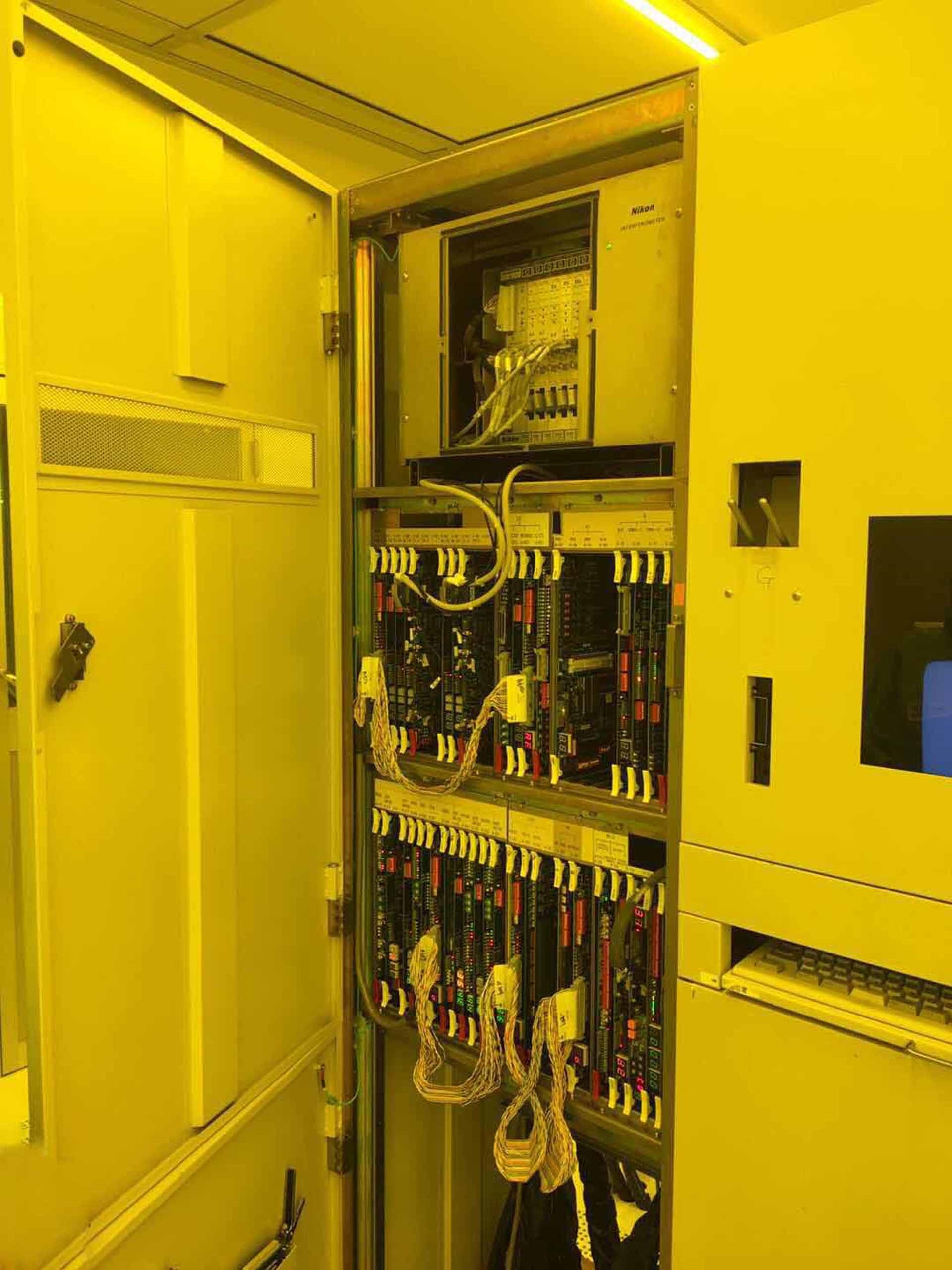

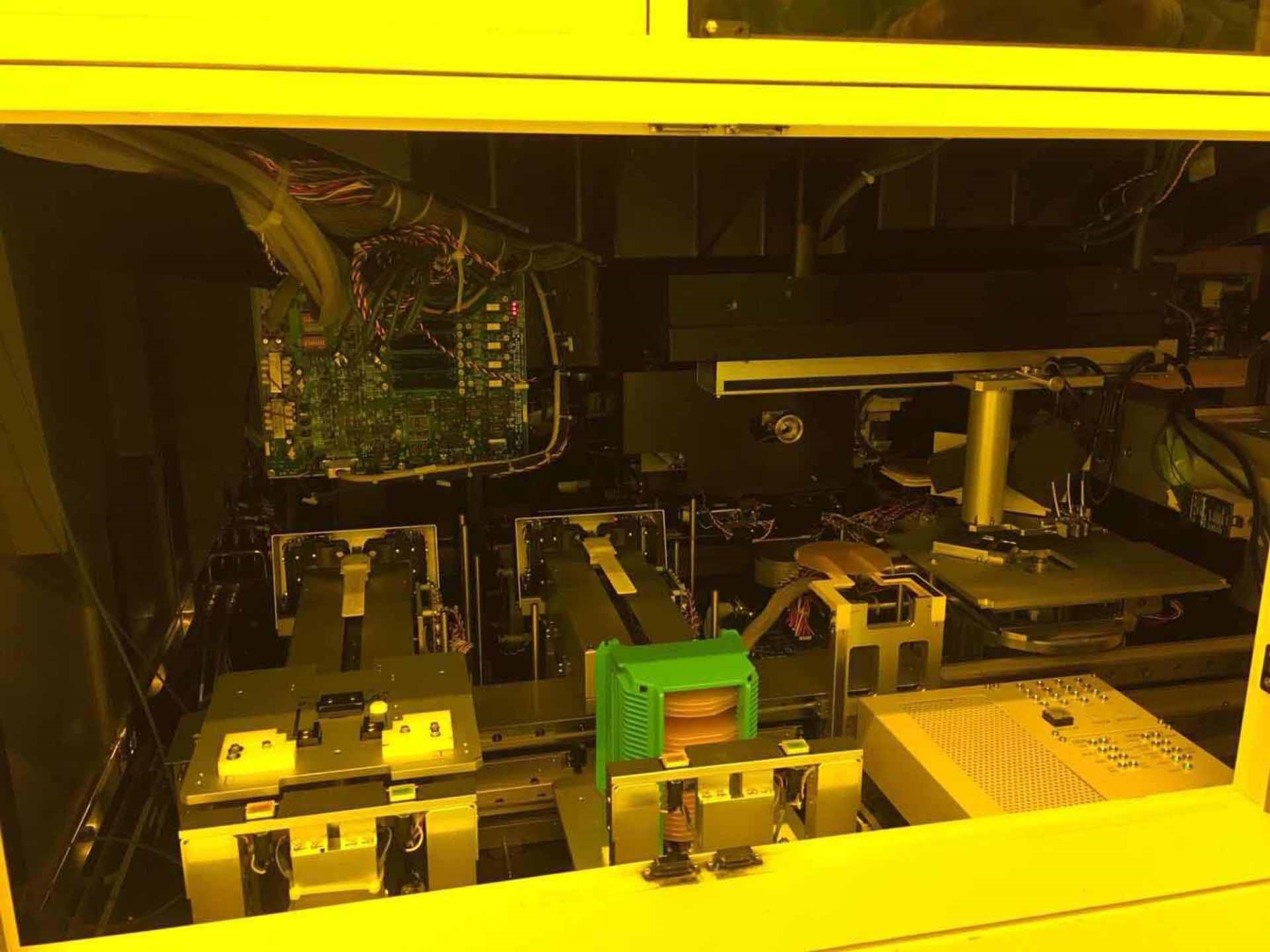

Used NIKON NSR 2205 i11C #9224341 for sale

URL successfully copied!

