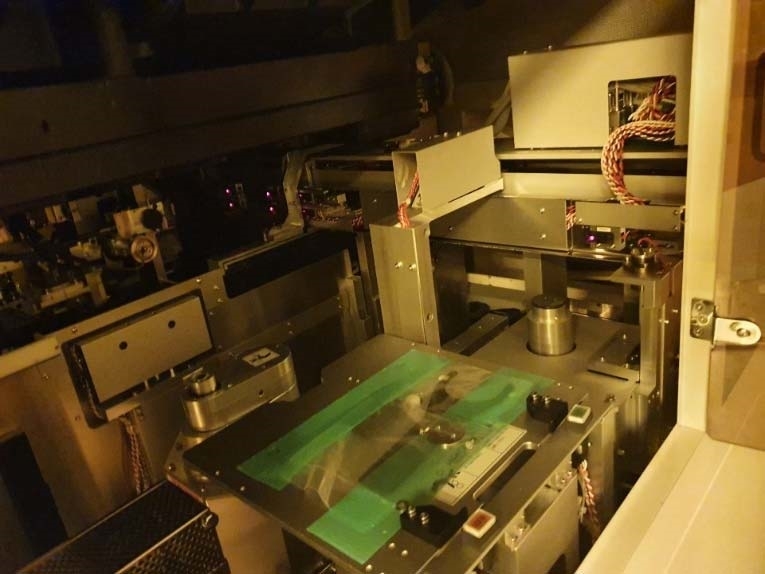

Used NIKON NSR 2205 i11D #9284006 for sale

URL successfully copied!

Tap to zoom

ID: 9284006

Vintage: 1995

Stepper

Temperature: 23°C

Chamber type: ASAHI N2A

NA Variable system

Reticle size: 6"

Field size maximum: 22 mm

Reticle barcode reader

Reticle case, 6"

Wafer: Notch, 8" (6C)

Pre alignment 2

Wafer loader: Type 3

Chip leveling

Wafer carrier table: Left, right

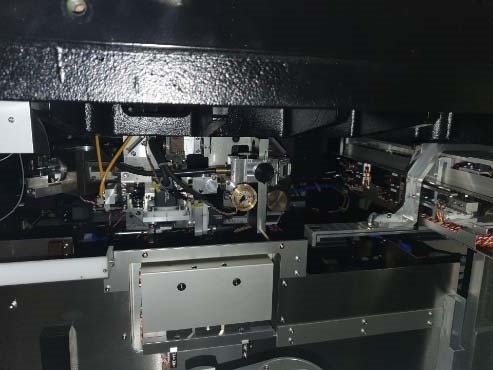

Alignment sensor: LSA, FIA

Rack type: Normal

Body OP ruck cable: 3m

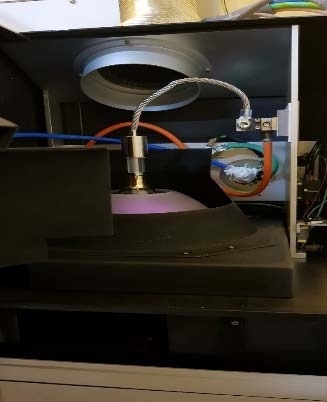

Lamp power: 2 kW

Illumination: SHRINC3

No PPD

No reticle SMIF

No in-Line

No extend R library

No signal tower

No wafer edge exposure

1995 vintage.

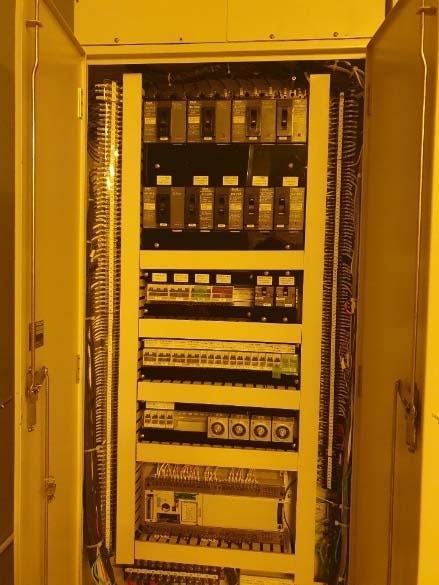

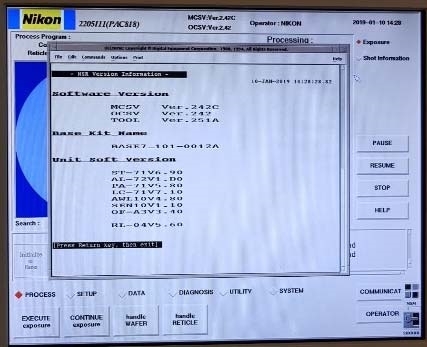

NIKON NSR 2205 i11D is a two-beam, two field stepper for high-end semiconductor device manufacturing. It is capable of producing critical, yet highly accurate geometric patterns with a high resolution of 0.2 μm. NIKON NSR-2205I11D has a multi-aperture, interferometric optical equipment, with a compact high NA optical system to achieve the highest resolution possible. Its optical unit uses mirrors, lenses and a curved illuminator to accurately shape the energy shape for optimized pattern detection. This machine also includes two linescan cameras, which have a pixel size of 0.13 μm and a set of low-level binary processing algorithms to minimize calculation time and minimize the impact on device production cycle times. The wafer stage of NSR 2205I11D is designed to meet the requirements of high accuracy, high speed, and low noise operation. The linear stage is made of an aluminum alloy frame and is designed to provide the best combination of stiffness, damping, non-linear motion, and stability. An embedded magnetic motor tool powers the stage and has special features such as pulse-width modulation and real time auto-compensation. This magnetic motor asset is combined with advanced kinematic coupling and gear mechanisms for precise beam alignment. The dual-wavelength scanning mechanism of NIKON NSR-2205 I11D contains both a wide spectrum (UV to Visible) and a narrow spectrum (UV), offering higher accuracy and more efficient operation. NSR 2205 i11D has a high scanning accuracy, allowing for precise positioning and controlling of the wafer in a semiconductor production line. Additionally, the stepper is equipped with a high-speed shutter to prevent wafer pattern aberrations from being caused by decreased brightness intensity. NSR-2205 I11D is user friendly and provides easy maintenance due to a wide selection of process parameters and Ethernet connectivity. Compared to conventional steppers, this model is more reliable, as it contains automatic alignment features and can be used both manually and remotely. Furthermore, its built-in self-diagnosis model allows real-time observation of information, such as power supply voltage, illumination intensity, and spectral composition, notifying the user when errors occur. Overall, NSR 2205I 11D pulses high-resolution patterns to the wafer, mounting smaller die in a very short period of time using its dual-field scanning technique. Its high-resolution optics and advanced control equipment ensures synchronized operation and accurate production, which makes it ideal for high-end semiconductor device manufacturing.

There are no reviews yet