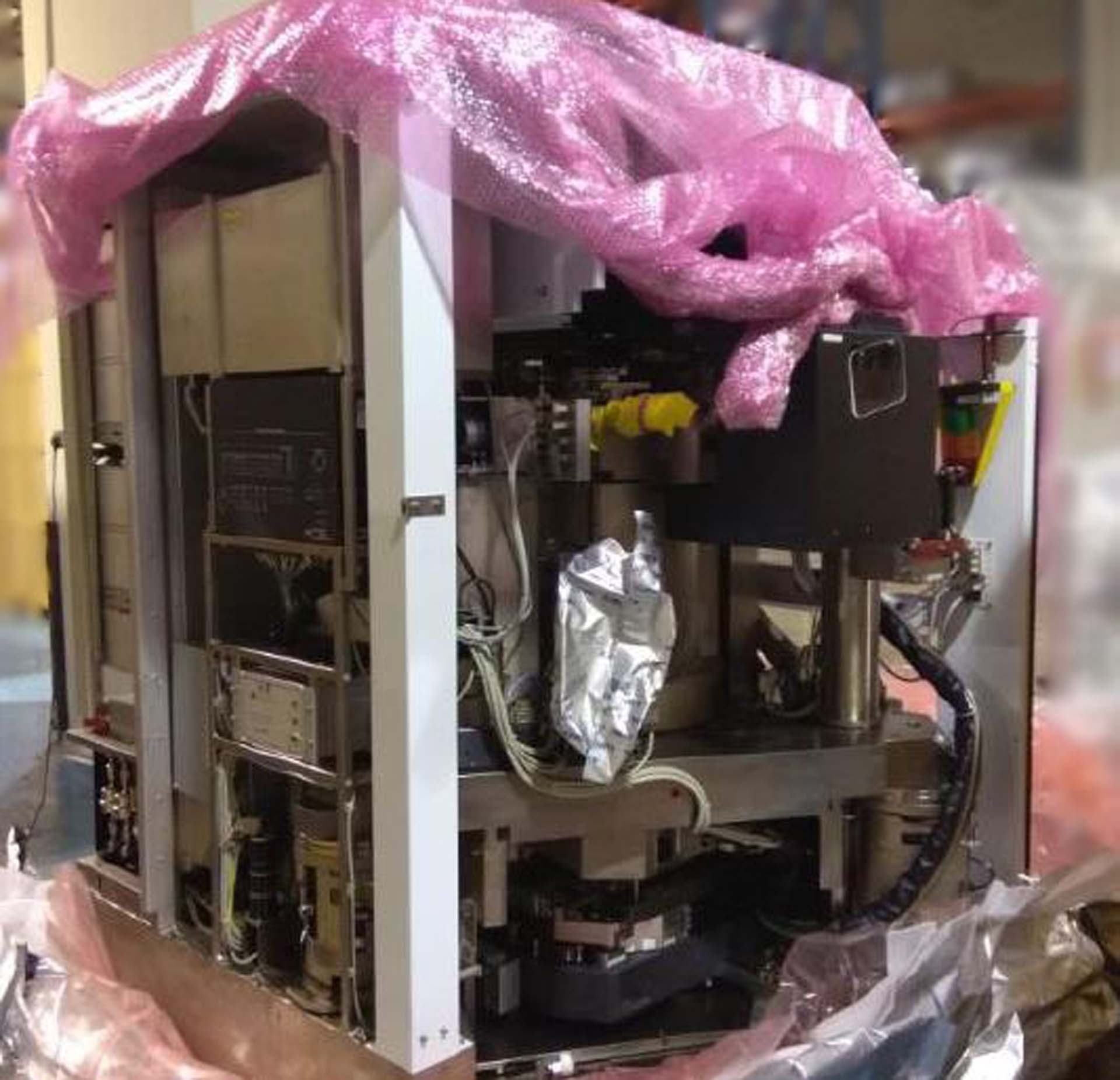

Used ASML PAS 5500 / 100C #9228851 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9228851

