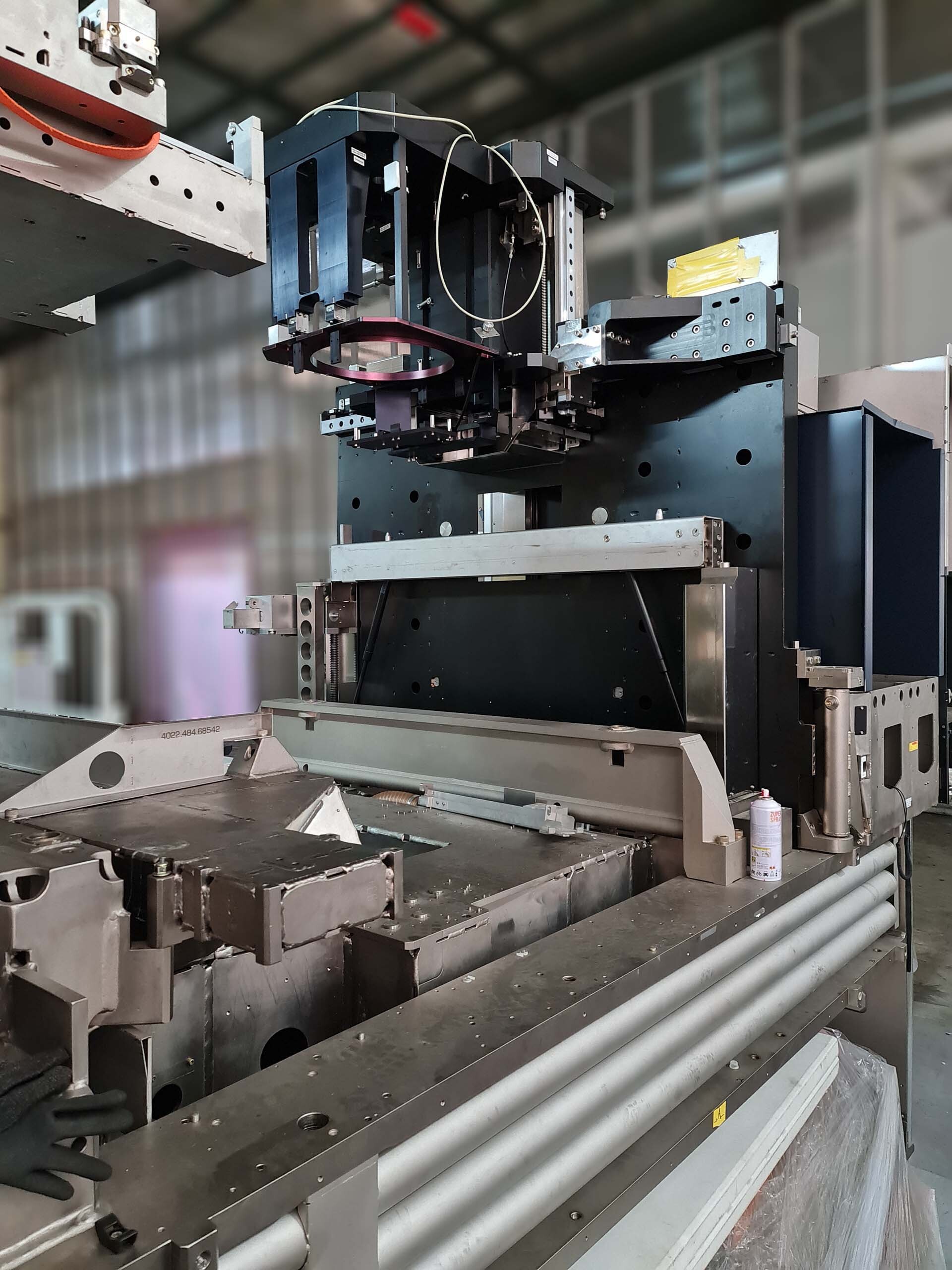

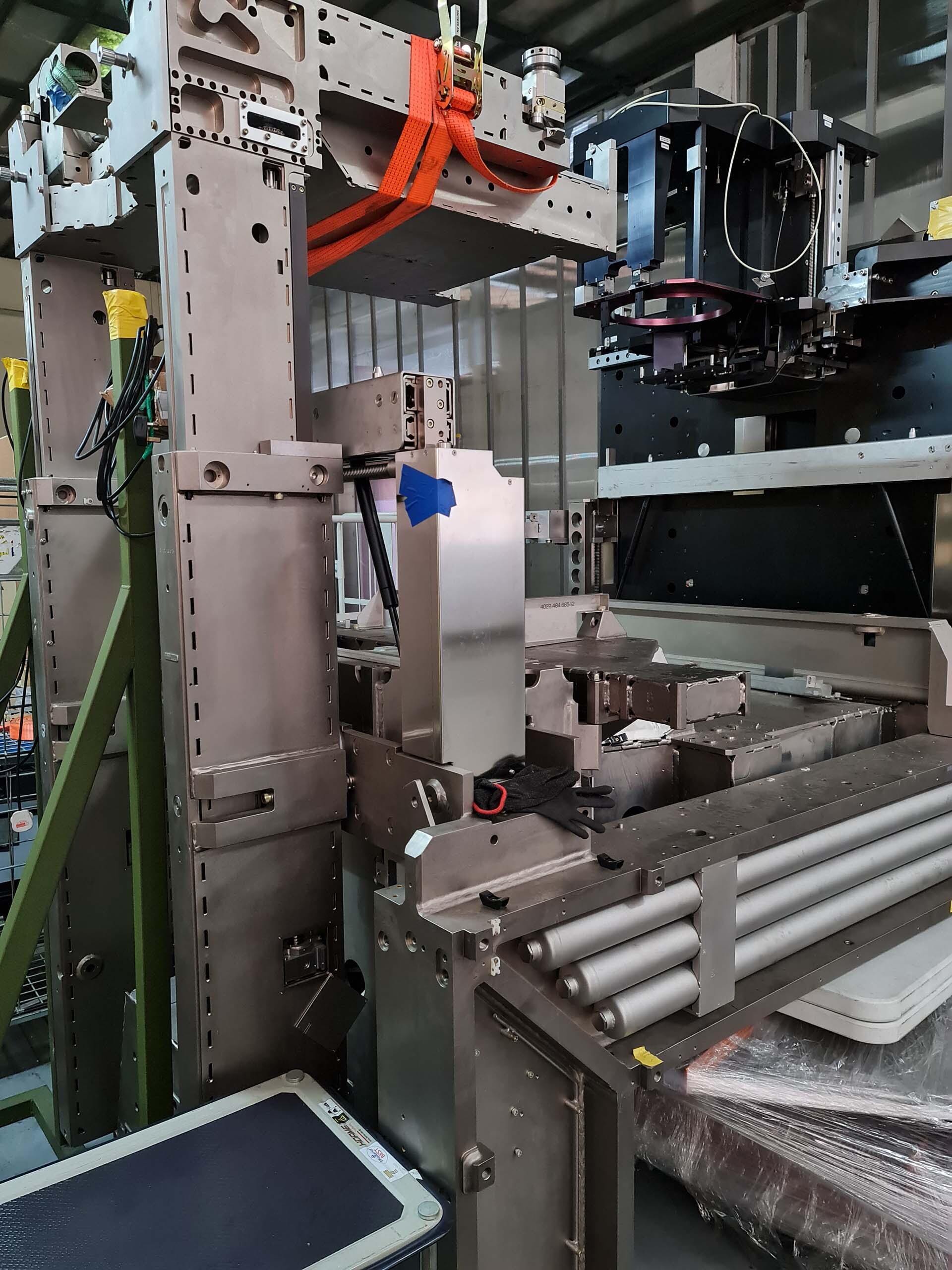

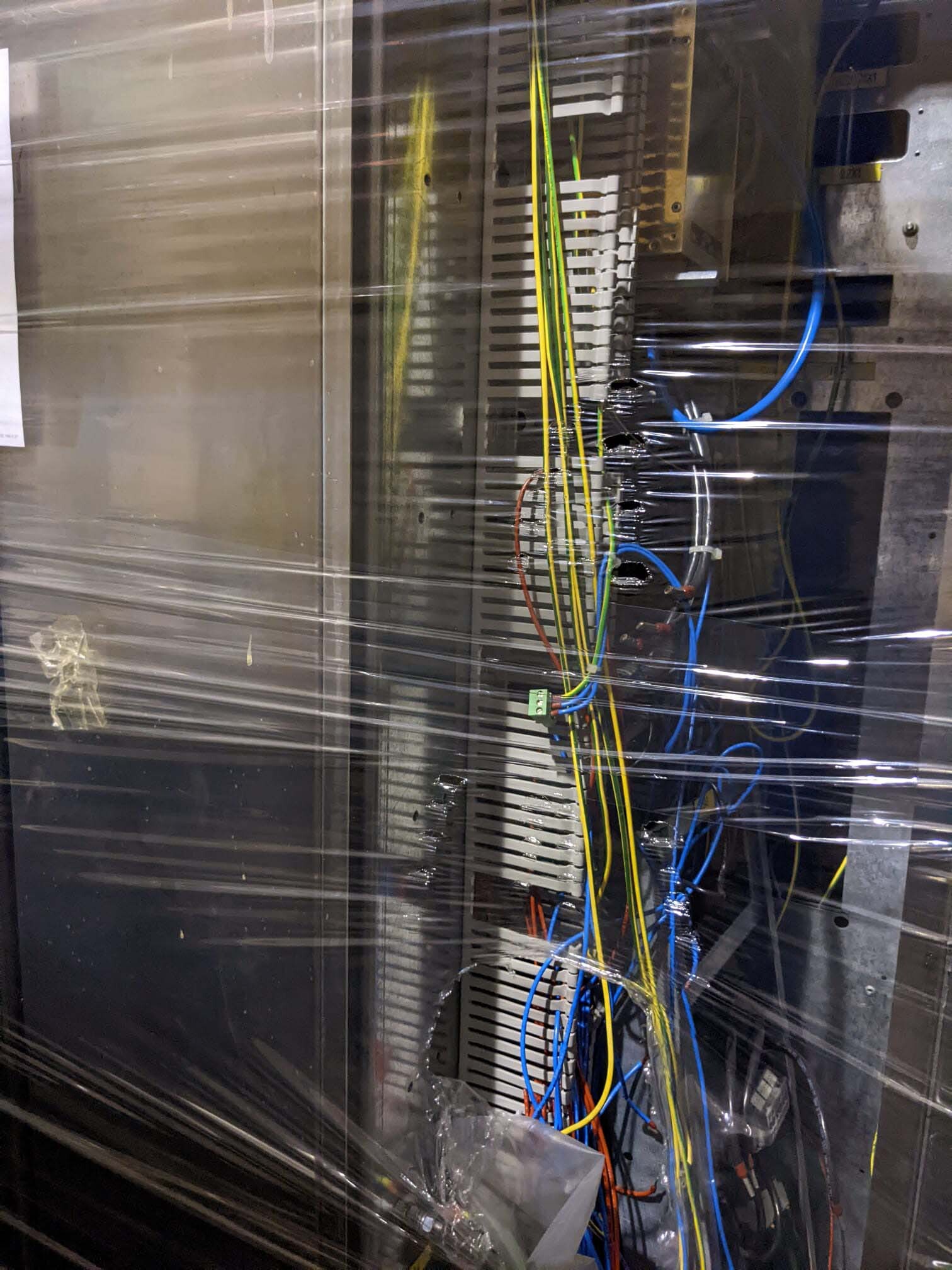

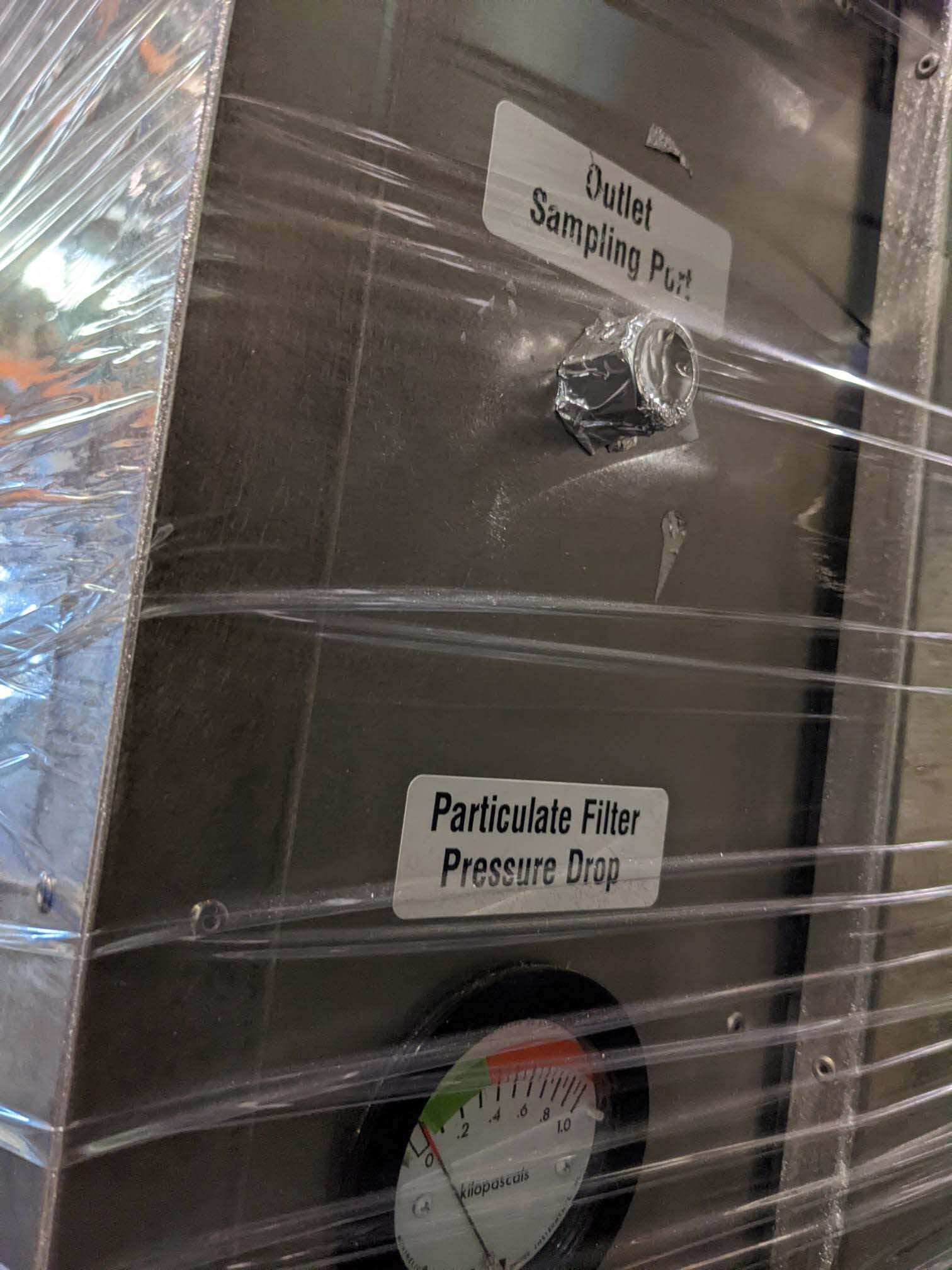

Used ASML AT-850D #293597577 for sale

URL successfully copied!

Tap to zoom

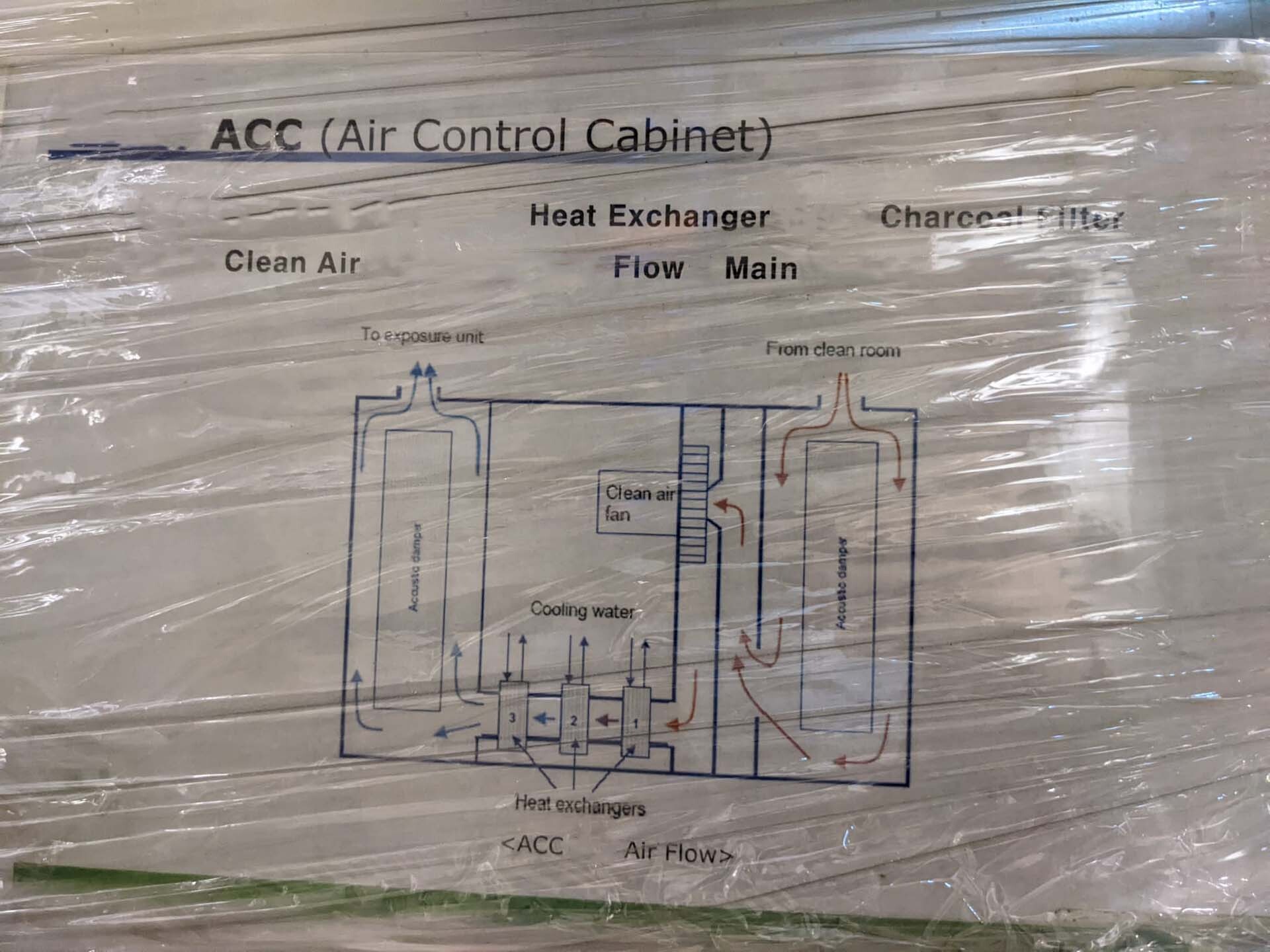

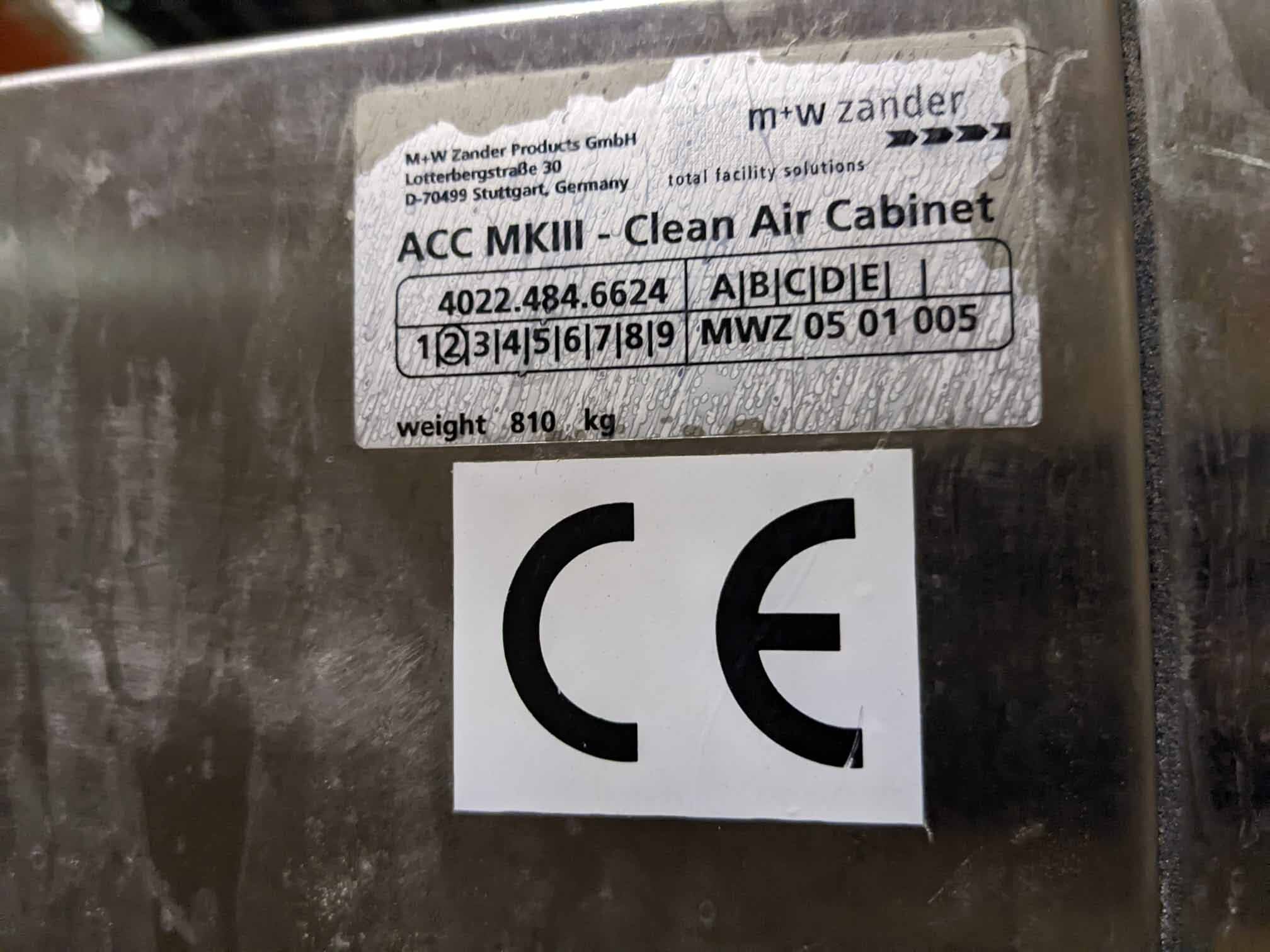

ASML AT-850D is a 4-axis precision lens alignment equipment for optical lithography. It is a fully automated, deep ultraviolet (DUV) 157nm