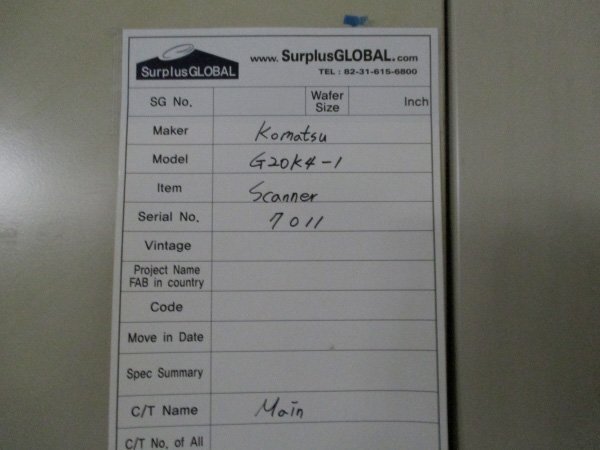

Used KOMATSU G20K2-1 #9095922 for sale

URL successfully copied!

Tap to zoom

KOMATSU G20K2-1 wafer stepper is a precision machine designed for reliable operation in the wet etching process. KOMATSU G 20 K 2-1 is a 300 mm tool specifically made for photolithographic processes. It has a top-mounted burn box, a sub-auburn, and an upper-lift plate, all specifically designed to maximize accuracy during the wet etching process. The sub-auburn provides a perfect temperature and chemical environment, which allows for tightly controlled and uniform etching processes. G20K2-1 uses an automatic strobe control device to automatically adjust the exposure time based on the thickness of the wafer, allowing for efficient and precise wafer processing. Its ±12 μm resolution creates consistent results with tight dimensional tolerances, while its position registration equipment provides a high level of accuracy. In addition to this, an advanced micro-load mechanism provides greater accuracy and improved positional stabilization, which helps to improve the quality of the final wafer. G 20 K 2-1 utilizes a wet etching process that produces a polished and completely homogenous surface. When combined with its three-level masking process, this provides for exceptionally accurate register and dimensional control. In addition, its closed-loop background autofocus system is effective at controlling the focal drive to ensure that imaging is always correctly focused. KOMATSU G20K2-1 has a variety of features that make it well suited for its intended application. For instance, its advanced photo power unit reduces exposure time and reduces rubbing wear on the wafer, while its wafer chuck rotation compensation and secure loading machine help to ensure that wafer integrity and accuracy are maintained. Furthermore, its integrated cleaning arm ensures that debris and downtime are kept to a minimum. Overall, KOMATSU G 20 K 2-1 wafer stepper is a reliable and precise machine that is ideal for photolithographic processes. Its advanced features allow for efficient and precise wafer processing and provide enhanced dimensional accuracy, ensuring a high-quality end product with minimal downtime.

There are no reviews yet