Used NIKON NSR 2205 i12C #293603489 for sale

URL successfully copied!

Tap to zoom

ID: 293603489

i-Line stepper

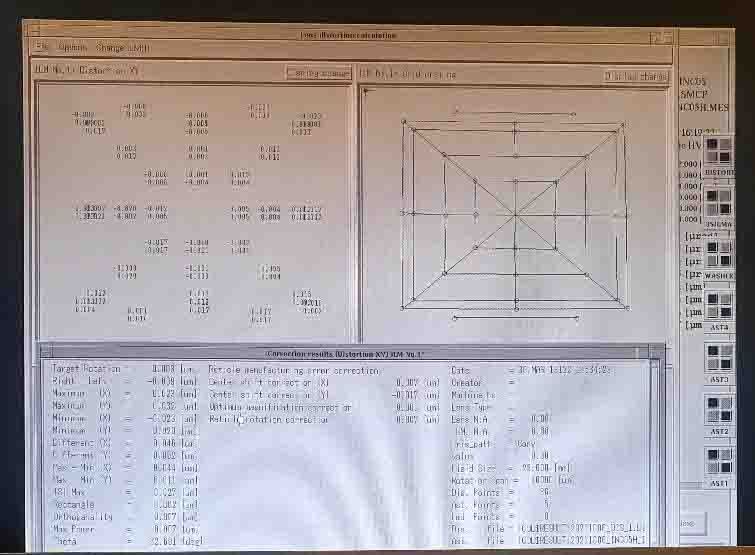

Lens distortion: Standard measurement

Reticle blind setting accuracy

Focus calibration repeatability: 20 times measurement

Exposure power (N.A=0.57): Mercury lamp

Integrated exposure control accuracy (N.A=0.57): i-line IR-Radiance meter

Alignment accuracy FIA: FIA-EGA (Standard measurement)

Alignment accuracy LSA: LSA-EGA (Standard measurement)

Array orthogonality: Standard measurement

Stepping precision: Standard measurement

Wafer pre-alingnment repeatability: Single wafer, 20 times measurement

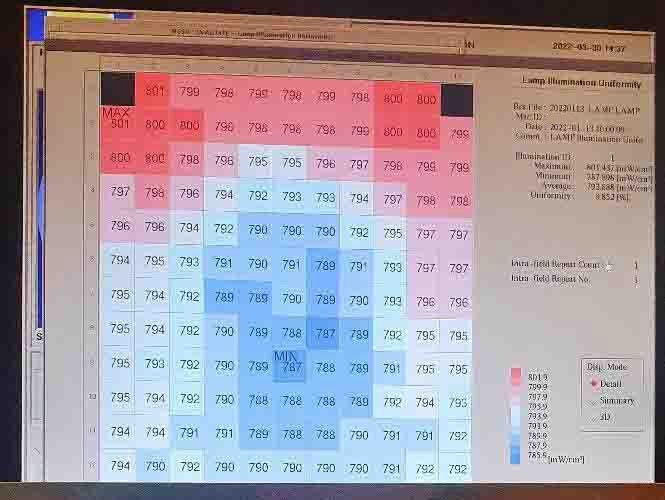

Illumination uniformity (N.A=0.57): 5 times measurement within the exposure area

Resolution, 0.4 µm:

L/S Conv NA: 0.57

CE V/H: 0.40

PR Film thickness: <1.0 µm

DOF: 0.45 µm:

5-Points V/H: 0.40 µm

PR Film thickness: <1.0 µm

CD Uniformity, 0.45 µm:

5-Points V/H: 0.40 µm

PR Film thickness: <1.0 µm

Coma, 0.45 µm:

5-Points V/H: 0.40 µm

PR Film thickness: <1.0 µm

Total Focus Deviation (TFD), 0.45 µm:

L/S Conv N.A: 0.57

Standard measurement

Astigmatism (AST):

Deviation L/S Conv

Standard measurement

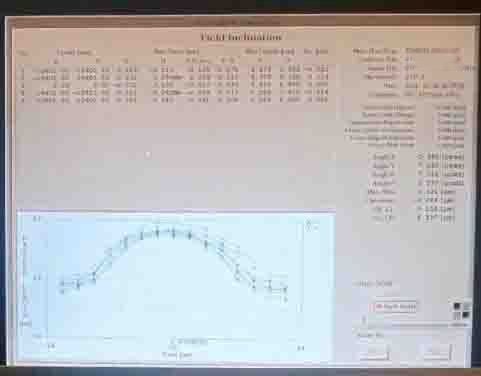

Lens inclination, 0.50 µm:

L/S Conv N.A: 0.57

Standard measurement

Lens control accuracy (Initial):

Heating: 150 min

Cooling: 180 min

Operation test:

Wafer system

Reticle.

NIKON NSR 2205 i12C is a twelve-step wafer stepper used to accurately and efficiently manufacture semiconductor chips. It is equipped with a built-in laser alignment equipment, allowing for high precision chip manufacture with minimal waste of time and material. The stepper is particularly suited to the production of chips requiring high levels of accuracy, such as those used in optical or pin grid array devices. The equipment boasts an energy efficient design and high throughput capability, thus allowing for rapid production of high-quality chips. The laser alignment system further speeds up the process, eliminating the need to manually adjust the wafer alignment. This results in faster chip production, avoiding the need for extra processing steps to ensure high quality end products. The stepper features an advanced luminous optical unit with a resolution of 0.25 microns, allowing for the production of tight line features and the production of chips with advanced three-dimensional features such as stepped surfaces. The optical machine is connected to an advanced main computer and precision motor drives, ensuring high-precision chip production. The stepper is further equipped with an advanced cross-linking design, providing unprecedented levels of accuracy even when processing different resist recipes. By allowing the stepper to accurately process different recipes simultaneously, production time is minimized. Overall, NIKON NSR-2205I12C is an excellent choice for semiconductor production. It offers extremely high levels of accuracy, even when dealing with the most demanding applications, and its energy efficient design results in rapid production of high-quality chips. This stepper is the perfect tool for the production of high-end chips, resulting in better yields and lower costs.

There are no reviews yet