Used NIKON NSR 1755 i7A #9250067 for sale

URL successfully copied!

Tap to zoom

ID: 9250067

Wafer Size: 6"

Vintage: 1991

Stepper, 6"

Hard Disk Drive (HDD)

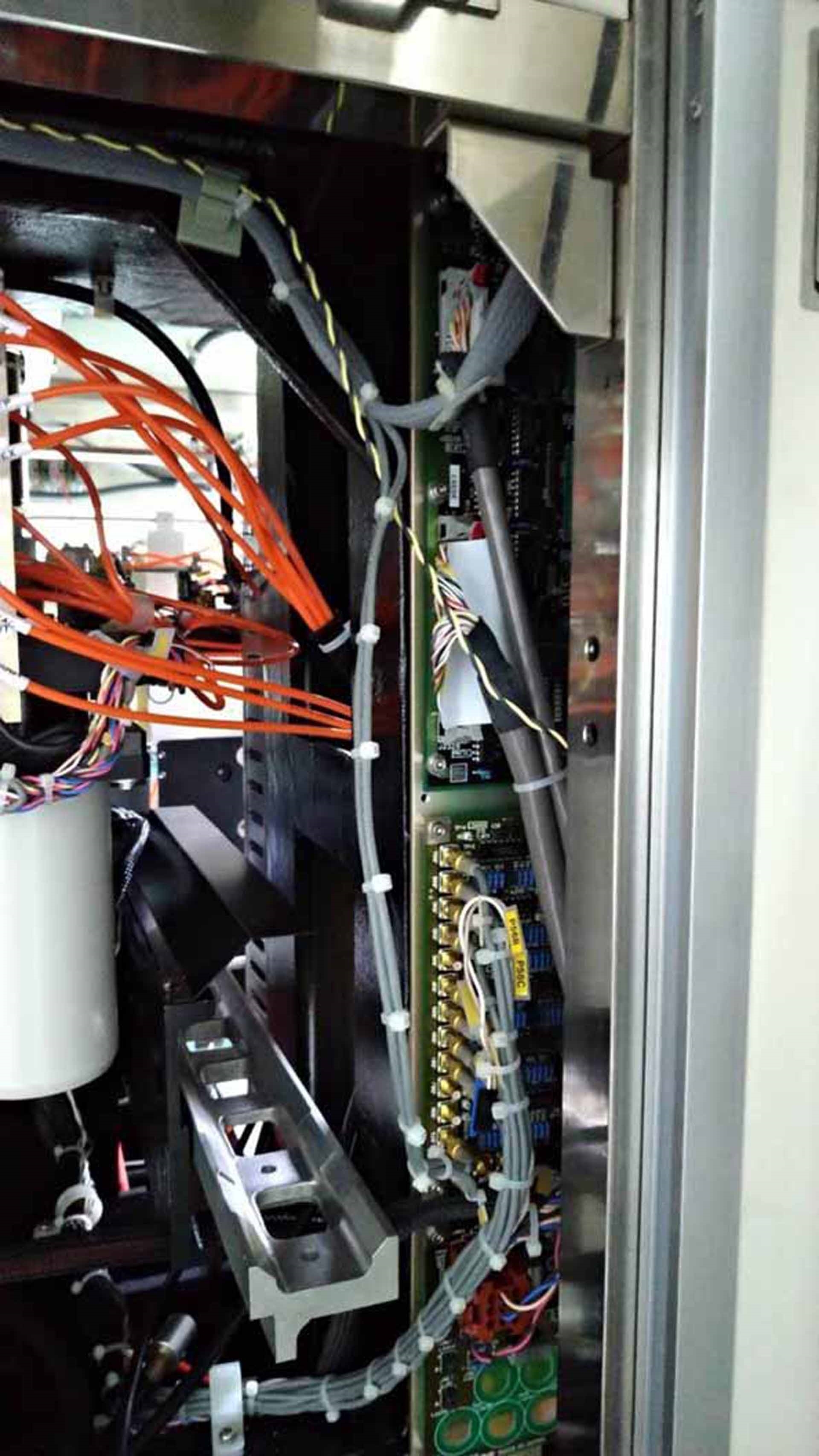

