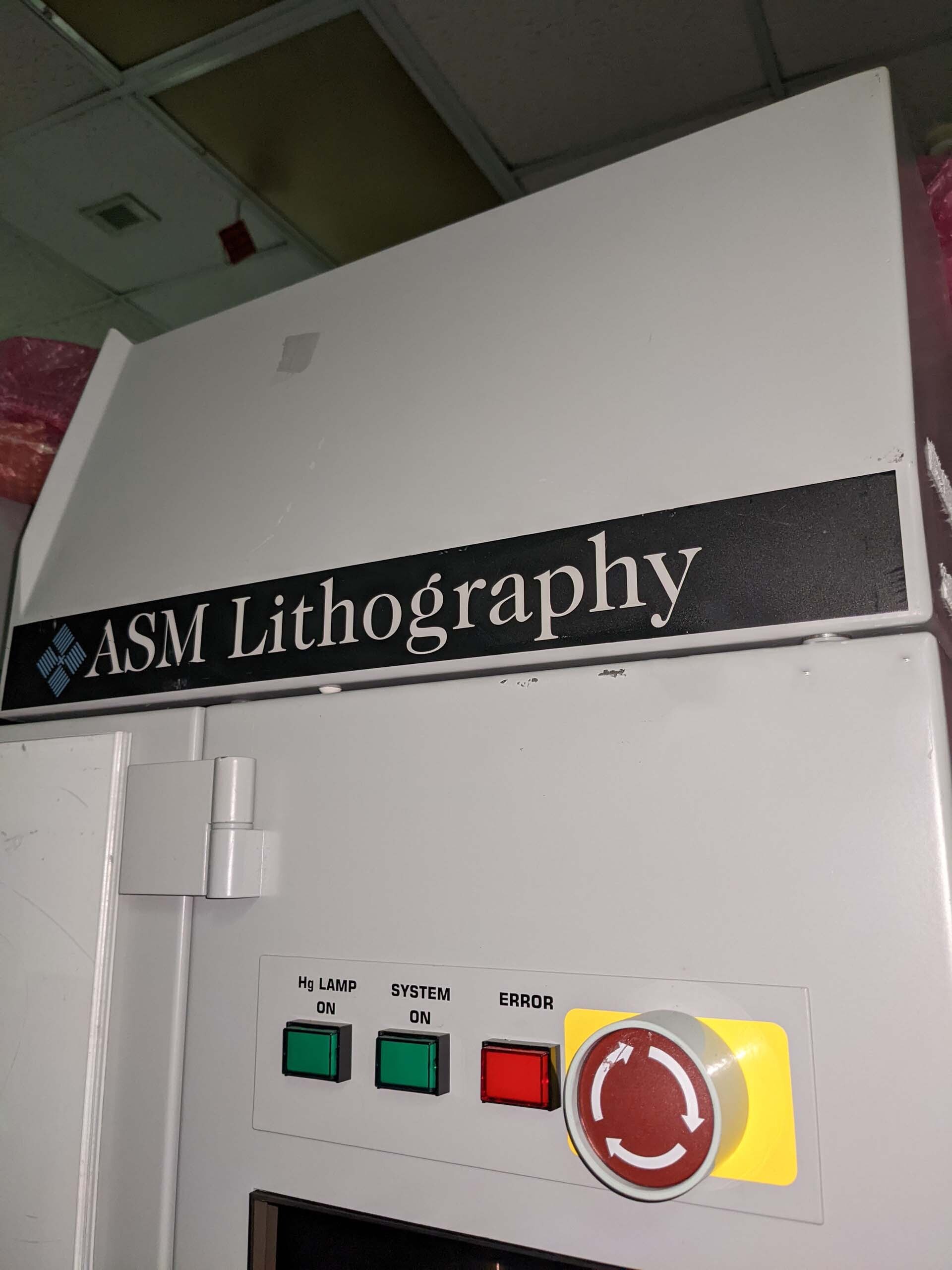

Used ASML PAS 5000 / 55A #293647910 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 293647910

Stepper, parts system

Missing parts:

E Chuck

P Chuck

Cassette transfer.

ASML PAS 5000 / 55A is an immersion-optical wafer stepper designed for semiconductor lithography. It is capable of producing semiconductor devices with sub 225 nm resolution in 167 mm exposure fields. ASML PAS 5000 / 55 A is powered by ASML IntelliWafer technology, which enables users to reduce cycle times, reduce wafer breakage, and improve quality and productivity. PAS 5000 / 55A's total imaging area is approximately 16.3 inches (414 mm) in diameter and is capable of producing patterns at resolutions as low as 225 nanometers. The system utilizes an advanced computer-controlled, ultraviolet illumination source which provides a wide range of exposure settings to accommodate different production requirements. The system also offers several advanced features that enable the user to produce highly efficient exposures efficiently. Intellitrace is a feature of PAS 5000 / 55 A that automatically adjusts the focus position of each exposure. The ProFlex feature allows the user to program a pattern orientation on the wafer surface, making it easy to convert larger scale patterns into smaller patterns. The alignment of the wafers is also improved with this feature. ASML PAS 5000 / 55A also offers developers a user-friendly programming environment, which is easy to learn and operate. As this system works with a variety of computer languages, users can program their own recipes for patterning those devices. The user-friendly graphical interface allows the user to make corrections quickly and easily, without the need for a specialist programmer. Due to its enhanced features and performance, ASML PAS 5000 / 55 A stands out as one of the most powerful and reliable wafer steppers on the market. Its high resolution, accurate alignment and repeatability make it suitable for a wide variety of production requirements. Its programmable environment also allows for easy conversion of datasets from larger to smaller dimensions. Making it suitable for both large and small-scale projects.

There are no reviews yet