Used NIKON NSR 2005 i9C #293601909 for sale

URL successfully copied!

Tap to zoom

ID: 293601909

Stepper

Resolution: ≤0.5 µm

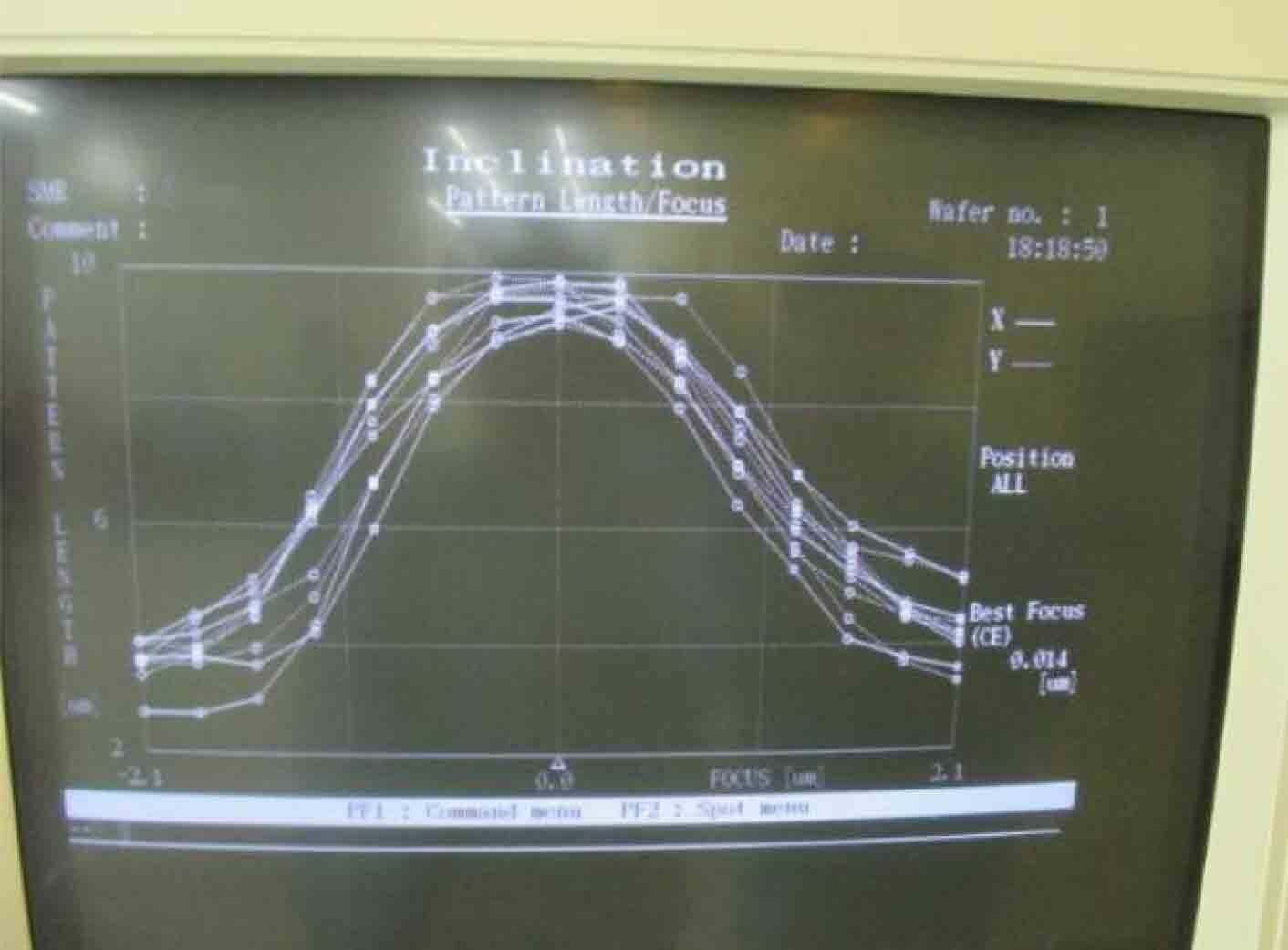

UDOF: ≥0.7 µm

CD Uniformity: ≤50 nm

Focus calibration repeatablity: 3σ, ≤0.1 µm

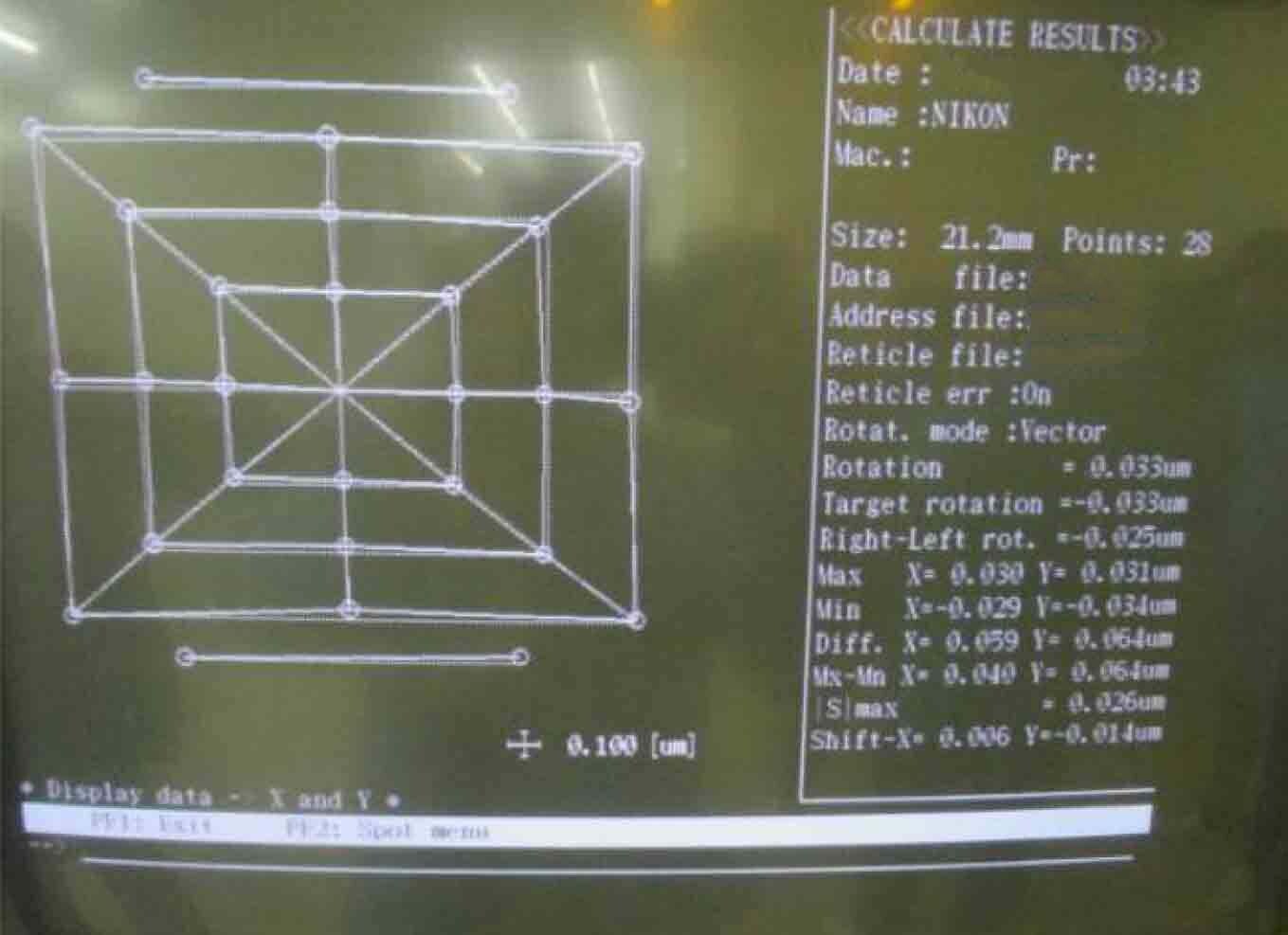

Lens distortion: Within ±70 nm

Maximum area: 20x20 mm

Recticle blind setting accuracy: 0.4 to 0.8 mm

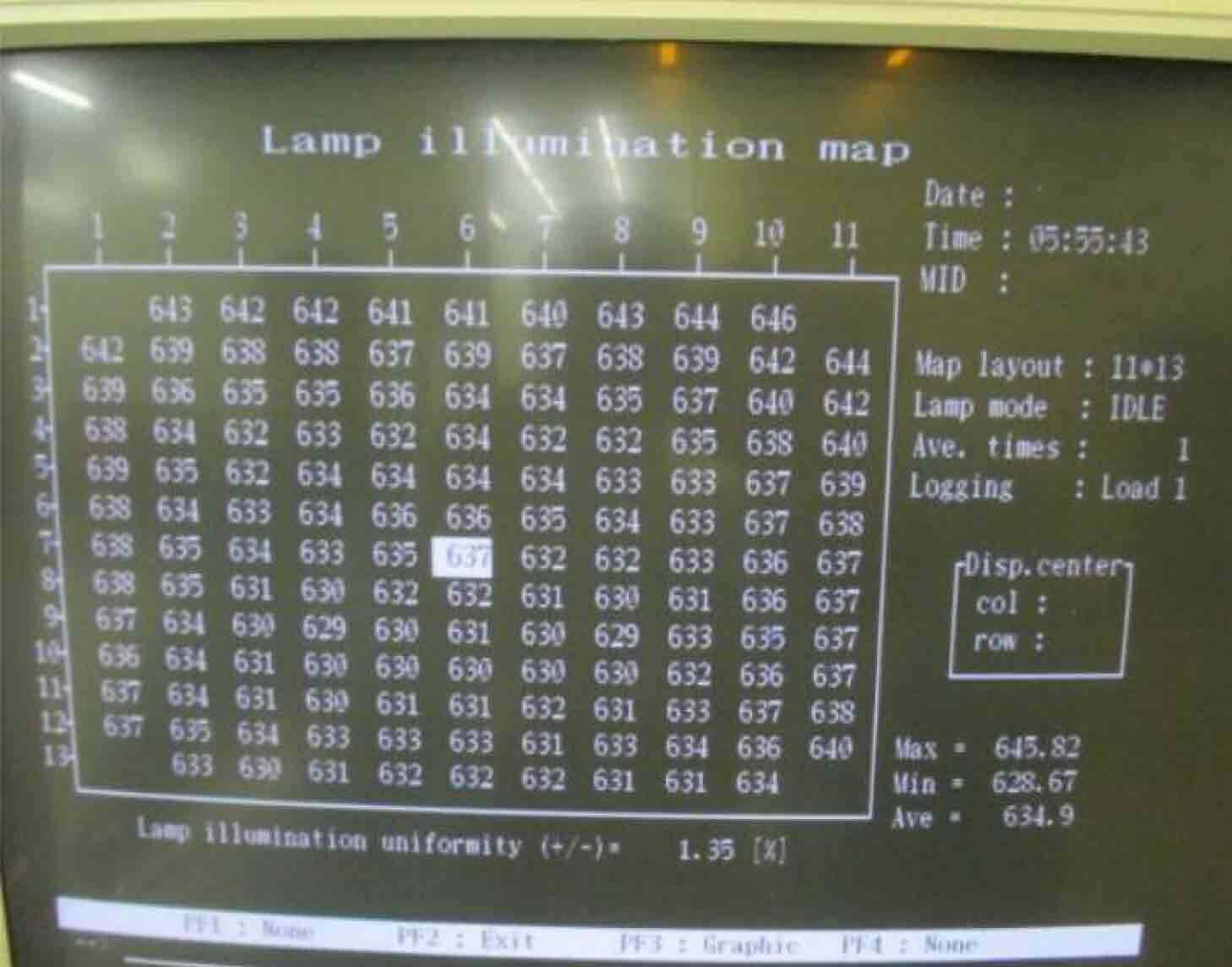

Exposure power: ≥550 mW/cm²

Integrated exposure control: Within ±1%

Illumination uniformity: Within 3%

Recticle rotation: Within 20 nm

Array orthogonality: Within ±0.1 sec

Stepping precision: 3σ, ≤70 nm

Operation test success rate: 100%

Wafer system success rate: 100%

Focus stability: ≤0.6 µm

Magnification error: Within 15nm

Field curvature: ≤0.3 µm

Chip levelling accuracy: Within ±1.5 sec.

