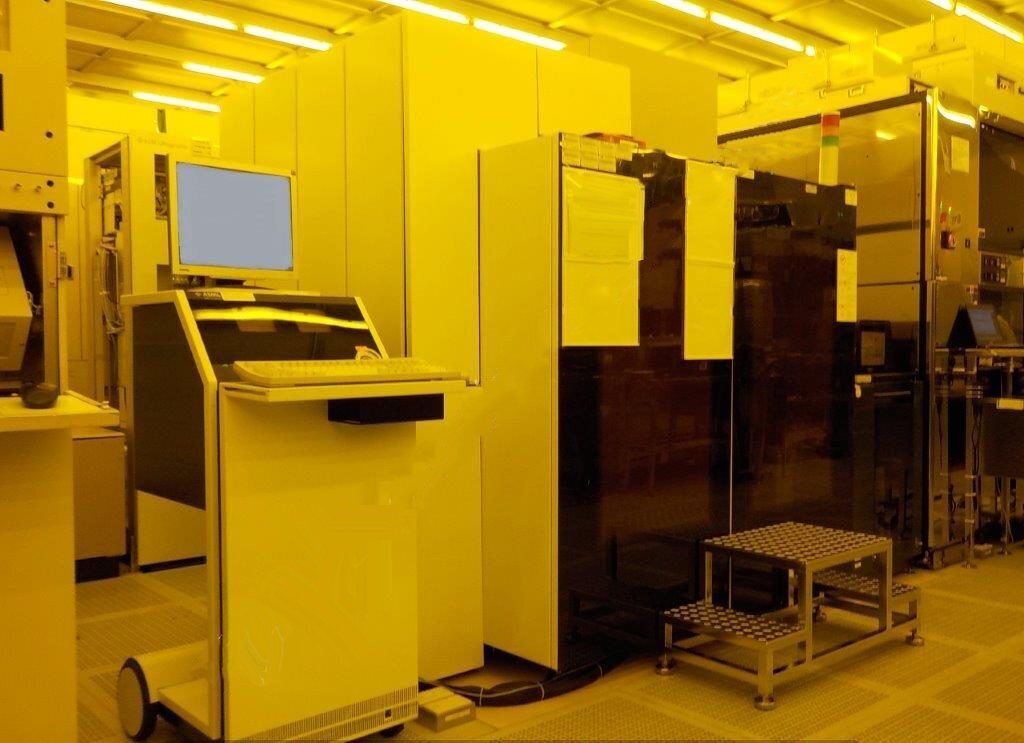

Used ASML PAS 5500 / 300C #9309192 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9309192

Wafer Size: 8"

Vintage: 1998

KrF Stepper, 8"

248 nm

Exposure unit

Aerial bottom module

Advanced Reticle Management System (ARMS)

SPARC5 Operator console

Wafer transport system

Electronics cabinet

Contamination and Temperature control (C&T) cabinet

ELS 5600 Excimer laser

Beam expander

Beam delivery system

Optional charcoal filter unit

Optional power converter: 208-400 VAC

1998 vintage.

ASML 5500/300C wafer stepper is a compact and cost-efficient exposure equipment designed for the production of photomasks for the manufacture of semiconductors. The stepper boasts an intuitive and user-friendly graphical interface, which enables the user to easily adjust the settings for the perfect alignment and exposure of wafers. ASML 5500/300C utilizes a dual-drop, laser-assisted stepper architecture, which creates two overlapping exposure patterns for each layer. This helps to ensure accurate positioning of the wafer being exposed and creates a smaller, more uniform feature size. The system also features a patented 'Laser-assisted Defocusing' (LAD) unit, which allows the machine to accurately adjust the focus of the laser beam to match the surface of the wafer for optimal alignment and exposure. ASML 5500/300C stepper is equipped with a large field of view (118 x 97 millimetres) and a special large-area beam splitter, which enables the tool to rapidly scan large areas of a wafer in order to render high-resolution images and features. This helps to significantly reduce cycle times and improve overall exposure quality. In addition to its exposure capabilities, ASML 5500/300C wafer stepper also incorporates a full-featured process control asset. This model allows the equipment to automatically monitor the position of the wafer during the exposure process, ensuring repeatable alignment and exposure parameters. The system also features an integrated Defect Detection Unit (DDS), which enables the machine to detect and correct defects in the pattern during the exposure process. Finally, ASML 5500/300C wafer stepper is compatible with a wide range of lens options, including telecentric lenses, scale lenses, and shift lenses, which helps to ensure accuracies of up to 0.3 microns. This helps to create photomasks with the highest possible resolution, allowing the user to achieve the finest details in their patterns, and enabling them to produce the best possible semiconductor parts. In summary, ASML 5500/300C wafer stepper is a sophisticated yet intuitive exposure tool that provides users with a high level of exposure accuracy and control. The asset's wide range of features help to enable user to quickly render high-resolution patterns with minimal effort, and thanks to its advanced process control and defect detection systems, the model ensures maximum yields and quality.

There are no reviews yet