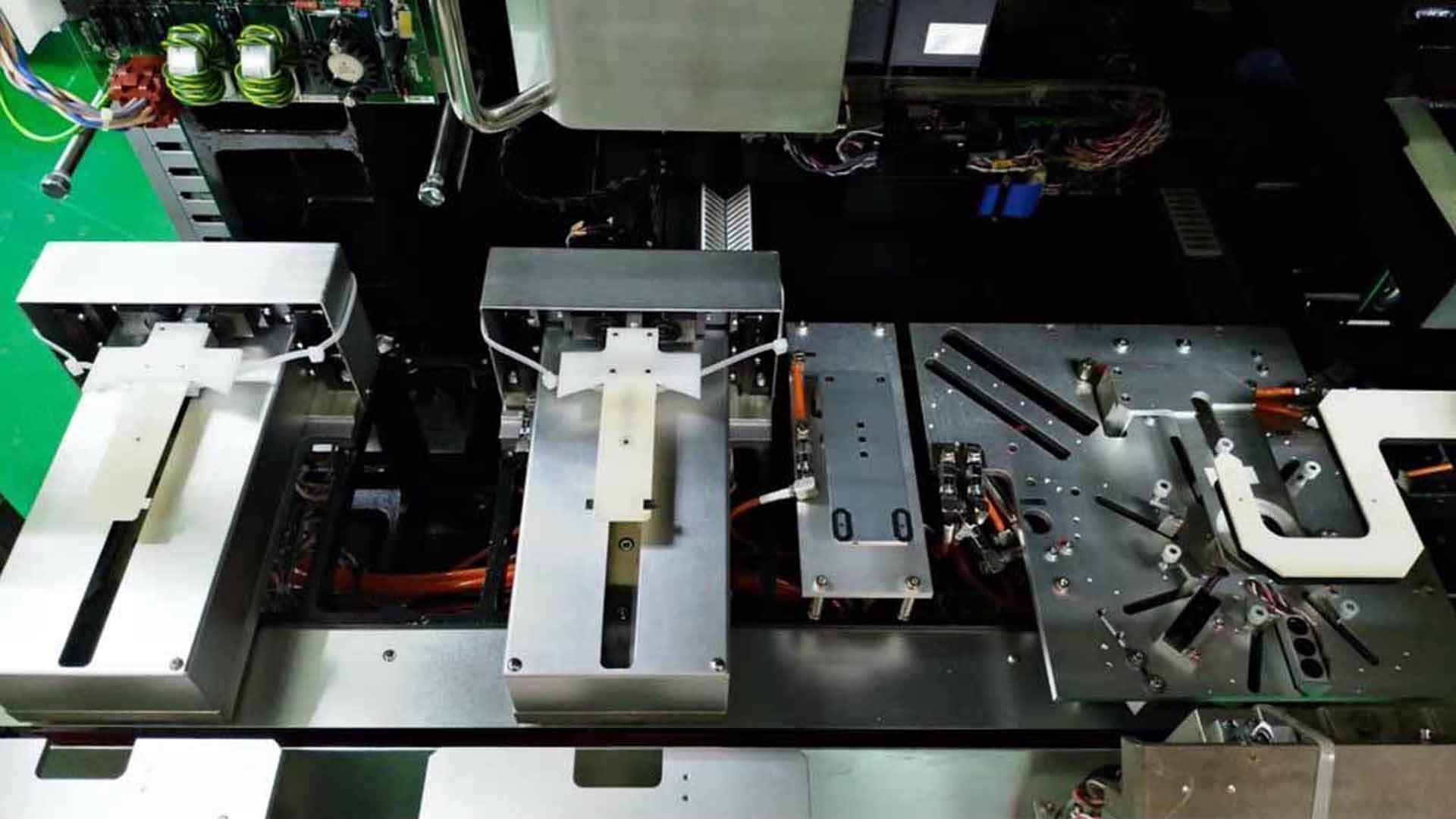

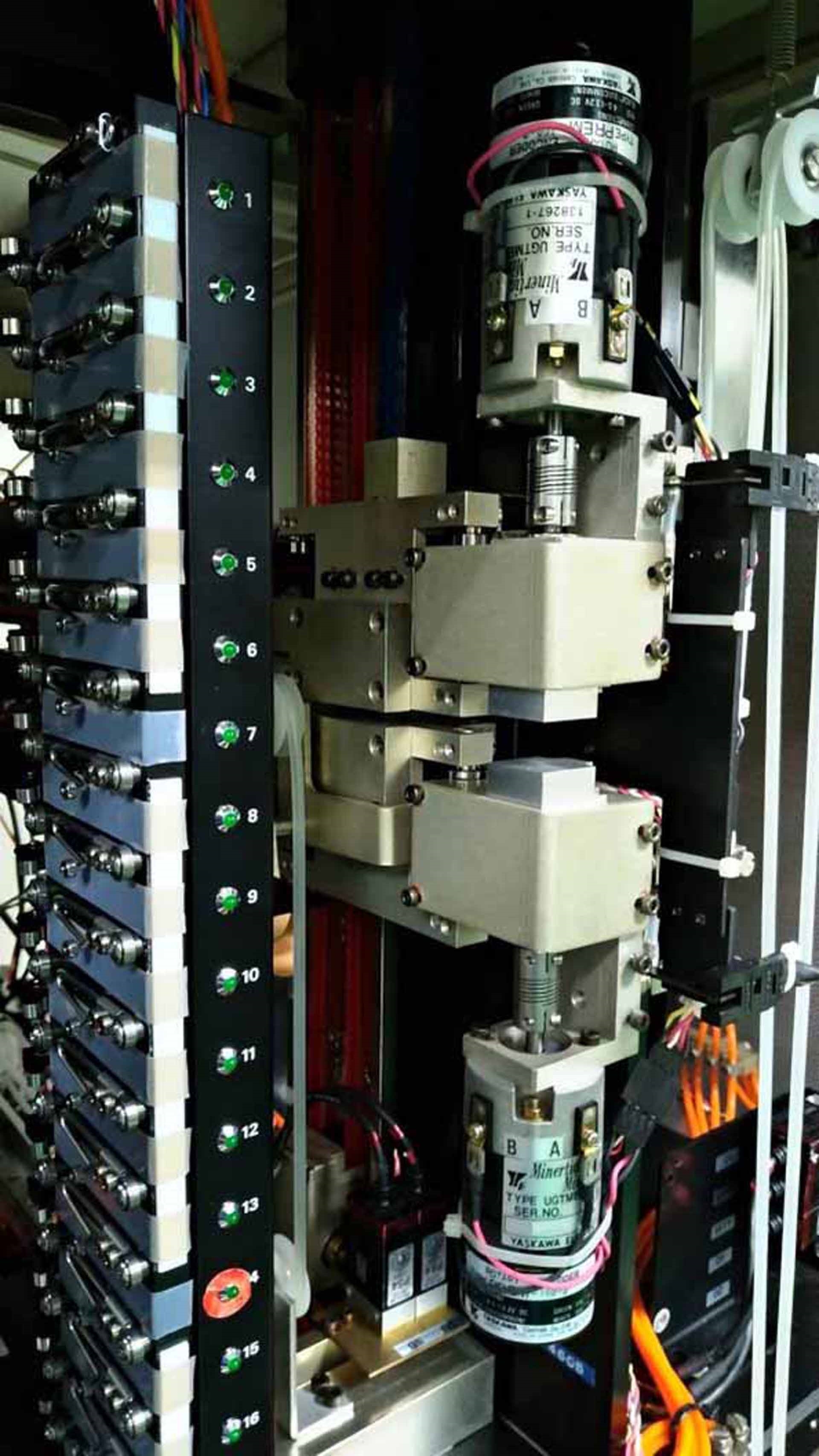

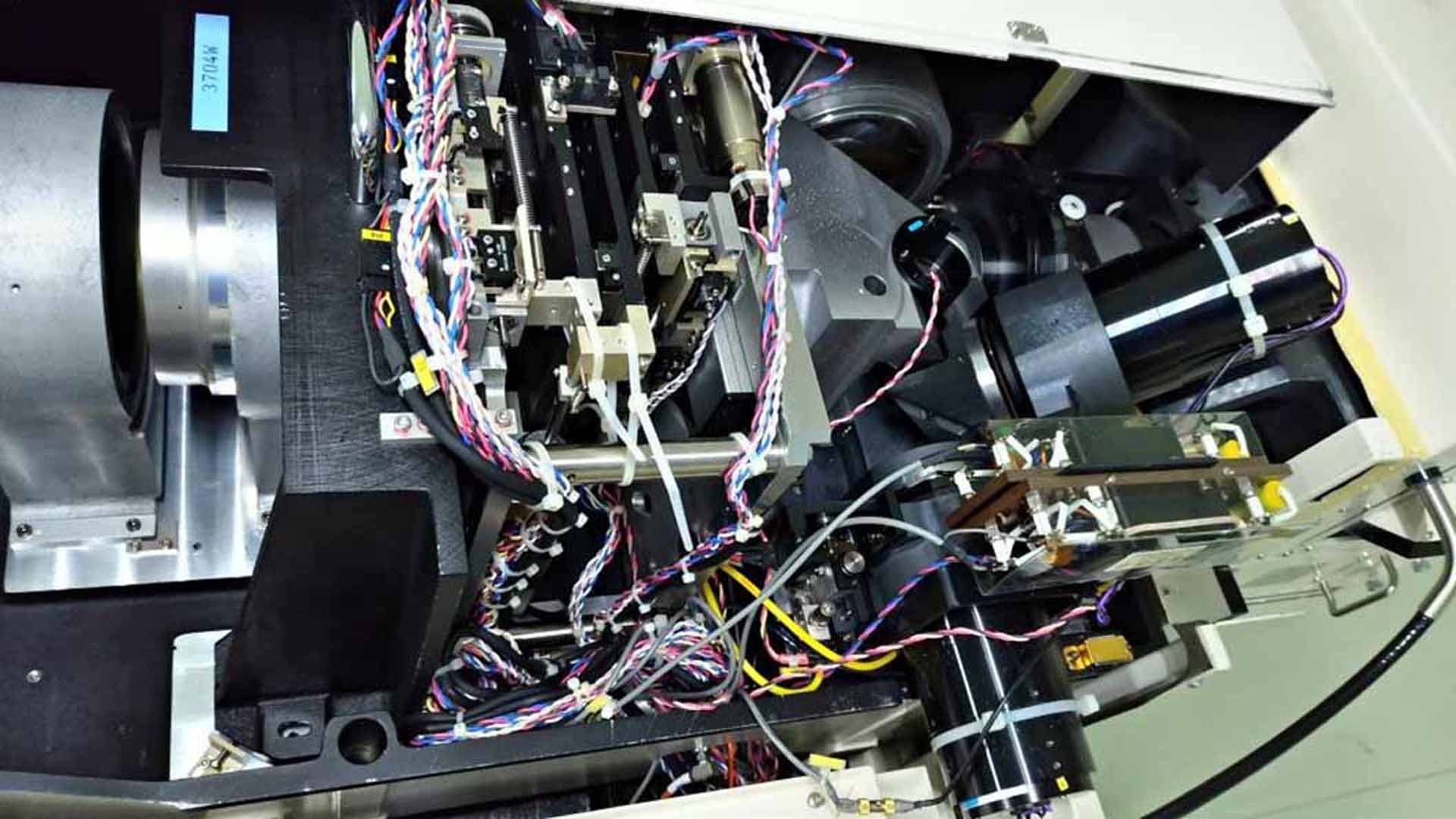

Control rack: Left

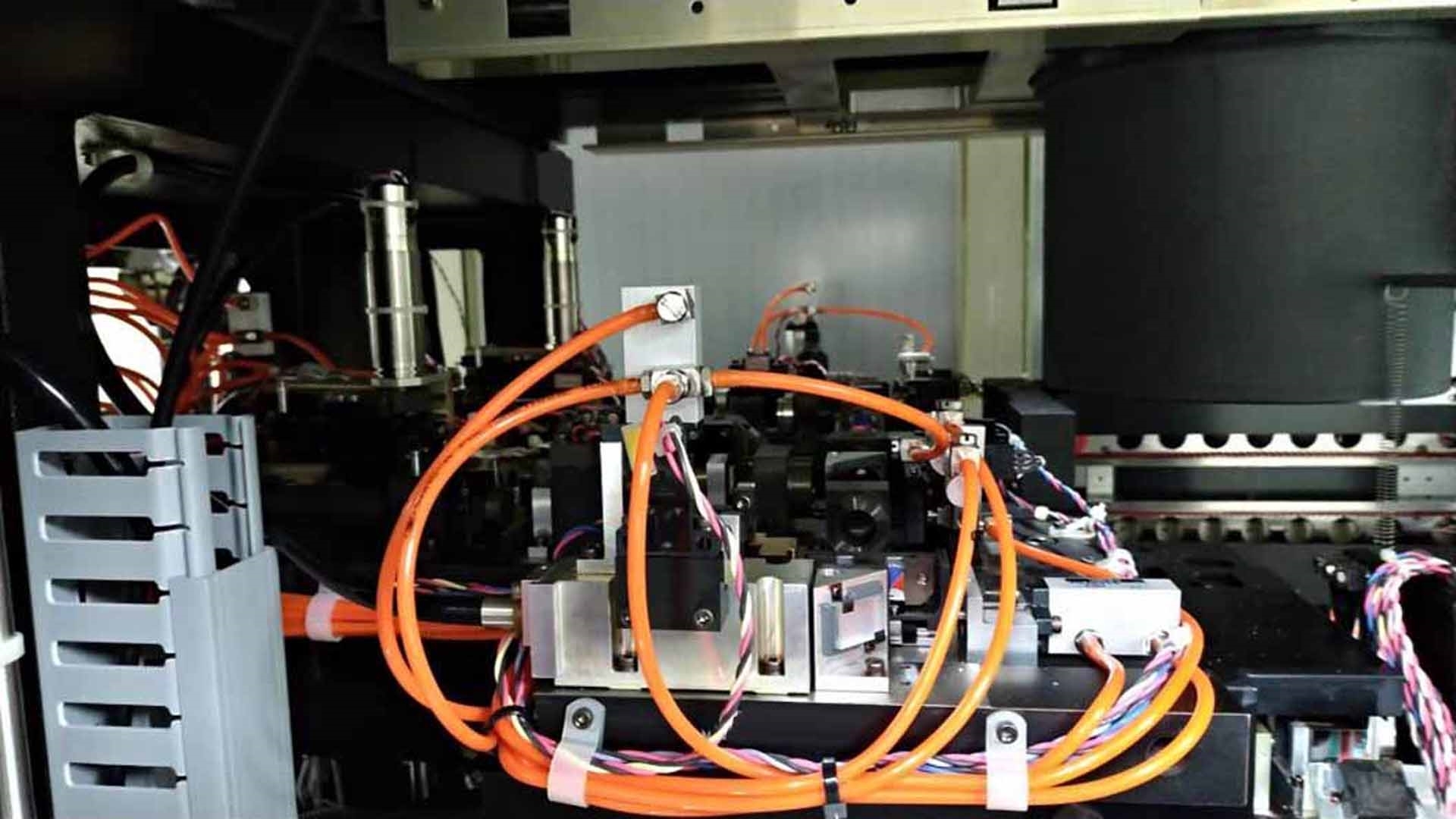

