Used NIKON NSR 2005 i8A #9016445 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9016445

Wafer Size: 6"

Vintage: 1991

i-Line stepper, 6"

Wafer stage results of last PM:

Wafer holder flatness (Spec. < 2.5 μm): 1.3 μm (no leveling)

Y mirror travel (Spec. < 5 μm): -0.7 μm

Orthogonality (Spec. ≤ 0.96 μrad): 0.2 μrad

Stepping (Spec. 3σ≤ 70 nm): 3σ X: 27 nm, 3σ Y: 27 nm

Back-step (Spec. 3σ≤ 70 nm): 3σ X: 45 nm, 3σ Y: 36 nm

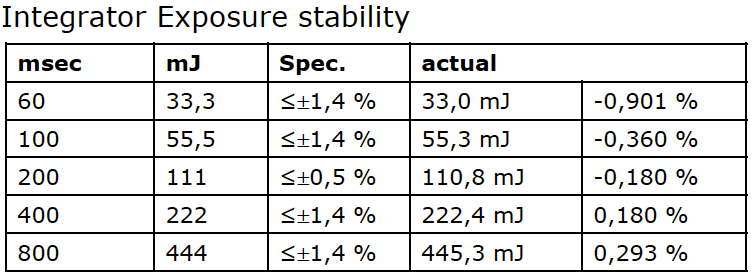

Illumination system results of last PM:

Lamp power: 447 mW/cm²

Uniformity (overall ≤ 1,5 %): 1.26 %

Actual vs. displayed power (≤±5 %): -3,712 %

Illumination tele-centricity (Spec. ±1 μm Z < 40 nm):

Xmax/min: 38/-17 nm

Ymax/min: 6/-32 nm

Lens results of last PM:

Lens inclination (Spec. Tilt ≤±0.2 μm)

UR-LL: 0.030 μm

UL-LR: 0.069 μm

Distortion (Spec. ≤±70 nm)

X max/min: 19/-32 nm

Y max/min: 47/-24 nm

Chamber:

Chamber front chamber temp: 23 ± 0.1 °C, 23.01

Pressure supply: 3 ± 0.1 Kg/cm², 3.1

Vac supply: > 460 mmHg, 650.00

Freeezer pressure:

High pressure: 15 ± 1 Kg/cm², 15.0

Low pressure: 4.85 ± 0.65 Kg/cm², 4.40

Wafer stage:

Clean and grease leadscrew X: OK, Y: OK

Clean and lubricate needle bearing X: OK, Y: OK

Perform stage running ca 10 min only after stage PM: OK

Check Interferometer mirrorsl X: OK, Y: OK

Check fiducial: OK

Wafer holder flatness (no leveling): 6" < 2,5 µm, max-min mm 2.2

Orthogonality: to customer wafer ≤ 0.5 µrad, Wafer_ORT= µrad 0.3

Stepping STEP spec: 3 sigma ≤ 70 nm, stepping 3 sigma X = nm 36

3 sigma Y = 27 nm

BACK spec: 3 sigma ≤ 70 nm, backstep 3 sigma X = 51 nm

3 sigma Y = 42 nm

Nikon i8 body:

Sr6c 5ib2

Sr lens 5ib2

Sr6b standard control rack

Sr6 accessory part 1

Sr6b lia

Sr6b lc 2

Sr6c iu 5ib2

Sr6c 5ib2 fe 5

Sr6c ws 8

Sr6 ceramic wh 5-8

Sr6c arl 56

Straight arm 5

Sr6c library adapter 5p 56

Sr6c wl 6 8

Sr6c wl extra carrier 68

Sr6c wa

Sr6c fia

Sr6c lia attachment part

Sr6c reticle table 5 6

Sr6c interferometer

Sr6c vacuum control

Sr6c pedestal

Sr6c avis

Sr6c control unit

Sr6c chamber s

Sr6c chamber panel 5 6

Sr6 lsa measurement software ver2.2

Sr6c ra 2 4 axis cameras mechanism 5

Sr6c aircondition 1b nema

Sr6 wl safety

Sr6b hg trap metal mesh

Sr6b rack modification us

Sr6 hg lamp outlet

Sr6c export tool

Sr6c laser safety part usa

Sr6c machine label

Sr6c safety label usa

Sr6c chamber label usa

Sr6c/8 high reflection board attachment parts

Sr 5ib2/c2 relay lens

Sr6 wafer cassette positioner if

Sr6c fia step 1

Sr6b/6c glass filter u-360

Sr6c extension cable protection cover

Sr6c ra2 cover for 4 axis camera

Sr6b hg lamp power supply ib2

Sr6c hg lamp power supply change ib5

Sr6c export mod ibm 973

Disassembled and crated

1991 vintage.

NIKON NSR 2005 i8A is a wafer stepper designed specifically for wafer level processing with integrated high throughput and high accuracy. The unit is capable of accommodating substrates up to 200 mm in diameter, allowing for a larger area than most conventional stepper systems. The precision optics equipment provides a high degree of accuracy and repeatability, allowing for a foundation of repeatable processes. Additionally, the integrated motion control and autofocus help minimize cycle time for improved throughput. The advanced alignment system of the unit features both coarse and fine alignment capabilities with a high level of accuracy and speed. The unit uses below field optics and high-resolution CCD cameras to precisely detect the exact position of each wafer after alignment. Further, the focus and alignment functions can be customized as needed to address specific substrate-level applications. The machine's illumination feature is highly customizable with a choice of wavelengths, numerical apertures and uniformity levels. This feature is essential for optimizing lithography results and ensuring the highest-quality images. Additionally, the unit integrates highly sensitive laser sensors and laser interferometry to measure the exact positions of each wafer, decreasing process variability and potential for errors. Additionally, the unit offers a large range of overlay compensation abilities and a variety of pattern recognition functions. This ensures that each wafer is accurately placed in the stepper without costly errors or rework, saving time and reducing costs. Further, a fully-automated main-load handling facility is available for hassle-free substrate loading, unloading, and changing. NIKON NSR 2005I8A comes equipped with a powerful, easy-to-use NIAS control interface that allows for complete process control. The intuitive graphical user interface allows for efficient process design, which increases throughput and helps reduce downtime. Additionally, the unit meets UL, CE, and FCC standards, meeting tightening safety and environmental regulations. Overall, NSR-2005I8A is a powerful and accurate wafer stepper designed specifically for medium- to high-volume wafer level processes. The unit features integrated high-precision optics, a highly customizable illumination tool, and automated main-load handling, allowing users to achieve fast, repeatable, and reliable results.

There are no reviews yet