Stepper

Uniformity: %

22x22 mm: </= 1.6

14.7*27.4mm: </= 1.6

Intensity: >/= 850 mW/cm^2

Lamp Life: 1500W: </= 150 hrs

Dose repeatability & accuracy: </= 1

Reticle masking black border size: </= 475

Image performance:

Astigmatism: </= 0.35

Focal plane deviation: </= 0.45

UDOF @ 0.40 um lines: >/= 1um

Focus / Leveling:

Focus repeatability focus: </= 50nm

Rx: </= 3 urad

Ry: </= 3 urad

FOCAL: Valid positions ≧ 14

Best focus < ± 0.2 um

Image tilt Rx < ± 5 urad

Image tilt Ry < ± 5 urad

Image distortion (lens):

Max X (NCE): </= 60nm

Max Y (NCE): </= 60nm

Magnification: </= 2 ppm

Rotation: </= 2 urad

Symmetrical T: </= 10 nm/cm2

Trapezoidal: </= 10 nm/cm2

Overlay performance:

Stage repeatability

Max x: </= 15nm

Max y: </= 15nm

Single machine: </= 60nm

2-NA Global overlay:

NA=0.48

NA=0.57

Prealigner accuracy:

Edge sensor

X (3sig): </= 8.5um

Y (3sig): </= 8.5um

Rotation (3sig): </= 180 urad

Edge sensor:

SD Y < ± 2.1 um

SD Rot < 45 urad

SD X < ± 2.1 um

Mark sensor:

SD Y < ± 2.1 um

SD Rot < 45 urad

SD X < ± 2.1 um

Image quality control (3sig):

Focus: </= 50 nm

Image Rx: </= 2 urad

Image Ry: </= 2 urad

Translation: </= 20 nm

Magnification: </= 2 ppm

Rotation: </= 2 urad

Throughput

(70) Shots at 200 mJ, 8": >/= (70) Wafers / Hour

Reticle exchange time: </= 29 Seconds

System reliability: > 500 PCs

Particle: 0.2um < 10ea

Laser output:

Alignment laser: > 12 mw

Interferometer HP laser: > 220 μw

Missing parts:

MVR Rack power supply

Lens bag inactivity

Workstation hard disk

(2) ACU Air pipes

Wafer handler elevator: 3/4 Cover.

ASML PAS 5500 / 100C is a wafer stepper used primarily for projecting masks onto a range of substrates. It is widely used in industries such as semiconductor manufacturing, solar, and flat panel displays. It boasts a range of features designed to maximize throughput while minimizing noise and other adverse factors; for example, the equipment offers a repositioning time of under 0.9 seconds, ensuring fast turnaround times for jobs. This system also contains environmental sensors that support intelligent monitoring of the ambient atmosphere, allowing for response and control in temperature, static and humidity. The unit is compatible with a range of optics and light sources, including ArF laser sources, deep UV light sources, and more, ensuring that jobs of all sizes and complexity can be completed. It also contains specialized features required for tasks such as OPC processing and stitch printing. Its modular design allows users to freely swap out and configure their equipment according to their needs, ensuring maximum efficiency. The machine is designed with advanced robotics to minimize vibrations, both vertically and horizontally, ensuring precise patterns and high-quality images. Its highly efficient cooling tool ensures particles heat is evenly distributed throughout the chamber during processing for uniform surface quality. Additionally, its advanced laser scatterometer asset is designed to provide a high degree of accuracy, ensuring that images are consistently aligned to sub-micron levels. ASML PAS5500 / 100C features ultra-fast motion control, capable of operating at frequencies of up to 2kHz. It's highly responsive design ensures fast response times to react to control commands from the operator for immediate adjustments. The model also contains a comprehensive library of profiles and a range of other features for total control over the imaging process. Additionally, it is designed with many safety features, such as power-down shutdown safety, lifted objects detection, and stage collision detection. This wafer stepper is designed for maximum versatility, boasting a range of features which make it suitable for a variety of applications. Its range of features makes it highly reliable and efficient, a key factor in its popularity among silicon device manufacturers.

There are no reviews yet