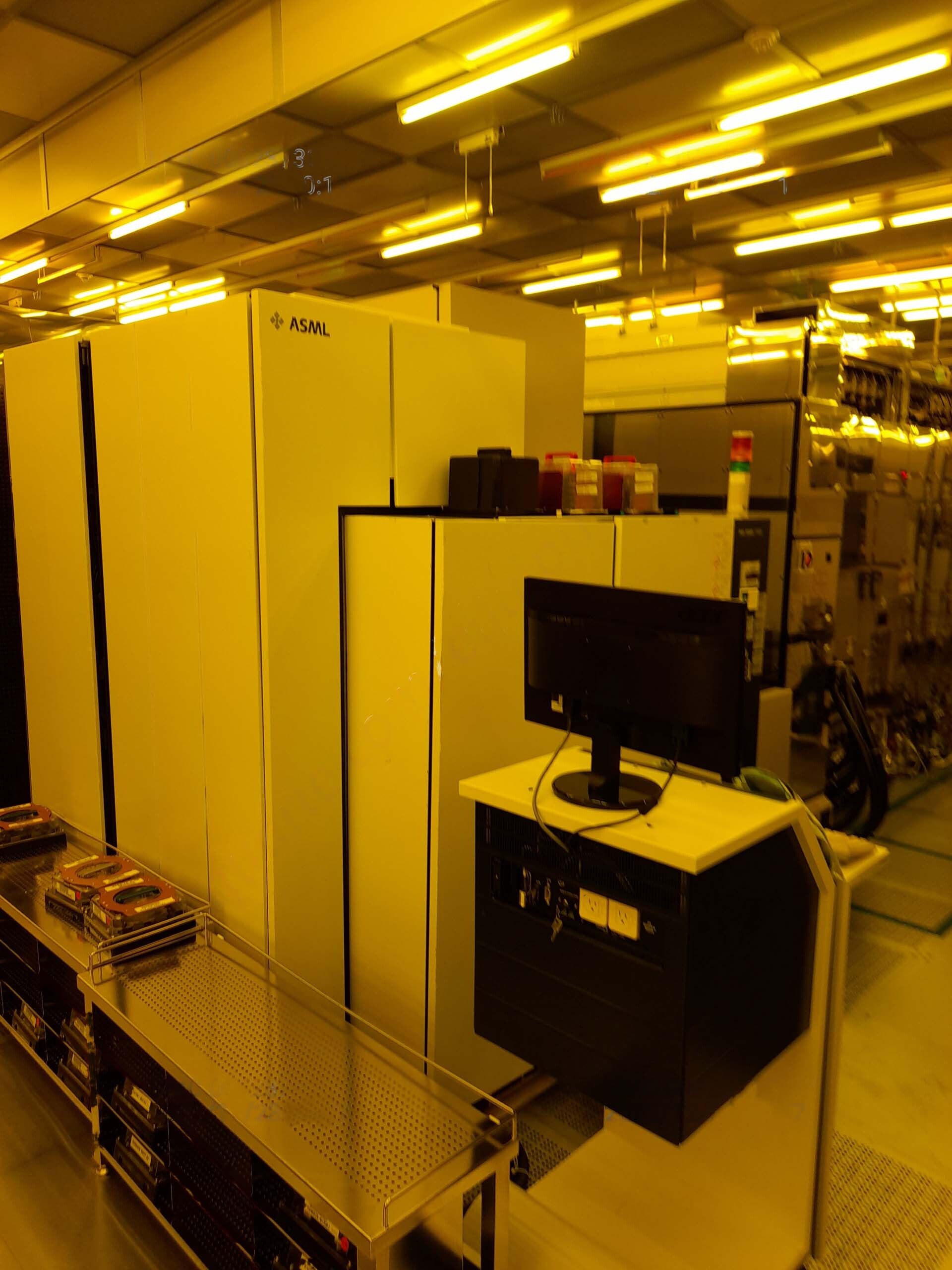

Used ASML PAS 5500 / 1100 #293668650 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 293668650

Wafer Size: 8"

ArF Scanner, 8"

Wavelength: 193 nm

Wafer type: Notch

SMIF

Illumination source: Laser

CYMER NL-7600 Laser

IRIS Reticle

ATHENA Alignment system

Narrow alignment mark

Reticle blue align

Focus system: Enhanced 8

(24) Character barcodes

Grid mapper

QUASAR illumination

PEP Image screening

AUX Port wafers

Beam delivery system

Stand alone workstation

ESI Air filtration

Cabling

Does not include Hard Disk Drive (HDD).

ASML PAS 5500 / 1100 is a wafer stepper equipment used for the fabrication of integrated circuits on wafers. The stepper system is composed of an alignment microscope, a projection optics, and an Advanced Stepper Module (ASM). The alignment microscope is a specialized optical microscope with high resolution capabilities used to precisely align the photomask and the wafer. The projection optics offers high-resolution imaging of the photomask onto the wafer allowing very precise alignment of features for the lithography process. The ASM is responsible for finely controlling the movement of the stage that holds both the photomask and the wafer in order to create the desired pattern on the wafer. ASML PAS 5500/1100 is designed to allow for flexible layout of up to twelve different process modules, with the ASM, microscope and projection optics modules being shared between them. The stepper unit can be operated both in step and scan operation, with the machine utilizing a dual-column configuration to separate scanning and alignment function when in scanning mode. The tool has an XY stage that allows stepper head to move and accurately position the photomask and the wafer relative to each other. The ASM provide closed-loop control for highly precise movements in the XY plane and the focus adjustment to satisfy the lithography requirements of a wide range of wafers. The asset is designed to have an independent closed-loop control for each module, thereby allowing highly precise setups and maximum stabilization of each module during production. The stepper has a large field of view that can support large number of patterns on the wafer and the wafer stage is designed to be low-kV and vibration-free to support advanced processes. PAS 5500 / 1100 offers great performance, accuracy, and reliability. The model has a programmable step size and can step up to 6,000 μm in X and Y and offers an exposure accuracy of +/- 1.5 μm. It also offers high quality imaging, with 39nm resolution, power efficient operation and improved cycle times. In addition to these features, the wafer stepper equipment has a robust network of integrated sensors, including temperature, relative humidity, and vibration sensors, as well as various camera systems, that help monitor the environment and maintain an optimal cycling temperature and humidity. The system is monitored at all times during the lithographic process, allowing for continuous process optimization. Finally, PAS 5500/1100 offers engineers advanced automation and control tools to optimize their processes and achieve the highest quality standards.

There are no reviews yet