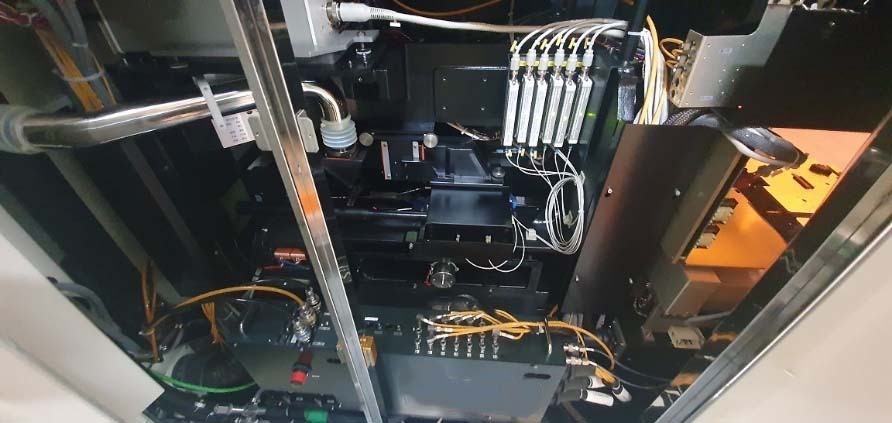

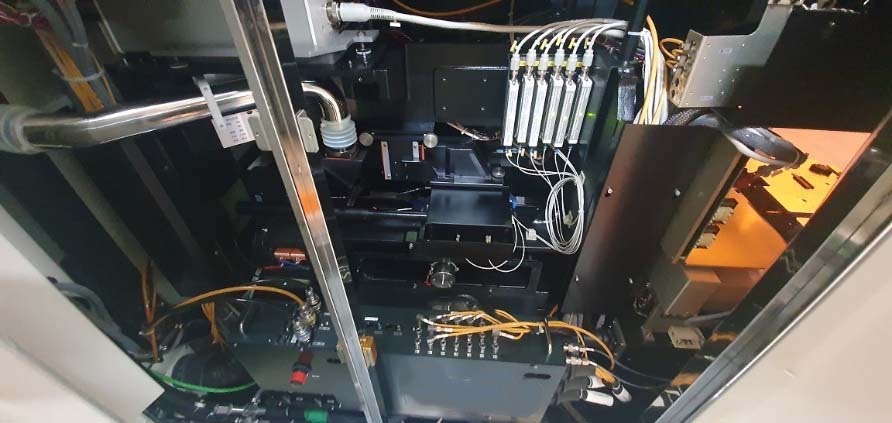

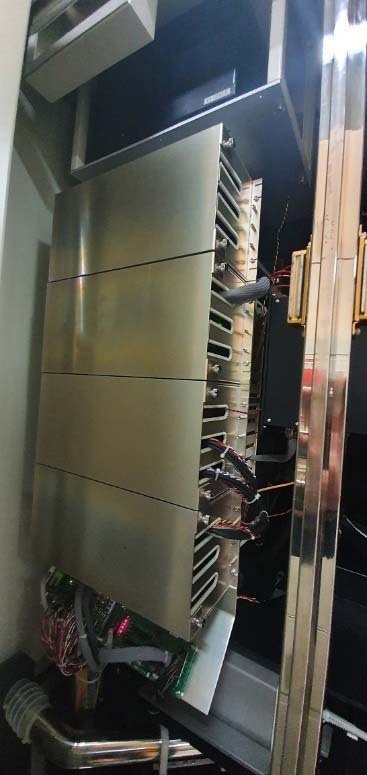

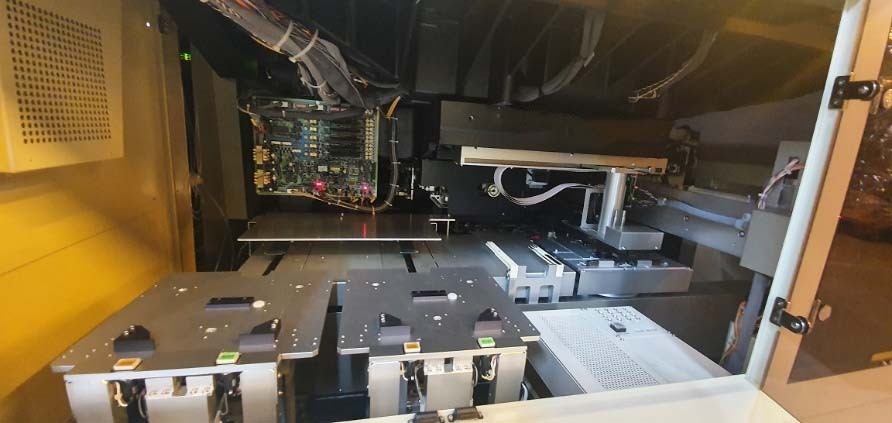

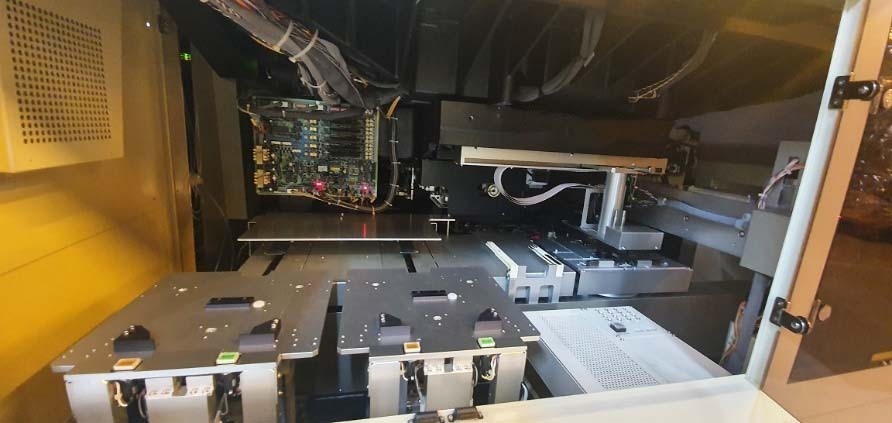

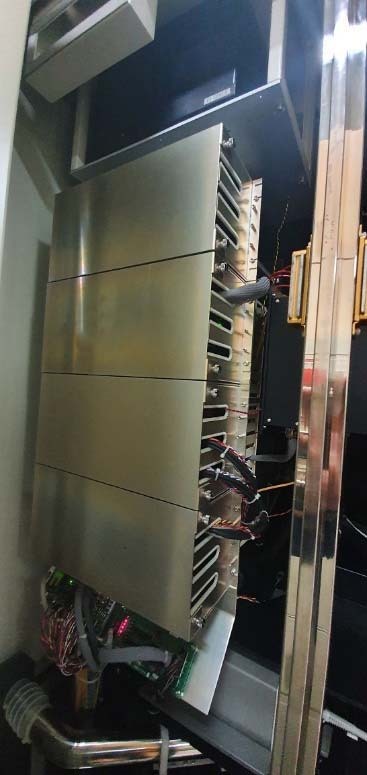

Used NIKON NSR 2205 i12C #9379646 for sale

URL successfully copied!

Tap to zoom

ID: 9379646

i-Line stepper, 6"

Chamber temperature: 23°C

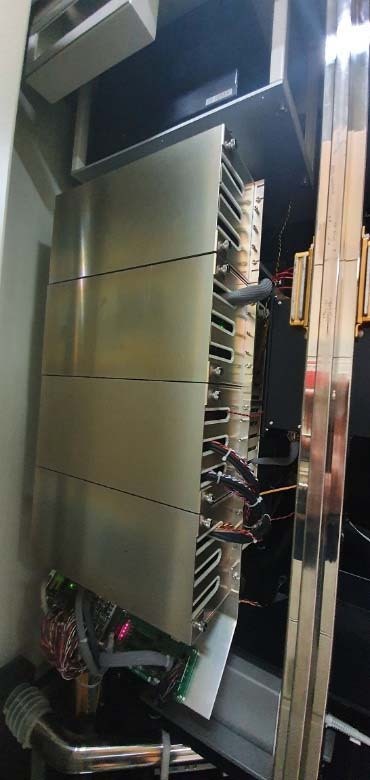

Chamber type: S16

NA Variable system

Reticle, 6"

Fixed reticle microscope

Maximum field: 22 mm

Reticle loader: Standard, 13-Slots

Reticle case: Standard, 6"

