Used ASML AT400S #293638713 for sale

URL successfully copied!

Tap to zoom

ID: 293638713

Wafer Size: 12"

Vintage: 2001

i-Line scanner, 12", parts system

Wavelength: 365 nm

(2) XCWC

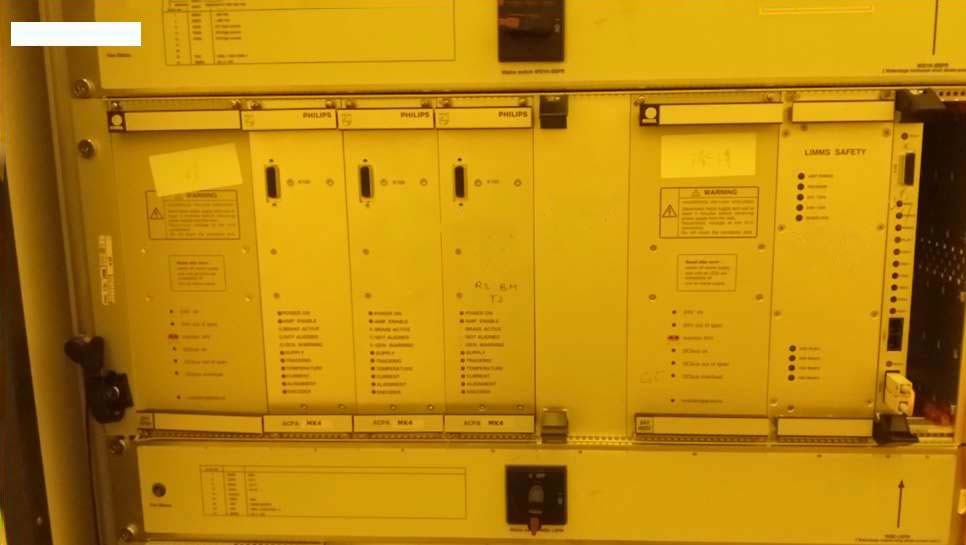

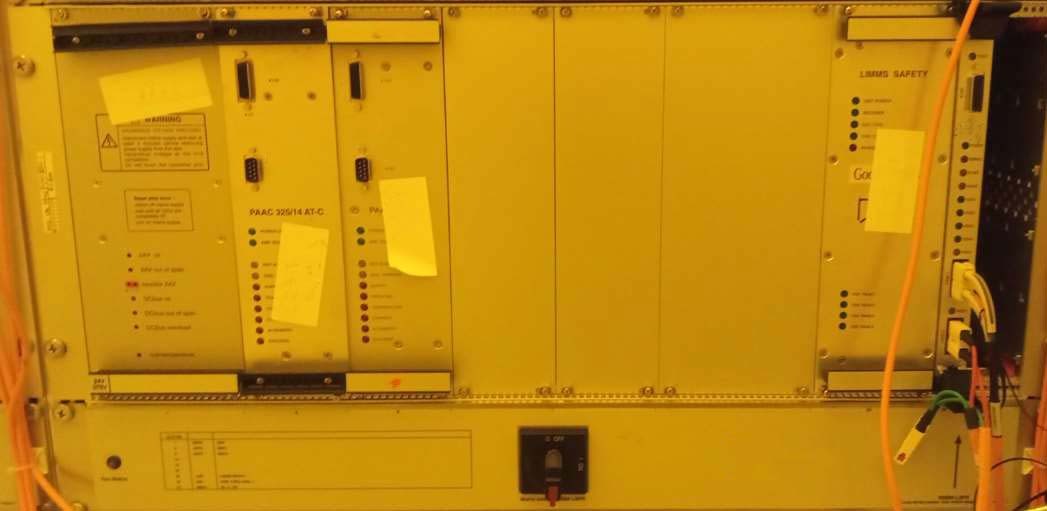

Racks:

MCWC

LCWC

MDC

AA LMA

Airmount

AA

CT

MO

MI

IPDR

RH

PFU

RS

WS

MO

MI

WH

RS Balance mass

RS Long stoke-Y

WS Short stroke-Z

RS Short stroke-XZ

WS E-side long stroke

WS Balance mass

WS Short stroke horizontal

Bottom module

2001 vintage.

