Used NIKON NSR 2205 EX14C #9375190 for sale

URL successfully copied!

Tap to zoom

ID: 9375190

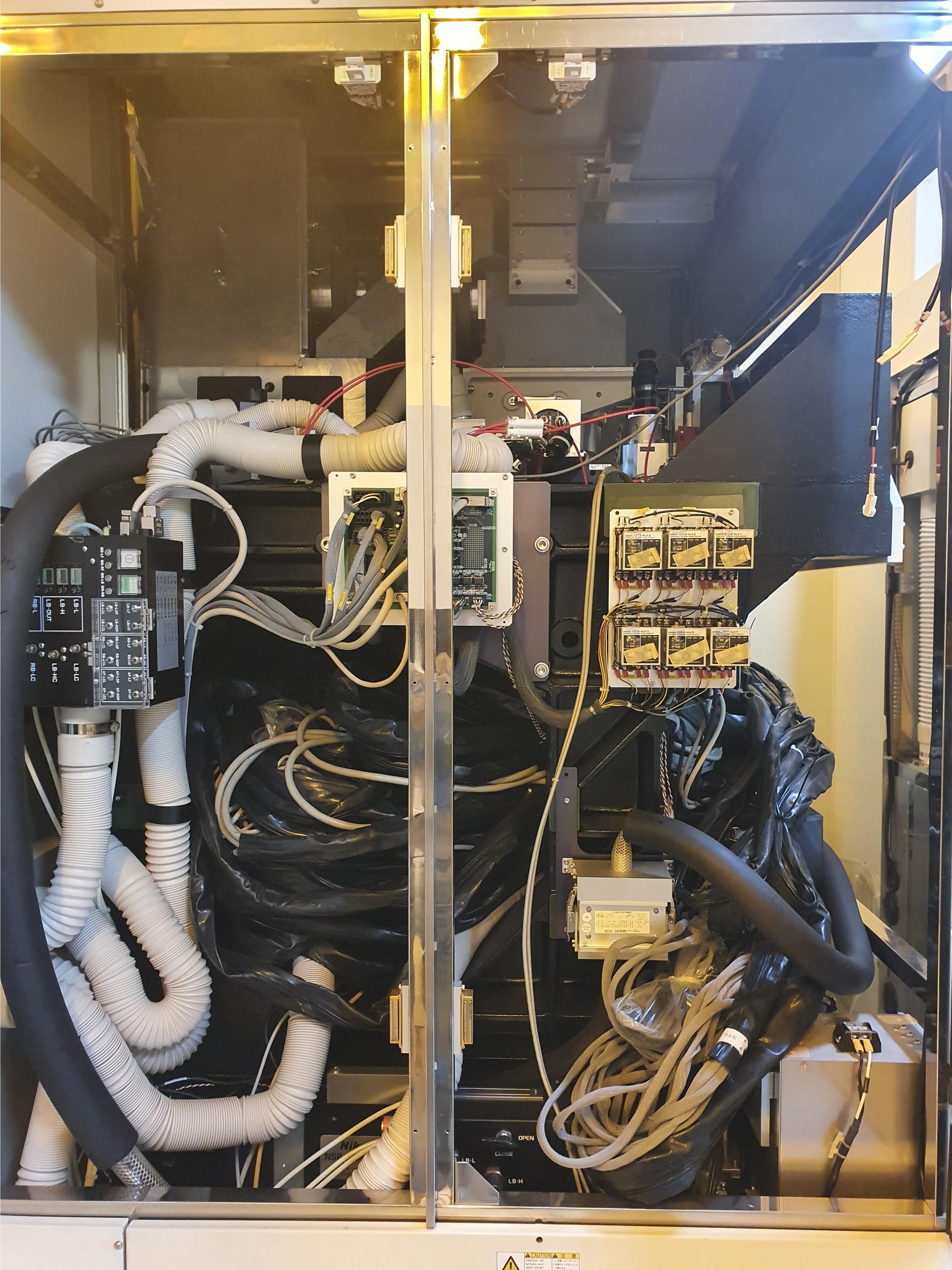

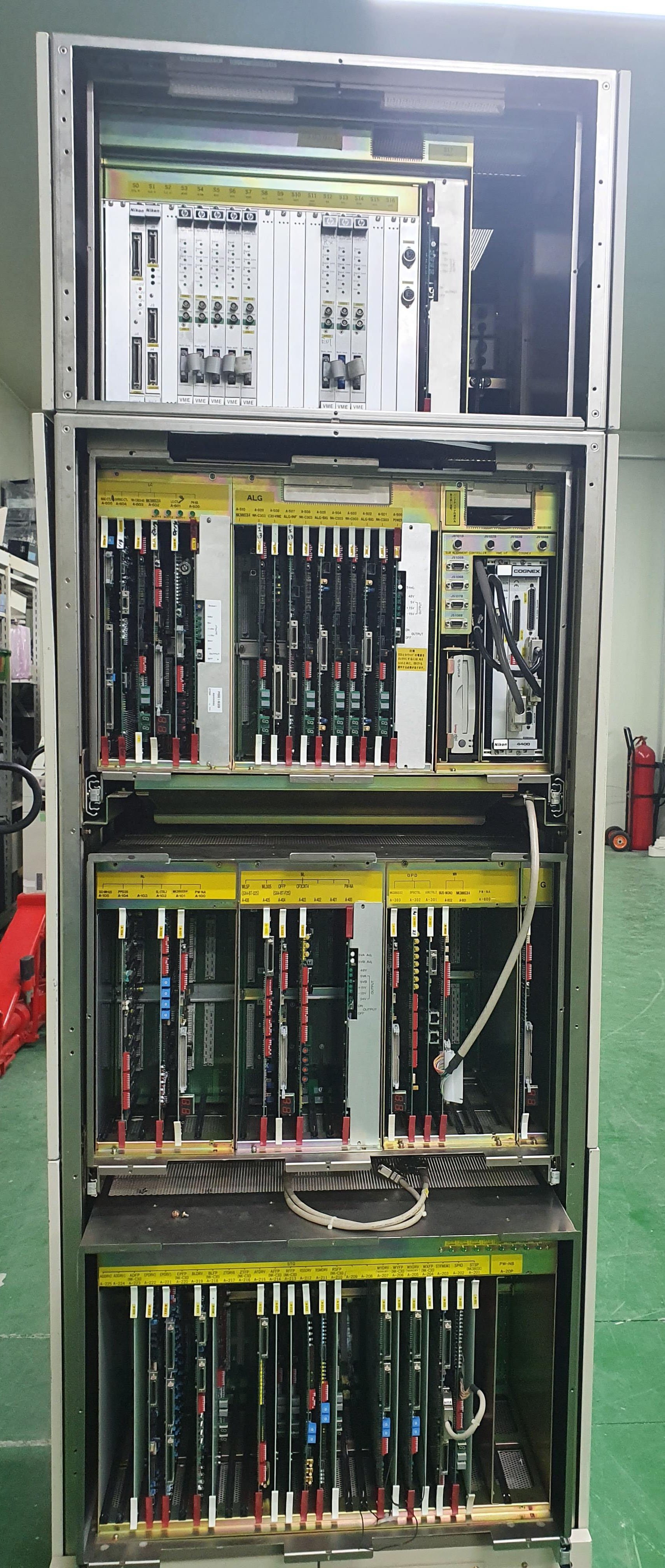

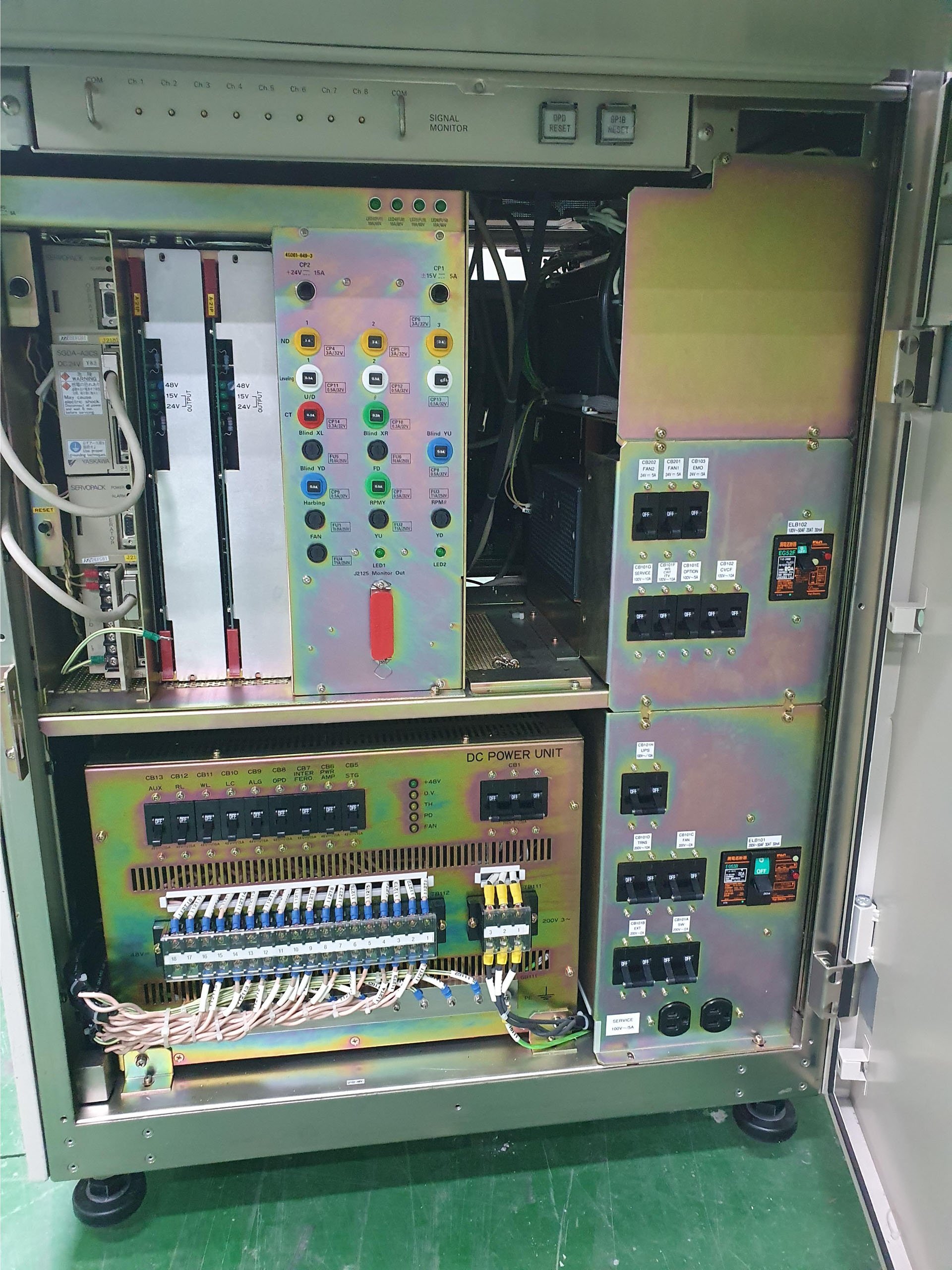

Stepper

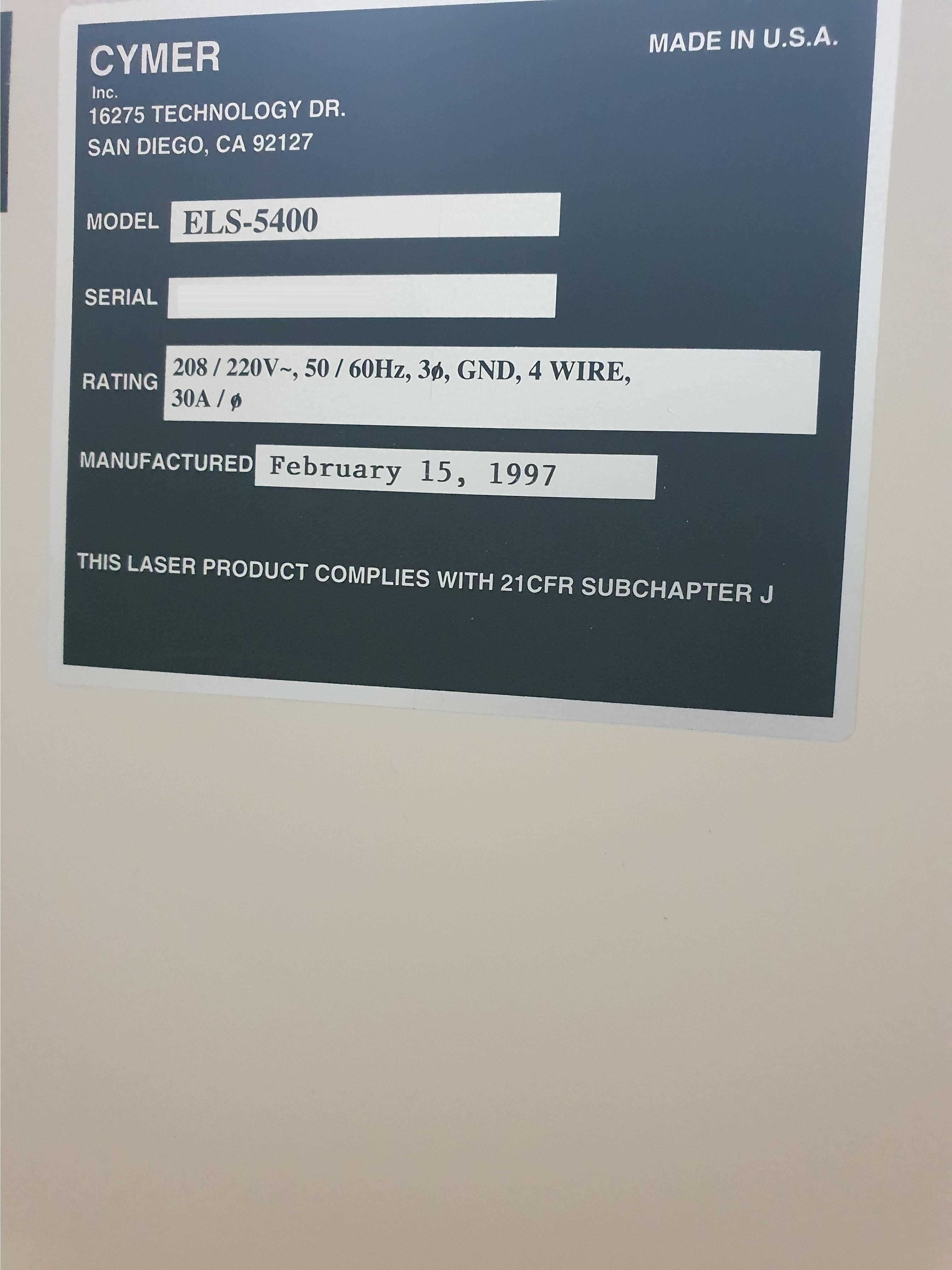

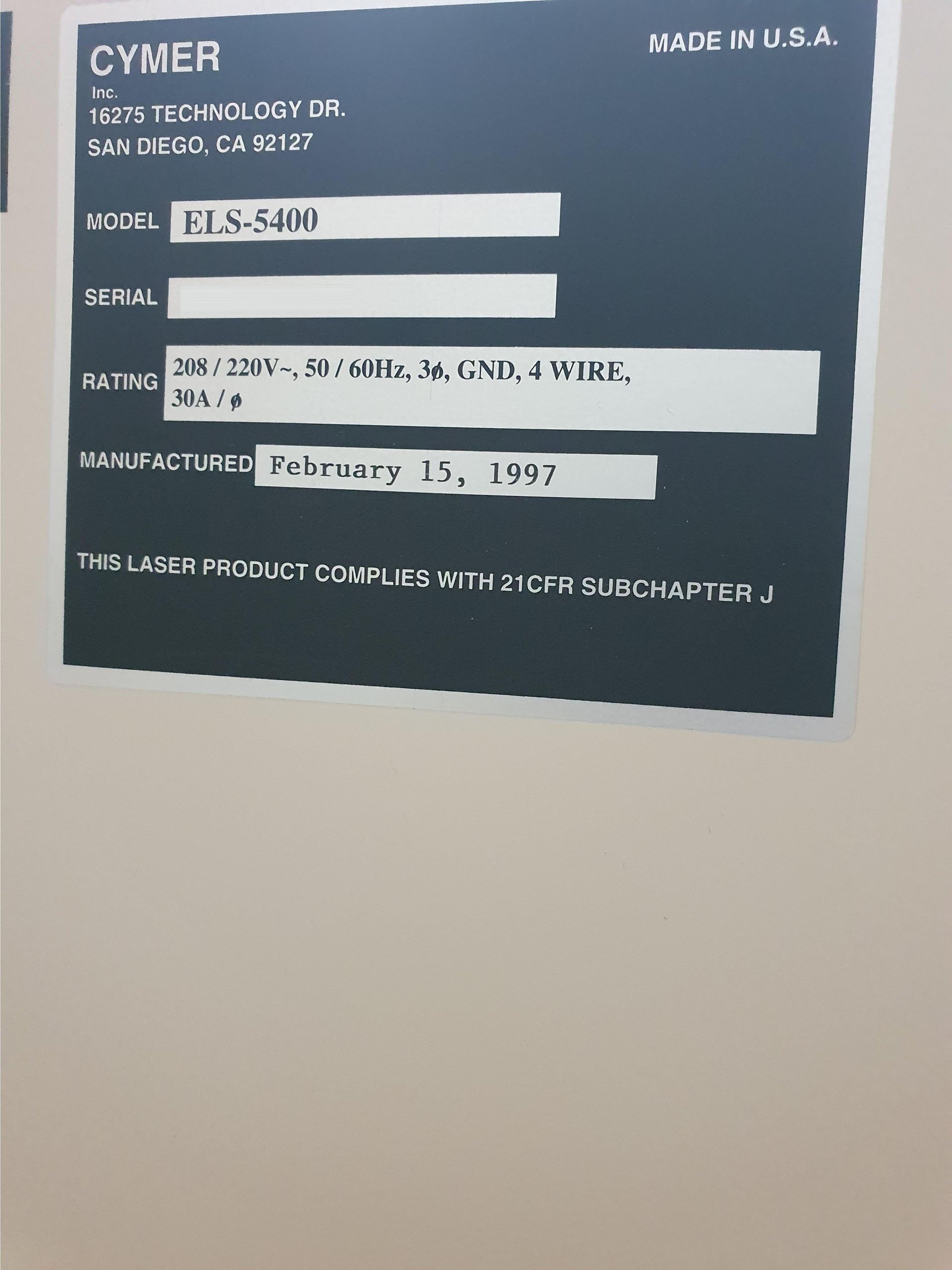

CYMER ELS 5400 Laser

Missing parts:

Wafer loader unit:

Wafer loader: Type III

A-406 WLSP Waiting table plate

P/N: 4S015-151

Reticle loader unit

A-100 PW-NA, P/N: 4S001-062

A-105 PPD-DRV, P/N: 4S007-608

A-800 PW-NA OPD Unit

Stage unit:

Wafer holder

CT Pin

Power AMP Unit

P/N:

A-20P PW-NB, P/N: 4S001-063

A-216 ZTFP, P/N: 4S069-668