Pre alignment-2

Wafer loader: Type II

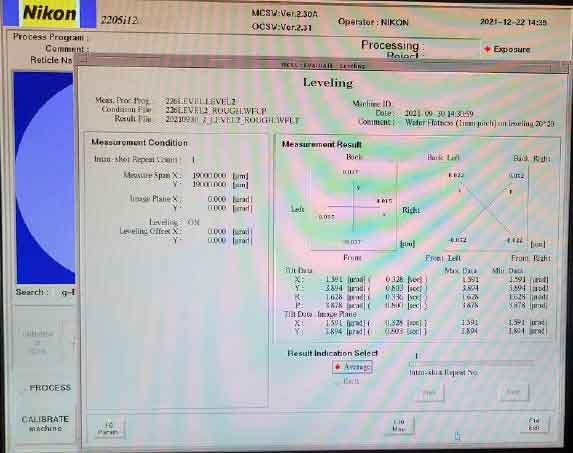

Chip leveling

Wafer carrier table: Left, right

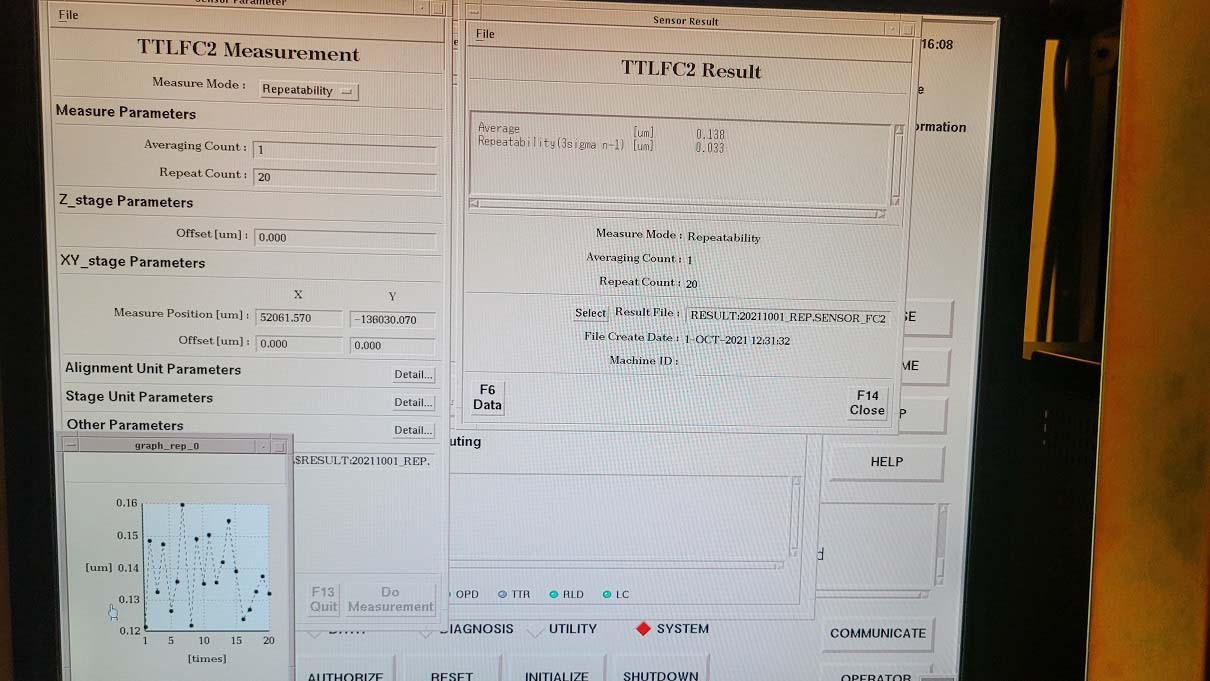

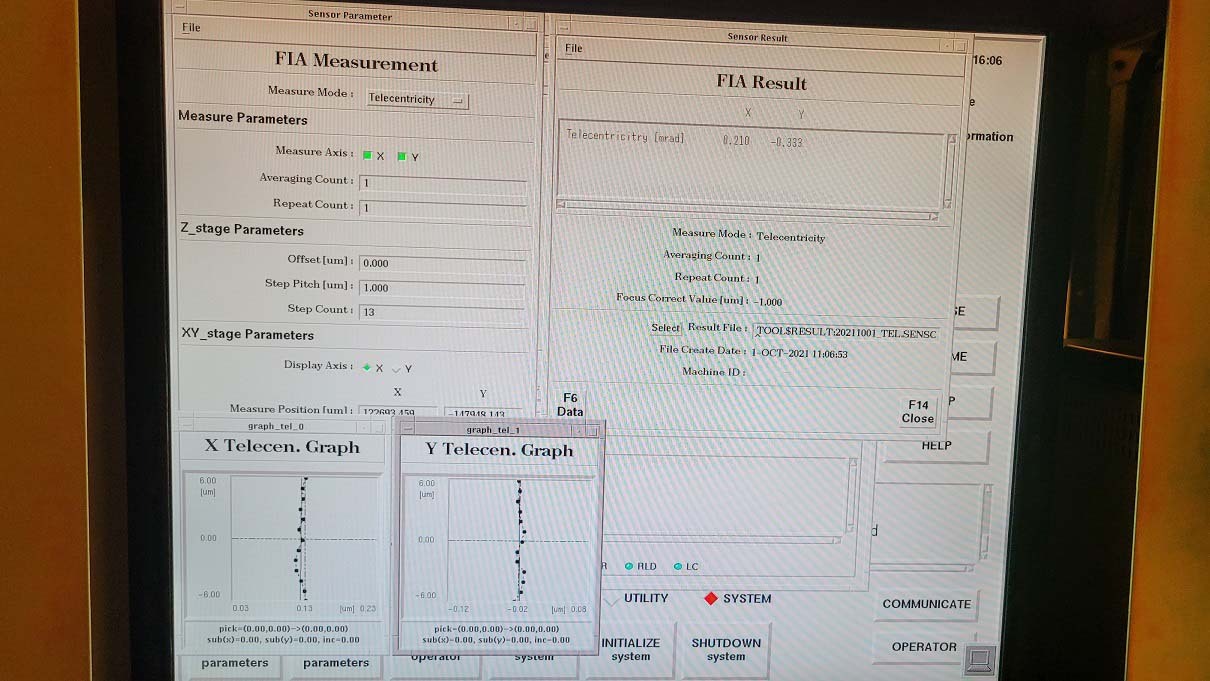

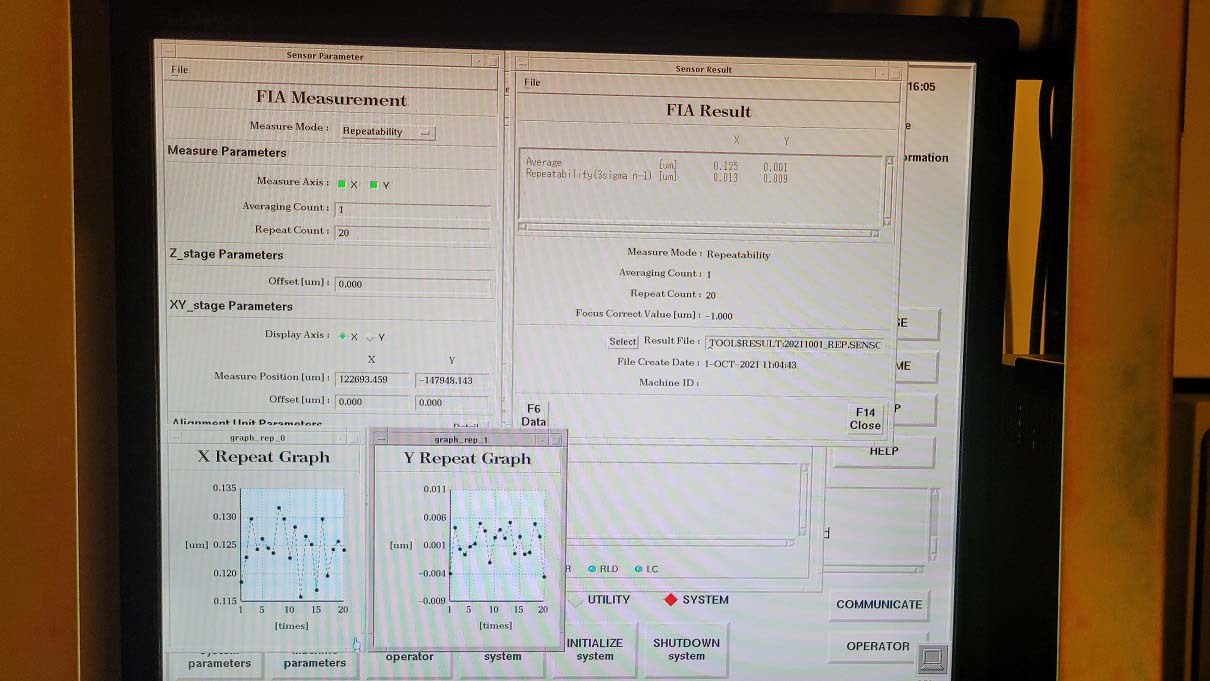

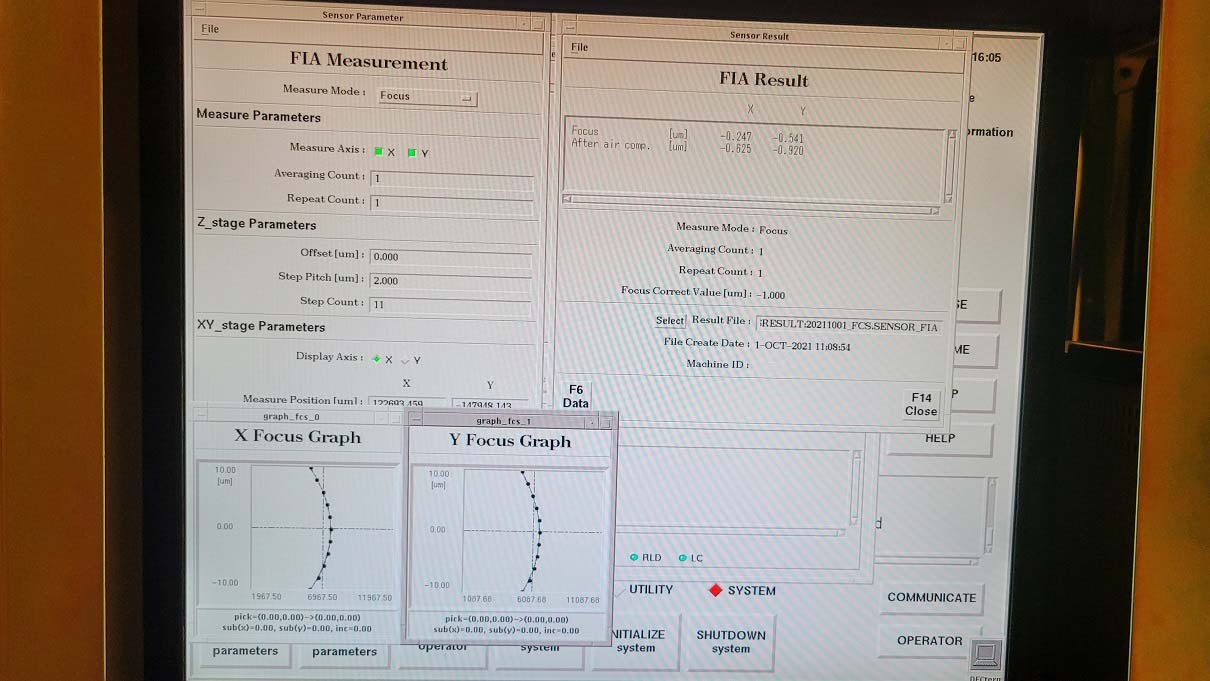

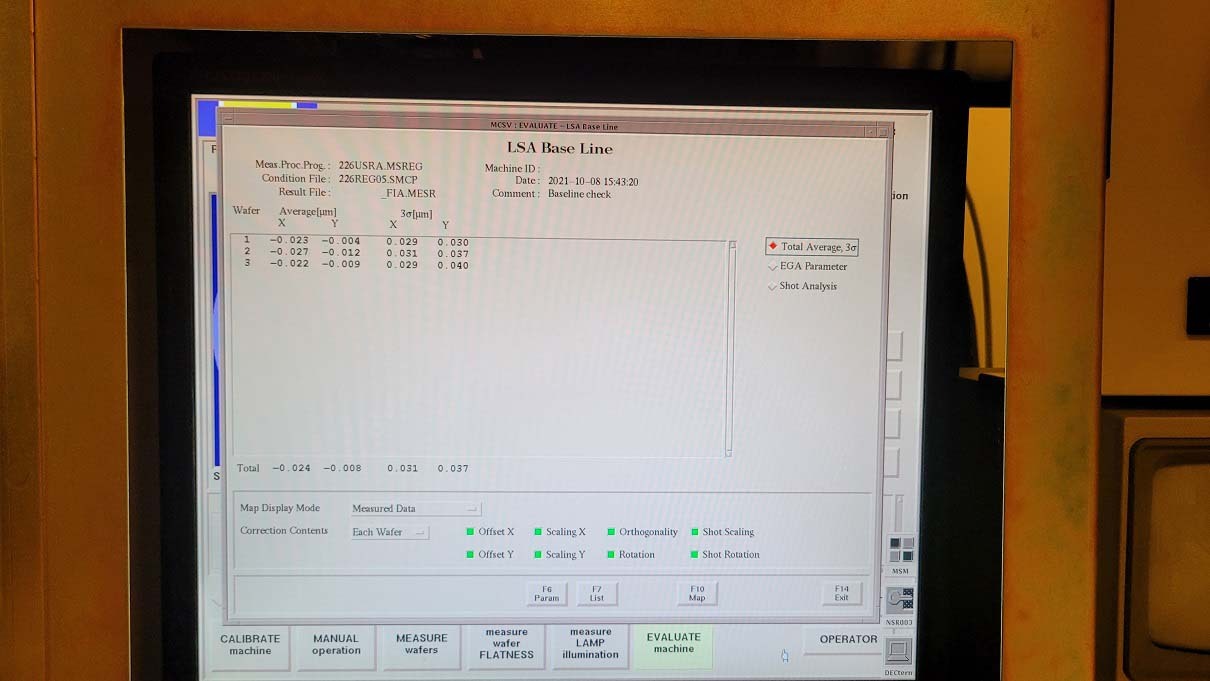

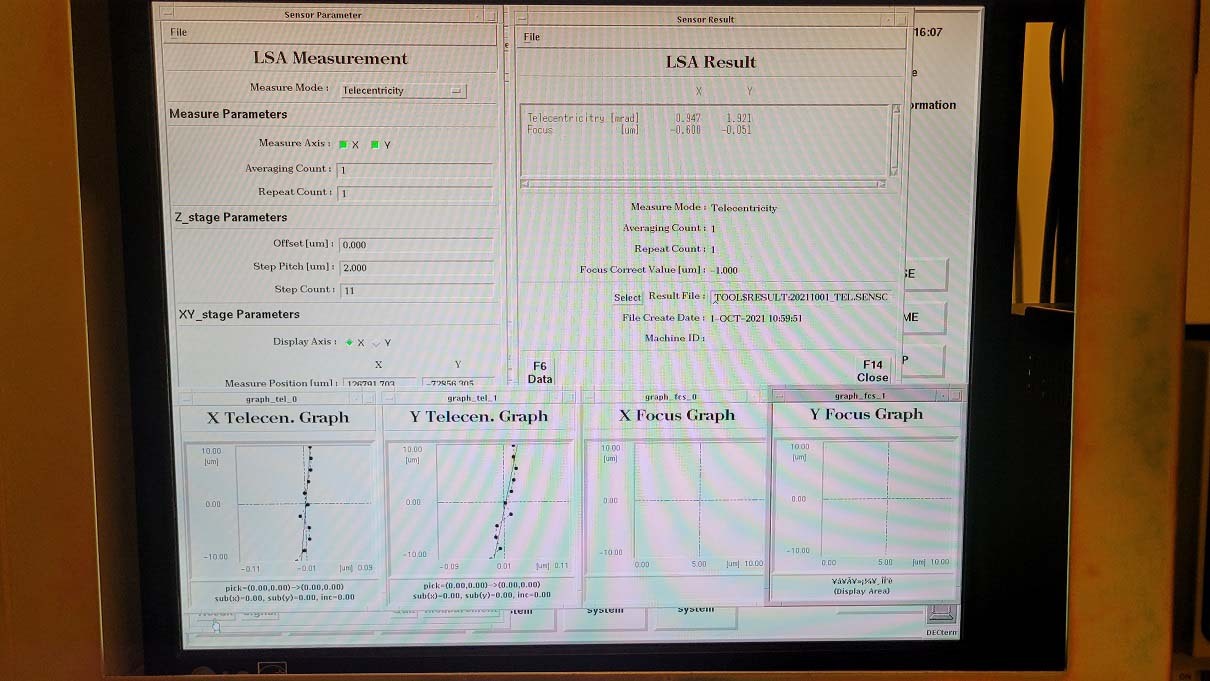

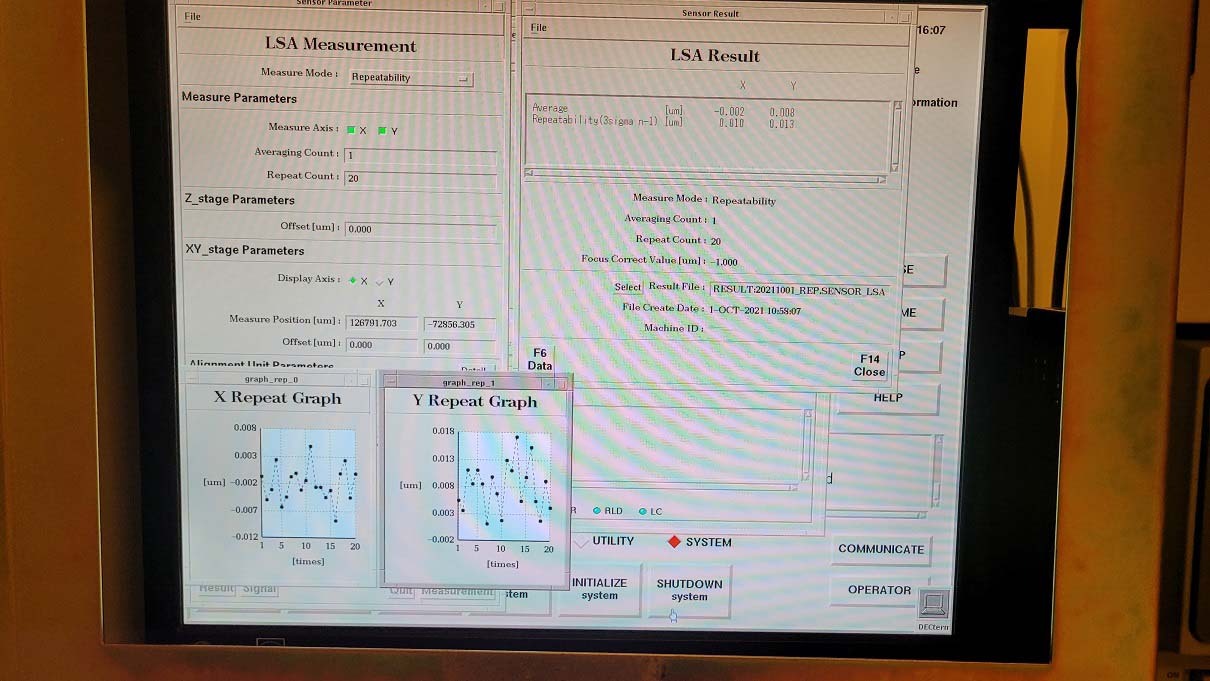

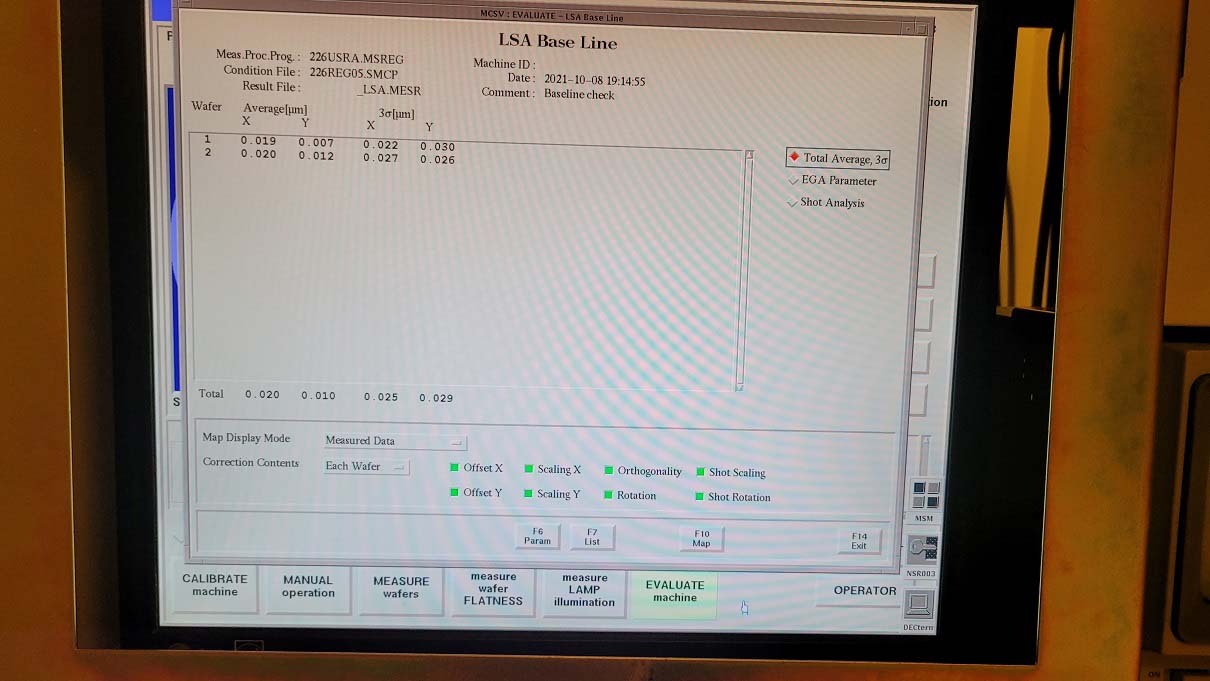

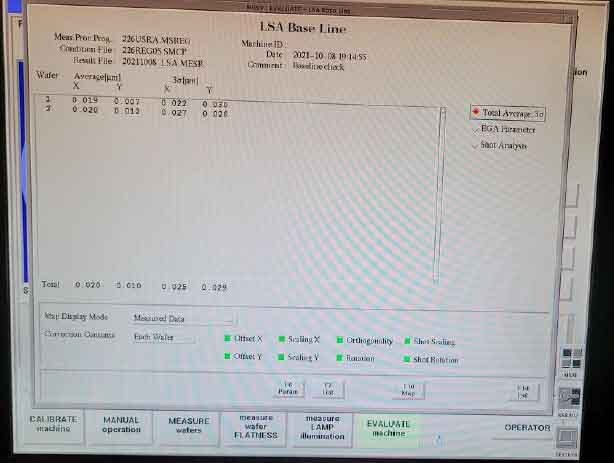

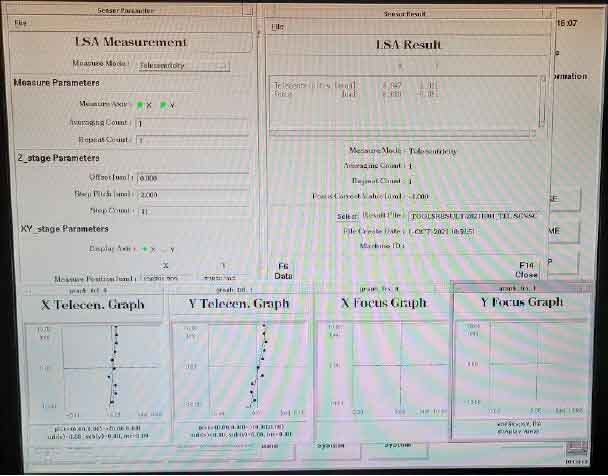

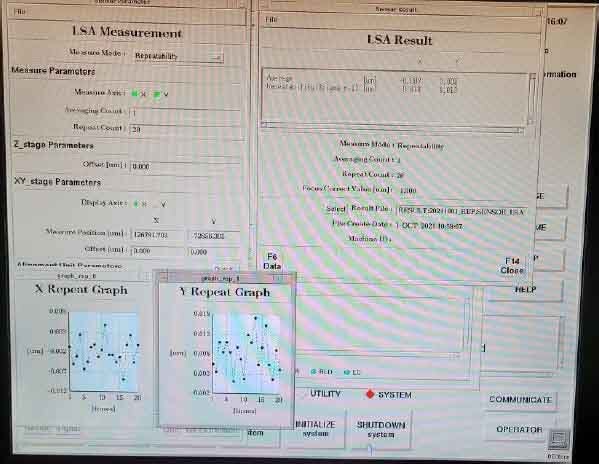

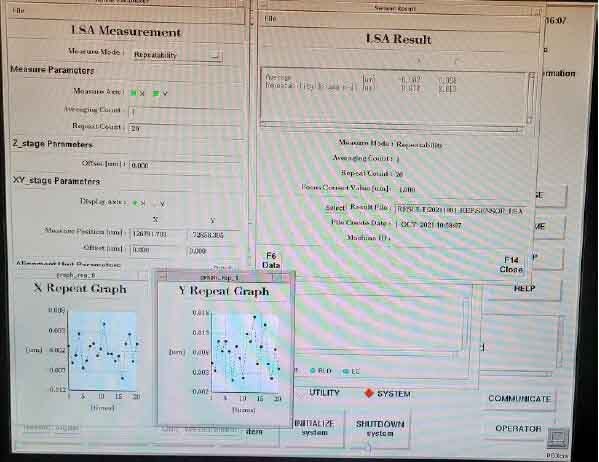

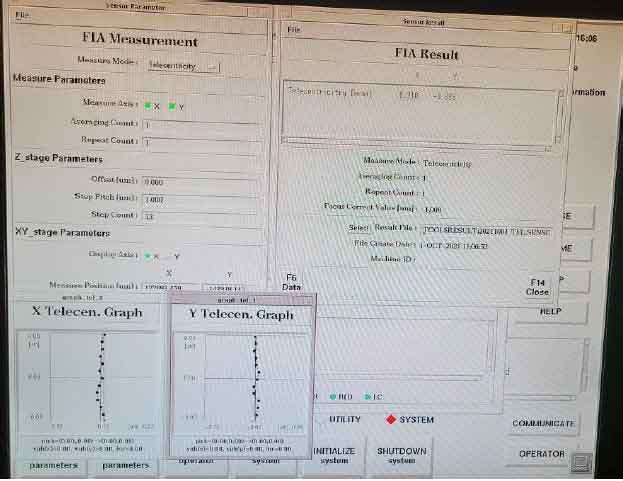

