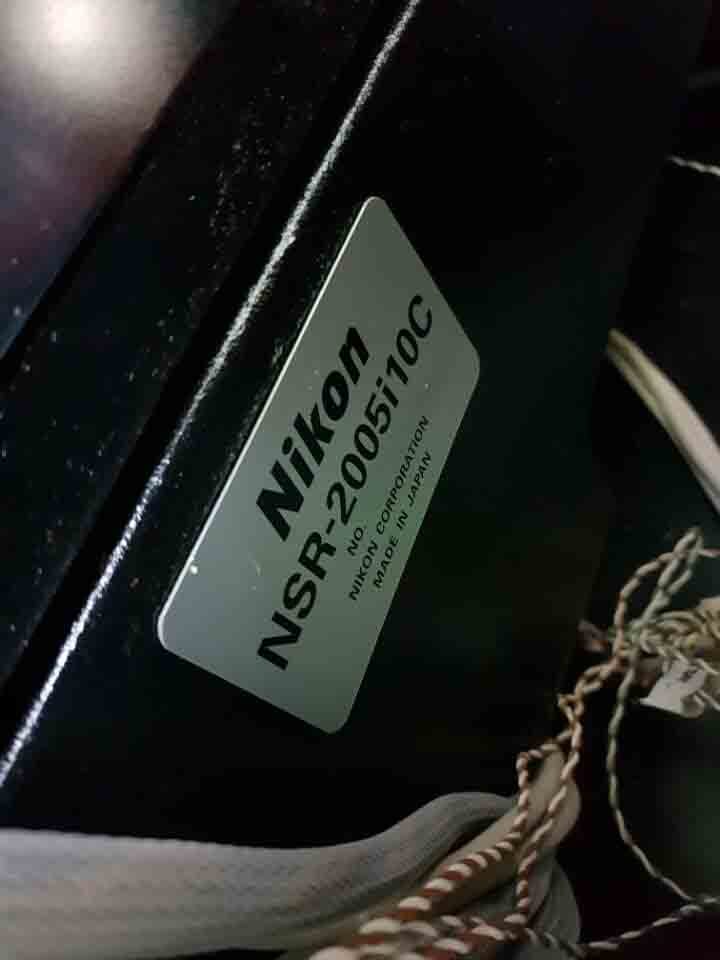

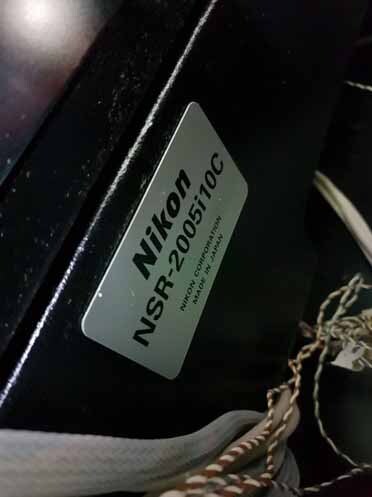

Used NIKON NSR 2005 i10C #9408135 for sale

URL successfully copied!

Tap to zoom

ID: 9408135

Wafer Size: 8"