Wafer stage: Flat, 6"

Wafer stage screw: Ball

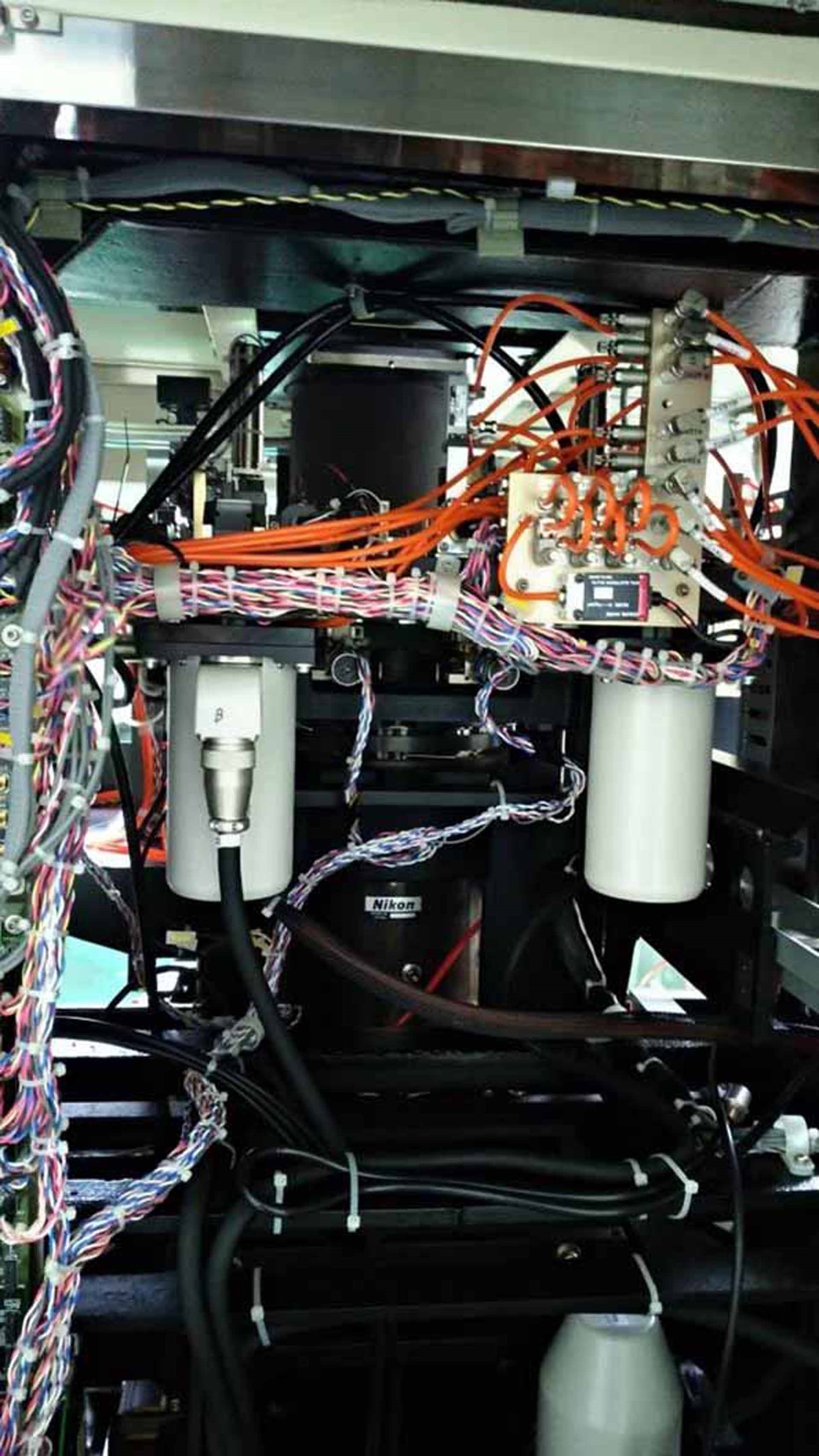

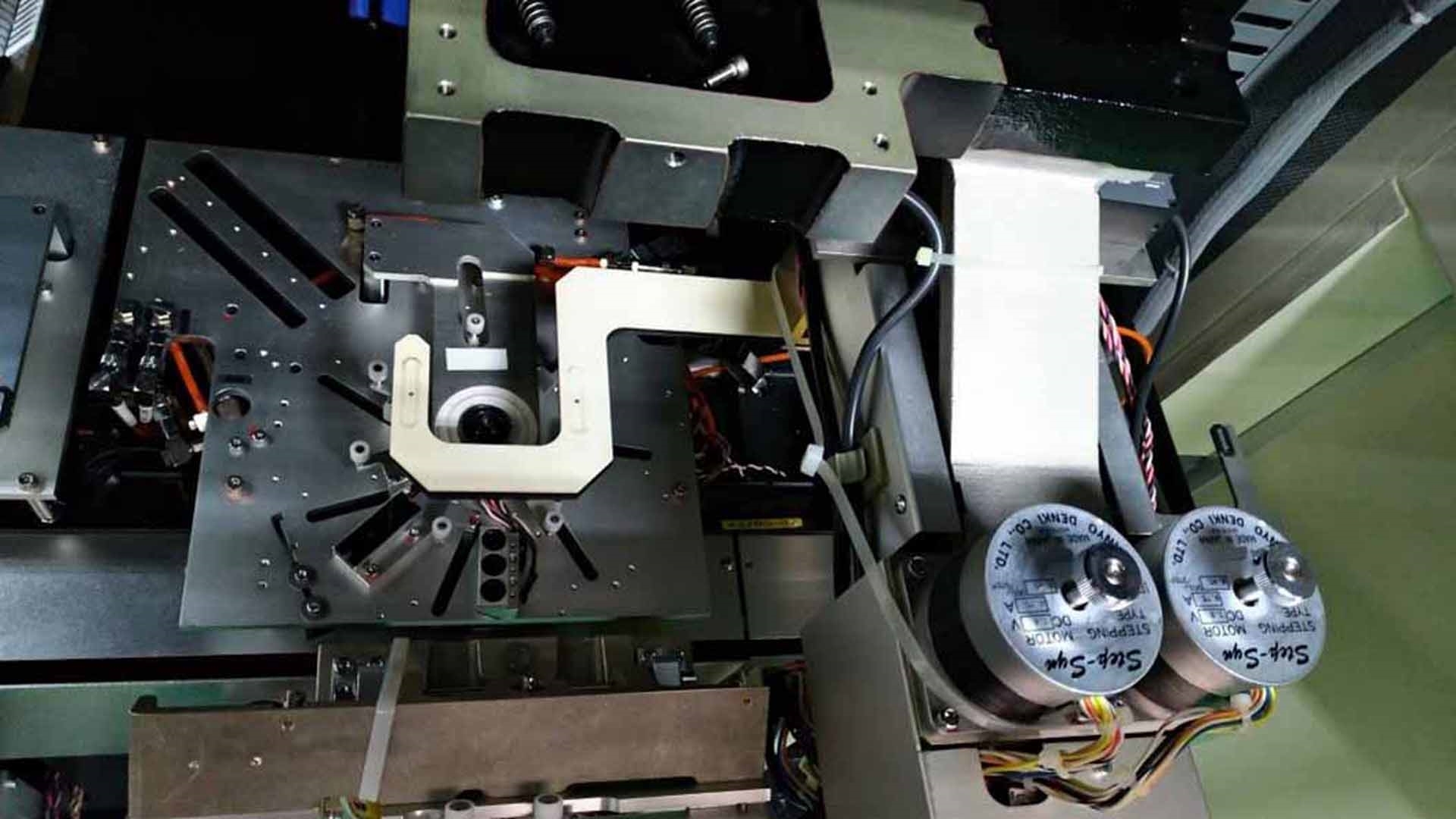

Wafer alignment: LSA

Auto focus: Single point

Wafer loader:

