Used CANON FPA 3000 i4 #9384534 for sale

URL successfully copied!

Tap to zoom

ID: 9384534

Vintage: 2000

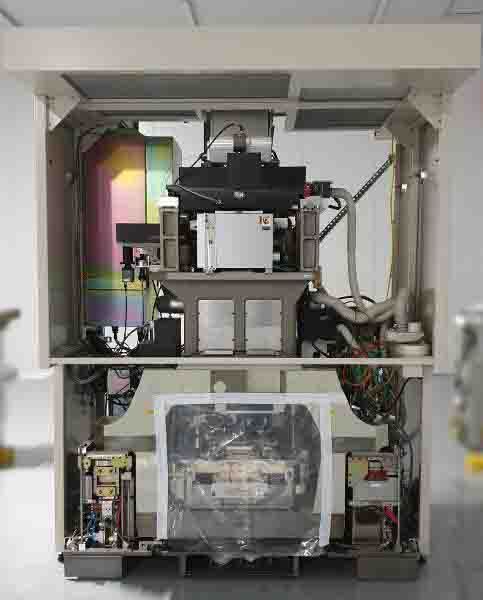

i-Line stepper

Reticle, 6"

EWS: 715/100

X-Terminal console

A/F Type-6: Right

W/F Size: 8"

PA Type: Flat

Library 12-Slot

Option: PPC

Cassette type: NIKON

Mount: Passive damper

BB Halogen lamp

Illuminatior: 2 kW

RASCO TBW-CD-83 Clean chamber

Lens edge distortion: U Lens

MO Drive

With CF Type

PCB and P/S Missing

Wafer stage:

Type: Air bearing

ZYGO Laser interfermeter

Chuck type: Pin

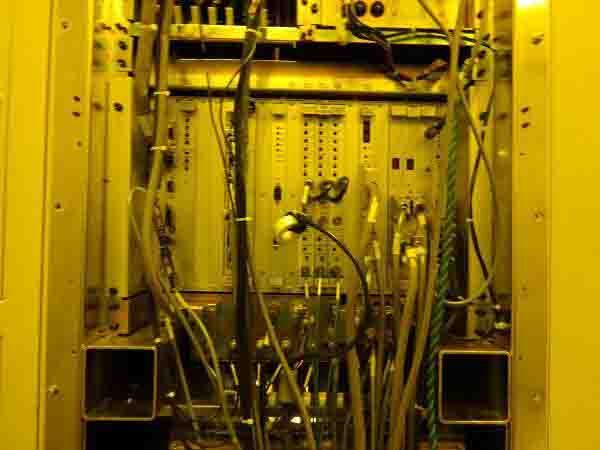

Image rack:

Part number / Description

BG4-6632 / TV Image CPU

BG4-9715 / ADP PCB

BG9-4084 / ACC1 PCB

BG9-4085 / ACC2 PCB

BG4-9716 / IMP2 PCB

BG4-6582 / HRD Processor PCB

VME Rack:

Part number / Description

BG4-6628 / Cam unit

BG4-6626 / Main CPU PCB

BG4-8817 / M-RGEN

BG4-6631 / CD I/F PCB

BG4-6629 / X, Y Stage CPU PCB

BG4-8818 / S-RGEN

BG4-6456 / Stage DSP

BG4-6465 / Measurement PCB (X)

BG4-6466 / Measurement PCB (Y)

BG4-6467 / Measurement PCB (Θ)

BG4-6457 / X, Y Pre PCB

BG4-6459 / OFCD IF PCB

BG4-6460 / PIEZO Analog PCB

BG4-5459 / PIEZO Drive PCB

BG4-6603 / CCD OPTF CAP2 PCB

2000 vintage.

CANON FPA 3000 i4 is an advanced and efficient wafer stepper that utilizes an ultraviolet projection optical equipment and modern lithography technologies to accurately pattern photomasks onto the wafers. This advanced device provides a number of features to minimize defects, maximize process throughput, and provide rapid throughput, which can reduce total processing time and consequently improve the device yield. The stepper utilizes the combination of lens elements with an advanced scanner to achieve the highest possible levels of accuracy. The lens elements give the device a numerical aperture up to 0.72 and offer a state-of-the-art demagnification ratio from 1 to 4. The stepper is also able to process both Positive and Negative Contrast resist types, as well as achieving pattern overlays at both high and low light intensities. The device features an improved optical system that provides small features, such as line-end edges, and a large polarization, flattening, and uniformity on the imaging field. Moreover, it has a semi-grazing incidence that improves light utilization of the lenses and significantly reduces the overlap of photomasks. This makes the device suitable for a wide range of photomasks and even more complicated patterns. CANON FPA-3000I4 is equipped with pattern alignment systems that enable it to accurately process both frame and field imaging. Two pattern alignment systems are used for the frame and field imaging, respectively. The frame alignment unit is capable of aligning the entire frame by comparing three points, and the field alignment machine can identify smaller features compared to the frame alignment tool. The device also provides a range of options for reticle scanning, deflecting, and focusing, including high-efficiency rectangular scan optics, high-performance deflector optics, and high-precision autofocus optics. Together, these features enable the device to process a variety of patterns with a large margin of tolerance and high levels of accuracy. FPA 3000I4 also offers a robust lithography process, which is an important feature as lithography is the core of the device. The air-cooled lamps used in the device create a deep UV light to create patterns on the photomasks, which helps reduce the risk of defects. Additionally, the lamps can also be efficiently replaced without necessitating alignment or adjustment of other optics. Overall, FPA-3000 I 4 is an advanced wafer stepper that offers a range of features for improved process efficiency, less downtime and faster throughput. It utilizes an array of lithography and pattern alignment technologies to create high-precision patterns, and boasts a number of features that help reduce the risk of defects and increase device yield.

There are no reviews yet