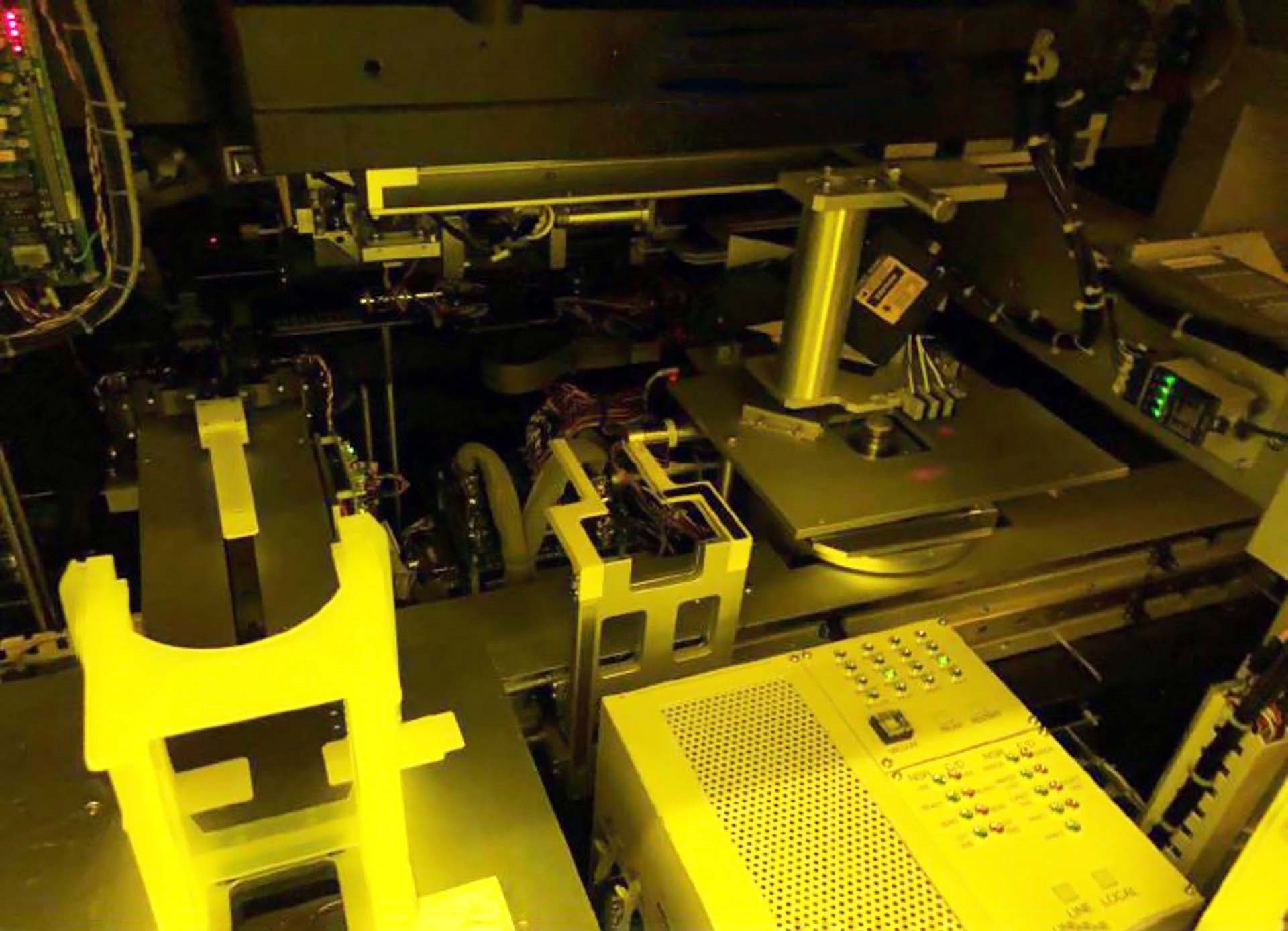

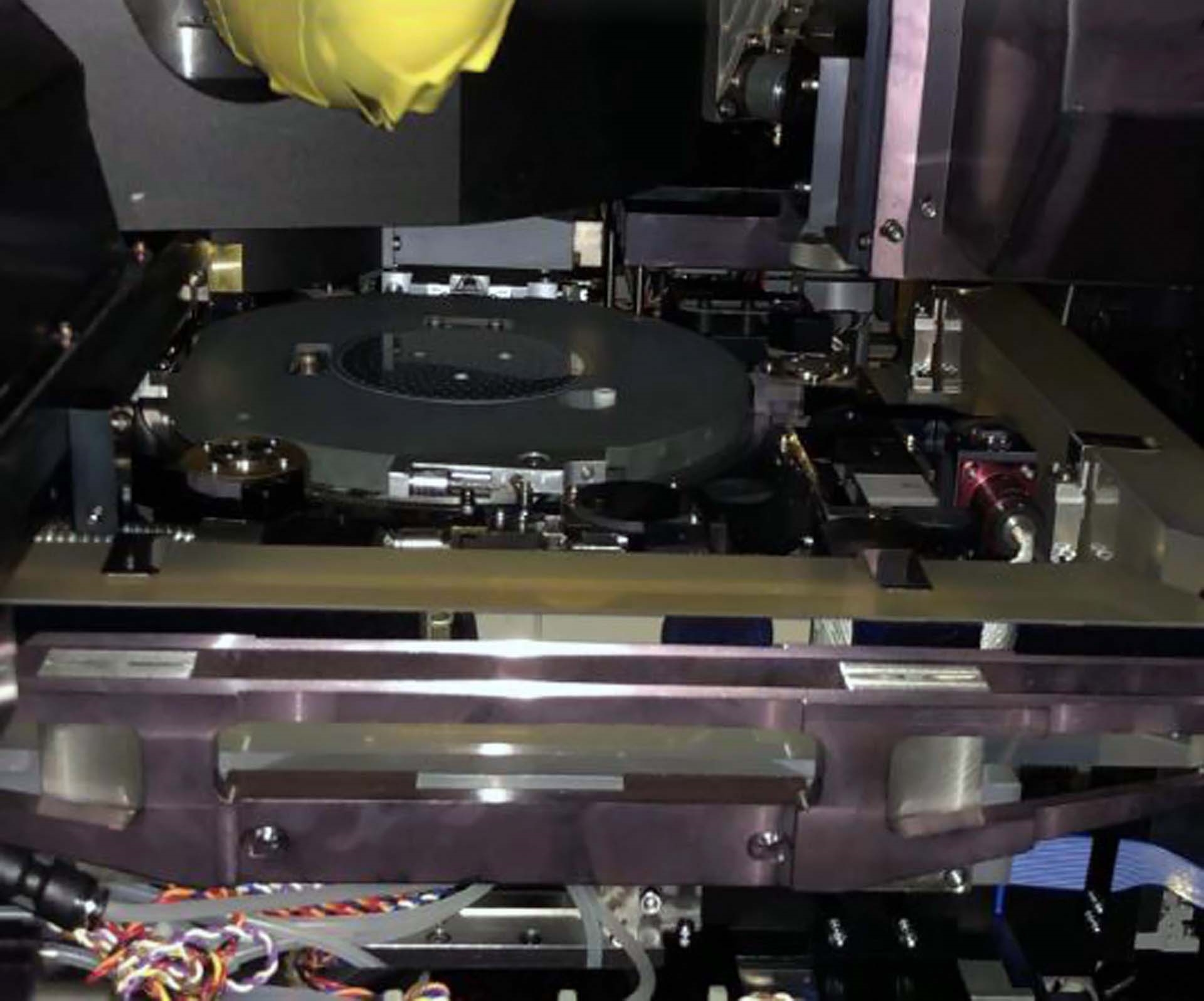

Used NIKON NSR 2205 i11D #9237618 for sale

URL successfully copied!

Tap to zoom

ID: 9237618

Stepper, 4"

