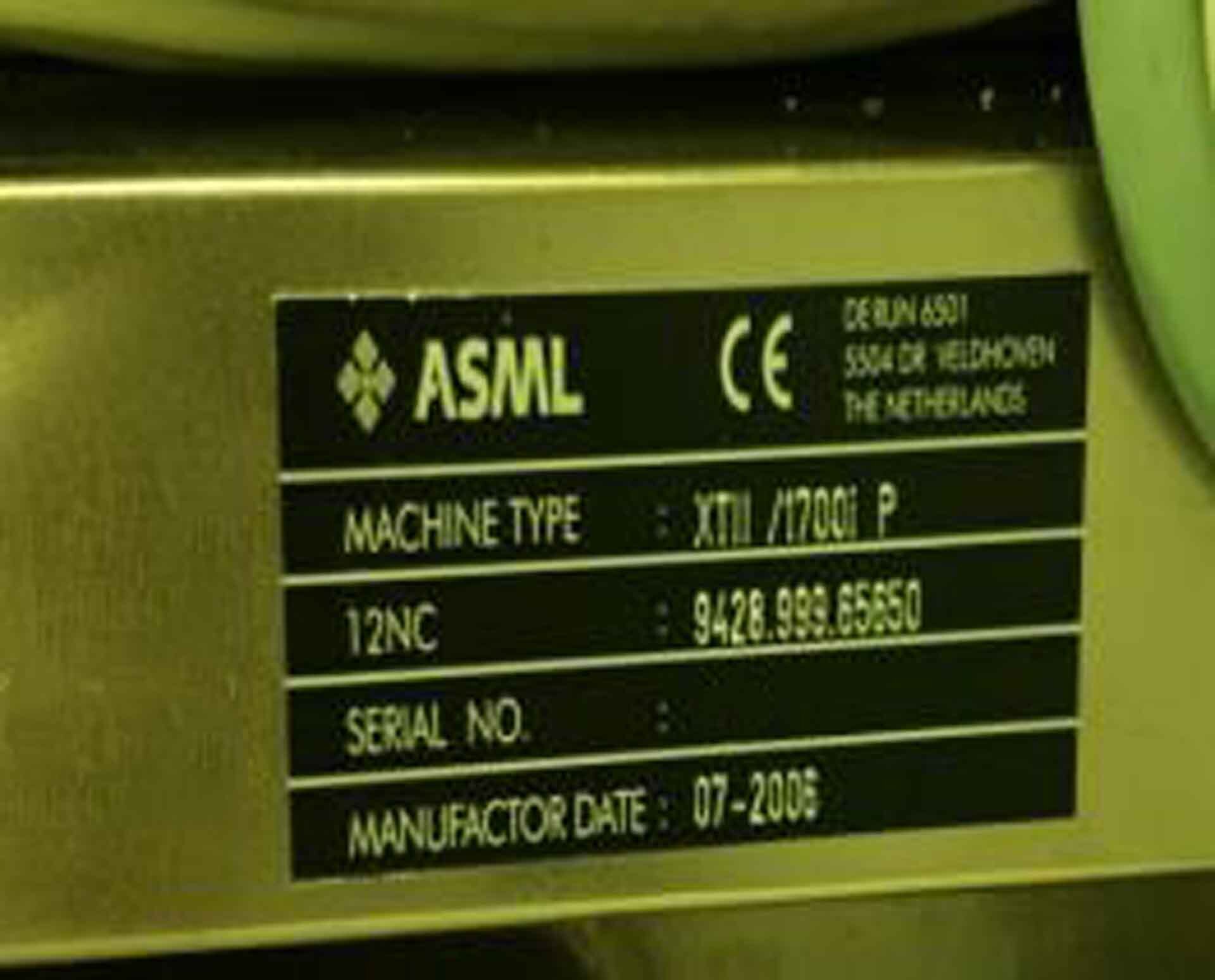

Used ASML Twinscan XT 1700i #293652050 for sale

URL successfully copied!

Tap to zoom

ID: 293652050

Wafer Size: 12"

Vintage: 2006

ArF Scanner, 12"

SMIF / FOUP

Projection lens

Material / Chemical: Align

Load Module: EFEM

Process module:

Wafer stage

Reticle stage

Wafer handler

Reticle handler

AOM Laser

Bottom module spacer

EIM

ELEC

Utility:

CYMER XLA360 Excimer laser

BSM

ACC

ENTEGRIS E51004802 Charcoal filter

AERONIX EGPS

MCWC

LCWC

WSRC

RSRC

MDC

WICC

WISC

2006 vintage.

ASML Twinscan XT 1700i wafer stepper is a highly advanced wafer processing machine designed to produce wafers with superior levels of accuracy and detail. The machine is capable of processing a wide range of wafer sizes, and with its high accuracy and repeatability it can produce a wide range of devices with extremely fine feature sizes. The XT 1700i is driven by a high-performance, high speed precision motor and associated motion equipment. This allows for fast and consistent movements throughout the entire scan range to ensure high levels of accuracy. Its motor is designed to ensure minimal vibration and continuous scanning speeds of up to 300 nanometers per second. The machine can also be quickly and easily adapted to meet the needs of a wide range of different wafers and production tools. The machine is also fitted with an advanced wafer handling system. This allows for a fast and efficient loading and unloading of wafers, as well as for accurate alignment, spacing and tilt adjustments of the wafer. It also has a special pattern-tracking alignment unit which ensures that the desired pattern is accurately replicated on each wafer. The XT 1700i is also equipped with advanced focus-control algorithms and high-speed imaging technology. These features allow for exceptionally high levels of performance even with difficult-to-pattern substrates, such as DRAMs and 3D structures. The XT 1700i also has a variety of high-tech metrology techniques to ensure that the output wafers meet exacting standards. These include an appearance metrology machine, a spectral metrology tool, and a full profilometer. This asset provides the user with high-accuracy measurements of the wafer's surface quality and the critical feature sizes of the tiny devices. In addition, the XT 1700i has an advanced environmental control model. This equipment uses a highly advanced active-cooling system to ensure the machine runs at an optimal temperature and that the wafers are protected from dust and other contaminants. All in all, Twinscan XT 1700i is an extremely advanced wafer processing machine, capable of producing extremely high-quality wafers with superior accuracy and precision. It is suitable for use in a wide range of applications, and its advanced metrology and environmental control systems ensure that it meets the highest standards of quality and reliability.

There are no reviews yet