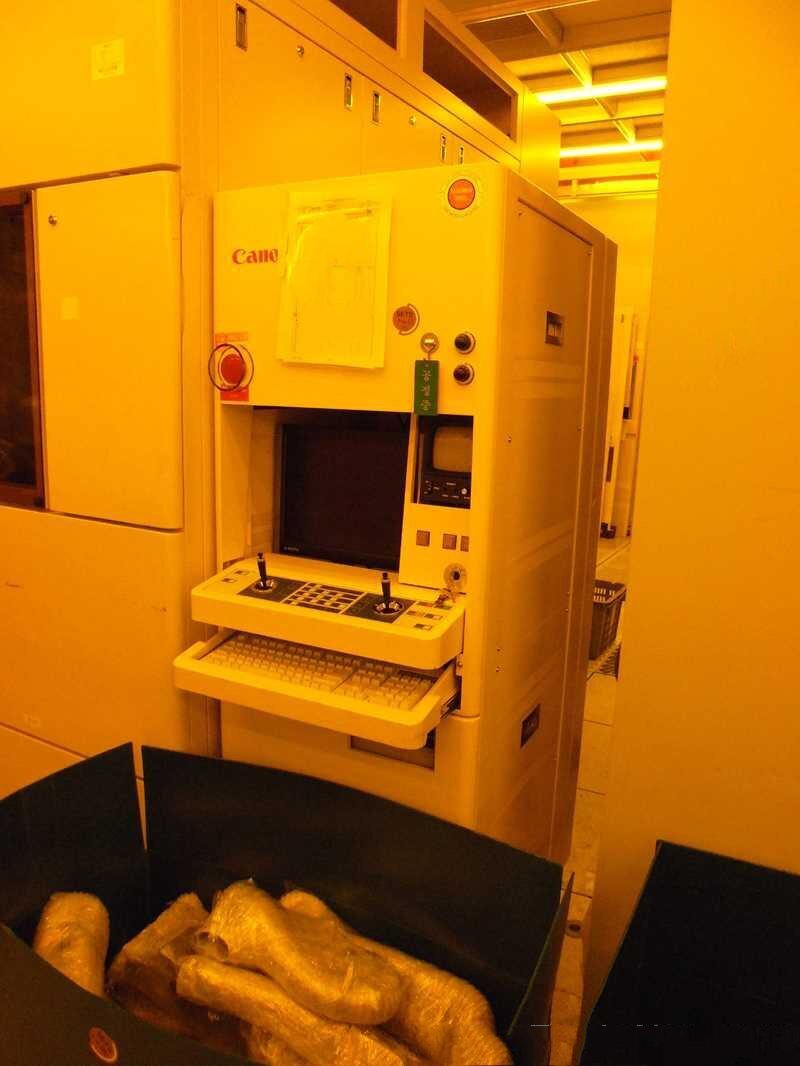

Used CANON FPA 2500 i3 #293595403 for sale

URL successfully copied!

Tap to zoom

ID: 293595403

Vintage: 1995

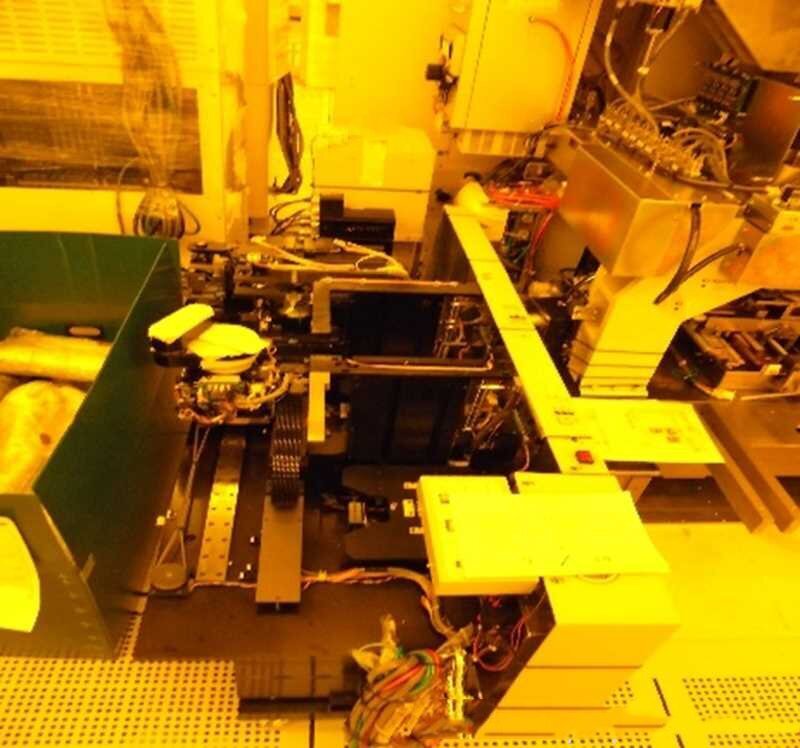

Stepper, 6"

Reticle size: CANON STD, 5"

Wafer feeder: L-Type

PA Unit: O.F Type, 6"

Chamber: TBW-CD73

Illuminator: FPA-2500 i-line

Console version: V 5.20 A

A Scope: i-Line, TTL

O/Z-Tilt unit: (3) Piezo stacks (L,M,R)

Support mount: (4) Servo passive dampers

Rated power: 18.7 kVA

Lamp house: 1.5 kW

Power supply: 200 V, 50/60 Hz, 3 Phase

1995 vintage.

CANON FPA 2500 i3 is a high-performance, high-precision, continually improving and upgrading wafer stepper designed for the production of advanced semiconductor devices. A wafer stepper is a type of photolithography tool used to transfer an image onto a silicon wafer by selectively exposure of parts of the wafer one at a time. CANON FPA-2500I3 is equipped with a 4kW laser exposure source and is capable of scanning wafers up to 300mm across. The machine can apply patterns to the wafers with a resolution of 0.22um across and 0.25um in thickness, providing high-precision exposure and unsurpassed accuracy and resolution. The stepper features a variety of features that ensure highly automated and efficient exposure, including a 14-inch full-color LCD panel with graphical user interface and compound-eye home position finder. The machine operates in a "square-by-square" exposing style, allowing for quick and precise wafer alignment. Additionally, it utilizes an auto-exposure system, allowing for accurate exposure times and automatically adjusting exposure to prevent any exposure errors or image quality issues. Other features of FPA-2500 I3 include fast write speeds, a low-background noise beam, a low-temperature flash lamp, and a newly designed beam transport system. This feature ensures extremely short write times, as well as complete control of exposure times. The machine is designed for a fast and efficient production process, requiring minimum changeover time and allowing for multiple exposures simultaneously. Overall, FPA-2500 I 3 is an exceptional wafer stepper. With its advanced features, high resolution, and high-precision exposure, it is capable of providing excellent results with high throughput. The machine is well suited for the production of advanced semiconductor devices, and its unique features make it ideal for use in today's busy and highly automated production environment.

There are no reviews yet