Chamber model: N2A

Panel: MPXIII

Chamber set temperature: Chamber / LLTC / IATC: 23°C

AGILENT / HP / HEWLETT-PACKARD / KEYSIGHT Laser: 5517B

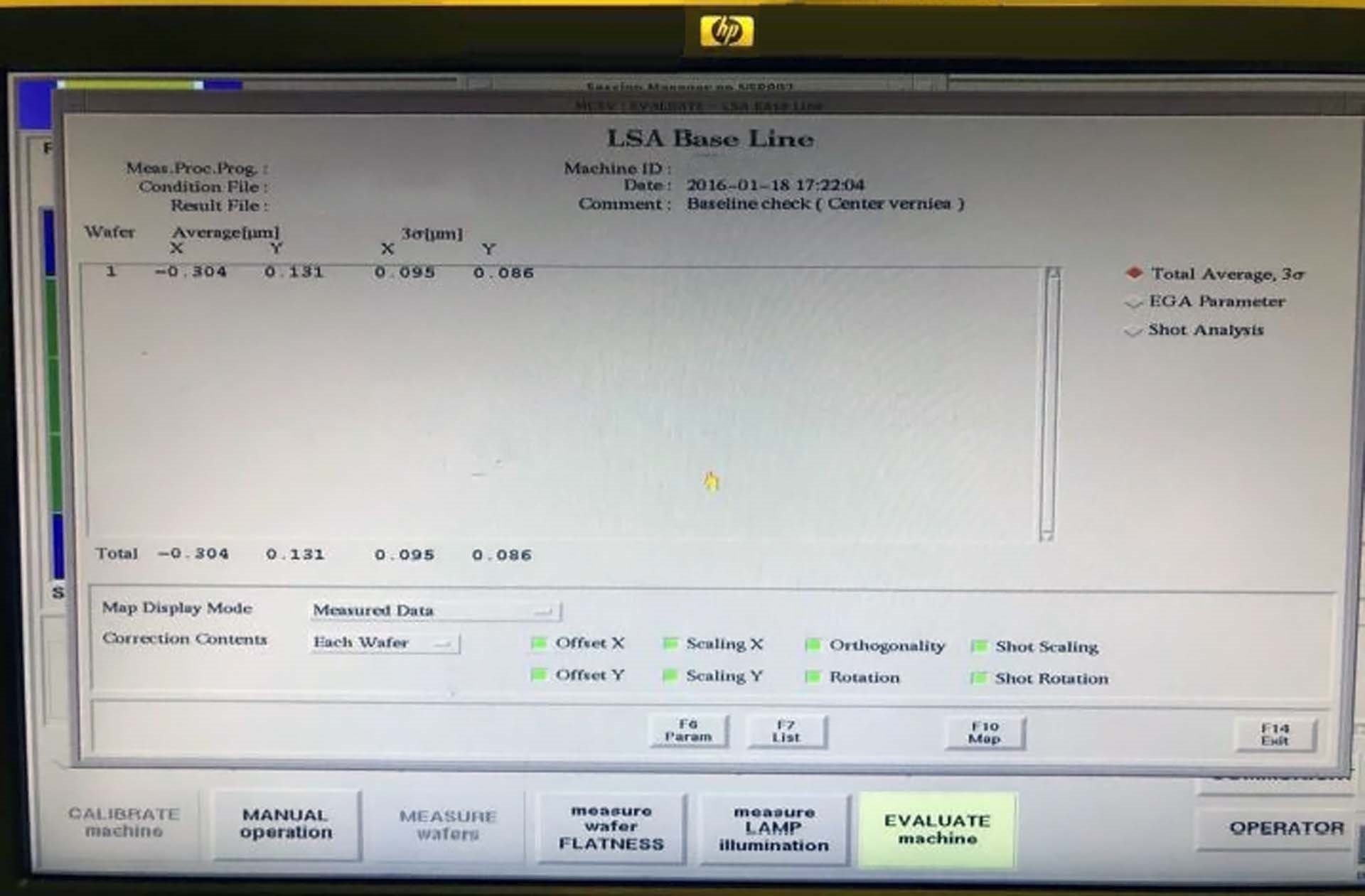

LSA Laser: 14.3 mw

ITV Camera: NIKON Original

OF Detection type: OMRON

No in-line

Wafer type: Flat

Wafer loader type: Type 2

Wafer condition: SAPPHIRE

Wafer carrier table: Right

FIA

Reticle size, 6"

Reticle library slot: 13 Slots

No barcode & PPD

Computer type: VAX 4000 90A

CDA / Vacuum pipe

WL/RL Belt

Fiducial mark

Control rack PCB

STG Guide

No SHRINC lens wheel belt.