NIKON NSR 2005 i9C wafer stepper is a high-precision device used in a range of applications from integrated circuit fabrication to printing, imaging and inspection. Featuring 9 axes of motion, the i9C offers unparalleled flexibility with long-term reliable performance. It is designed to minimize thermal distortion and provides built-in vibration isolation. NIKON NSR2005I9C offers an impressive optical equipment with a high-resolution 0.8NA condenser lens and high-performance objectives with a numerical aperture of 0.8. This powerful combination enables a wide range of imaging applications including patterning, overlay and wafer stepper inspection. The i9C supports a variety of high-quality reticles and features fine polarization, focus and alignment corrections to ensure ultimate accuracy. NSR-2005I9C wafer stepper stands out thanks to its superior performance and robust design. It is equipped with an advanced four-axis system and 4-level magnification that make it suitable for highly precise tasks. The unit offers a high scan speed plus a maximum exposure time of 1.5 sec. It also offers automatic reticle exchange, dual image field stitching and a wide scan range of up to 5.5 micrometers. NSR 2005 I 9 C wafer stepper is designed to increase production efficiency and reduce defects. It features an intuitive controller and advanced monitoring features that ensure high-quality manufacturing results. The machine is compatible with a range of process gases and supports Industry 4.0 automation. Finally, NSR 2005 i9C is easy to maintain and has a small footprint. It is compliant with various safety requirements and supports remote operation. All these features make the i9C an ideal device for high-end lithography applications.

There are no reviews yet