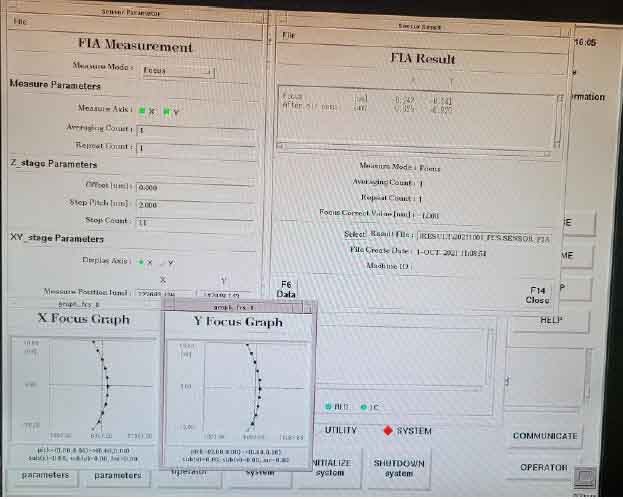

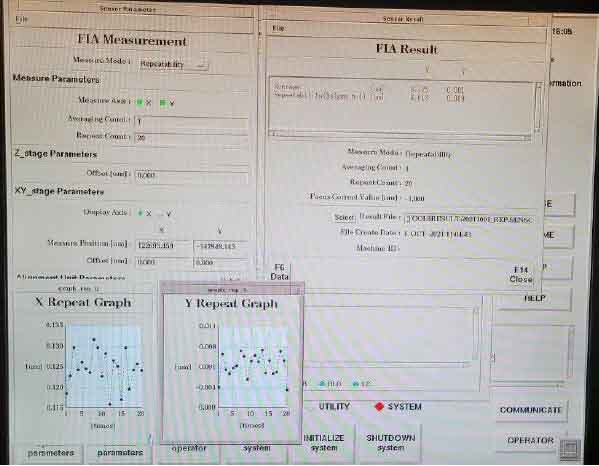

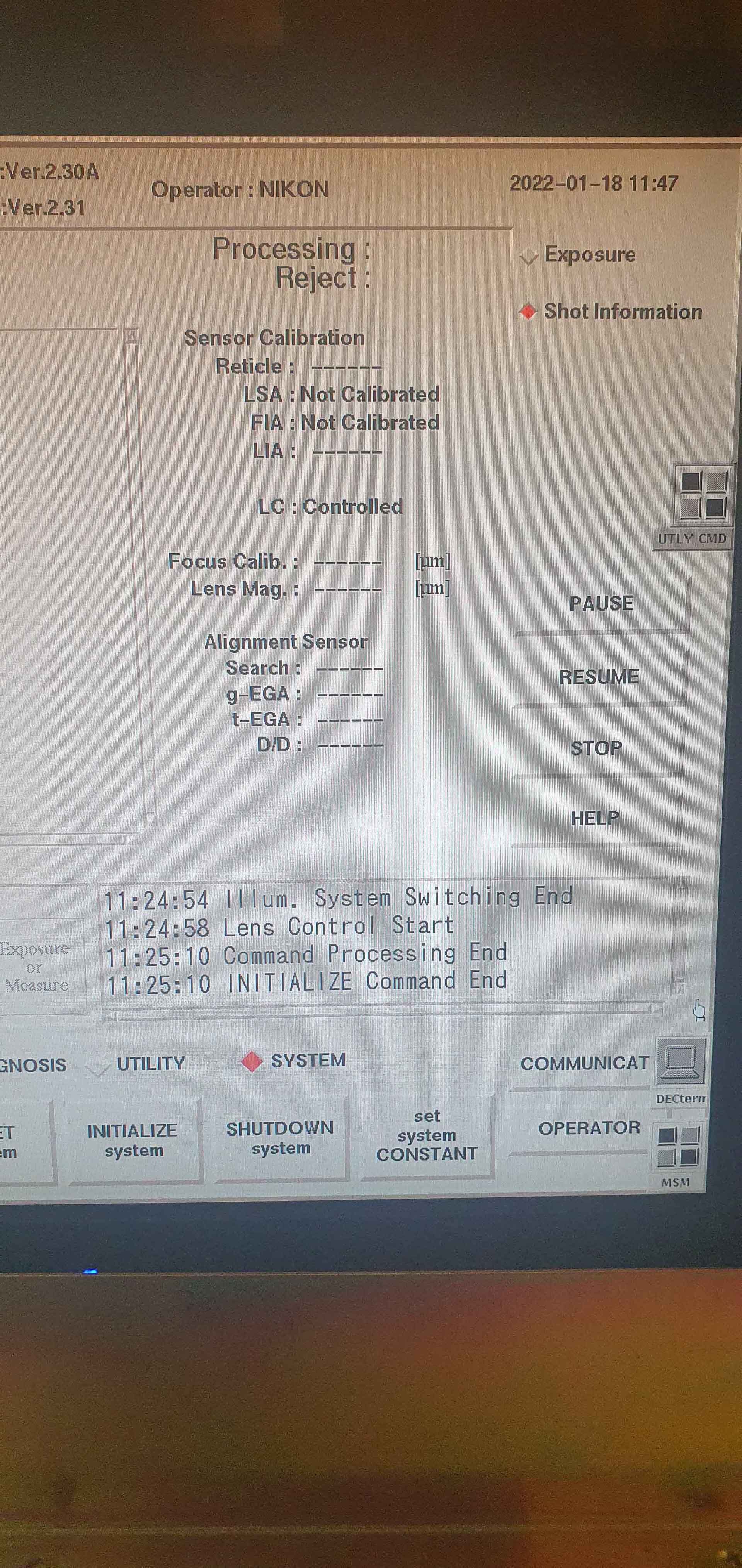

Alignment sensor: LSA, FIA

Body-OP Ruck cable: 3 m

Rack type: Right

Lamp power: 2000 W

SHRINC Type 3 Illumination

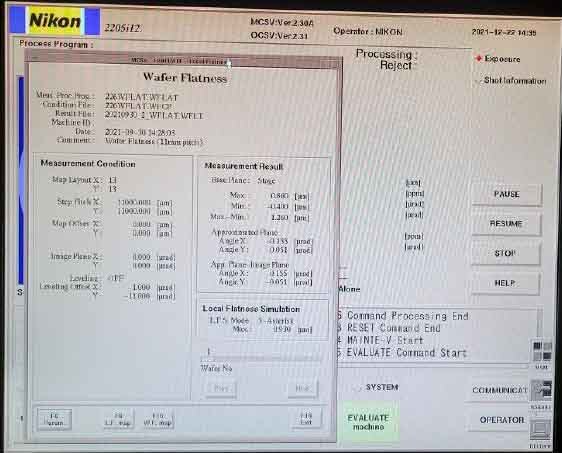

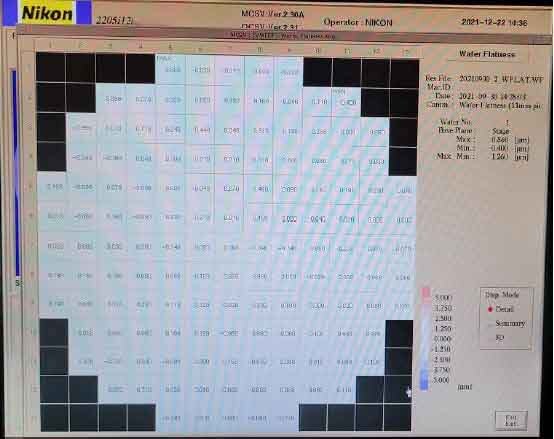

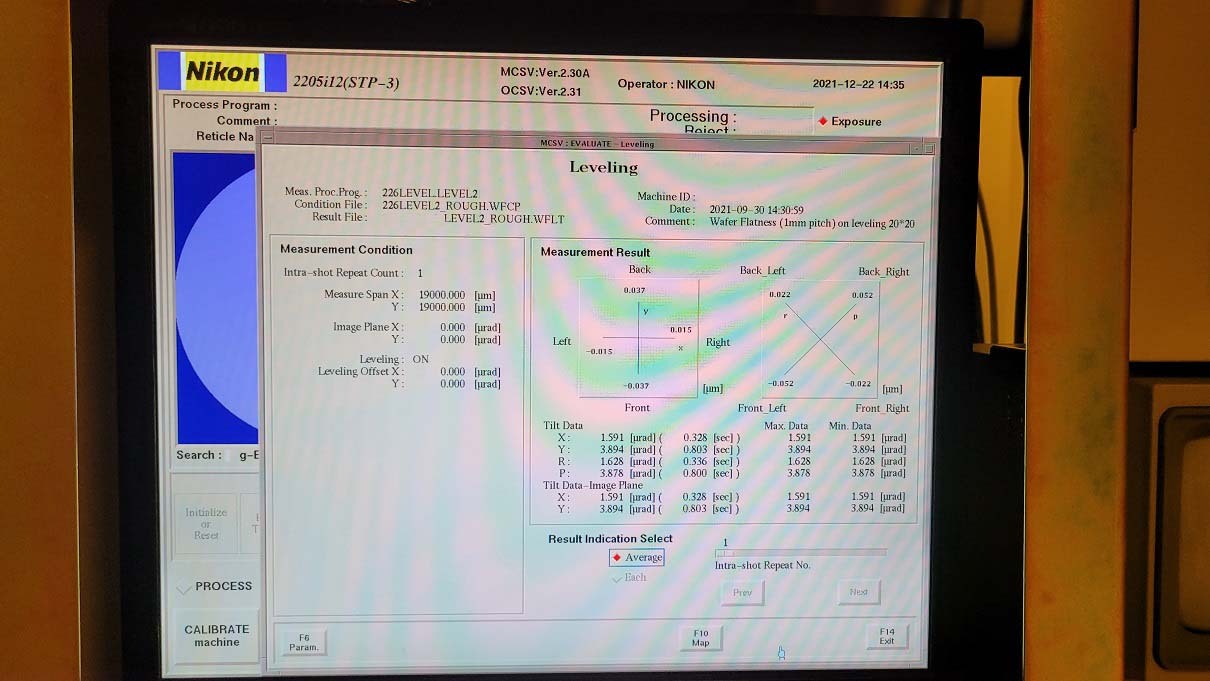

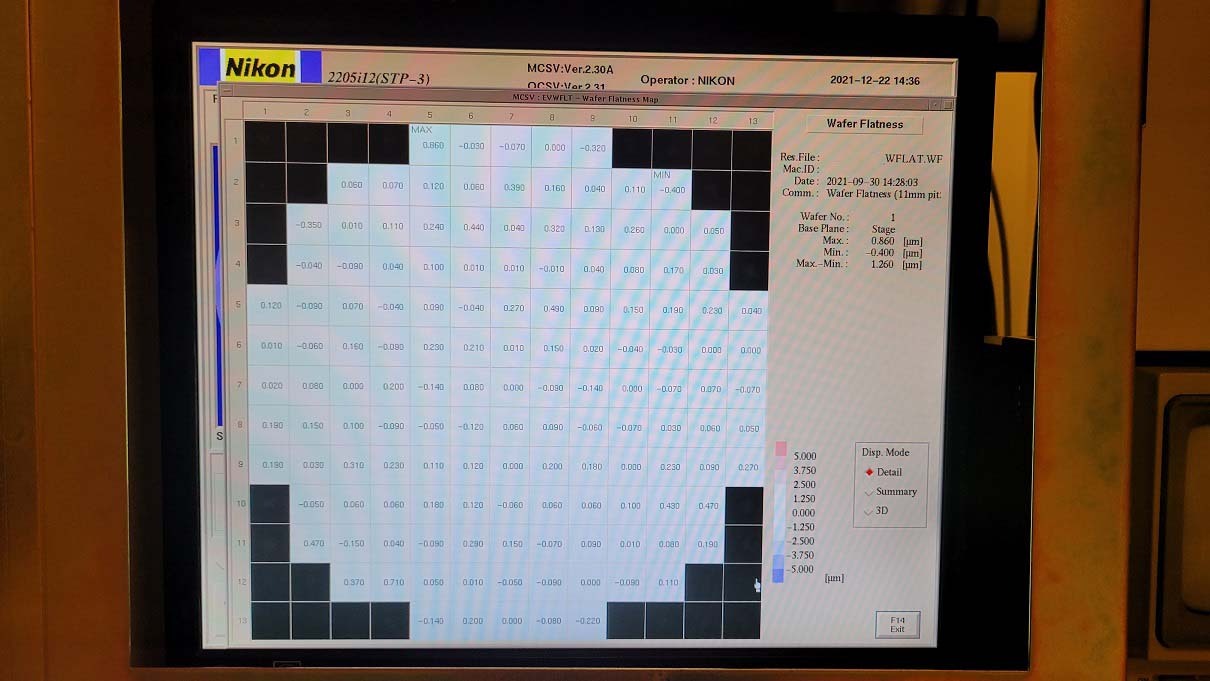

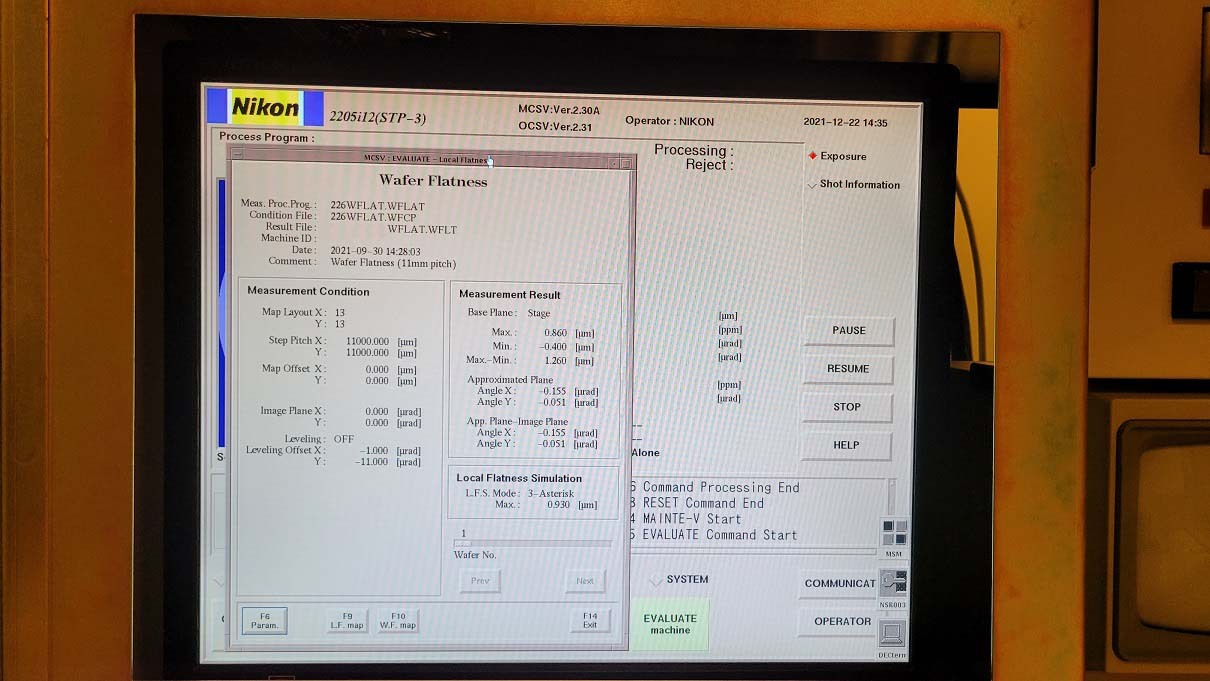

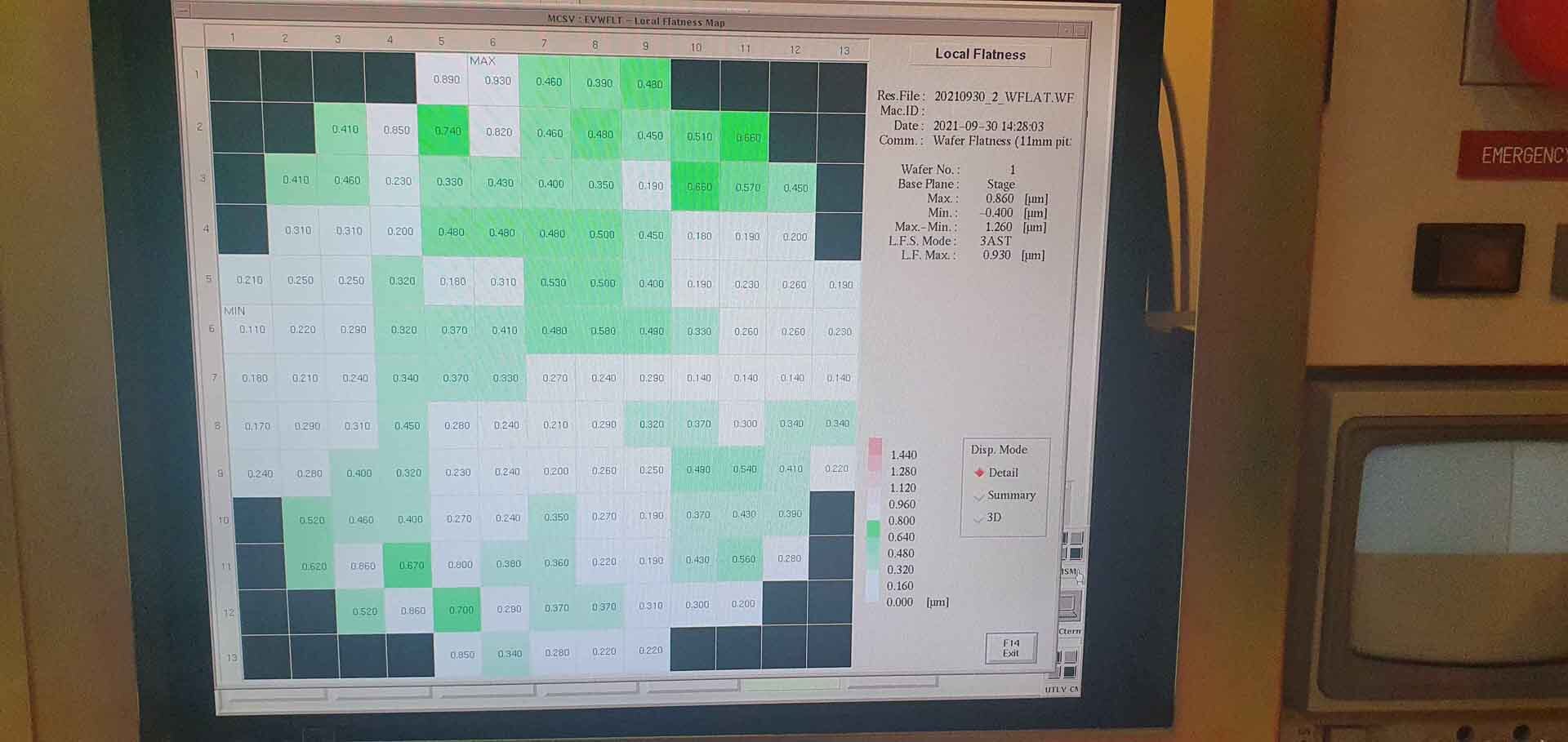

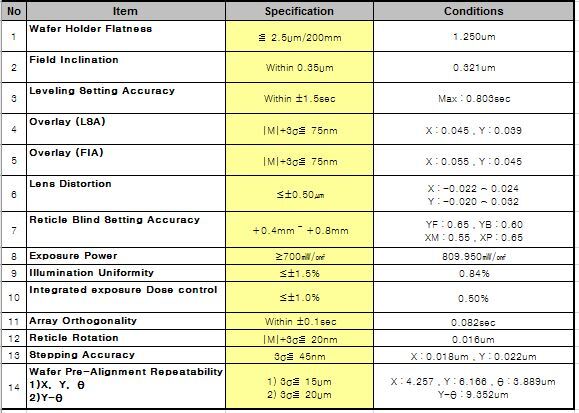

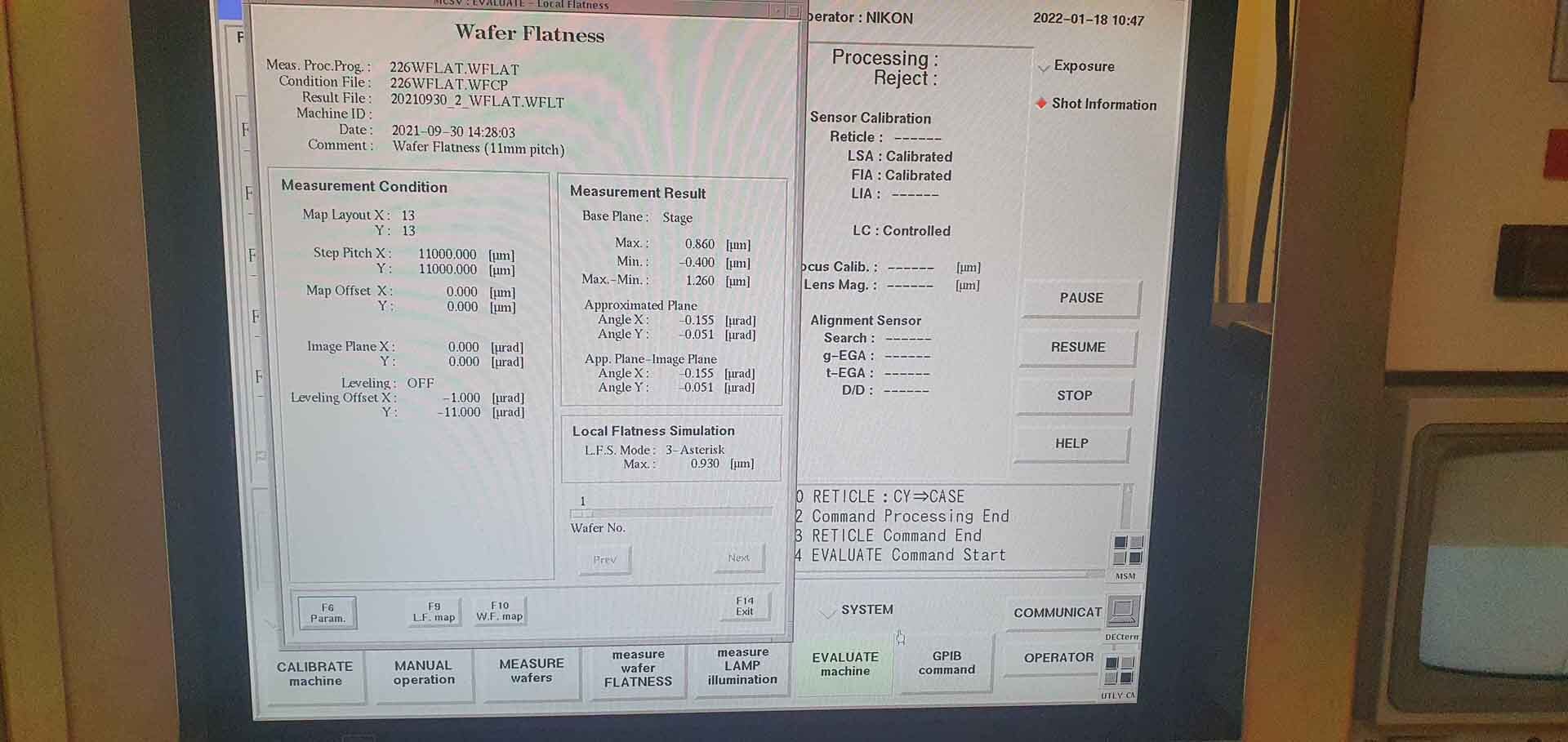

Wafer holder flatness: ≤2.5 μm / 200 mm

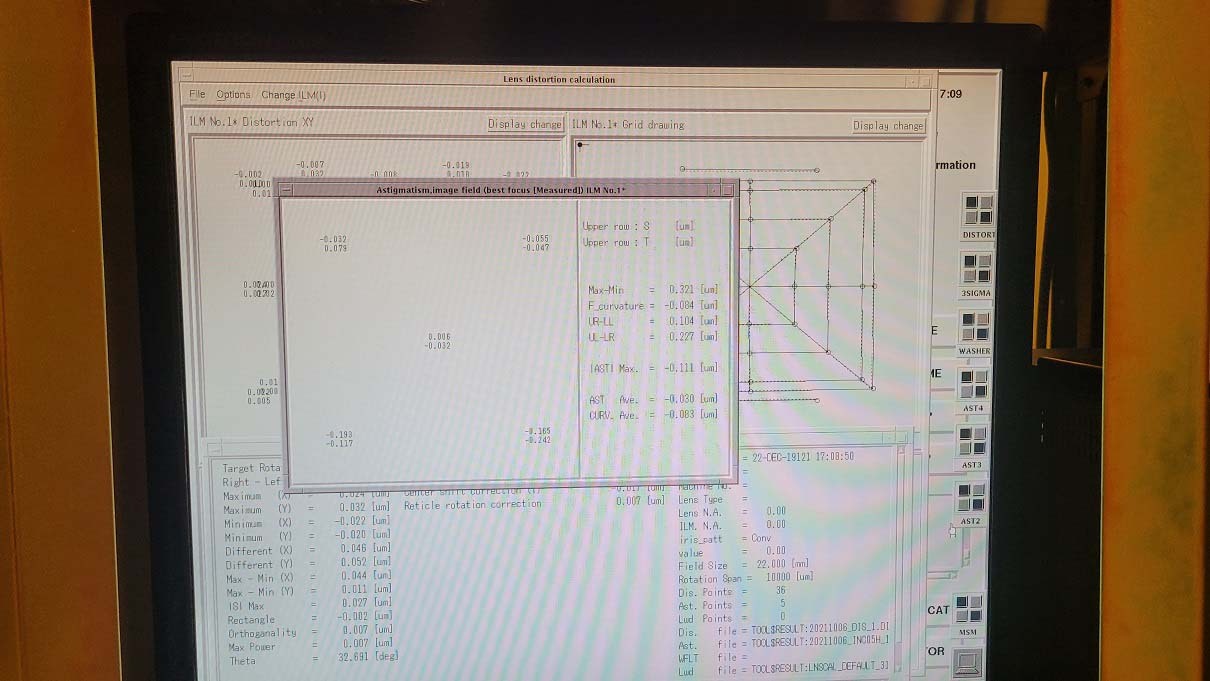

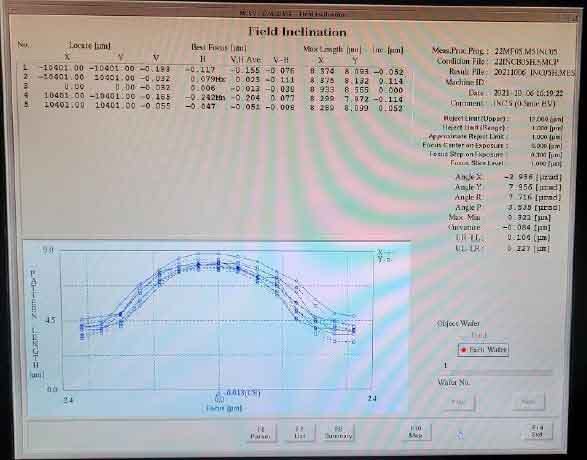