Flat, 6"

Type 1

Inline + Cassette (L)

Reticle size: 5"

Reticle microscope: 15 / 17.5 mm

Reticle loader: Normal

No expansion library

No PPD

No PD

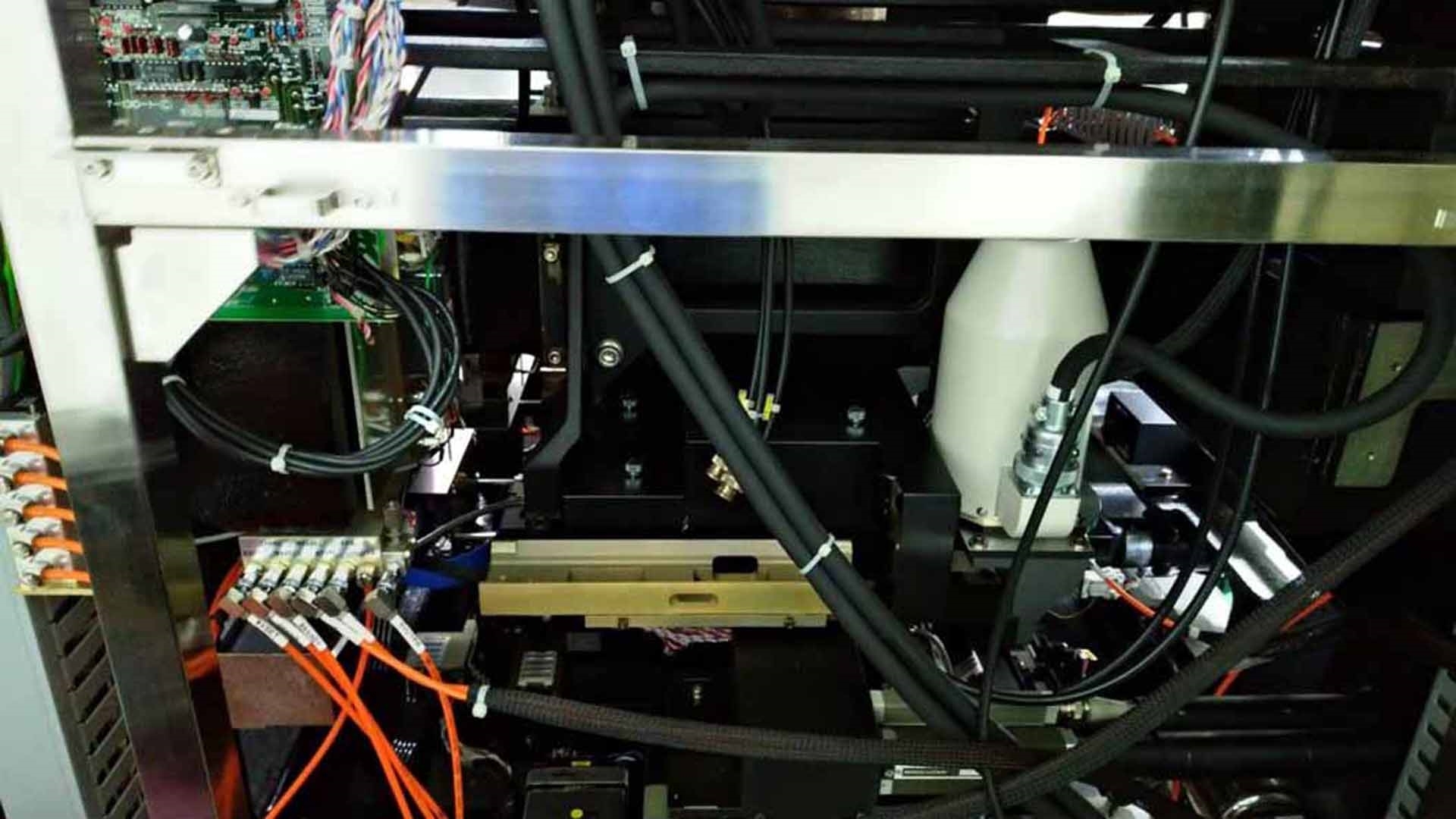

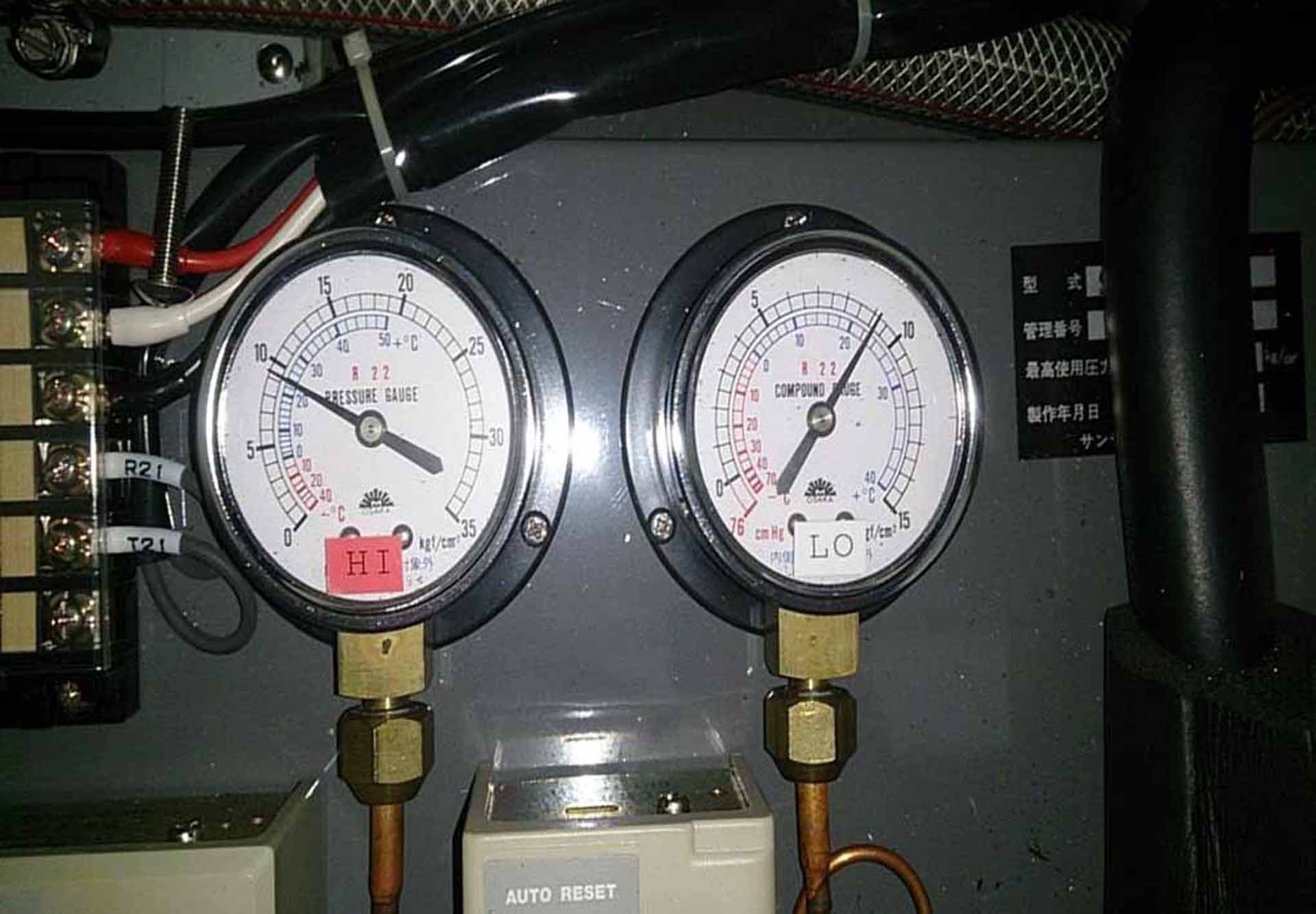

Control temperature: LATC and Chamber

Chamber: ASAHI S78

Chamber size: 1500

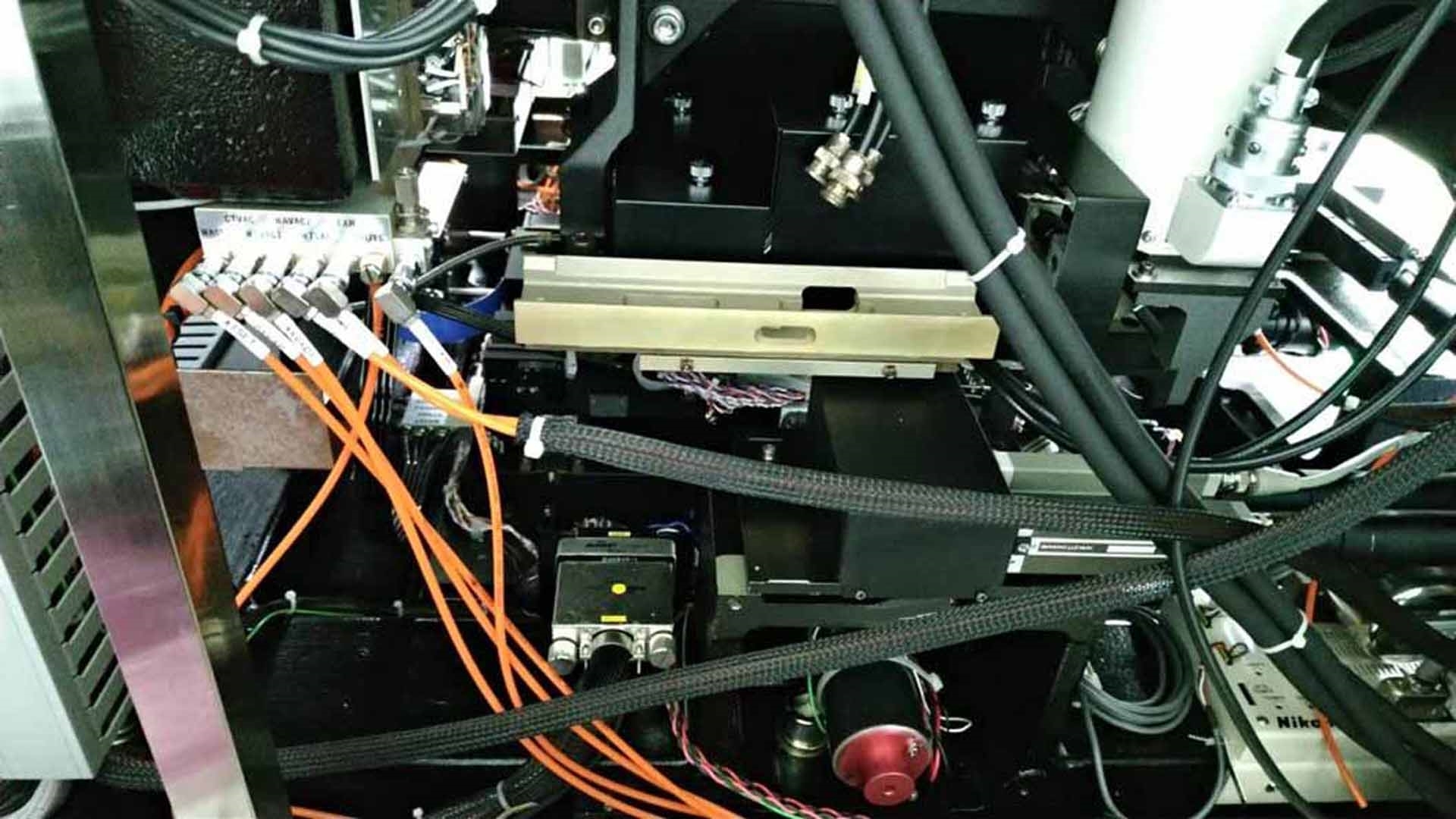

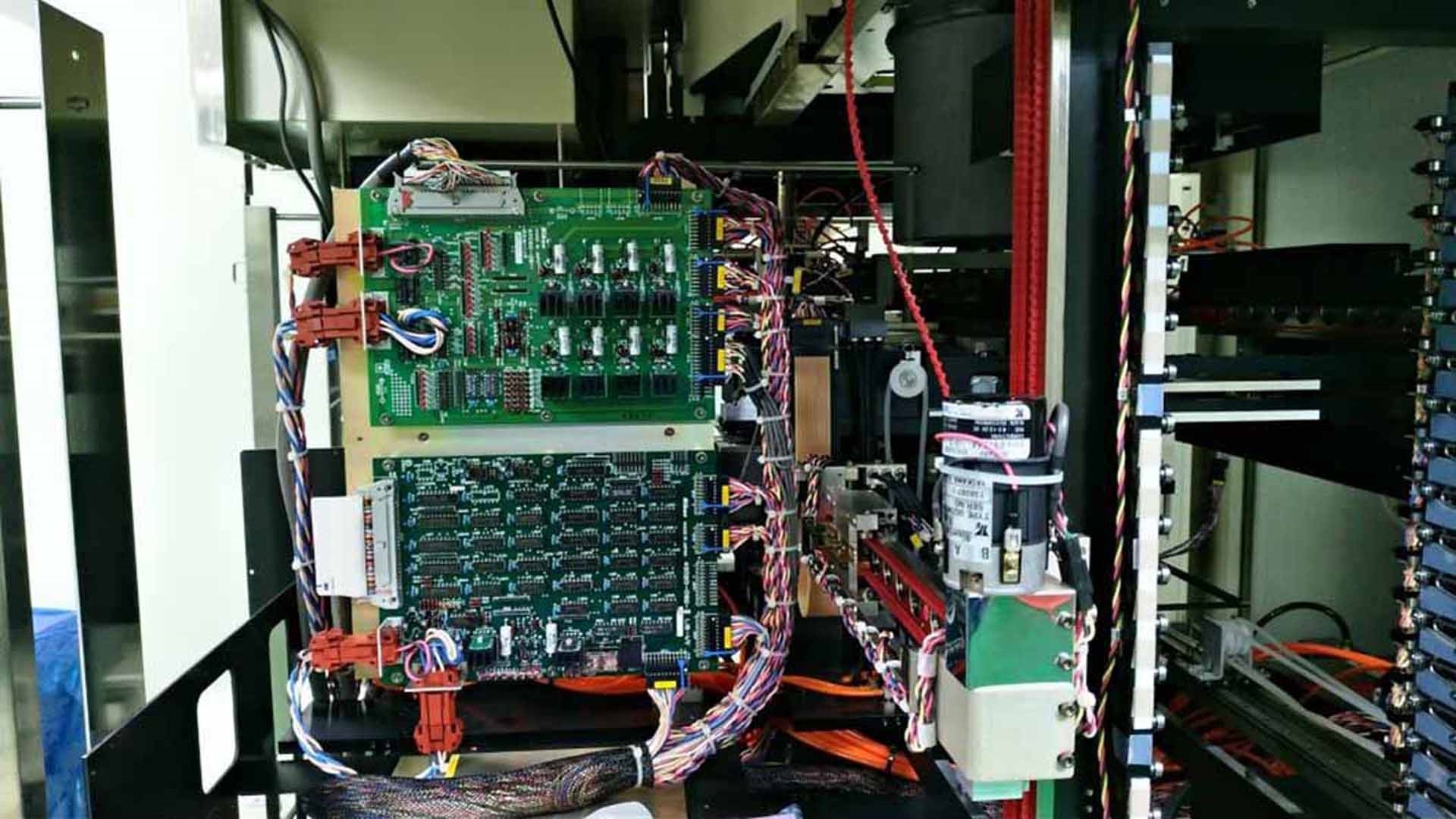

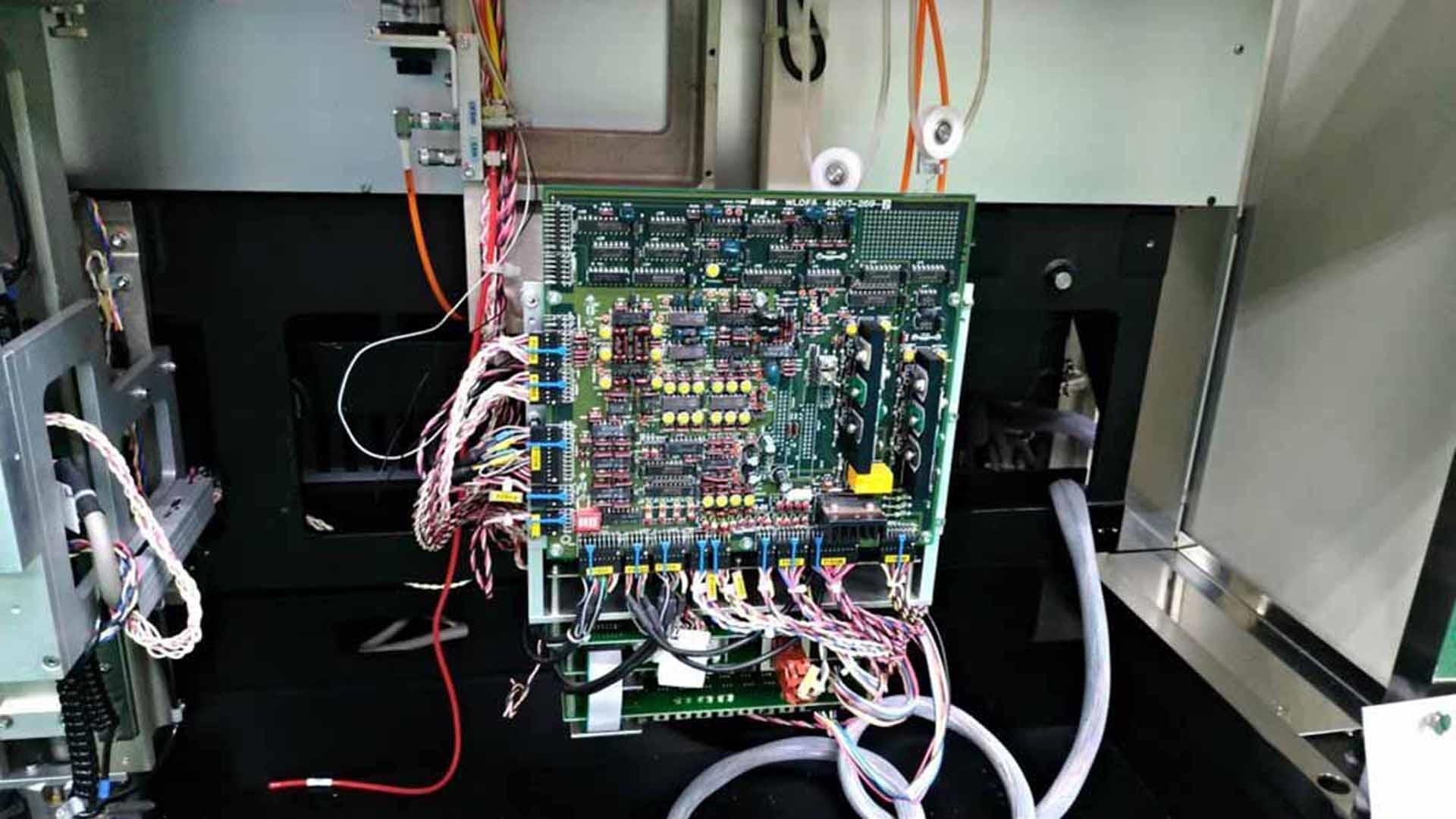

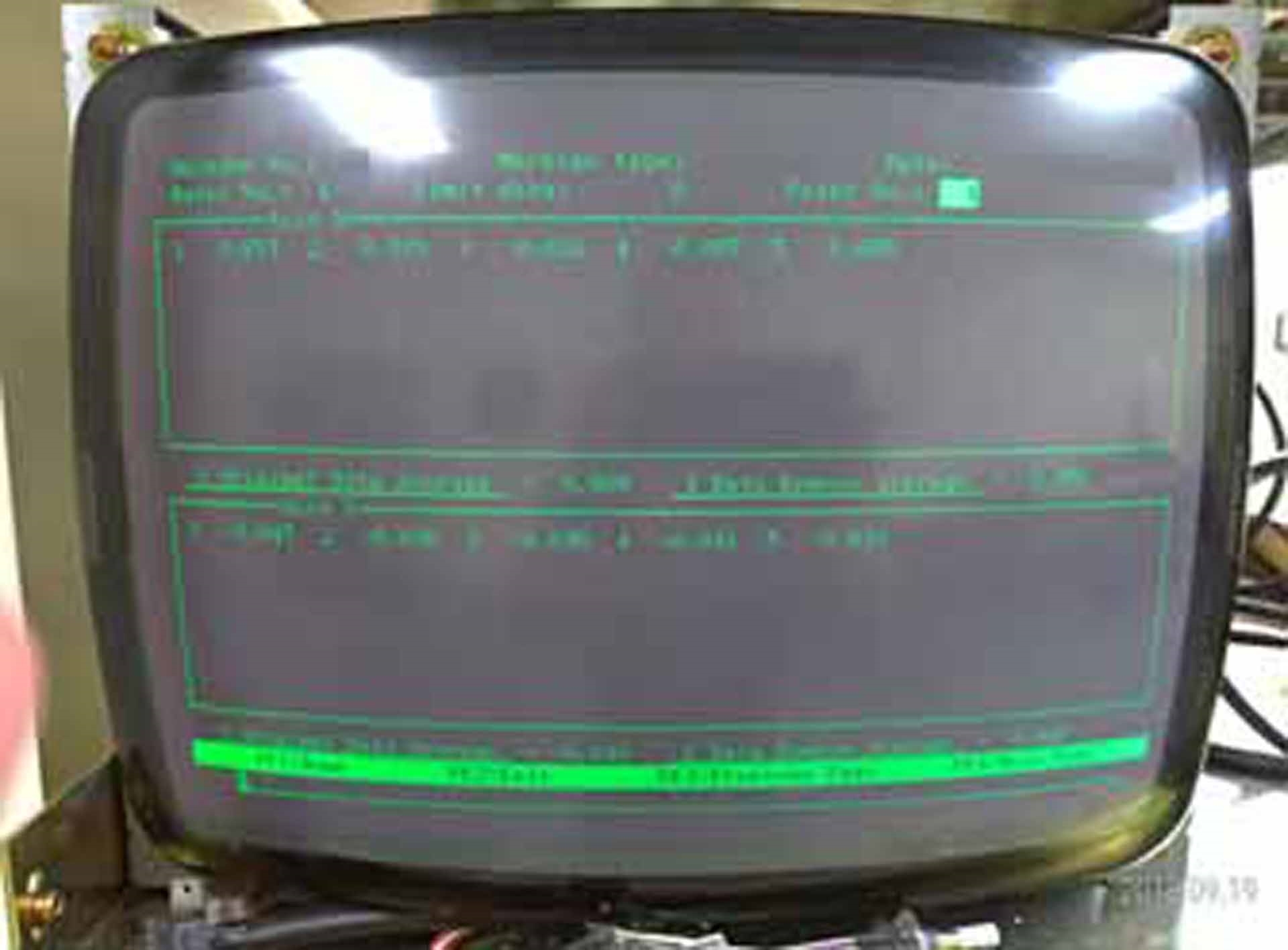

VT286

Camera control unit

Video converter 2

VDA1401A

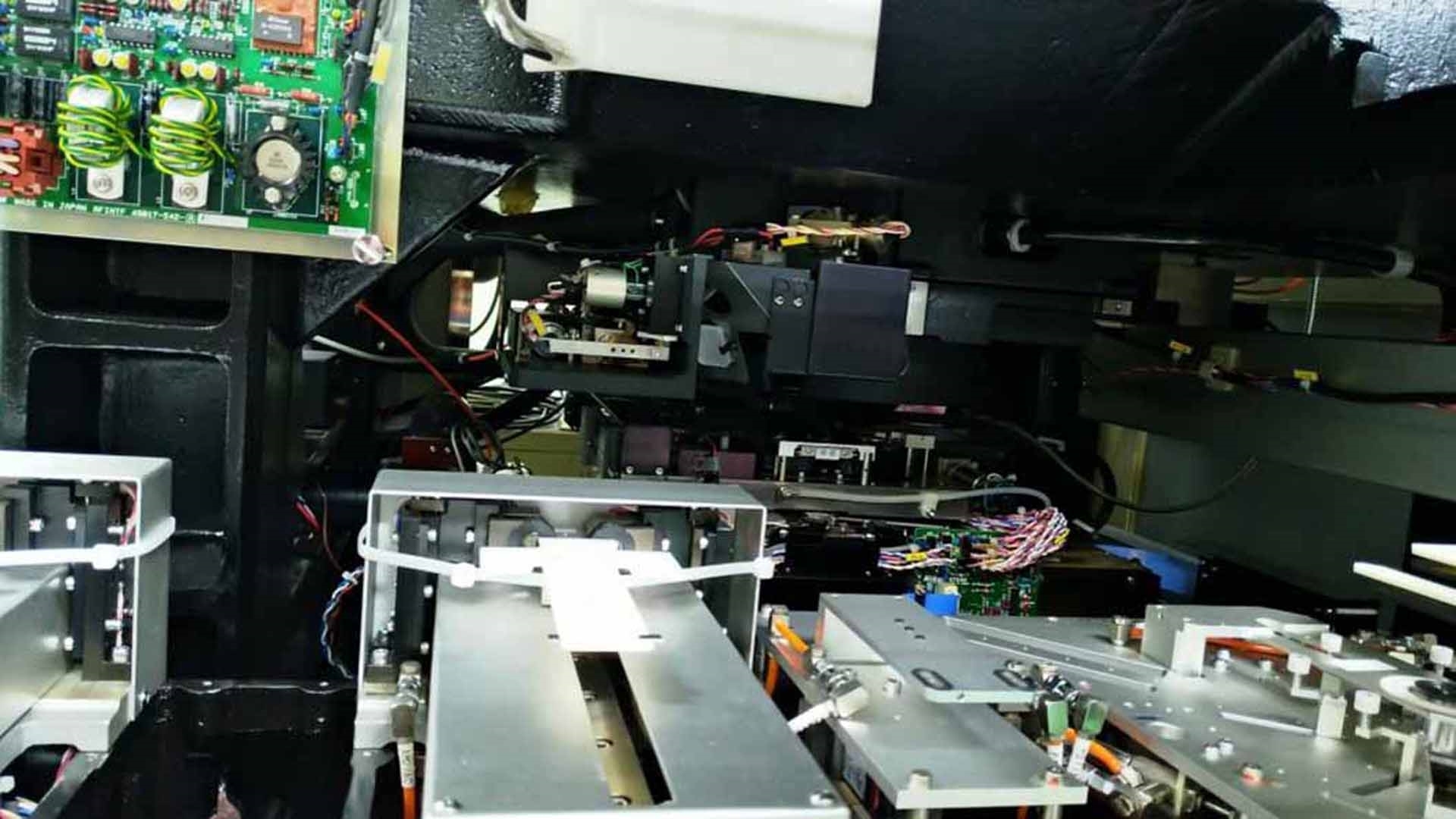

(2) Plates

LSA Laser tube

LC-SIG4

WGA Laser tube