Vintage: 1995

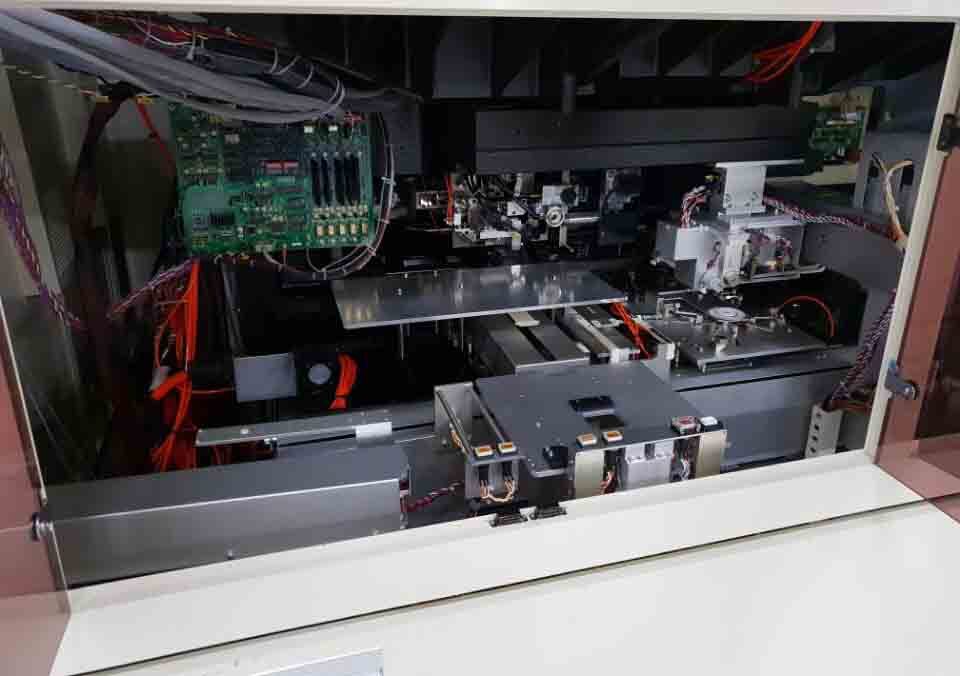

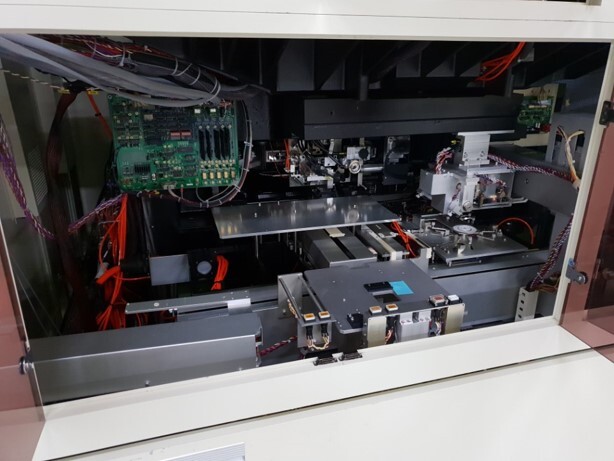

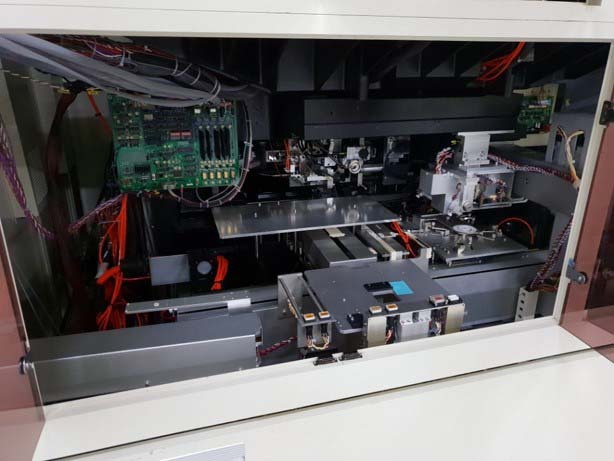

Stepper, 8"

Control rack

KOMATSU BCE-5051-A Chiller

Electric source: NEMA Box for CVCF

(2) NEMA Switches

Computer type: NEST3

EPROM Chamber:

Type: SENDAI S04

Body size: 1950 mm

Set temperature:

Chamber: 25°C

IATC: 25°C

LLTC: 25°C

ROM Version:

Reticle:

Loader: RL-04V7.00

Stage: RA-81V1.70

Wafer:

Stage: ST-63V3.50, XY-63V2.90

Loader: WF-80V3.70

Sensor: WA-6DV2.50

Operational panel: PA-61V2.51

Lens controller: LC-6NV2.20

HEWLETT PACKARD 5517B Laser:

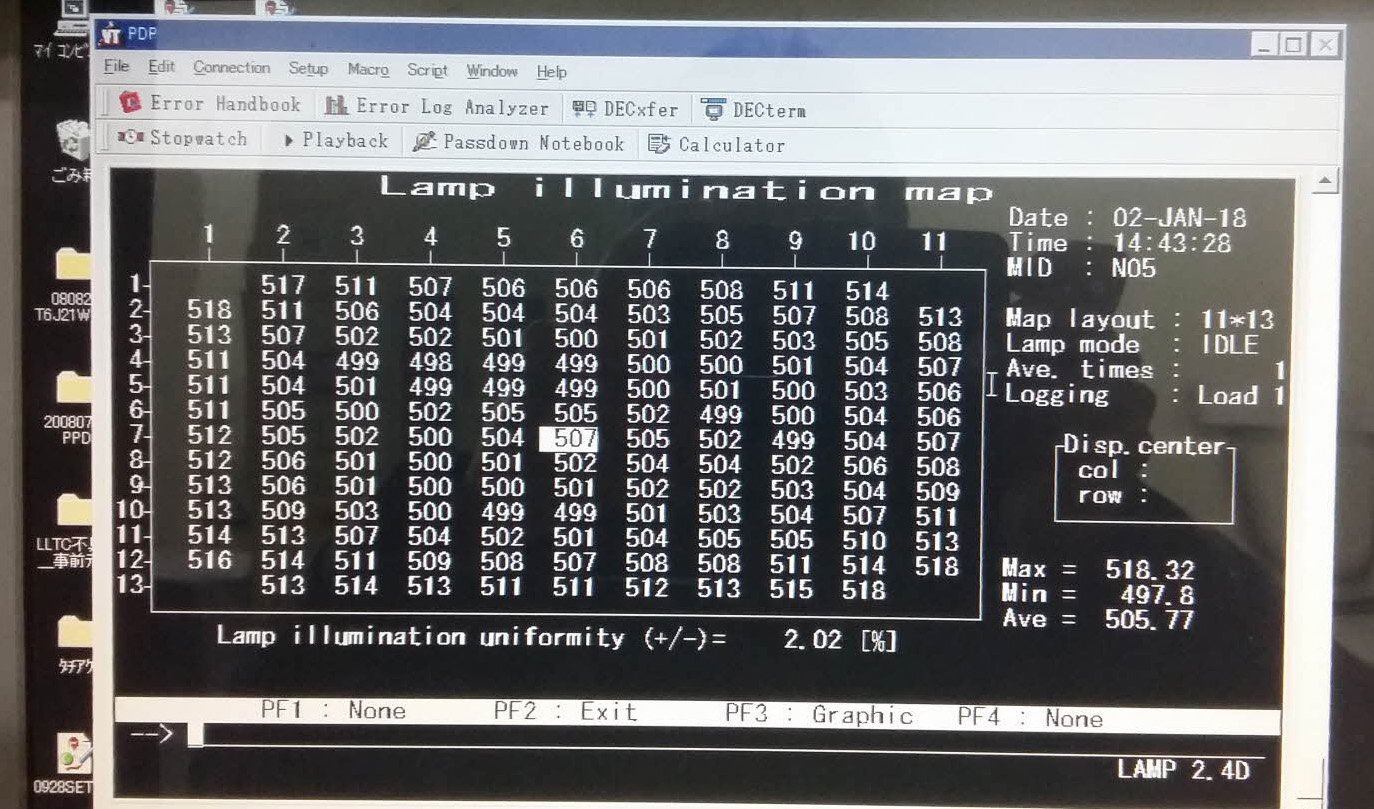

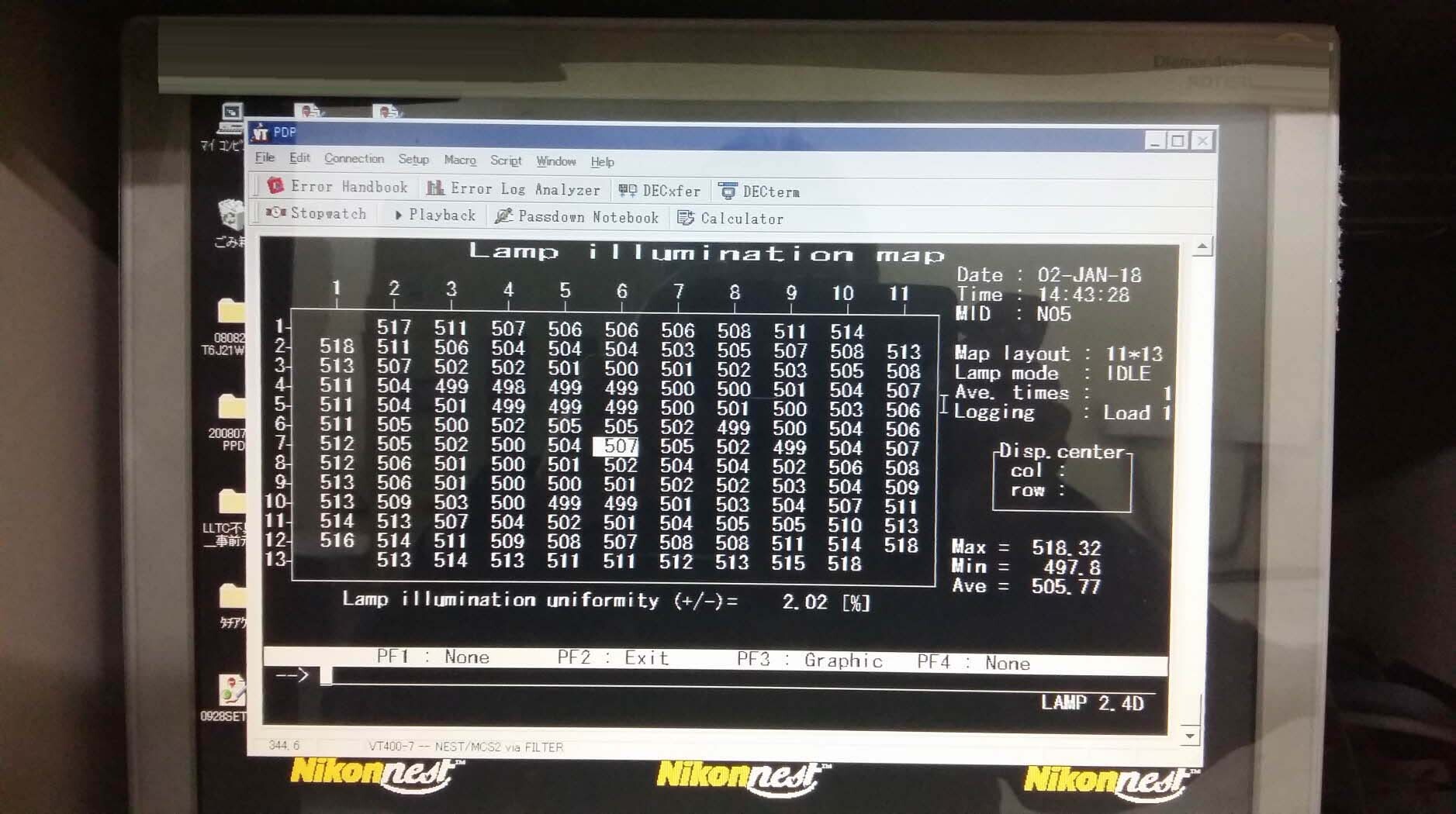

Lamp power: 1.75 kW

LSA Laser: 5 mW

Fixed reticle microscope: 20 mm

Wafer type: SILICON, 8"

Wafer stage: Ball screw

Chuck type: Ring

OF Detection type: Notch, 8"

Wafer loader: Type1

Notch wafer type: 90°

Right wafer carrier table

Reticle, 6"