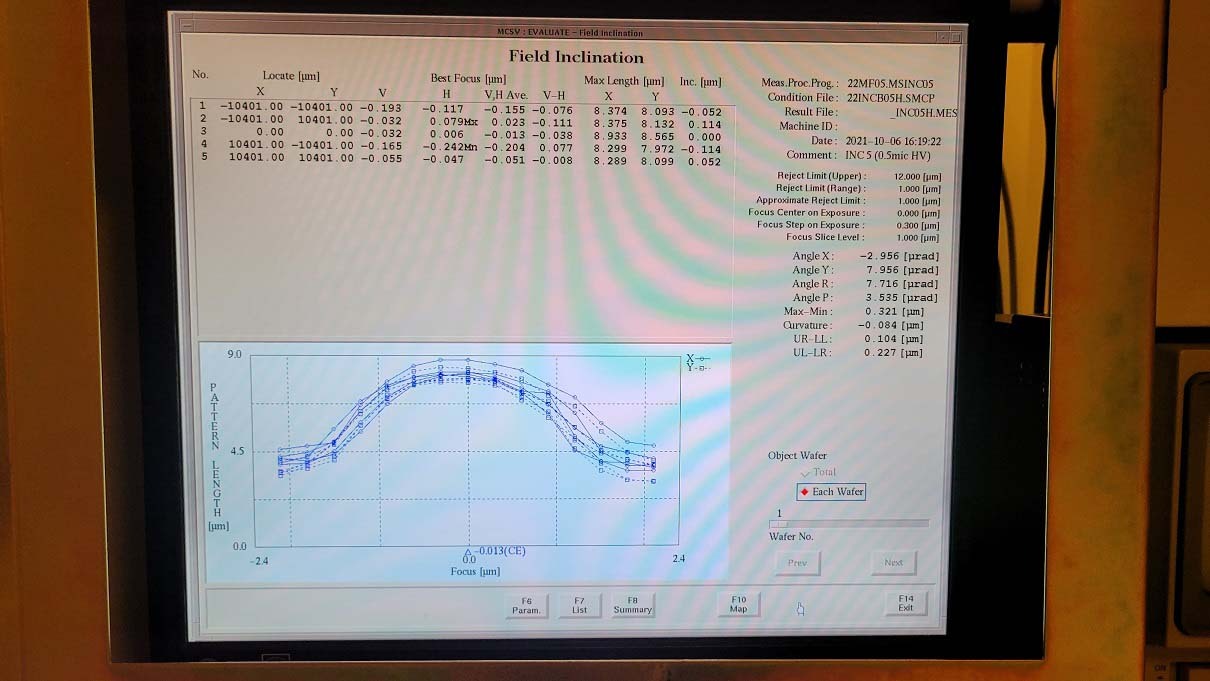

Field inclination: Within 0.35 μm

Leveling setting accuracy: Within ±1.5 sec

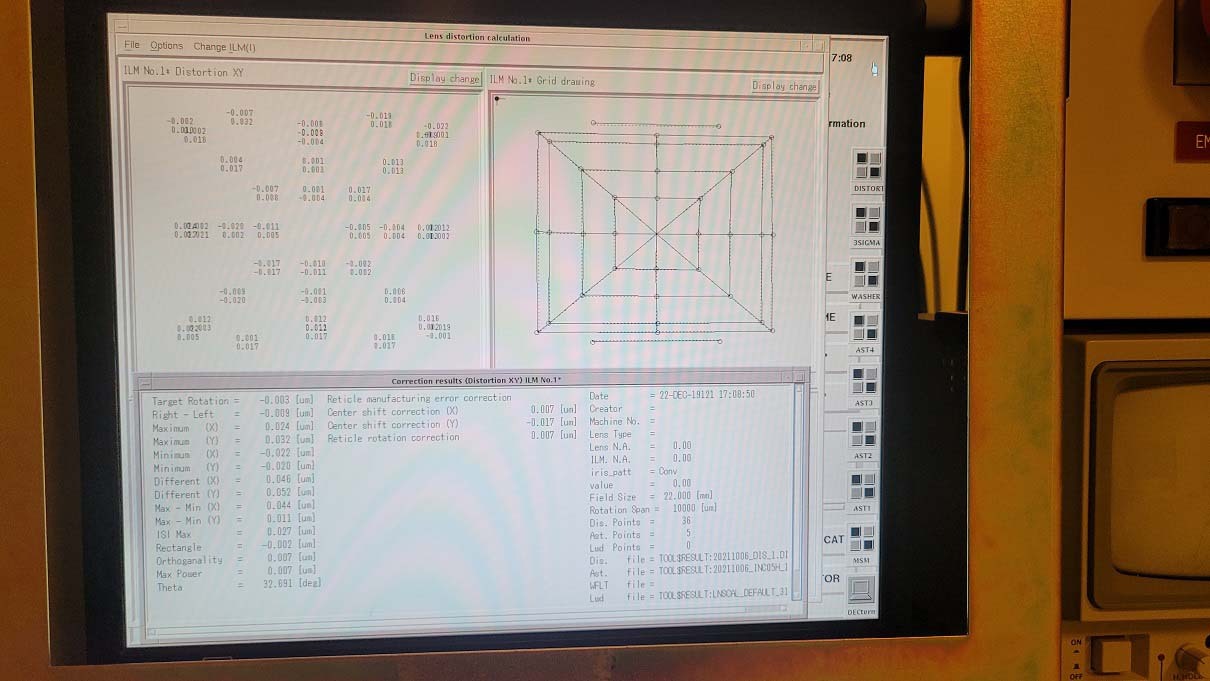

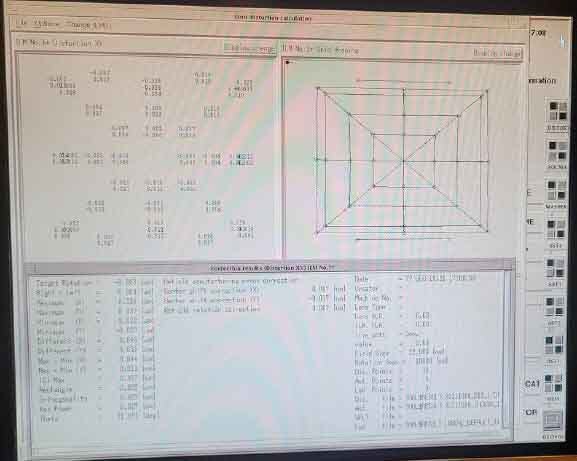

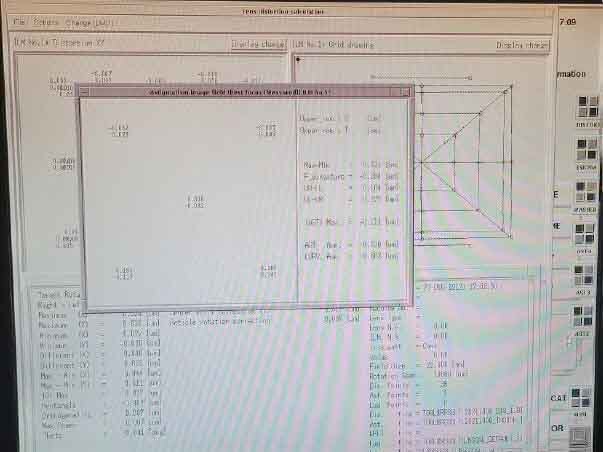

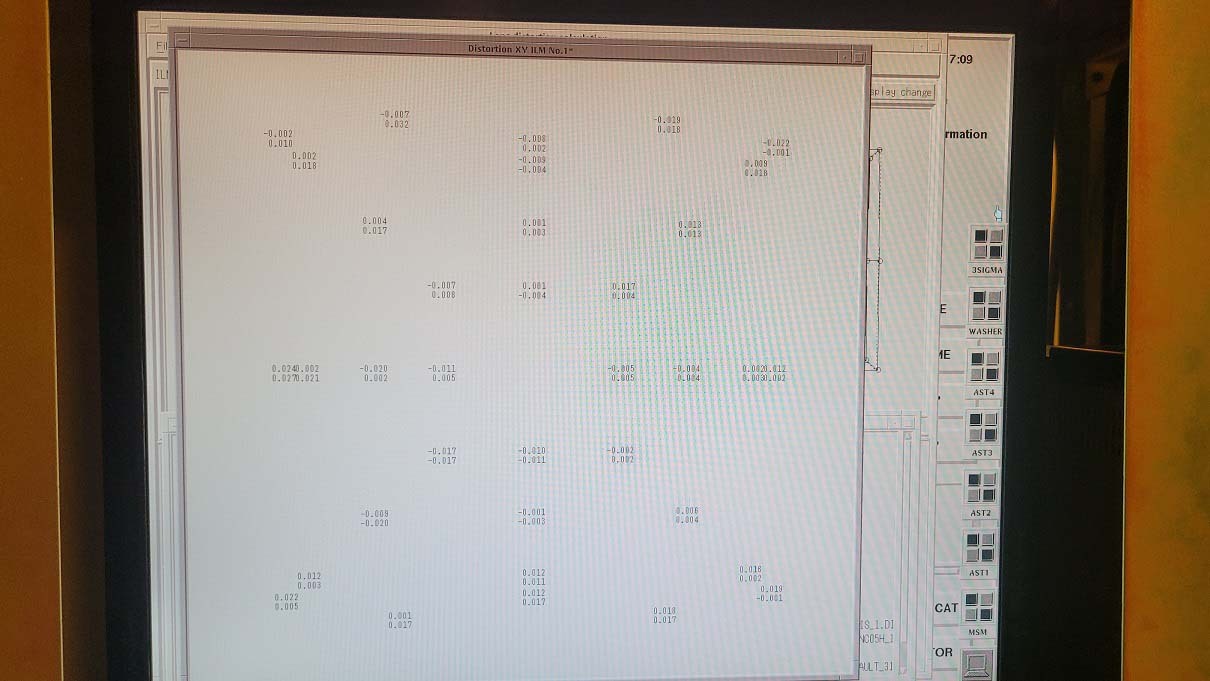

Lens distortion: ≤±0.50 µm

Reticle blind setting accuracy: 0. 4mm - 0.8mm

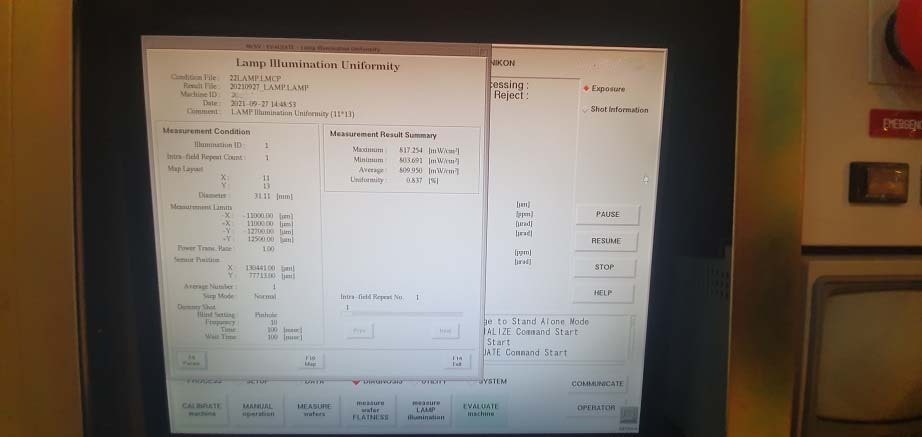

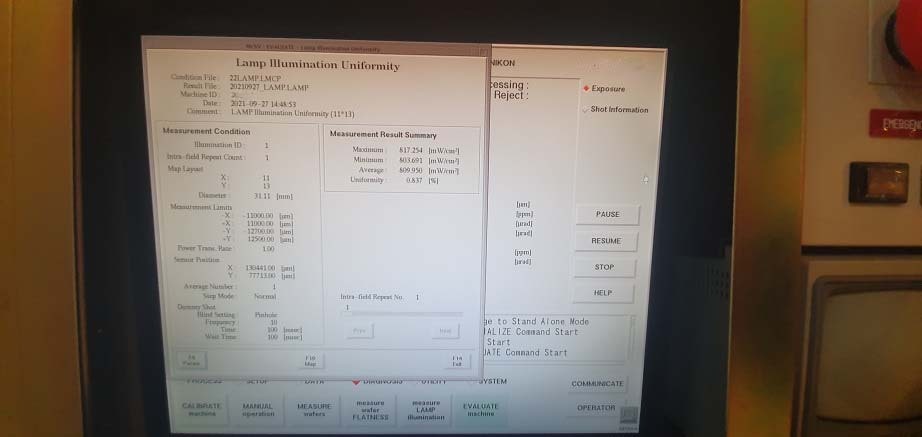

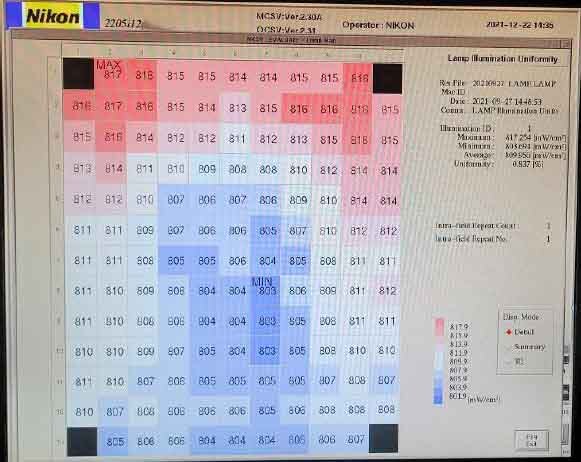

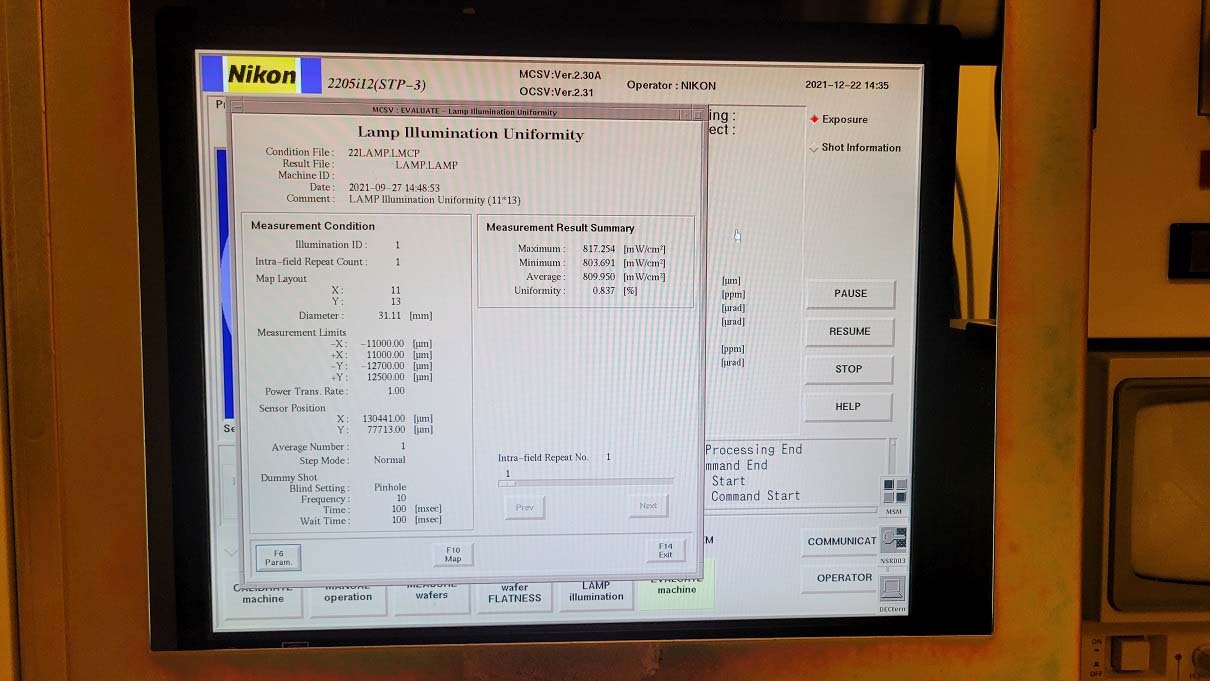

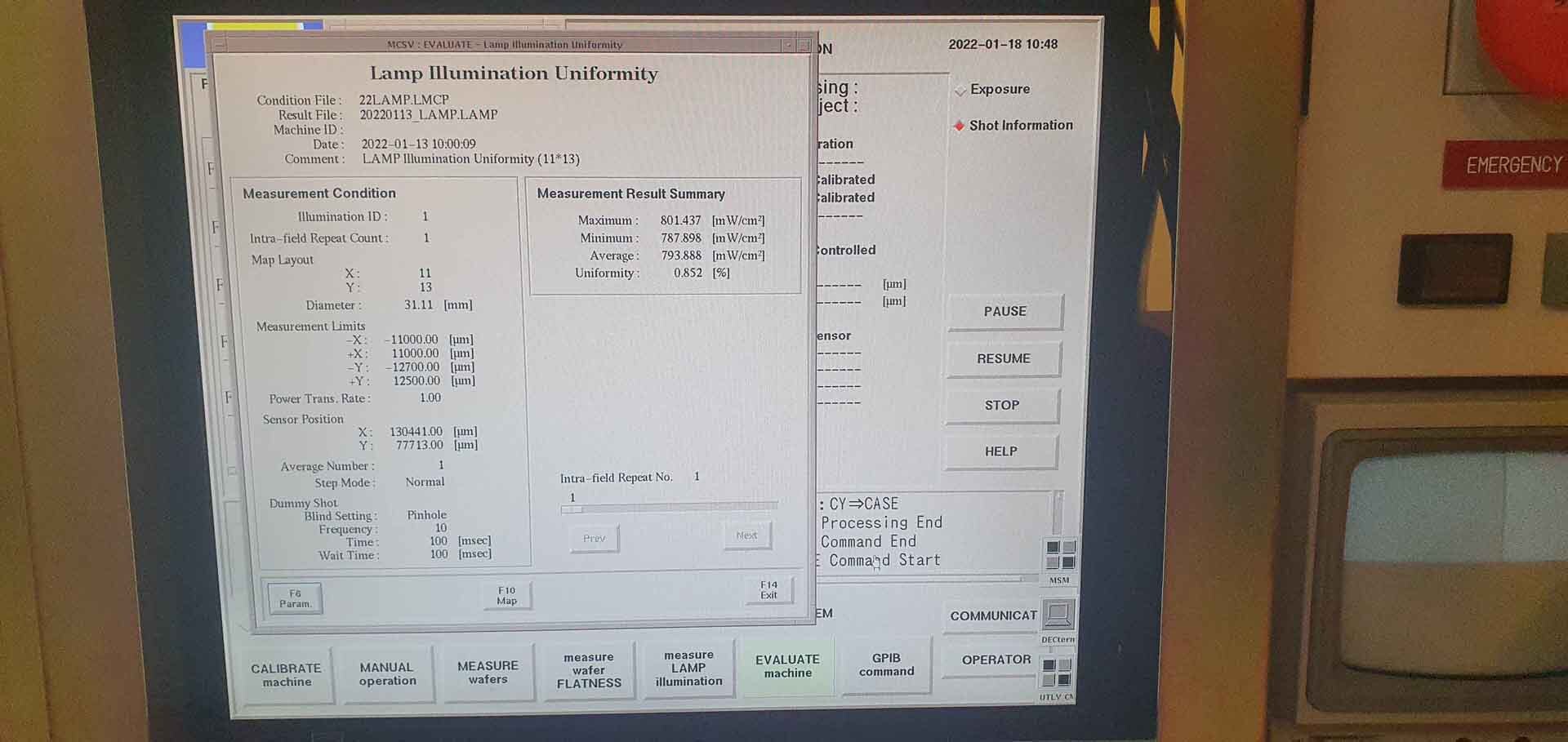

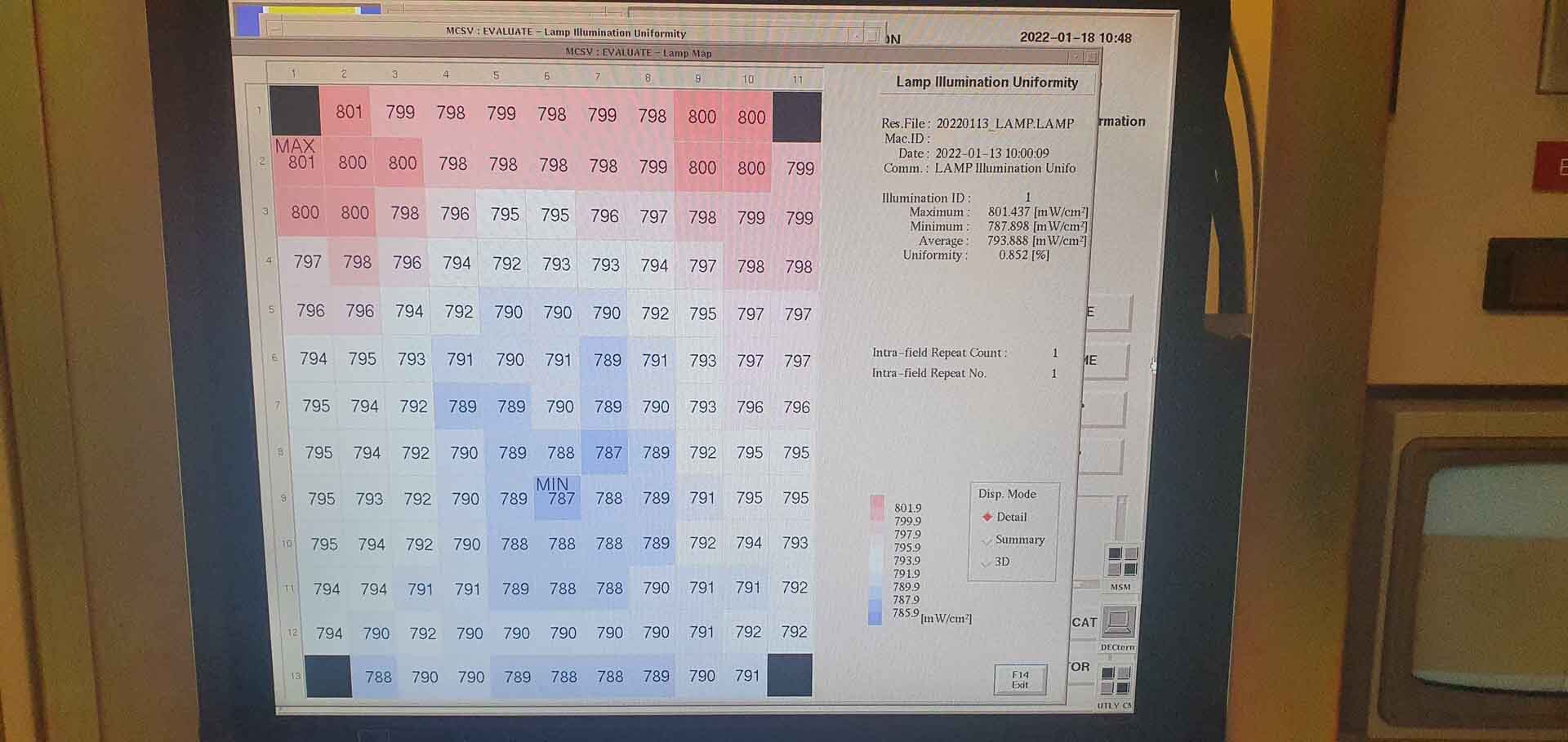

Exposure power: ≥700 mW/cm²

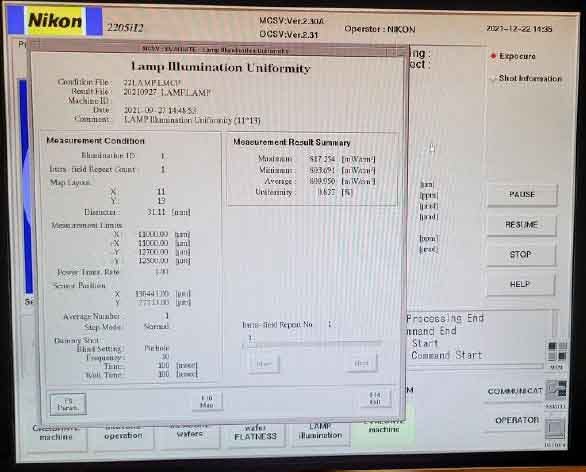

