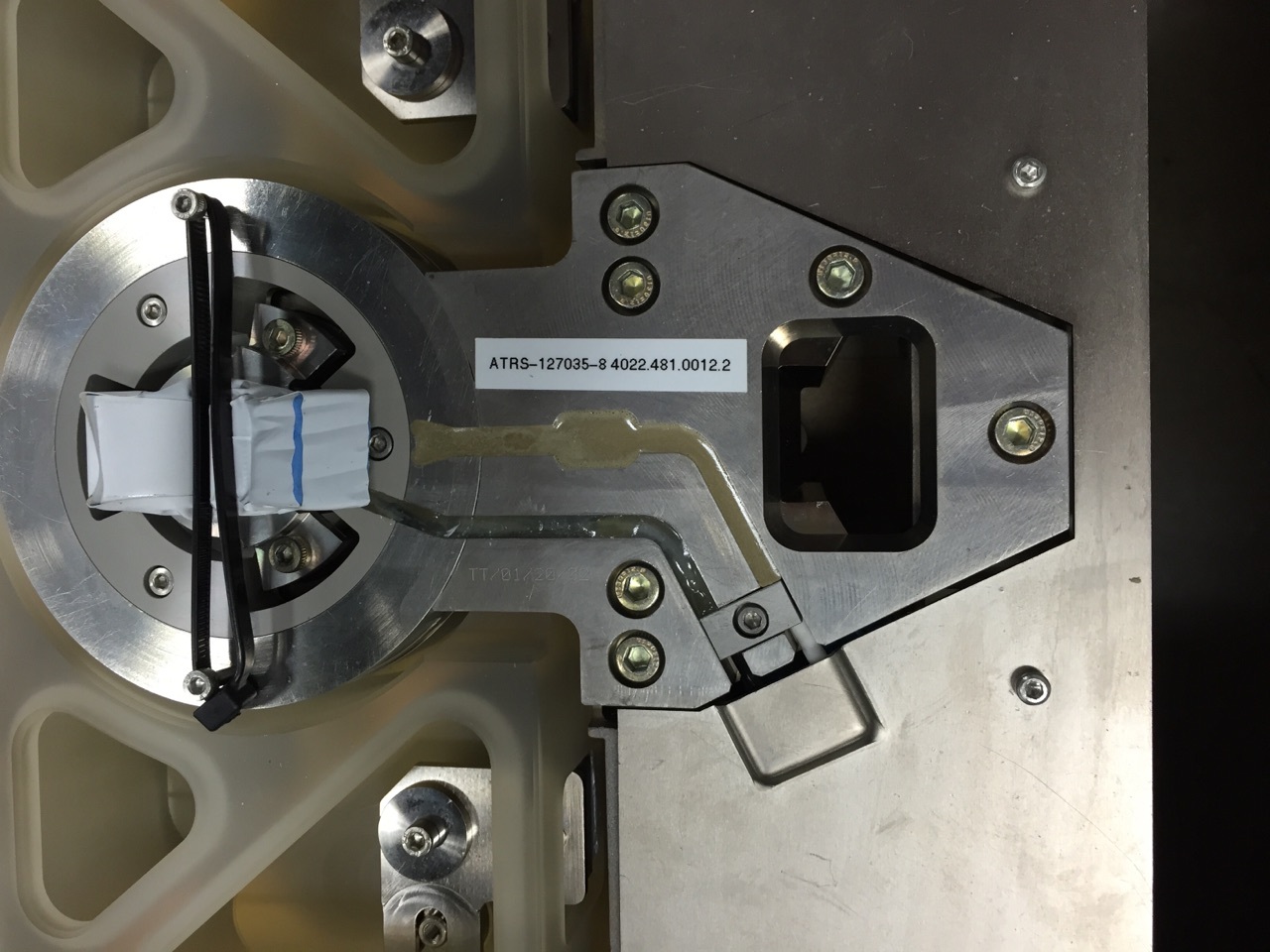

Used ASML Twinscan #9133014 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ASML Twinscan is a type of wafer stepper used in the semiconductor manufacturing process. A wafer stepper is a machine that uses a series of illuminators to expose a photosensitive film on a wafer. This exposure is used to form patterns on the wafer, which are ultimately used to create chips and other microelectronic devices. Twinscan is an advanced and precise wafer stepper that is used in the fabrication of semiconductors. Its unique feature is its dual exposure mechanism, which is capable of simultaneously exposing a single wafer to two different sets of optics. This allows for greater control over pattern placement and accuracy. The machine also has an automated alignment system that ensures precise registration of patterns on both the front and rear of the wafer. ASML Twinscan is capable of working with both DUV (Deep Ultra-Violet) and i-line illumination sources, and offers a variety of options for specialize wafer imaging. Its high-end optics packages offer a high degree of control over the patterning process, while its high throughput capabilities make it one of the most efficient wafer steppers available. The machine also has a wide range of safety and defect detection features, allowing it to quickly and accurately detect errors and defective patterns. Twinscan wafer steppers are incredibly important for the production of semiconductors, as their precision and accuracy make them ideal for the production of complex devices. Their dual exposure mechanism and automated alignment system provide the user with unparalleled control over the patterning process. In addition, their high throughput makes them one of the most reliable and efficient wafer steppers available.

There are no reviews yet