Used NIKON NSR 2005 i9C #293605792 for sale

URL successfully copied!

Tap to zoom

ID: 293605792

Wafer Size: 8"

Vintage: 1995

Stepper, 8"

Notch wafer type

Wafer loader type I

Wafer exposure

Wafer transfer

Left and right carriers loading

High and low pressure: 8 kgf/cm²

Reticle loader:

Mask size, 6"

Reticle library: 33 mm

Reticle stage:

RA Microscope

Position: 22 mm

FIA

LSA

Monitor

Interferometer type: 5517 B

1995 vintage.

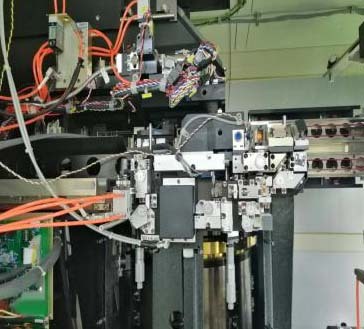

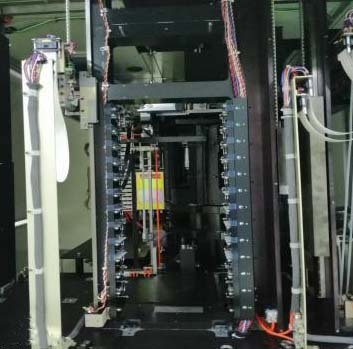

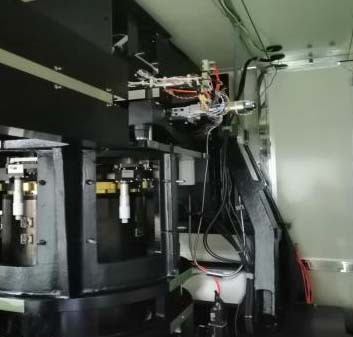

NIKON NSR 2005 i9C is a wafer stepper used in photolithography, the process of transferring a pattern from a mask onto a substrate in order to fabricate integrated circuits. This equipment includes all the components needed for lithography and is characterized by its high precision, versatility, and speed. The i9C uses advanced stepper optics, minimized deflective and astigmatic aberrations, and superior patterns. The system is designed with a Variable Beam Spot Size (VBSS) feature, which allows for a range of beamspot sizes from 0.6 to 5 µm diameters, providing users the flexibility to use the best settings for each pattern. Along with its patented scanning technology, NIKON NSR2005I9C is equipped with unique and versatile Cassette Changer Systems (CCS). The CCS is fully automated and consists of a nine-bay cassette holder and two blade racks with automatic blade transfer capability. This unit allows users to quickly change and adjust for different part types. The exposed patterns produced with the i9C have low remaining distortion and low jaggedness. The machine uses NIKON proprietary Automatic Distortion Correction (ADC) to detect and correct distortions at every exposure, reducing errors and maximally improving pattern quality. In addition, the i9C delivers highly accurate and repeatable results, allowing users to mass-manufacture components with confidence. The tool utilizes a precision alignment monitoring asset, which continuously monitors the position and tilt of the stage throughout the movement process. This ensures excellent part position and stable shots. NSR-2005I9C wafer stepper boasts a wide array of features that make it an ideal choice for producing high-yield, high-quality patterns for integrated circuit fabrication. With its advanced optics, CCS, and ADC, it enables users to easily transfer a varied range of patterns with greatest precision and repeatability and minimal distortion.

There are no reviews yet