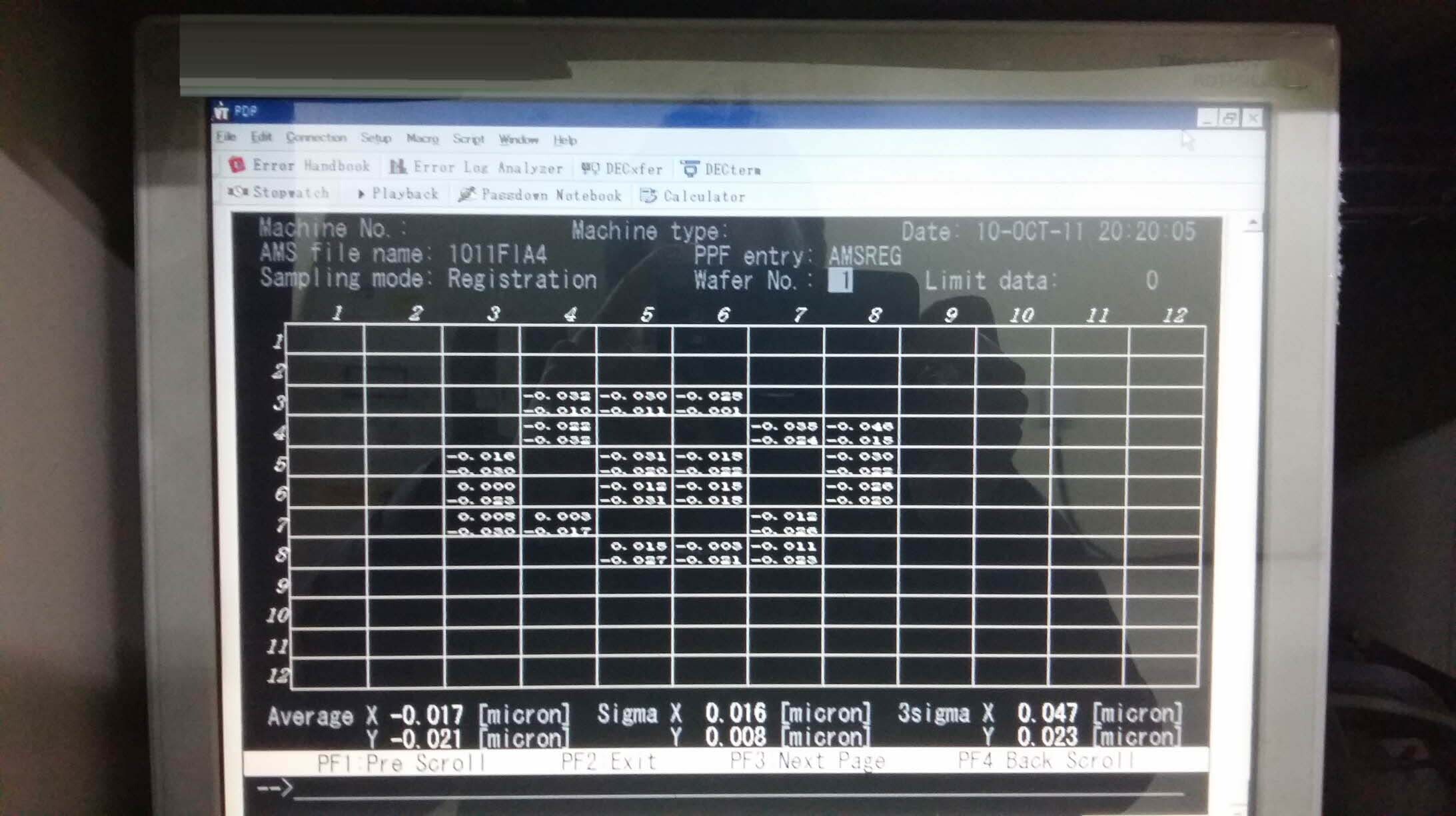

FIA

Reticle library type: NIKON

13-Slots

Rack type: Right

SHRINC

Does not include:

In-line

LIA

PPD / PD

1995 vintage.

