runs. AT:850C has been designed with advanced features for higher throughput instances. This includes an integrated, robust Litho Inspector, which can monitor for patterns, defects, and other lithographic issues during production runs. The wafer stepper has advanced stages which provide ultra-stringent control of alignment for even the smallest features. The stages can also perform processes at two different rotation speeds, which gives the user better control over multiple processes. ASML AT 850C also features a number of methods of illumination, including Laser Direct Imaging (LDI) and Photolithography Imaging (PI). Using either of these imaging methods, it is possible to create high-resolution images by exposing different areas of the wafer to different levels of optical radiation. Features as tiny as 0.35 microns can be resolved, allowing AT 850 C to produce highly intricate and detailed silicon components. ASML AT 850 C also possesses advanced synchronous and asynchronous motion controls and dynamics, which allow for extremely fast scan speeds and repeatability. The system is based on a modular platform, meaning it can be tailored to specific applications and processes, giving complete flexibility to the user. Finally, AT850C is an extremely rugged, robust, and reliable stepper, which is constantly undergoing stringent quality assurance testing to ensurethat it is always running at peak performance. With its advanced features and production capabilities, it is one of the most technologically advanced wafer steppers available on the market today.

There are no reviews yet