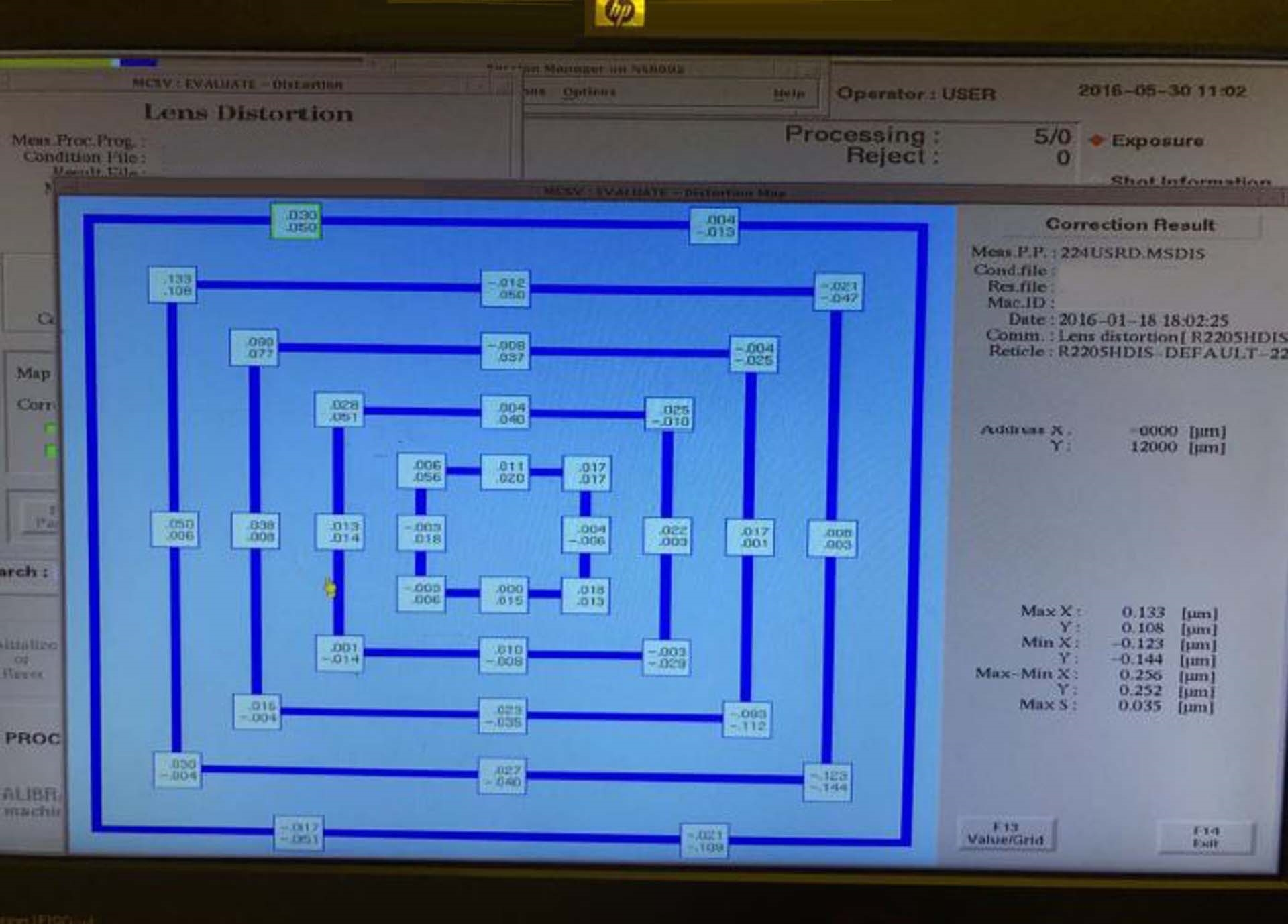

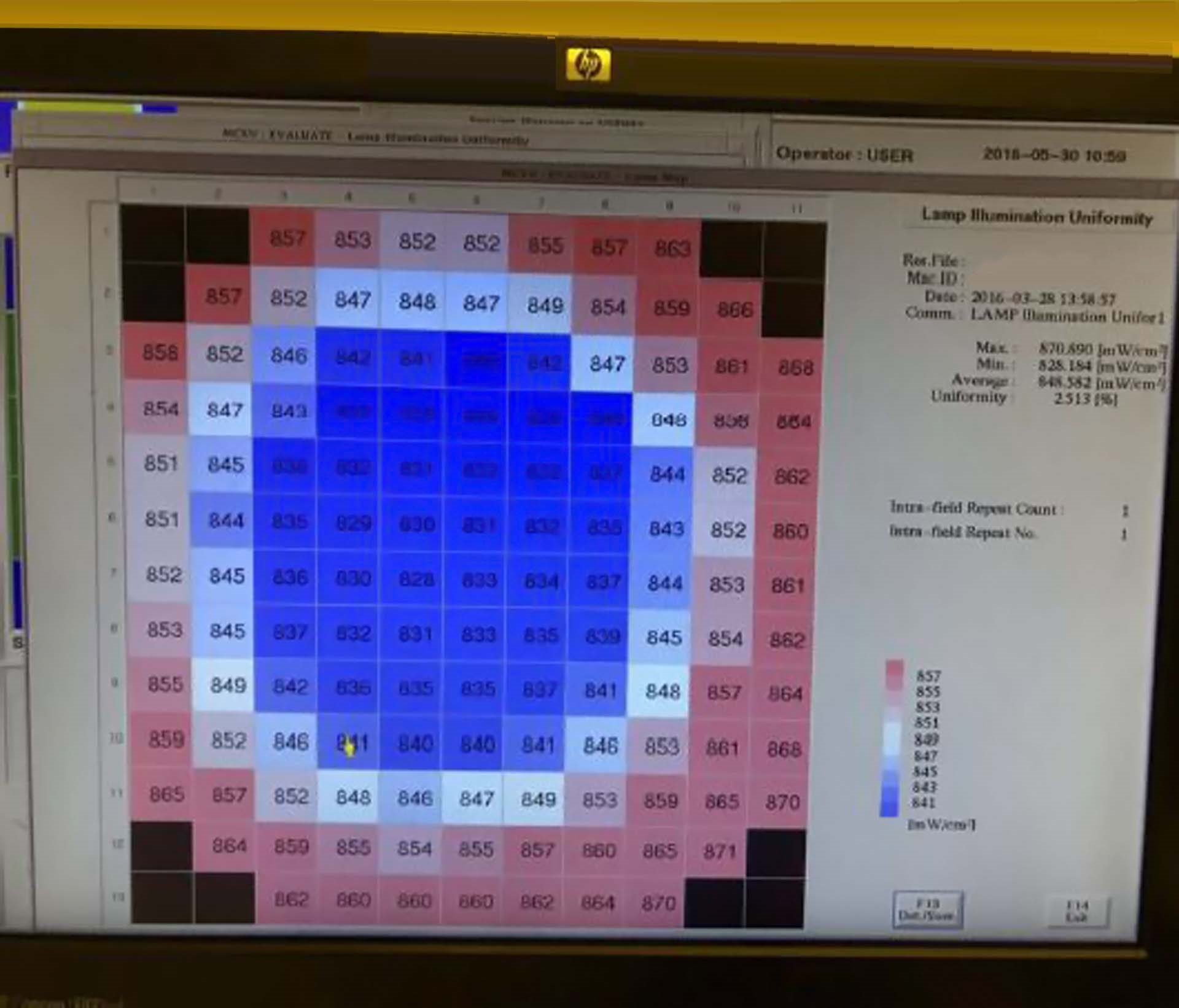

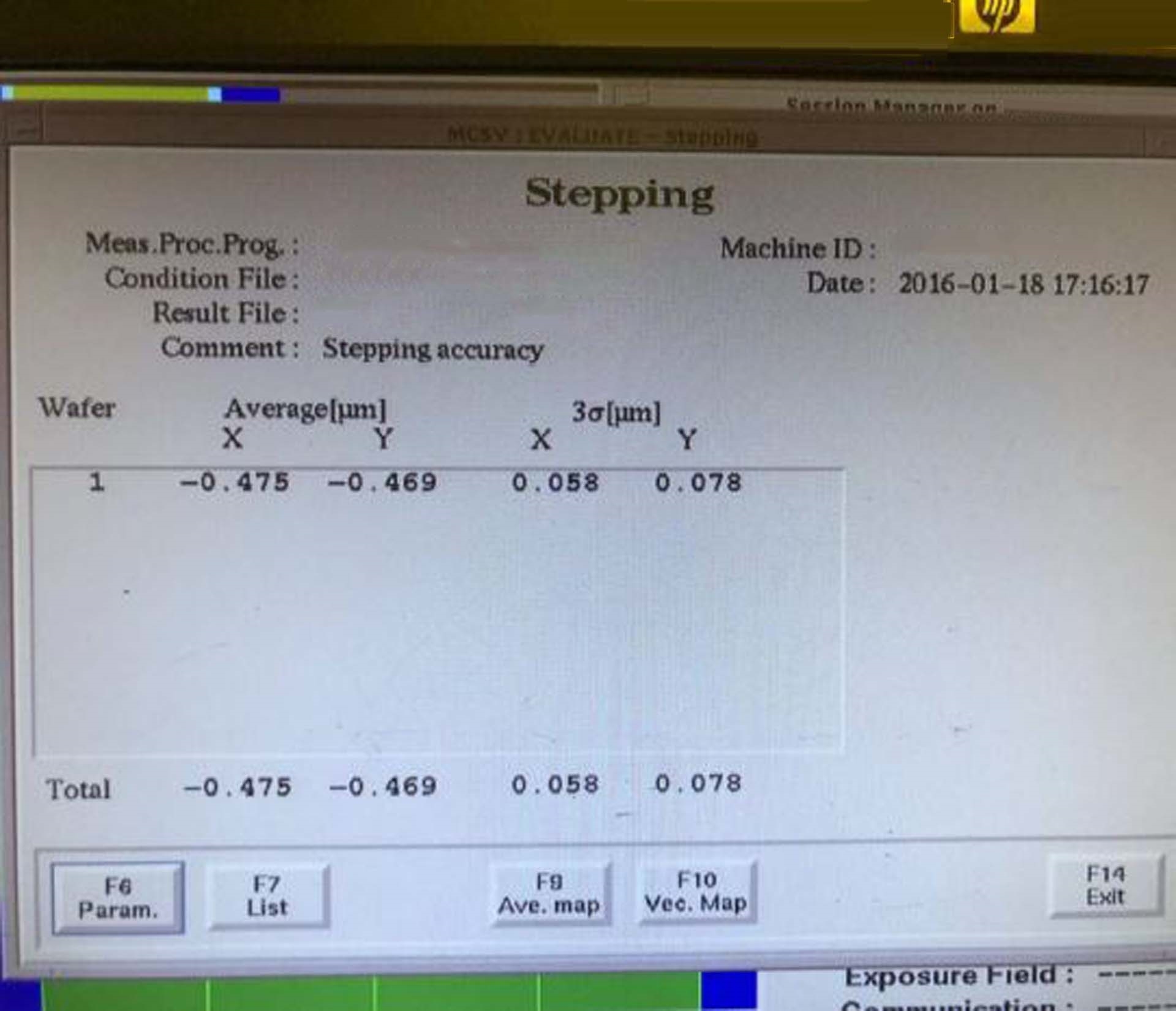

NIKON NSR 2205 i11D wafer stepper is a highly advanced lithography equipment designed for the fabrication of semiconductor devices. This stepper uses a powerful optical system, high-precision scanning stage, and high-performance motor drive unit to deliver superior device performance. The stepper utilizes a full-field image based on the steps-and-repeats method to deliver image uniformity across the entire substrate. The modular structure of the machine allows for added flexibility and scalability, allowing for operations and maintenance with minimal downtime. The stepper uses advanced optics to increase the uniformity and resolution of the images produced. The tool utilizes an 11-lens and an 8-lens asset which provide uniform imaging performance across the entire