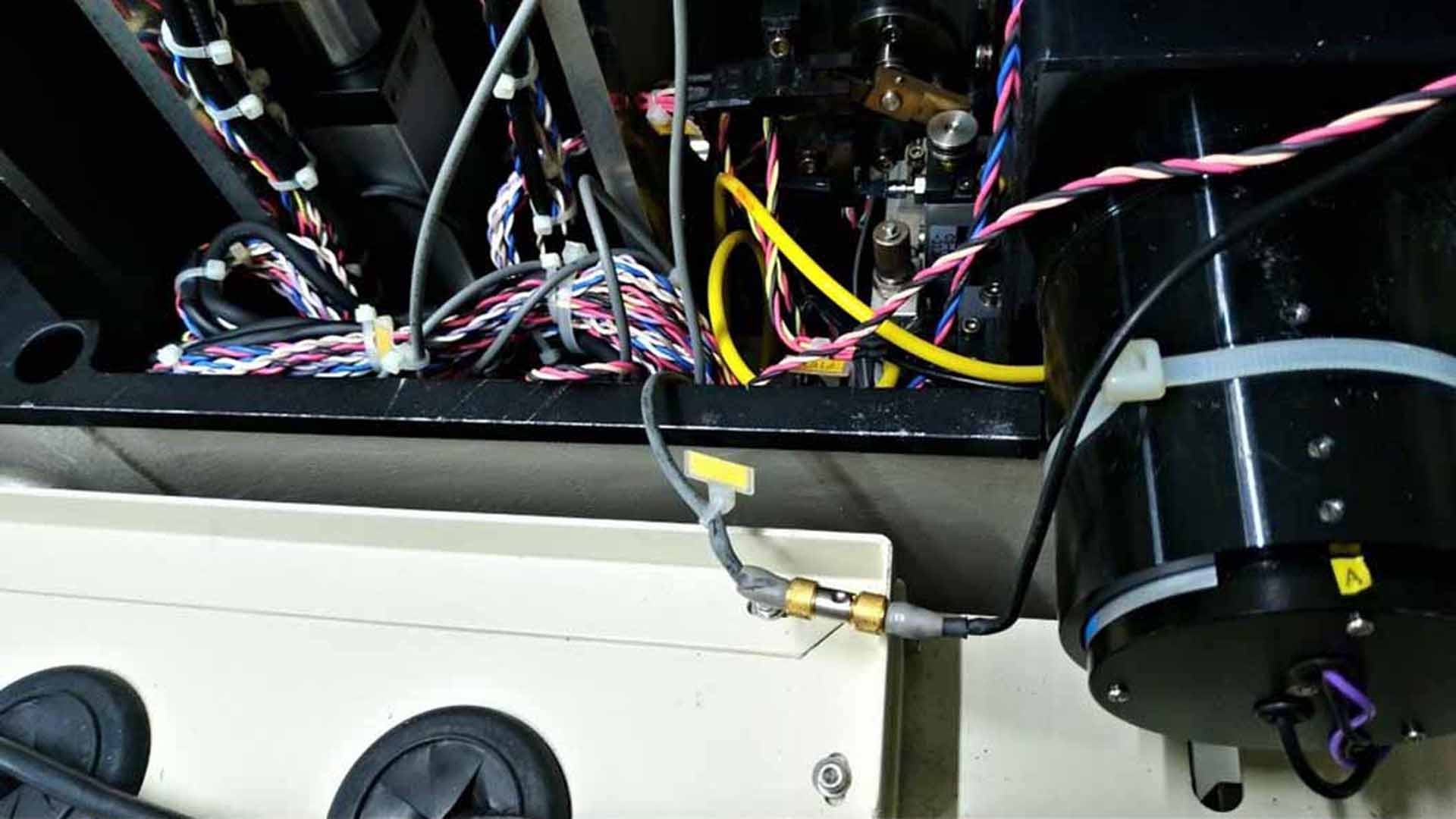

X & Y Ball screws

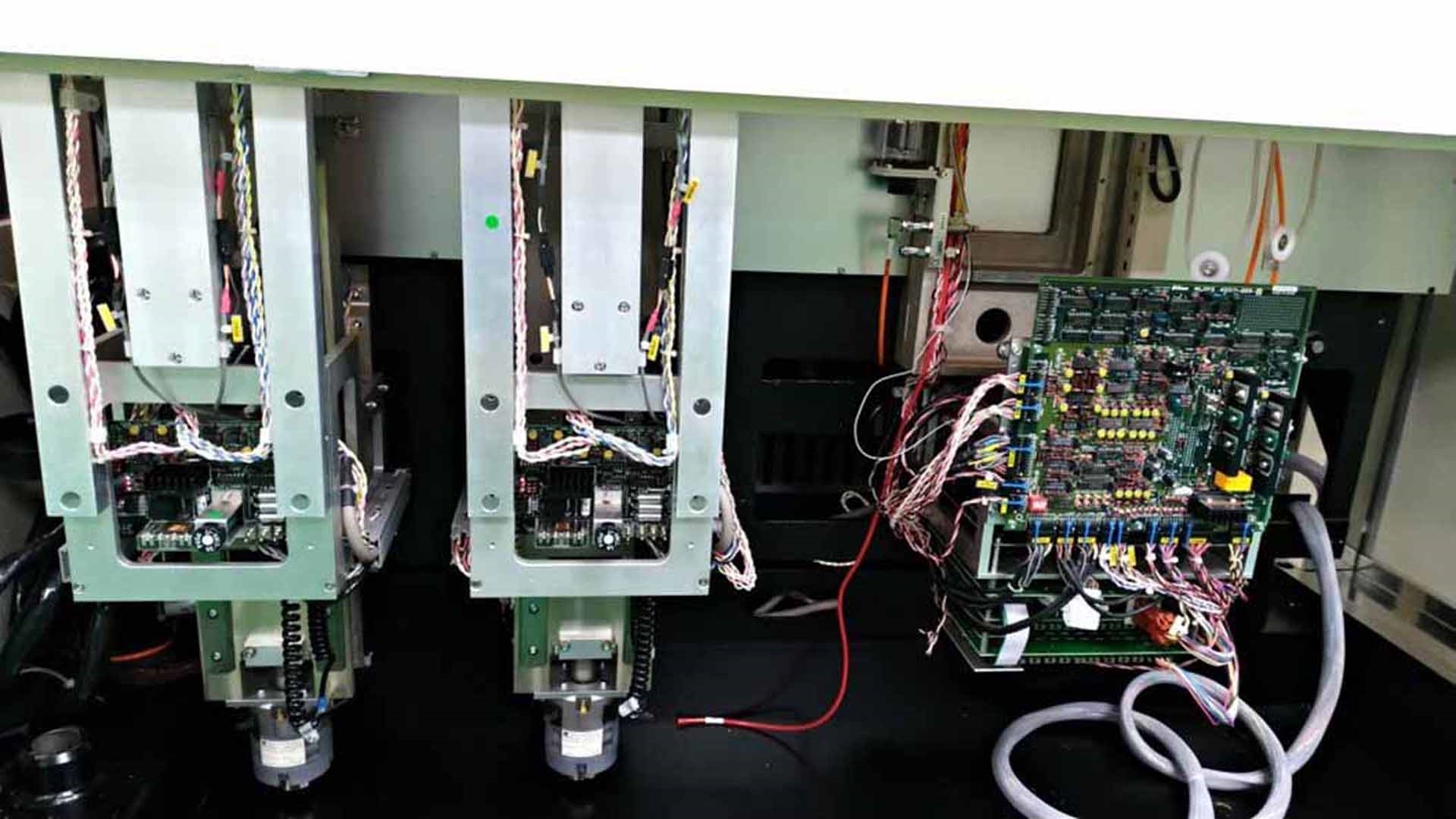

X, Y & Z Motor units

AFINTF AF68

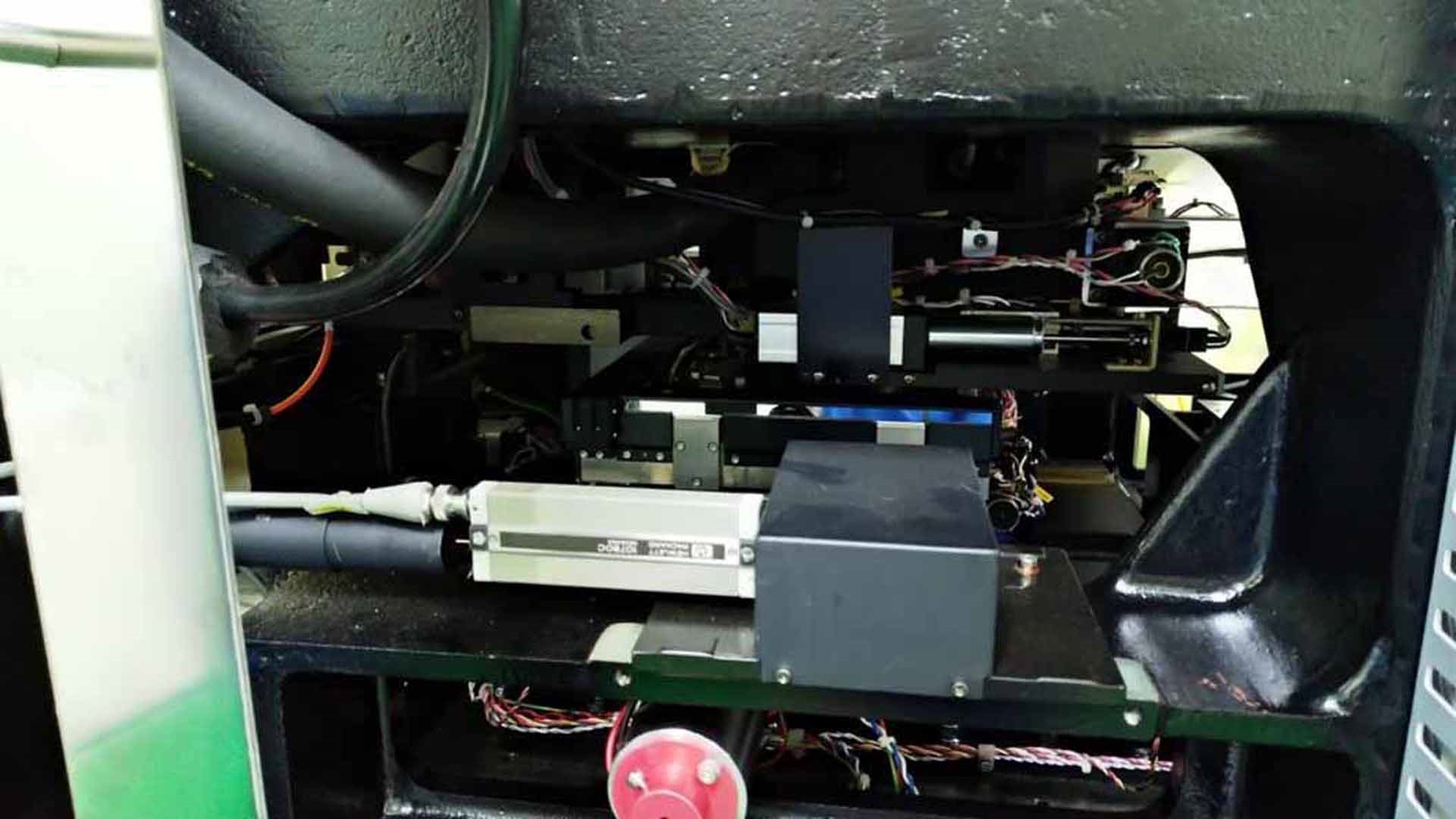

HP / HEWLETT-PACKARD 5517A Laser head

AF Motor unit

CT Unit

Pre 1&2 Units

Cassette plate

Vacuum box

(2) Laser power supplies

Power supply

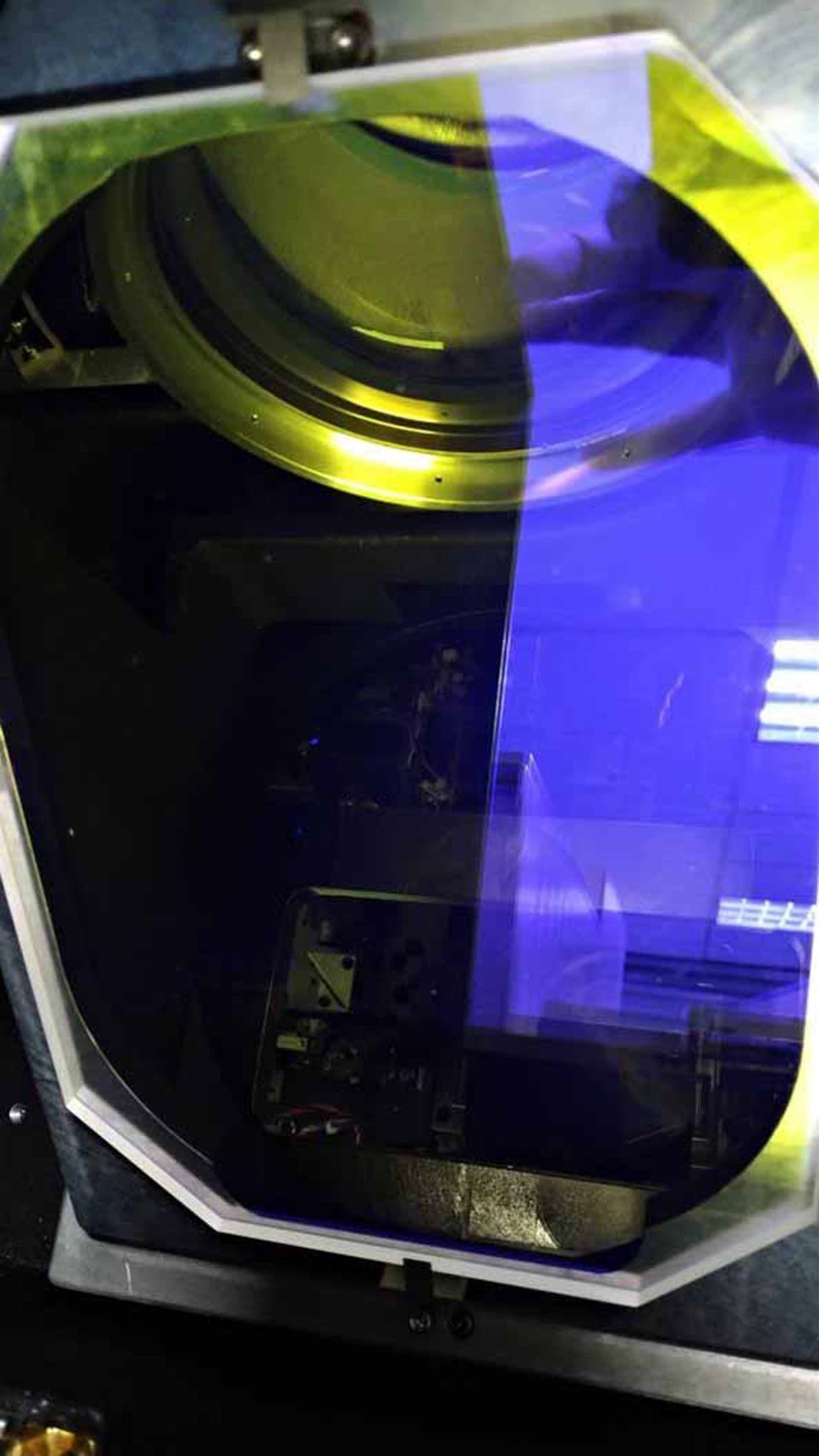

Fly eyes unit

(2) PLC CPU

Missing parts

1991 vintage.

NIKON NSR 1755 i7A is a state-of-the-art wafer stepper designed to meet the demands of next generation semiconductor fabrication. This machine uses digital optics technology to produce high-resolution imaging of photomasks with tight feature