Used CANON FPA 3000 i5 #9086289 for sale

URL successfully copied!

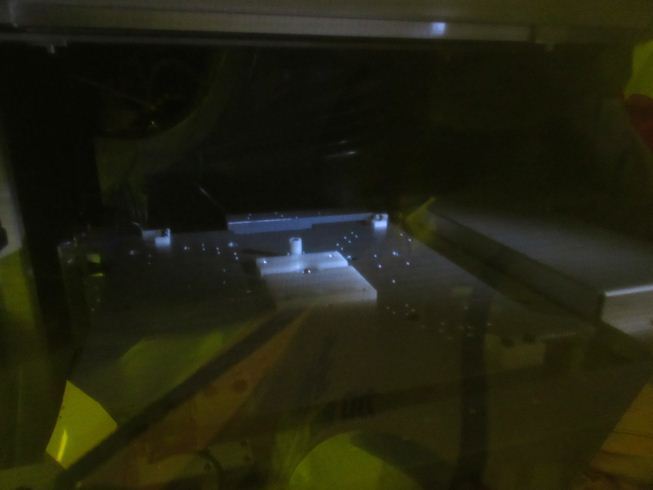

Tap to zoom

ID: 9086289

Wafer Size: 8"

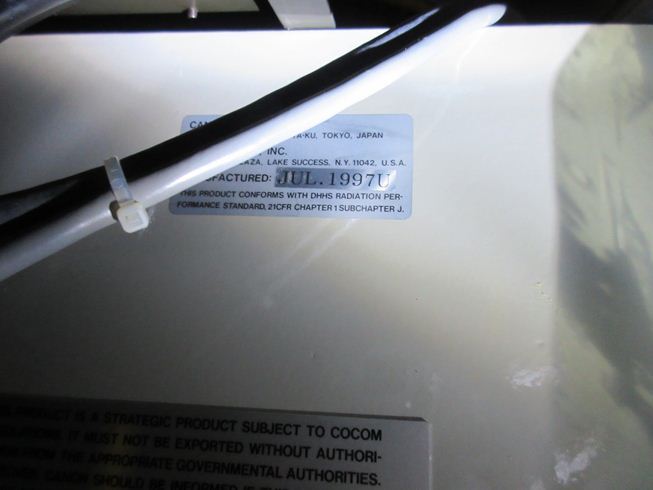

Vintage: 1997

i-Line stepper, 8"

Wafer type: Silicon, notch

Wafer chuck: Notch ring

Wafer feeder:

Type: L

Inline station: Yes

Edge exposure unit: No

Reticle changer, 6"

Type: Normal

Additional library: Yes

PPC: Yes

RPC: No

Cassette barcode: No

Reticle barcode: No

AGV: No

EWS:

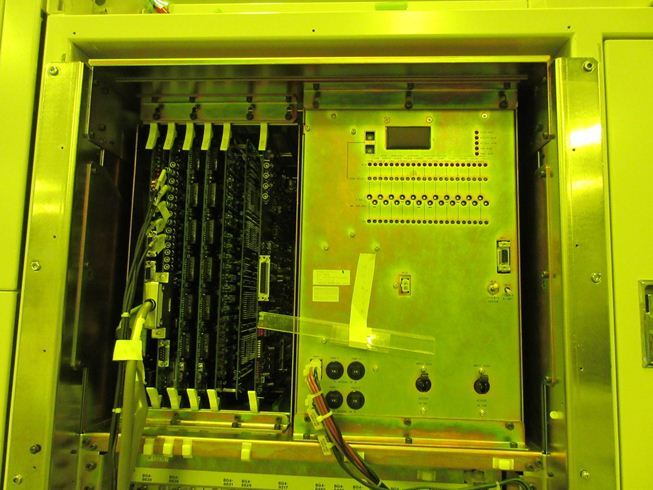

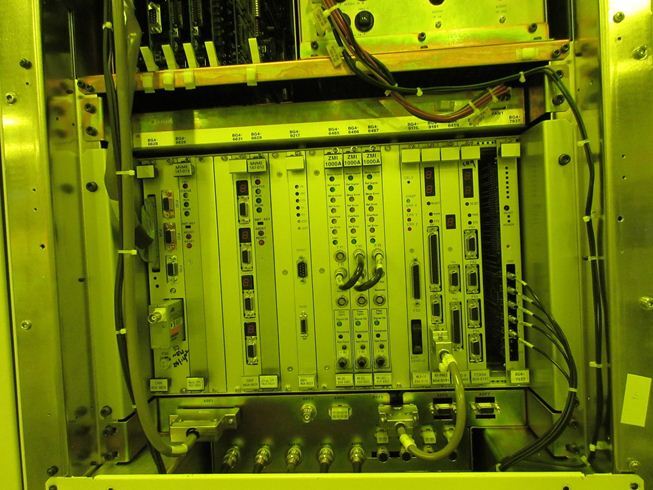

Type: 715

CPU: 64

2nd Lan Board: Yes

Console:

