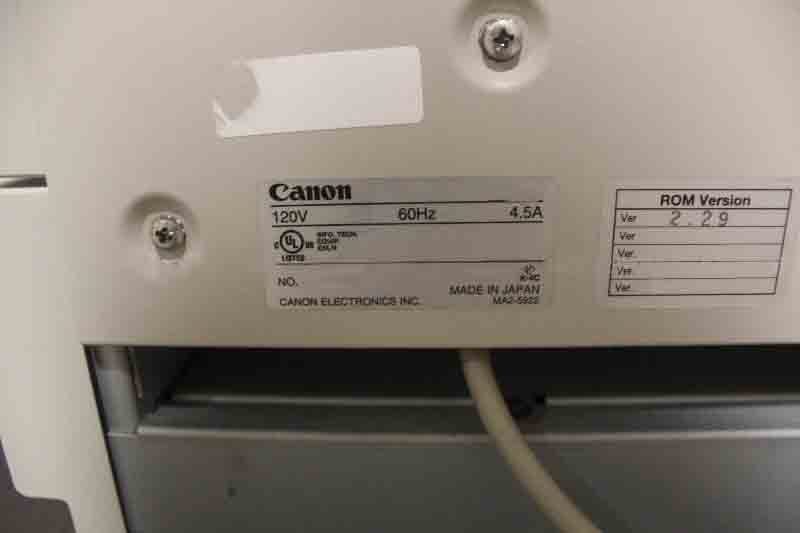

Used CANON MS800 #9409285 for sale

URL successfully copied!

Tap to zoom

ID: 9409285

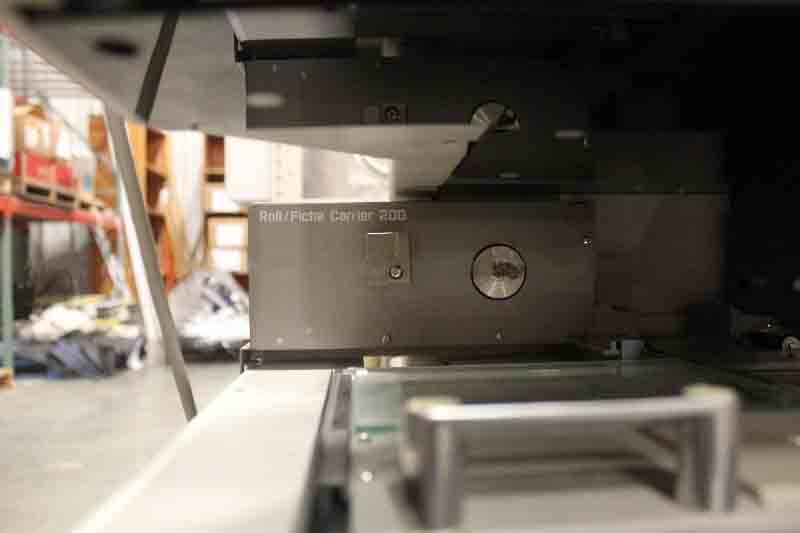

Microfilm scanner

Screen size: 11-3/4 x 17

Image scanning resolution: Up to 600 dpi

Power supply: 120 V AC, 60 Hz, 4.5 A.

CANON MS800 is an industry leading wafer stepper used in semiconductor processing. The machine uses a highly efficient optical equipment that provides superior accuracy and speed. It also has advanced auto-sampling capabilities to ensure precision of alignment and exposure. The machine is ideal for large-scale production as well as R&D applications. It features an ultra-short focal length lens for high-speed exposure and a large exposure field for uniform exposure. This ensures maximum accuracy with minimum distortion when exposure is done at higher sensitivity levels. The machine has an integrated vibration isolation system (VIS), which minimizes the effects of environmental vibrations on exposure accuracy. In addition, the machine offers a flexion-reduced stage and a clip cover unit for high-precision alignment. CANON highly advanced exposure control machine allows for fine tuning of exposure settings for each exposure with high accuracy. The tool offers feedback which enables the exposure to be adjusted in real-time to compensate for changes in the wafer surface. MS800 has an advanced autofocus asset with a 12-zone matrix that detects and adjusts the focal plane of exposure. The machine also offers three-dimensional alignment and automatic exposure control. The machine has an integrated vision inspection model (VIP) which helps to detect defects on the wafer surface. The vision equipment is powered by a high-resolution camera and image-processing algorithms to provide detailed and accurate reports. This enables detection of minute defects that would otherwise go unnoticed. The machine is capable of maintaining a clean environment with an advanced electrostatic charging system. This helps to maintain the accuracy of the exposure process. The machine is also equipped with an integrated surface cleaning unit that uses special brushes to clean the surfaces of the stepper. This helps to ensure a clean production window and prevents contamination. It also has a built-in photoresist removal machine that minimizes the risk of contamination. The tool can be driven by vacuum or spectroscopic pressure, depending on the complexity of the photoresist removal process. CANON MS800 wafer stepper is a leading-edge production machine designed specifically for high-volume production of semiconductor components. It provides efficient, accurate, and reliable operation with a range of features to help maintain the quality of the product.

There are no reviews yet