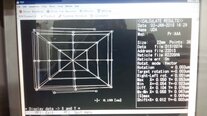

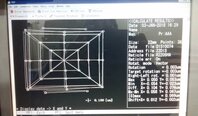

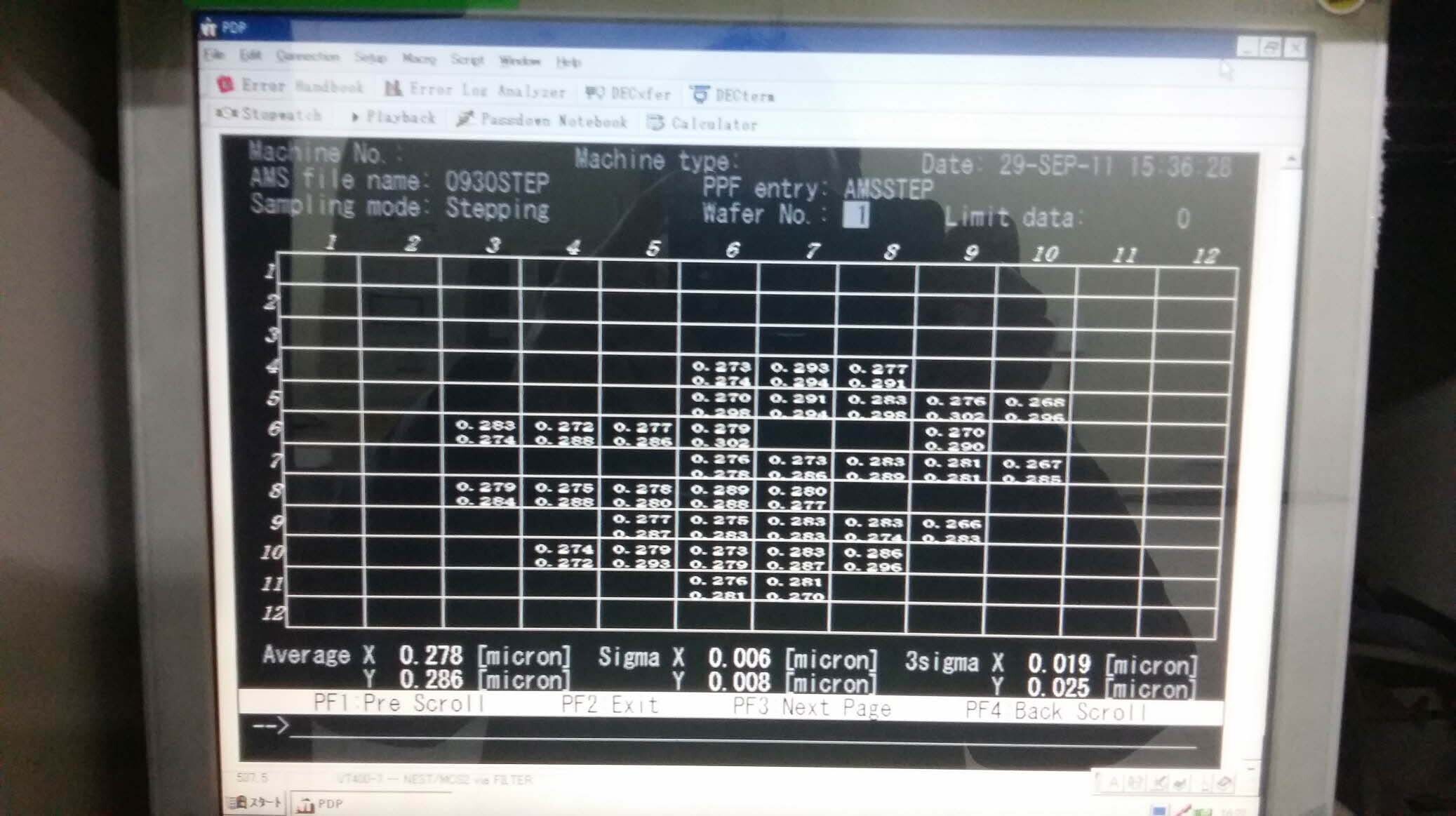

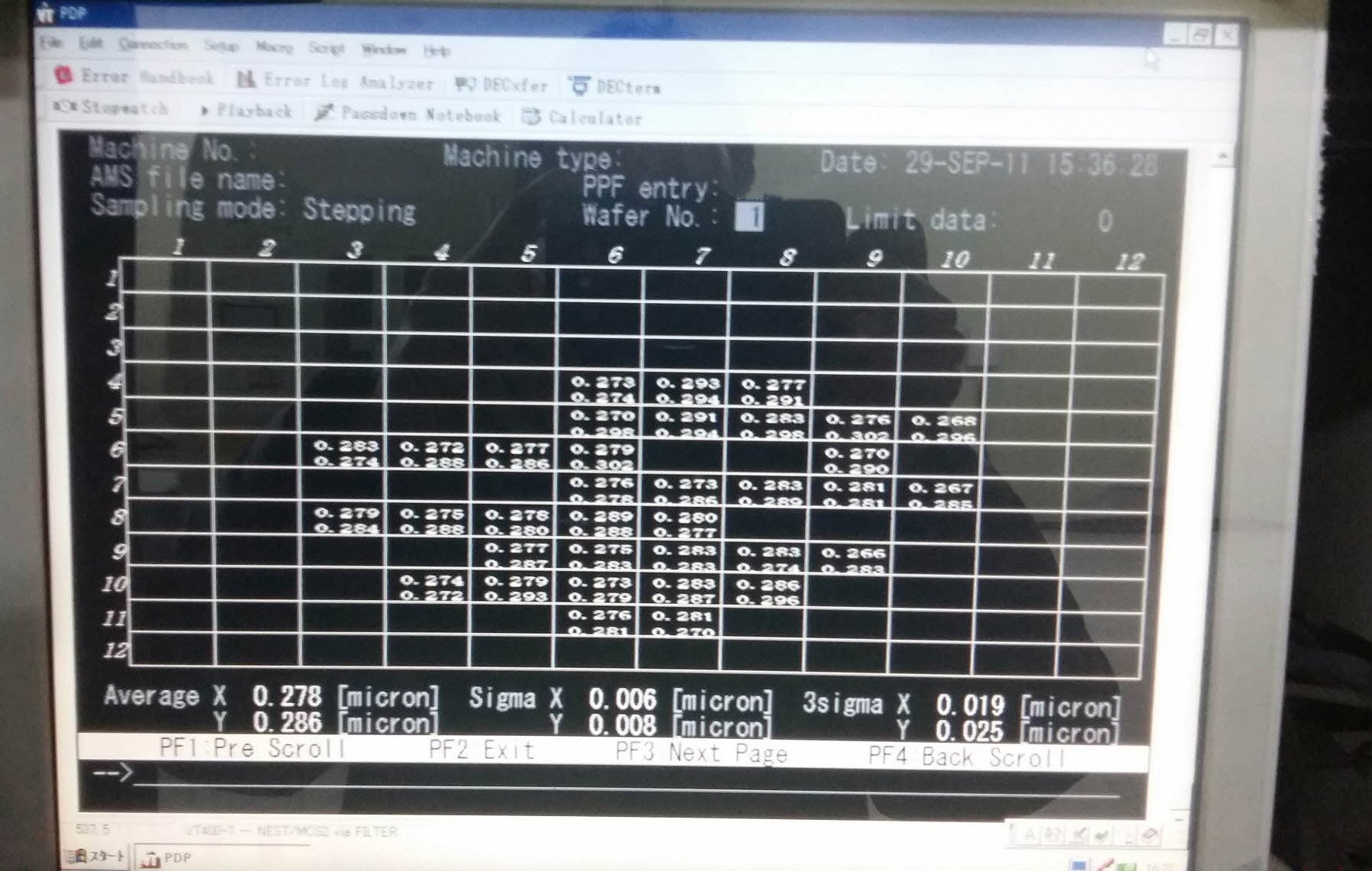

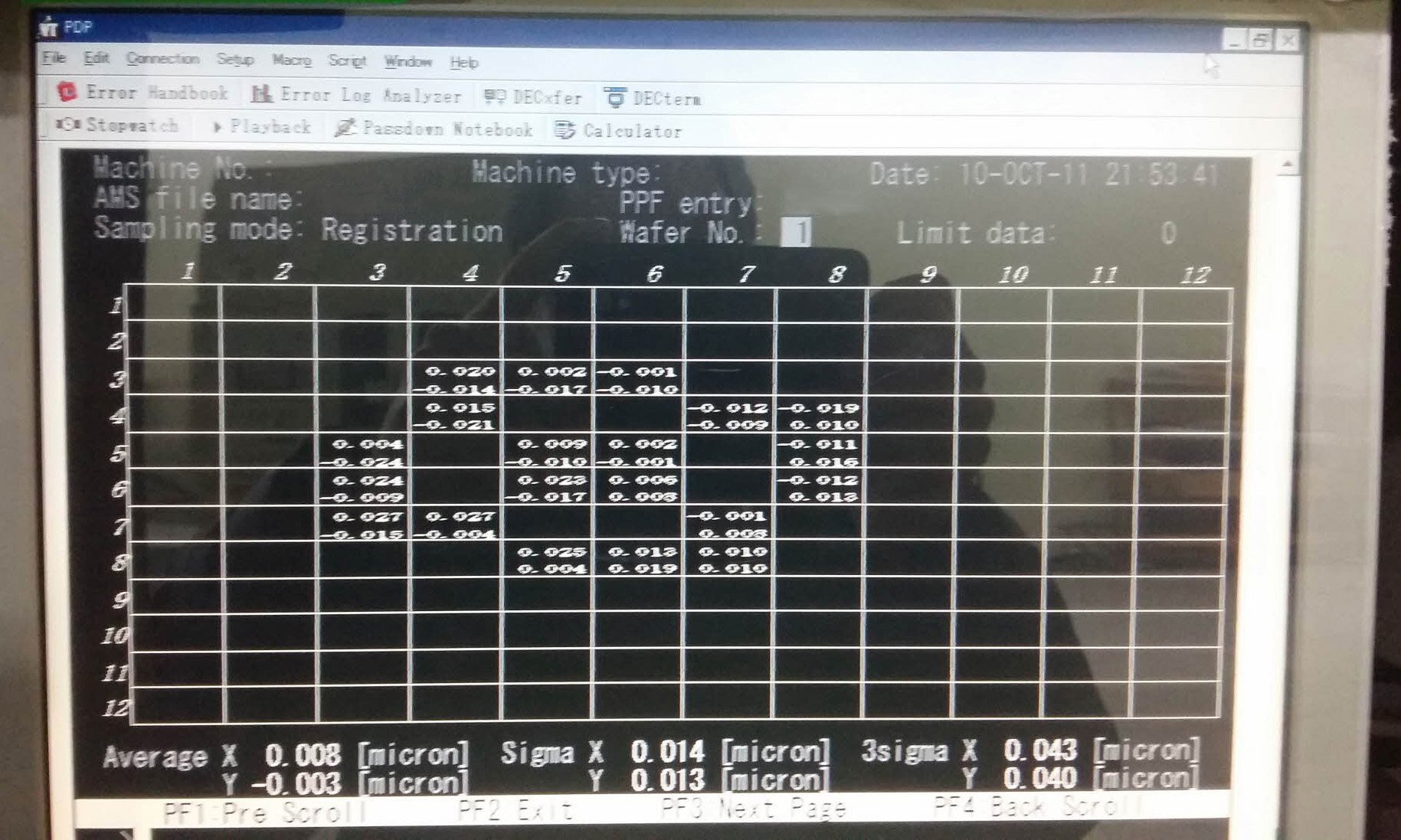

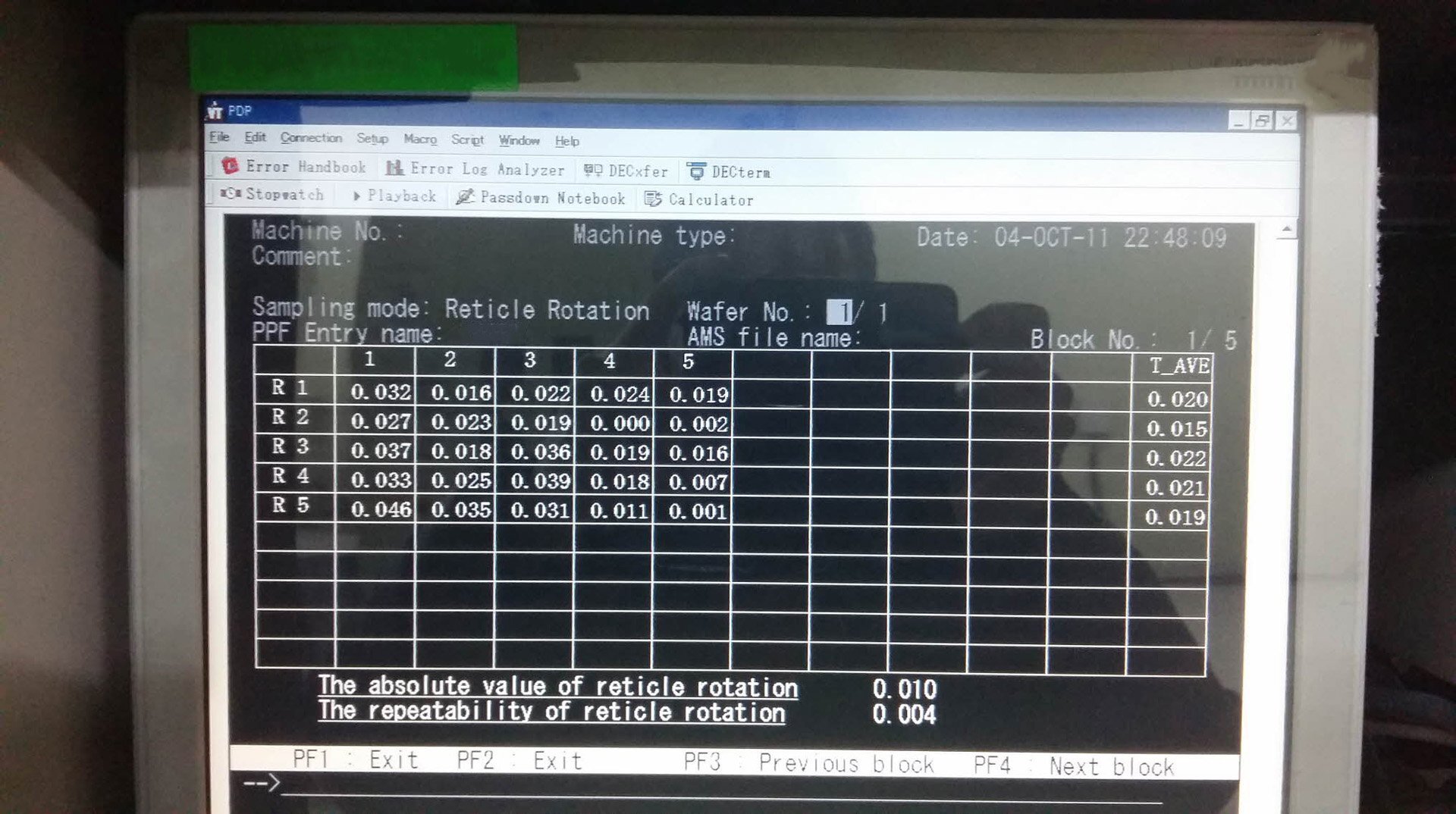

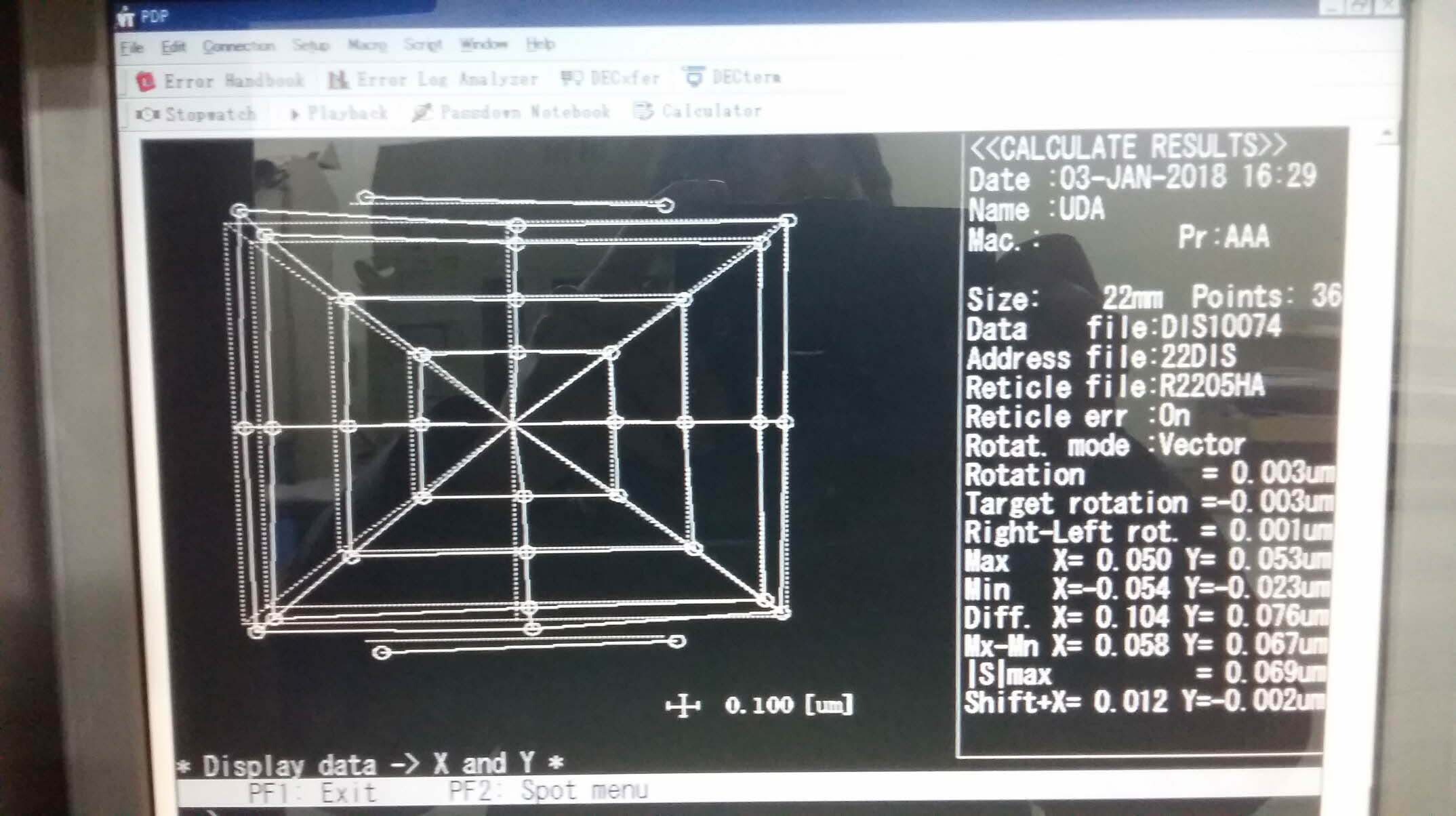

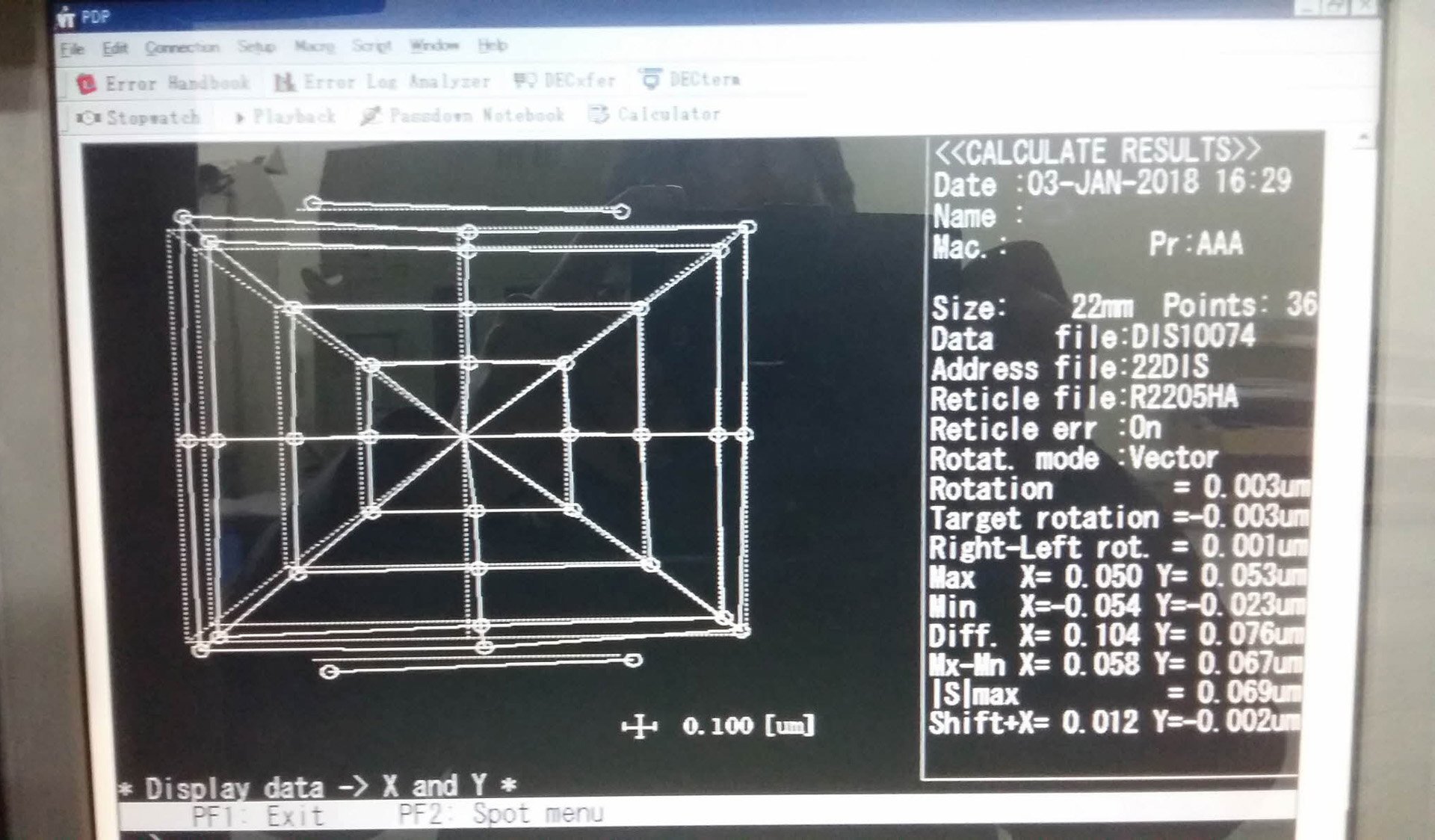

NIKON NSR 2005 i10C is a high-end, ultra-precise wafer stepper used in semiconductor manufacturing. It is an advanced, highly-adaptable machine capable of producing chips and other components with extremely high accuracy and repeatability. NIKON NSR 2005I10C has an automated, modified