Tap to zoom

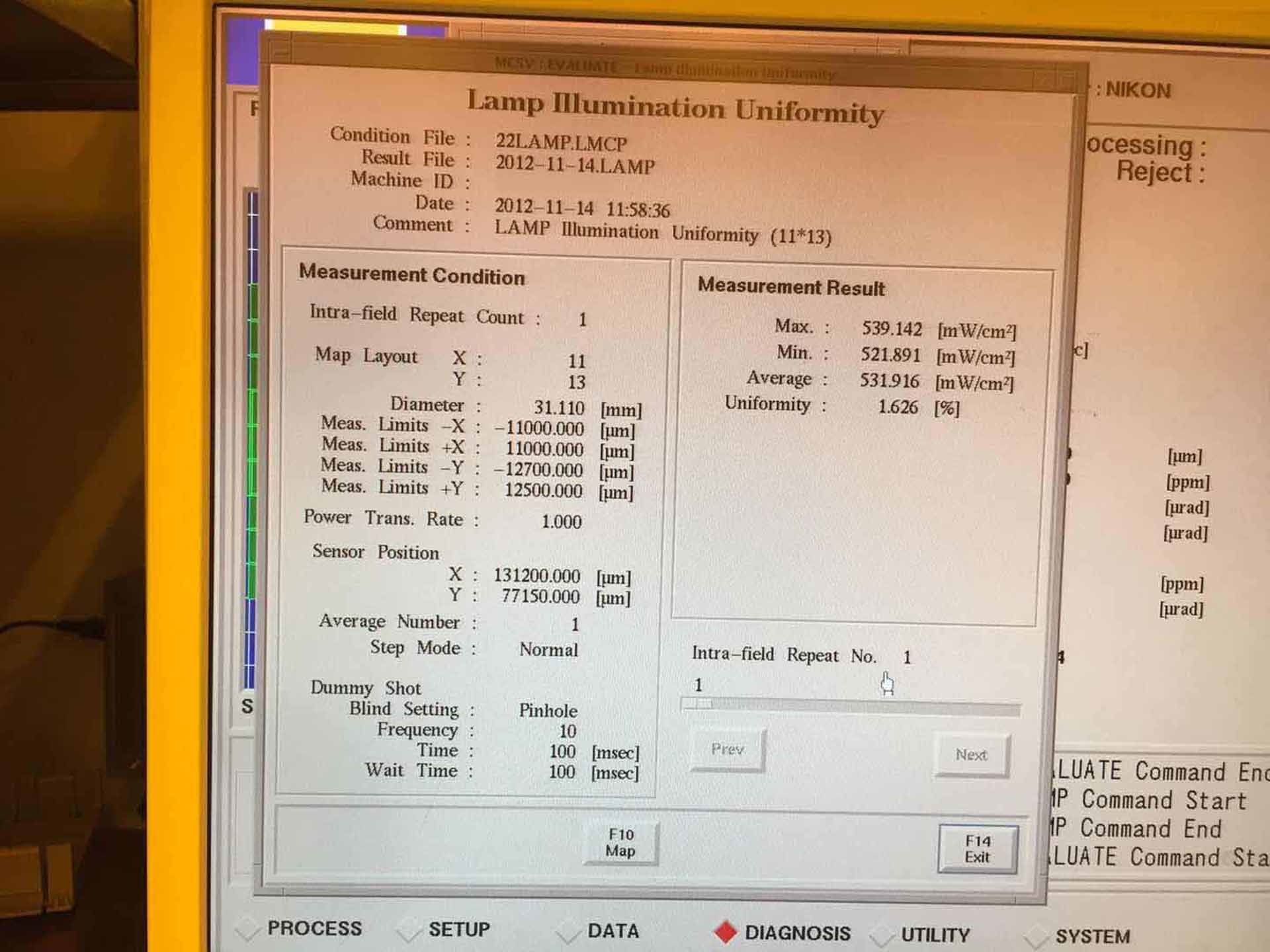

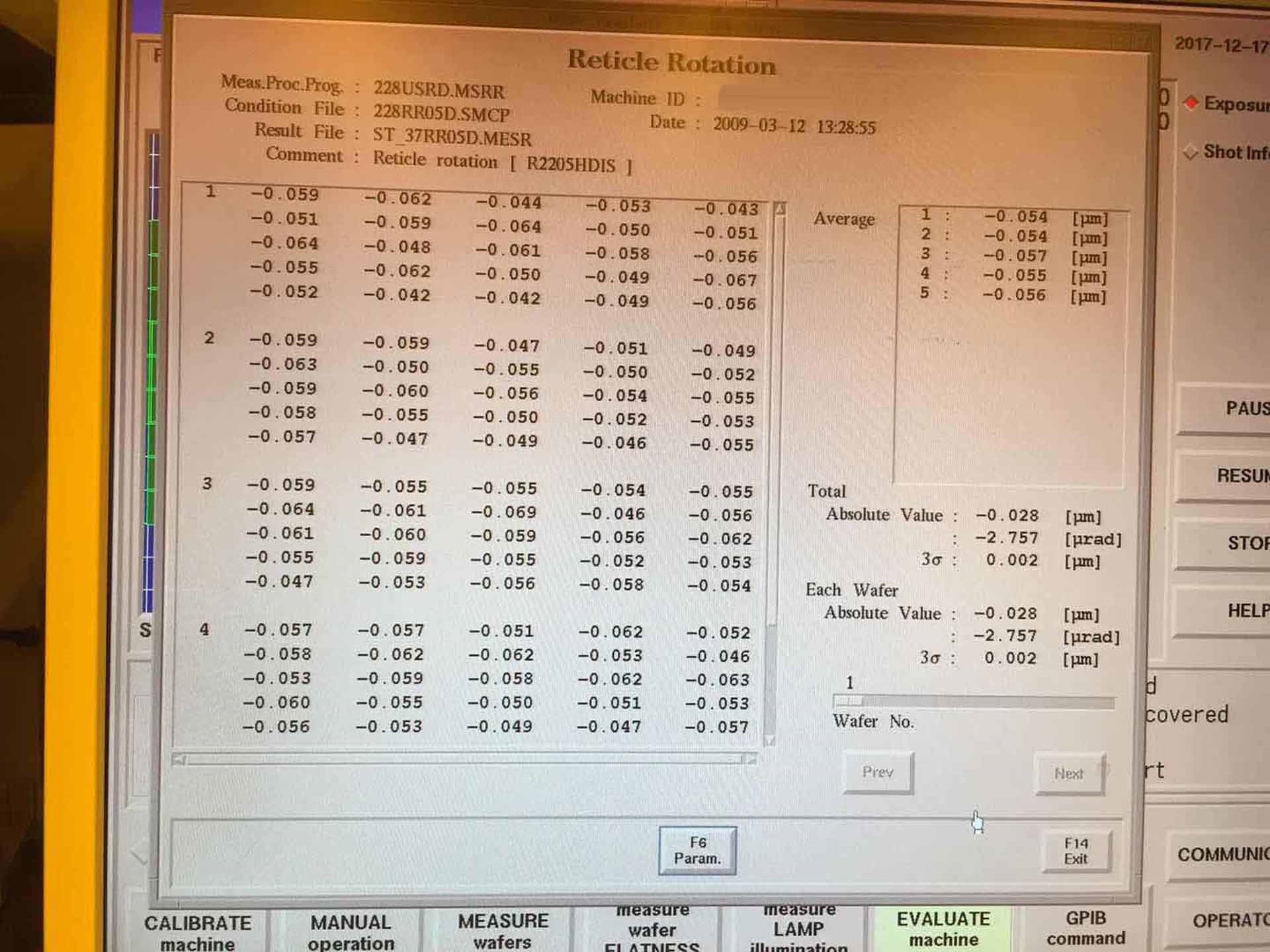

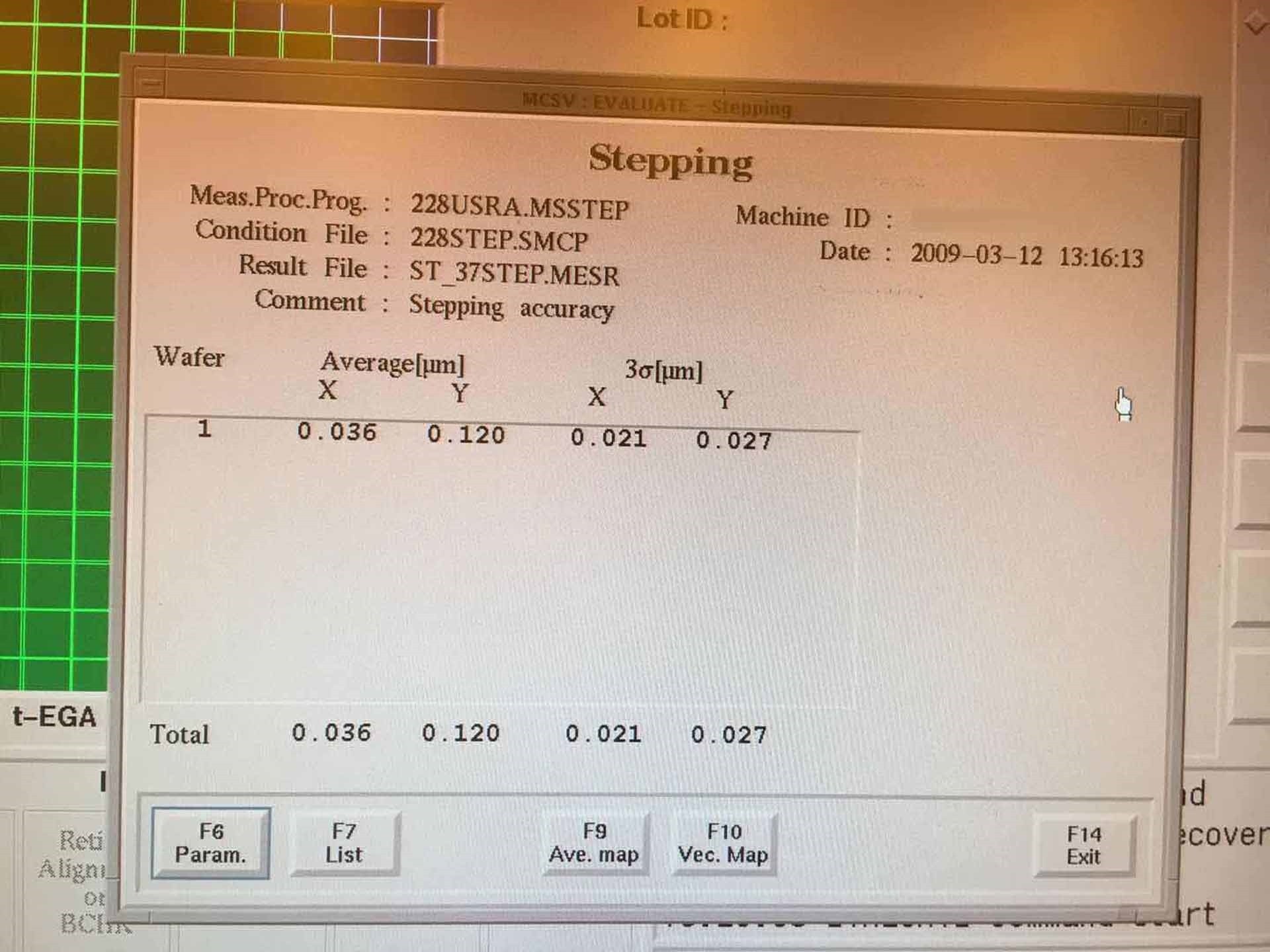

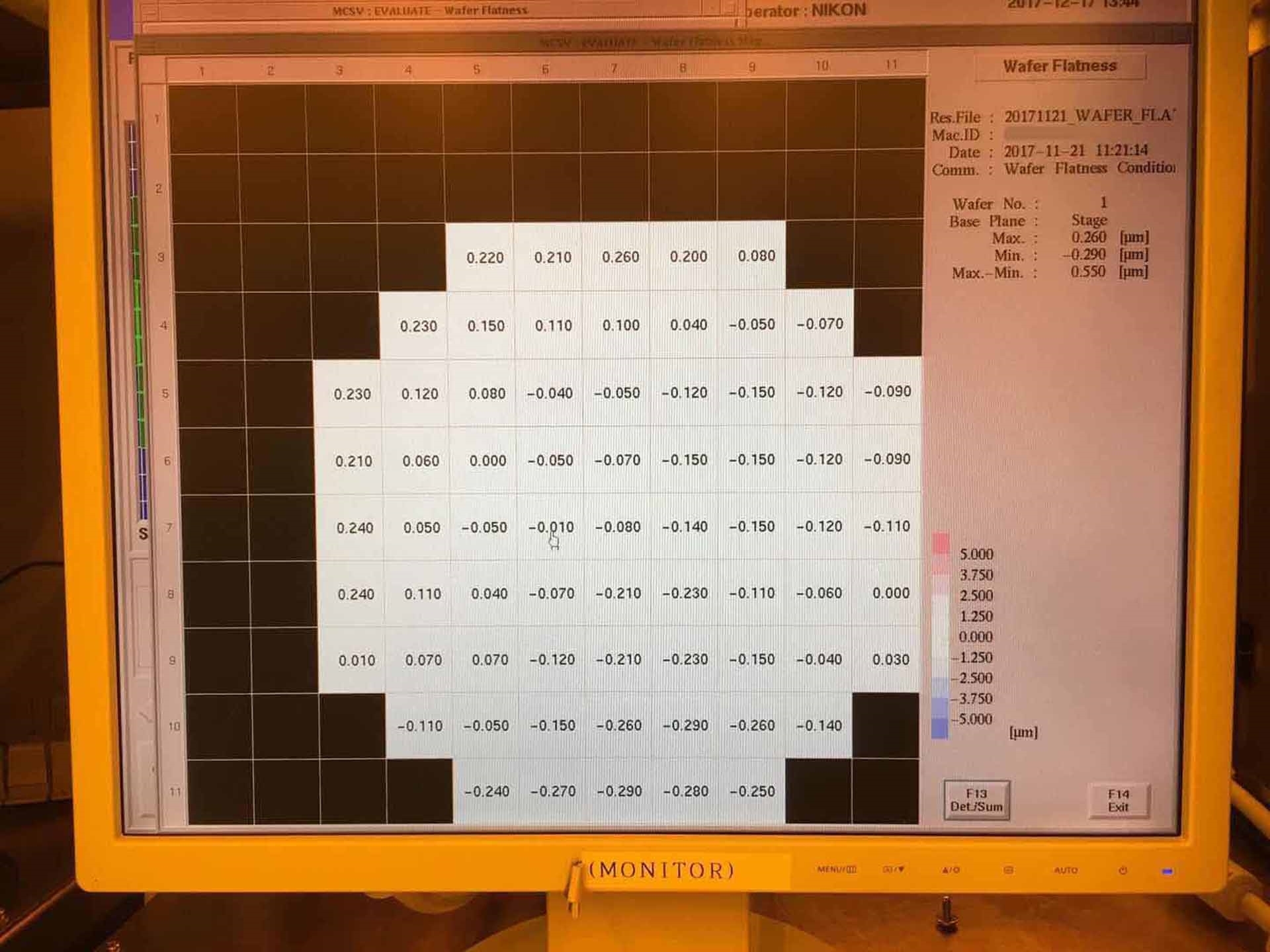

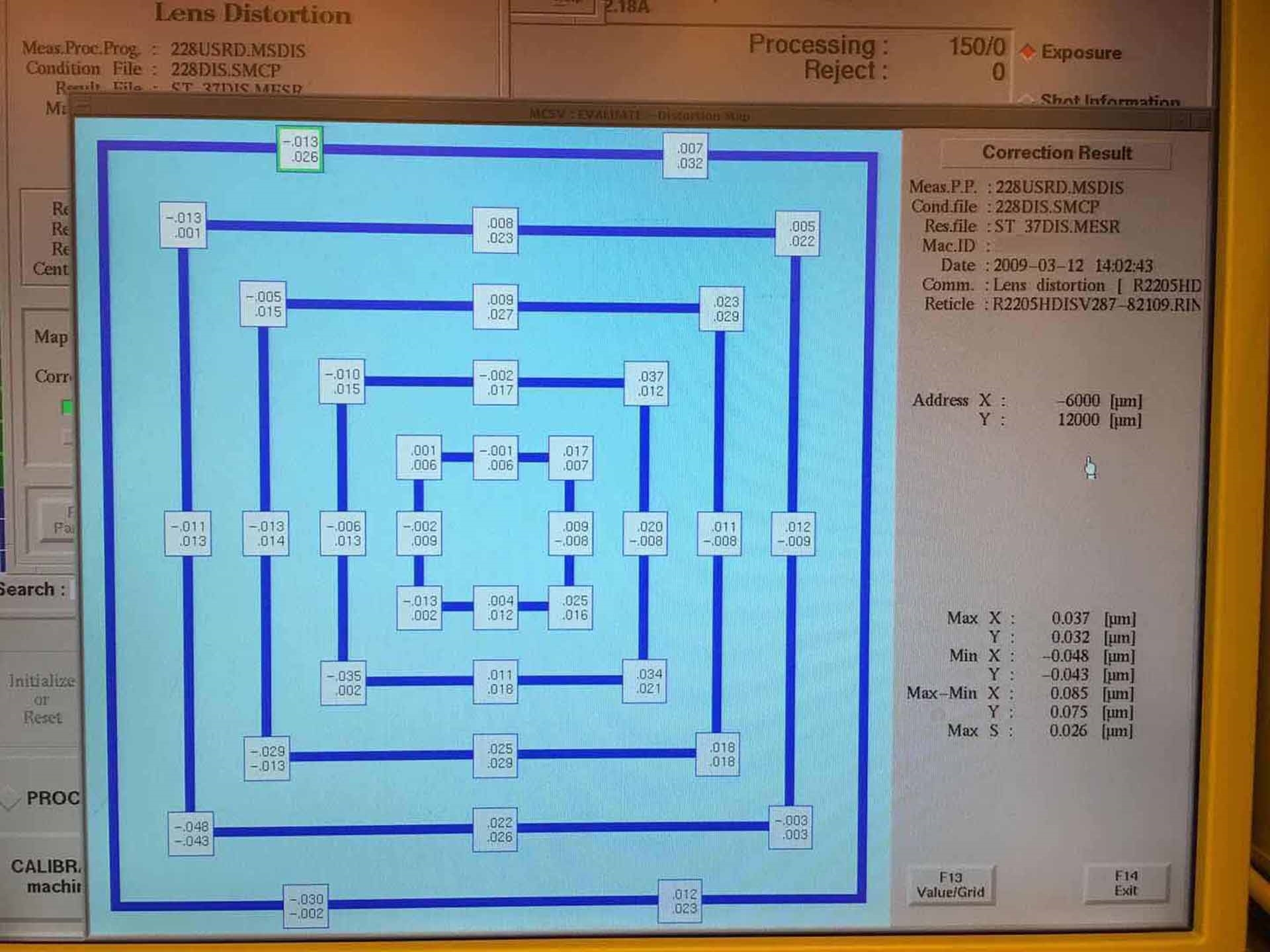

NIKON NSR 2205 i11C is a wafer stepper machine that uses ArF (Argon Fluoride) laser lithography for its imaging processes. This machine is designed for semiconductor device manufacturing, particularly for the production of modern complex designs. It offers superior imaging throughout the full range of current lithography