A-217 ZTDRV8, P/N: 4S018-137

A-220 EPFP, P/N: 4S069-668

A-224 ADDRV1, P/N: 4S018-317

ADE(Z) Power AMP unit

Alignment Unit

NC-PRE2 Unit

Cable

A-510 NK386SX4, P/N: 4S015-150

Lens control unit

Mouse

Inverter

CATC Filter guide

CATC Filter.

NIKON NSR 2205 EX14C is a high-precision, high-volume wafer stepper. The stepper combines advanced automation with enhanced low-power consumptions and a new stage design for superior productivity. It has an acceptable range of wafer sizes from 8-inch to 12-inch diameter in center-hole and shank standard configurations. Its unique feature is the High-Level Automation Equipment (HLAS) that performs with an improved rollover stage, integrated heat plate and integrated optics. This ensures optimum precision for high-volume, high-precision applications. The stepper has a highly stable, rock-solid scan field. It has a fast, high-resolution motor drive that adopts high-speed information exchange with its Robot Alignment System (RAS) for improved operation stability. It is also equipped with a Maximum Ripple Correction Unit (MRCS) which enables continuous wafer movement to correct wafer deformation while staying in alignment. This facilitates highly accurate layer-to-layer overlay without the need for frequent focus adjustments. The stepper has an improved Motion Control Machine (MCS) and a built-in Alignment Tool (ALS) for precise positioning, as well as a maximum non-3-dimensional alignment accuracy of 0.25 micrometers. It also has improved results with long exposure times that enable greater depth of focus. As a result, NIKON has achieved the industry's highest indexing accuracy and stable operation over several days. The stepper also has a High-density Illumination Asset (HIS) and High-power Illumination Disable Curve (IC) for improved illumination uniformity and reduction of particle levels. It also features NIKON Exclusive Autoagitation & Etching (FX) that is designed for efficient automatic agitation of corrosive fluids. This helps the model to improve yields and reduce operating costs without the need for additional human intervention. NIKON NSR-2205EX14C wafer stepper also has an advanced process control equipment that monitors conditions of the wafers to ensure optimal fabrication yield and long-term repeatability. The system is equipped with both parametric and statistical process control methods to deliver highly reliable results. Finally, it also features a cool-down mechanism to ensure uniform thermal distribution and protect the machine over long terms of continuous operation.

There are no reviews yet