telecentric optical equipment with a 200mm wafer platform. The optics system provides excellent light coverage and clarity, and can be adjusted to accommodate various wafer sizes. The optics are also chromatically corrected and are capable of producing nanometer resolution images. The i10C also has a high-speed 10 Megapixel (MP) camera and high-resolution lens to capture images quickly and accurately. The camera is specially designed to capture a wide range of frequencies, from high-frequency illumination to ultraviolet (UV) light, for maximum contrast and clarity when taking an image. The stepper is capable of producing high-quality images at up to 5000 exposures per hour, with a high resolution of up to 10mm per pixel. The images are captured at a rate of 9.6 gigabytes per second and stored in a 2 terabyte solid-state drive. The high speed and large storage capacity of the i10C ensure that no data is lost. NSR-2005I10C also has a powerful alignment unit. It utilizes a 5-axis correction technology, which can make adjustments to both physical and electronic components, as well as to the optics, to ensure alignment and accuracy. The alignment machine allows for extremely precise machining and microfabrication of chip components. The i10C is designed for easy maintenance and is capable of self-diagnostics and preventive maintenance. The tool can be connected to a diagnostics server for remote monitoring. The machine also has an intuitive, user-friendly operating asset, allowing even novice operators to use it efficiently and get the best out of the stepper. NSR 2005 i10C is a powerful, precise and reliable wafer stepper that can produce exceptionally high-quality images quickly and accurately. With its advanced optics, high-resolution camera and powerful alignment model, it is ideal for manufacturing complex, ultra-precise components.

There are no reviews yet