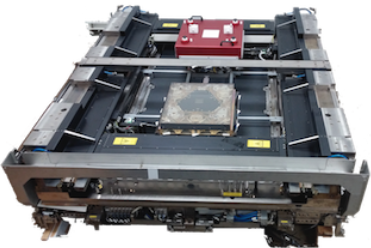

Used ASML Twinscan AT 1150i #9112188 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ASML Twinscan AT 1150i wafer stepper is a state-of-the-art lithography machine widely used in the semiconductor industry. The machine is capable of producing high-resolution optical patterns with a small spot size of less than 10 nanometers. The 1150i is a projection-type scanning machine that uses a laser beam to produce a pattern on a wafer. The laser beam is first reflected off a rotating spherical mirror, which focuses the beam onto a series of small movement stages. The stages move the laser beam across the wafer in a predetermined pattern. The wafer is mounted in a 5-axis stage which allows it to be moved in any direction. The stage is also capable of rotating the wafer while the laser is being scanned across the surface. This technique allows the 1150i to be used for multiple exposure jobs and can even create several different patterns on a single wafer. The 1150i utilizes a technique called step and repeat, where it scans the same section of the wafer multiple times. This allows multiple layers of a wafer to be built up in a single scan. Additionally, the machine has a multi-gate system which allows the focus of the laser beam to be adjusted on the fly. The 1150i also features a programmable control system, which allows the user to define specific speed and acceleration parameters around which the machine will operate. This feature allows the user to optimize the system for various jobs, such as high throughput or low pattern complexity, which can result in increased productivity. In addition to its superior scanning capabilities, the 1150i is also able to rapidly process data, ensuring quick and accurate pattern definition. The machine can process job information as quickly as within 10 milliseconds and is also capable of real-time alignment capabilities. The 1150i is an efficient and reliable machine, providing superior pattern fidelity and uniformity. Its robust design and integrated features make it an excellent choice for semiconductor manufacturing and research and development needs.

There are no reviews yet