substrate area at resolutions achievable with the best available stepper technologies. With a wafer stage size of up to 25 inches, the model can accommodate 200mm and 300mm diameter wafers with high throughput rates. The high-accuracy scanning stage can perform repeatability tests and provide feedback in fractions of a second while autofocus, image context, image analysis, and image verification functions are used during scanning to ensure accurate imaging. NIKON NSR-2205I11D wafer stepper also features a high-performance motor drive equipment combined with the latest in robotic control systems, which allow for both highly efficient wafer transfer and high-precision control for dynamic control of the stage. The motor control system is also capable of controlling the acceleration, velocity, and position with higher precision than conventional systems. This level of control allows for higher productivity with more accurate imaging and fewer misalignment errors. NSR 2205I11D wafer stepper also features the latest in imaging algorithms, which allow for fast and accurate image analysis and feedback. The unit can use this feedback to make adjustments to the imaging parameters in order to ensure optimal imaging results. Advanced optics, motion control, and imaging algorithms allow the machine to deliver high throughput rates while maintaining extremely low image errors. NSR 2205I 11D wafer stepper is capable of delivering extremely high-quality images with minimal downtime. The tool is highly reliable and versatile, allowing for a wide range of semiconductor device fabrication operations. The asset is an ideal choice for organizations or individuals looking for a reliable, high-precision wafer stepper to increase their production capacity and efficiency.

There are no reviews yet