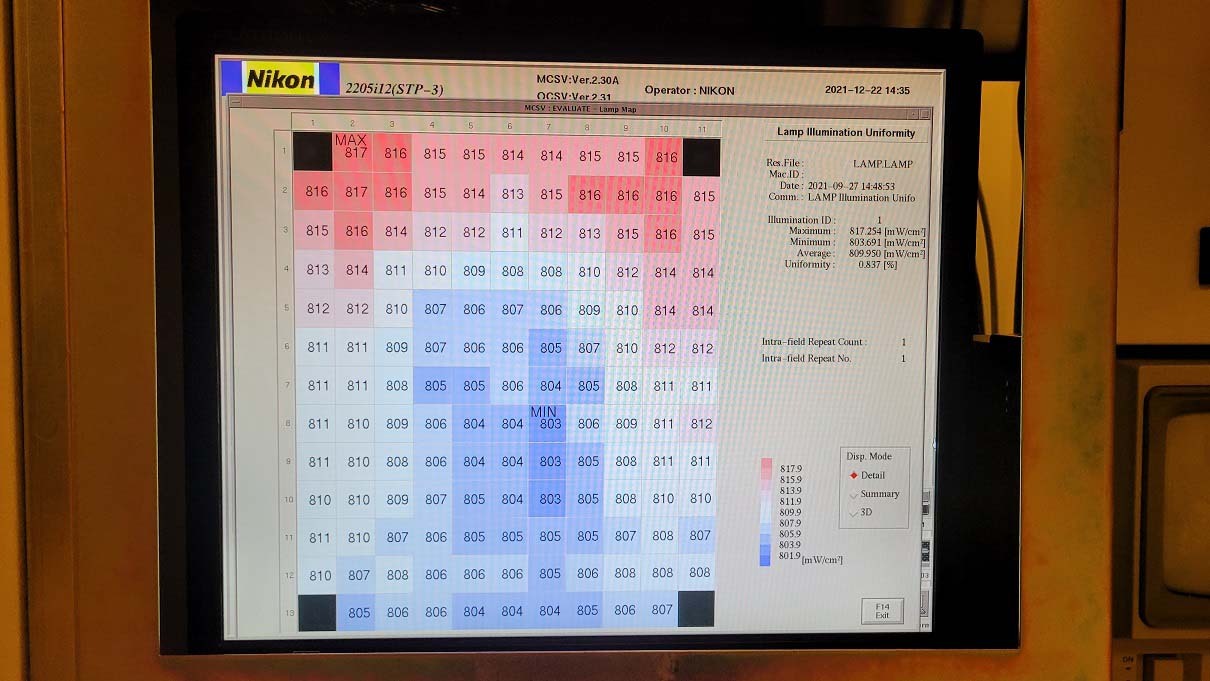

Illumination uniformity: ≤±1.5%

Integrated exposure dose control: ≤±1.0%

Array orthogonality: Within ±0.1 sec

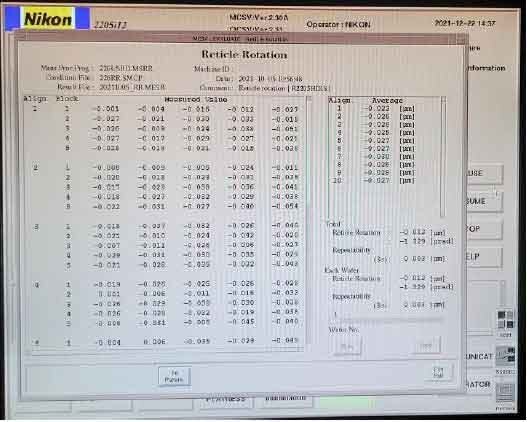

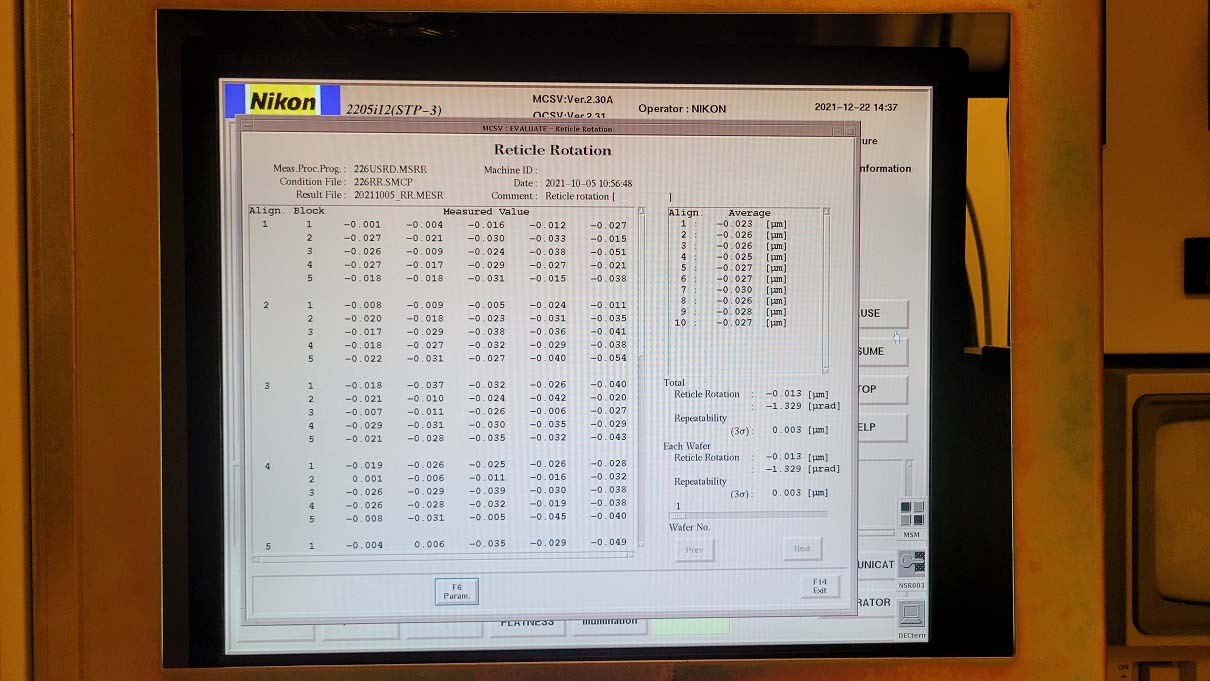

Reticle rotation: |M|+3σ ≤20 nm

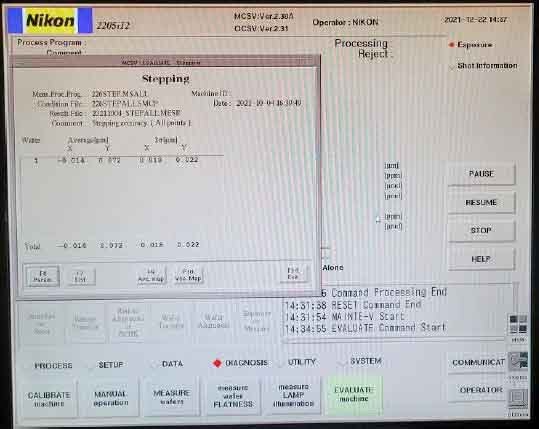

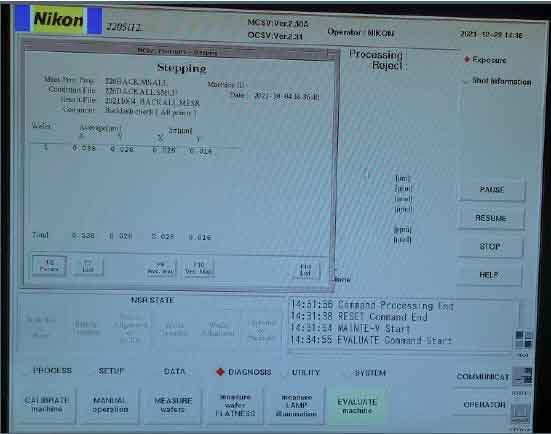

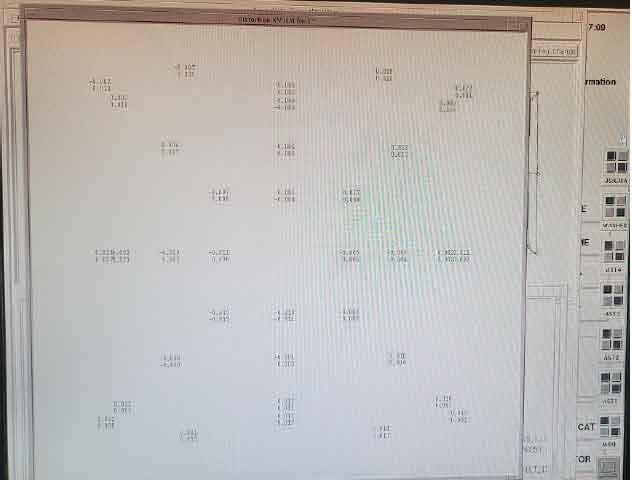

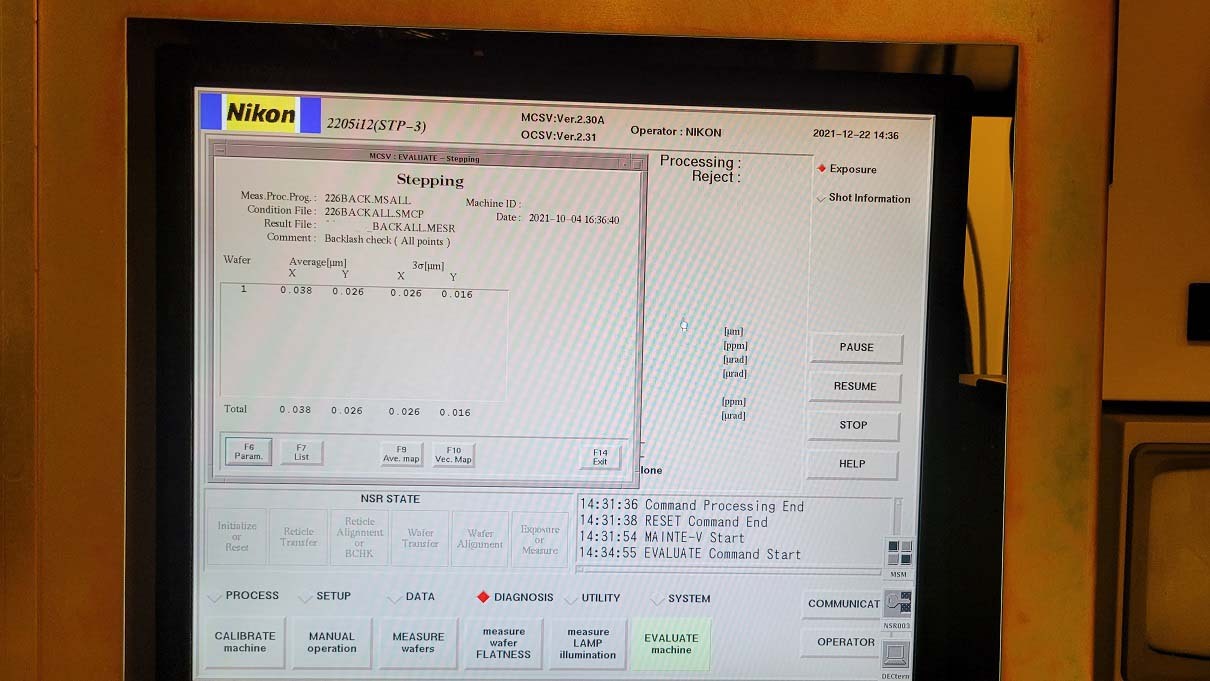

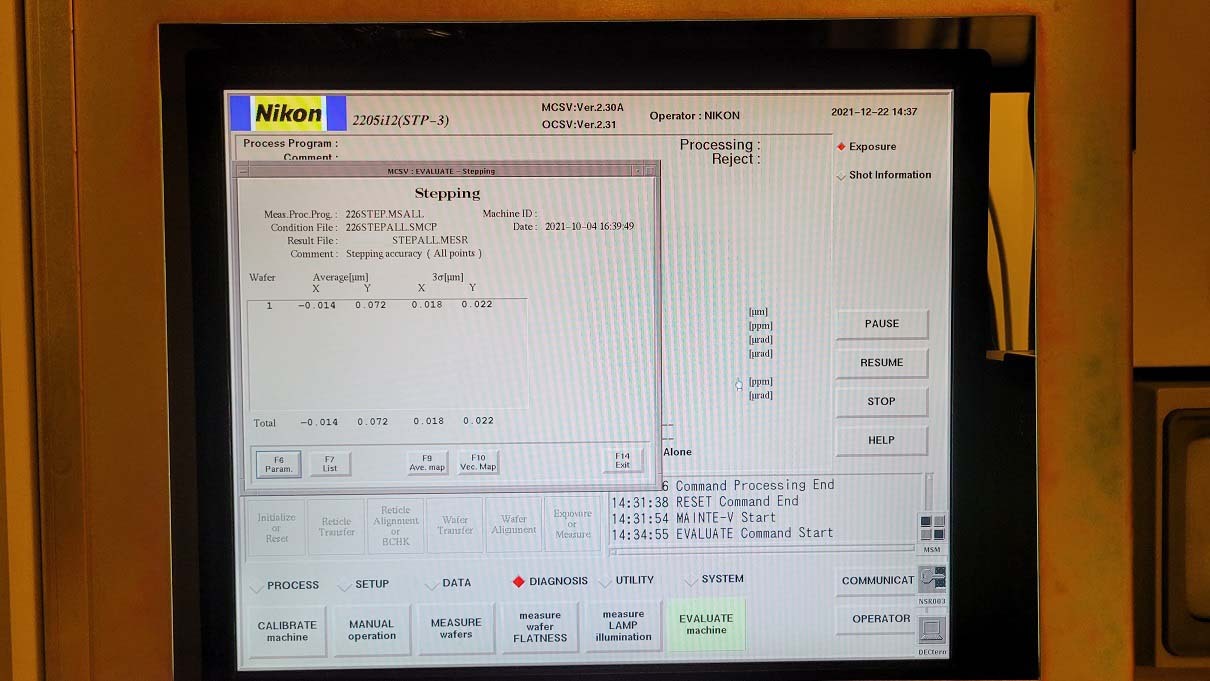

Stepping accuracy: 3σ ≤45 nm

No wafer edge exposure

No signal tower

No PPD

No reticle barcode reader

No extend R-library

No In-line

Overlay:

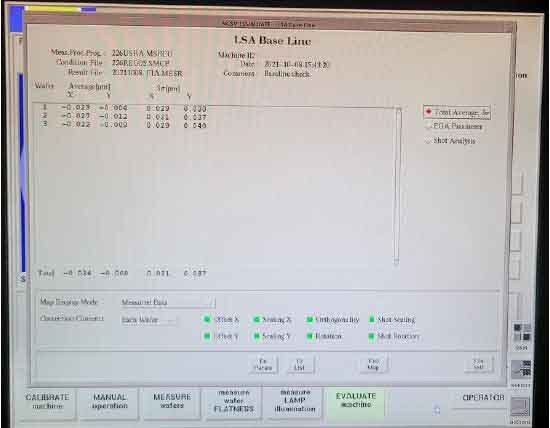

LSA: |M|+3σ ≤75 nm