control and excellent overlay in the most advanced technologies. The equipment is configured with two exposure beams, which can handle a range of substrates from 12 mm to 300 mm. It is coupled to a stage for automatic control of the wafer position and alignment. A high-precision 3-axis stage is combined with a 1-axis tilt control, ensuring repeatable control of all the axis necessary for imaging. It is capable of reaching a maximum resolution of 0.25µm, while maintaining alignment accuracy within 1.5µm. NIKON NSR 1755I7A comes with an automated process control platform which allows users to control the imaging process with minimal human intervention. This control platform monitors and adjusts exposure dose levels and process parameters throughout a task cycle, thereby optimizing the imaging quality. With its high measurement accuracy, it can detect minute defects on a wafer and stop the projection imaging system before non-compliance occurs. In addition, NSR-1755I7A comes with an advanced data analysis and data management software, allowing users to analyze images and capture data for further analysis. This data analysis and management unit supports the analysis of defect analysis, doses data and other quality control parameters. NSR 1755 i7A is built with high reliability and incorporates redundant components to ensure constant uptime of production applications. It is also designed with an Eco-Friendly Focus, reducing water and energy consumption for operation, creating a better environment. The machine is designed for safe operations and maintenance to ensure long-term performance. In summary, NSR-1755 I 7 A is an advanced and versatile wafer stepper that is designed to meet the high demands of next generation semiconductor fabrication. Its digital optics technology and sophisticated process control platform enable users to achieve optimal imaging results within the highest precision requirements.

There are no reviews yet