designs. NIKON NSR-2205I11C is built around its two ArF laser light sources. This laser light provides excellent resolution and avoidance of cross-contamination due to its 193nm wavelength. The laser light is directed towards the reticle, which is a thin, transparent plate with opaque patterns on it. The patterns on the reticle plate define the desired pattern on the wafer. The reticle is held on a calibration table, beneath a two-lens condenser, which then focuses the laser light onto the wafer. The wafer stage on NSR 2205 I 11 C is designed for precise movement and positioning of the wafer itself. Its positioning accuracy is within ±1μm and its maximum wafer size is 200mm. The wafer stage is equipped with a Zeiss primoStar HD automated alignment system for precise adjustment measurements. This allows for precise registration of the wafer on the stage, which enables precise alignment of the patterns from the reticle onto the wafer. NIKON NSR 2205 I 11 C also features a wide range of alignment marks, including phase shift marks, pupil variations, ring-patterns and alignment marks. These features allow for precise alignment of the photo mask onto the wafer during the projection lithography process. Furthermore, NSR 2205 i11C's auto-focusing ability ensures that the patterns of the photo mask printed on the wafer are accurately and consistently produced. Furthermore, NSR-2205I11C features graphical user interface (GUI), which is easy to use. It also has a library of pre-defined alignment and exposure recipes which can be stored and retrieved. Additionally, this wafer stepper has a series of smart sensors which can be used for accurately monitoring the process and environment conditions. NIKON NSR 2205 i11C is an efficient and reliable tool for semiconductor device manufacturing due to its precise imaging and alignment capability. Its two ArF laser light sources provide excellent resolution, while its Zeiss primoStar HD automated alignments ensure precise wafer positioning and alignment. The smart sensors and GUI enhance user control, and the pre-defined recipes make for quick and efficient implementation, aiding in the production of complex designs.

There are no reviews yet