FIA: |M|+3σ ≤75 nm

Accuracy: ±55 nm

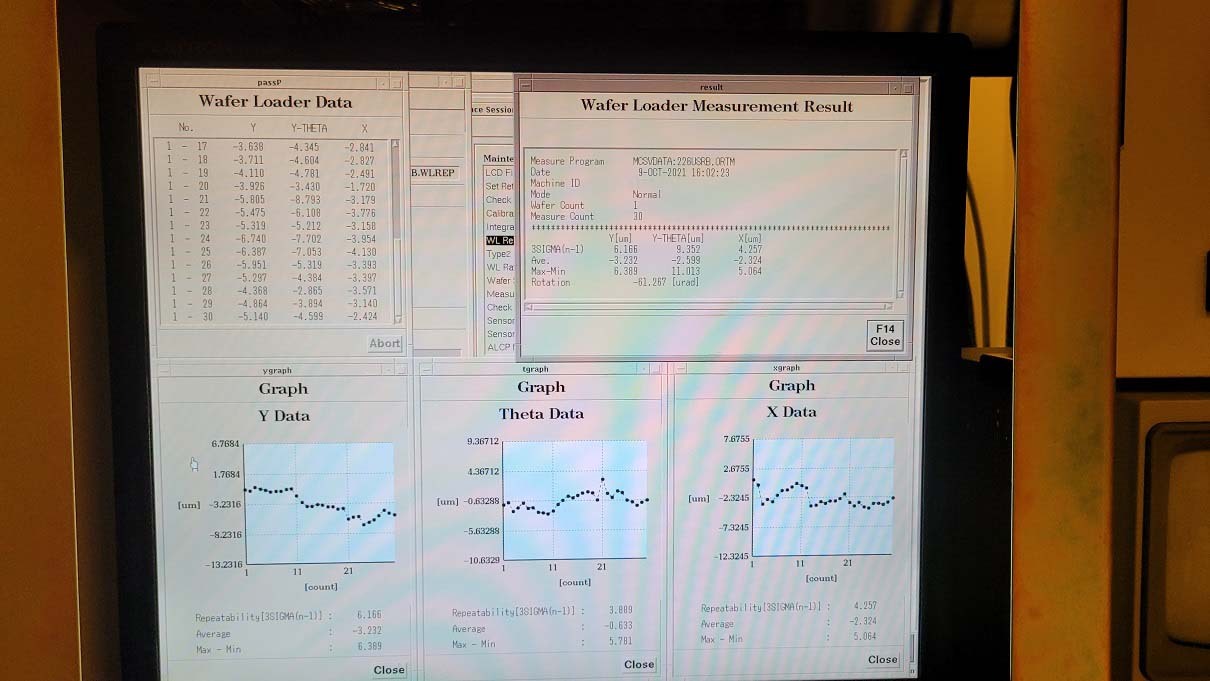

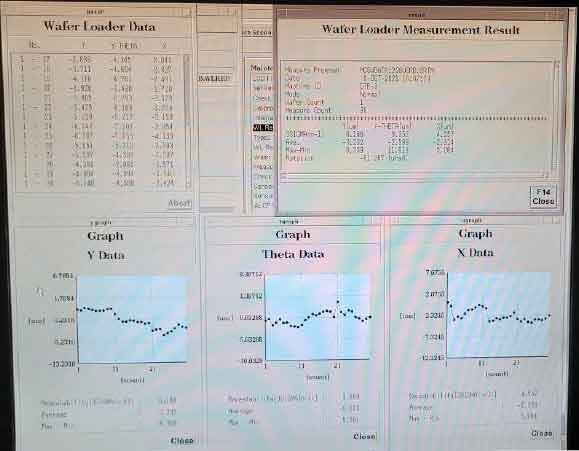

Wafer pre-alignment repeatability:

X, Y, θ: 3σ ≤ 15 μm

Y-θ: 3σ ≤ 20 μm

Resolution: 0.45 μm

Magnification: 5:1

Depth of focus: 2.00 μm

Exposure wavelength: 365 nm

1997 vintage.

NIKON NSR 2205 i12C is a wafer stepper providing sub-micron patterning accuracy and fast exposure times. It has a maximum exposure field size of 12 inches (305 mm) and a maximum wafer diameter of 8 inches (200 mm). Its optics have a numerical aperture (NA) of 0.63, enabling resolution up to 0.2 μm. The advanced UV light source, equipped with an iris shutter, offers user-selectable exposure energy with an accuracy of ± 0.5 % in 0.5 mJ increments up to 13 mJ/cm². NIKON NSR-2205I12C is designed to support a variety of different user requirements by allowing users to select from a range of process software drivers, including developed and verified conditions for all major resist materials. Process recipes needed for exposure can be managed using an intuitive graphical user interface. Additionally, easy-to-use inspection tools allow users to inspect and monitor both stitched and area exposures with off-axis integrated height, width, iso-or-resist measurements automated by the equipment (MAPS). Its wafer stage system offers highly accurate multi-field stitching and reduced stage vibrations during exposure. Furthermore, its simple design allows for easy consumables access, making maintenance and changing of components a breeze. This unit also features an automated wafer alignment machine for high throughput. Overall, NSR 2205 i12C wafer stepper is an advanced stepper that allows users to easily and quickly achieve sub-micron patterning accuracy. It offers a high-performance and intuitive way to manage process recipes, easy maintenance and an automated wafer alignment tool. Other features such as the advanced UV light source and the iris shutter enhancer make this asset suited for the most demanding lithography applications.

There are no reviews yet