immersion lithography system designed to produce integrated circuit (IC) products. The unit is designed to meet the needs of the leading-edge semiconductor industry in providing the best process control and cost of ownership. This stepper has excellent throughput and performance, invaluable features for production lithographers. ASML AT850D has many features that provide optimal performance. It is equipped with a large working area, making wafer alignment and substrate shifting easy. It is equipped with an advanced software suite that provides advanced pattern recognition and lithographic operations. Additionally, the step-and-repeat feature allows for rapid pattern replication, significantly speeding up the lithography process. AT 850D has a unique four-axis machine that is built with a precision moving table coupled to an XY CCD metrology tool. This XY CCD metrology asset is used for overlay measurement and defect inspection. With its high-accuracy lens navigation and alignment, the stepper can accurately shift coordinates between different pattern fields without having to re-align or re-burn the wafer. This feature helps improve wafer uniformity, which is critically important in semiconductor fabrication processes. AT-850D has an integrated vacuum load-lock model, which provides an automated, secure interface between a wafer transfer robots and the stepper, fully integrated into ASML lithography workflow. It also has an high-pressure aberration correction (HIPAC) equipment, which helps reduce optical distortions, enabling high-precision patterning even over small features. ASML AT 850D also offers multiple options for process adaptation and control, thanks to its versatile suite of software programs. For example, it has advanced lithographic simulation capabilities, so that process engineers can simulate exposures to determine optimal settings. It also allows for real-time data sharing between the stepper and the associated process tools. Overall, AT 850 D is a reliable and high-performance wafer stepper that enables top-notch lithography for IC fabrication. Its many features enable optical lithography to be produced and managed quickly, safely, and accurately. For these reasons, and many more, ASML AT 850 D is a widely trusted machine for lithography in the semiconductor industry.

There are no reviews yet