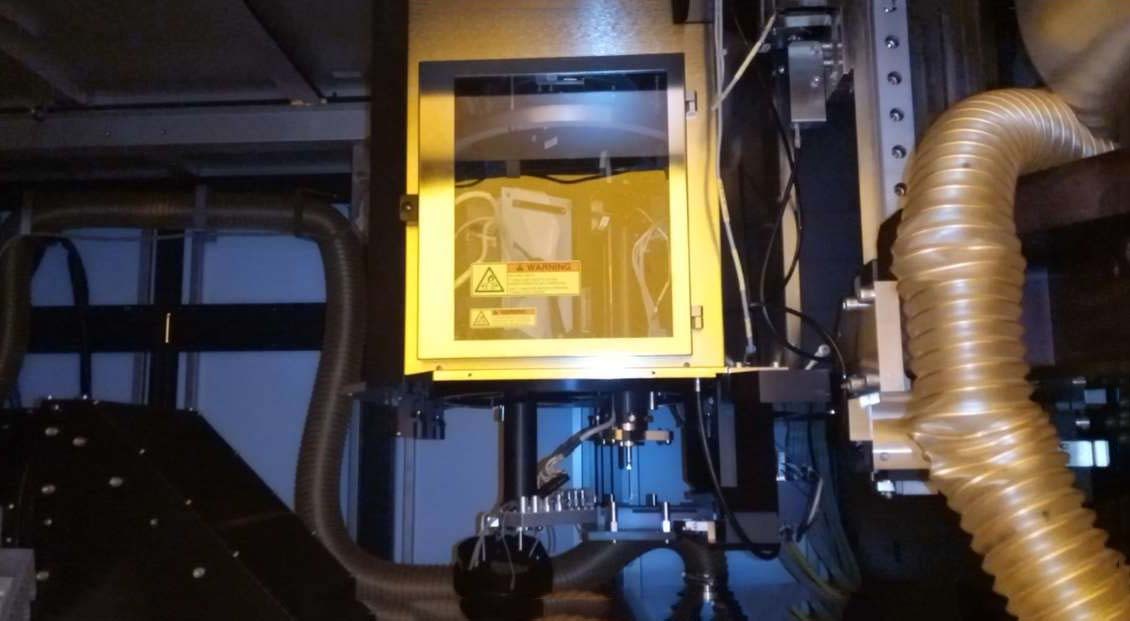

ASML AT400S Wafer Stepper is a device used to transfer patterns onto semiconductor wafers. It is a highly accurate tool that is capable of precisely patterning the circuit on a photo mask onto the wafer. AT400S Wafer Stepper is composed of a stage, an optical head, and a system controller. The stage has the ability to move the wafer along both the x- and y-axes, with a level of accuracy of up to 0.25 microns. In addition, the stage has a built-in heating element and thermal plate that can regulate the temperature of the wafer. This ensures the production of high-quality product. The optical head contains a reduction lens system that aligns the beam from the mask to the wafer. It utilizes a Rh-type of mask to generate the light for etching the wafers. The beam is precisely aligned to the wafer's surface so that the pattern is accurately transferred without distortion. The system controller is at the heart of the machine. It is responsible for monitoring and controlling the various parts of the machine (including the stage, optical head, intensity and focus of the beam, and exposure time). It also stores the necessary parameters of each circuit, so that the machine can accurately pattern each wafer. ASML AT400S Wafer Stepper is specifically designed to provide the highest degree of accuracy and precision in transferring the pattern to the wafer. It is a reliable and easy to use tool that minimizes the risk of errors and can guarantee a finished product that meets the highest standards.

There are no reviews yet