MO Driver: Yes

Remote: Yes

Printer: No

Job server: Yes

Online: Yes

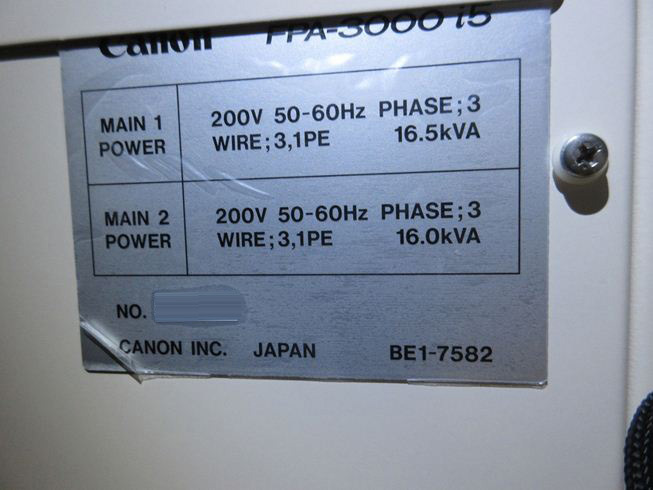

Power receiving box: Type 52B

(3) Signal towers

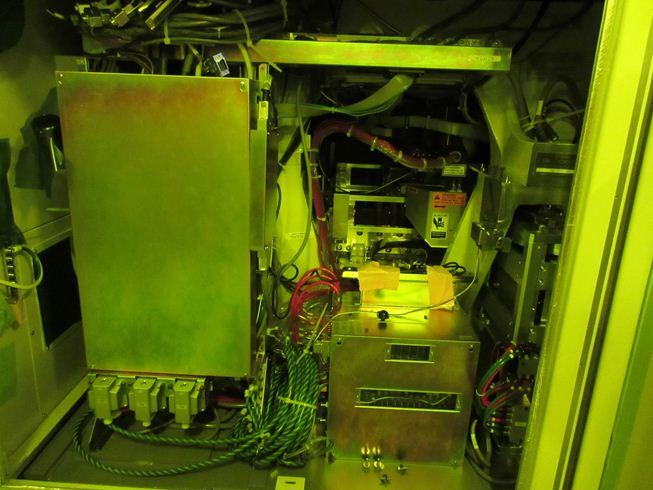

Damper: Active

Chuck maintenance tool:

Cleaning plate: No

Chuck fork: No

UPS: FUJI

Lamp / Laser:

Mercury lamp: No

Halogen lamp: No

He-Ne laser: No

Laser head (inter ferometer): Yes

Other:

Lock tool: No

Bar mirror case: Yes

Chuck maintenance tool case: yes

C-Oil: No

Manual: No

Currently warehoused

1997 vintage.

CANON FPA 3000 i5 Wafer Stepper is a precision alignment equipment designed to increase throughput and meet the exacting requirements of next-generation device manufacturing and wafer production. The system utilizes a five-axis, four-mirror scanning optical unit to achieve high accuracy and accuracy repeatability during lithography processes. CANON FPA 3000I5 Wafer Stepper is capable of handling up to 4" or 6" wafers with a high degree of precision. Additionally, the machine utilizes advanced lithography software to automate wafer alignment and wafer exposure processes. FPA-3000 I5 Wafer Stepper features an array of both optical and mechanical features designed to provide accuracy and versatility during wafer processing. Mechatronic actuators provide precise mechanical motion, enabling the tool to produce both high-quality images and minimal alignment errors. Additionally, two sets of laser pattern recognition cameras provide for high-resolution image acquisition and data input for lithography applications. The asset also features advanced alignment algorithms to accurately align the wafer and correctly adjust exposure parameters during the lithography process. CANON FPA-3000 I5 Wafer Stepper is also equipped with an advanced optical model, including a high-accuracy imaging lens and high-resolution zoom lenses, allowing for accurate focal length adjustment and focus matching between exposure stages. This ensures a consistently high exposure accuracy and ensures a high degree of repeatability during the exposure process. The stepper also utilizes a patented exposure equipment that integrates exposure and scanning in a single, unified exposure procedure. A comprehensive diagnostics system is integral to FPA 3000 i5 Wafer Stepper. This automated unit provides various advanced functions, including static image pattern evaluation, dynamic image pattern evaluation, laser image pattern alignment, performance evaluation and automatic adjustment of exposure parameters. Additionally, stored and archived data from prior processes can be used to provide quick and efficient process feedback when needed. Finally, FPA 3000I5 Wafer Stepper also features a full range of user-friendly features all designed to reduce operator workload and improve efficiencies. Fully integrated controls ensure that that exposure and scanning processes are properly controlled and optimized, while an intuitive user interface provides easy access to various exposure and scanning parameters. Additionally, the machine is compatible with CANON laser image processing software, allowing for advanced exposure and scanning rule configurations, data analysis and report generation. All in all, CANON FPA 3000 i5 Wafer Stepper is a reliable and highly capable tool designed to meet the exacting requirements of the latest device manufacturing and wafer production processes.

There are no reviews yet