Used NIKON NSR 2205 i14E #9223212 for sale

URL successfully copied!

Tap to zoom

ID: 9223212

Wafer Size: 8"

i-Line stepper, 8"

Main system:

Main body

Operation rack

Control rack

Non-SMIF system

PC: DMCC

Display: LCD Monitor

Halogen lamp: SE-025720-N1

PCB Boards:

Interferometer VME unit

LC Unit

ALG Unit

OPD Unit

STG Unit

S/G Unit

RL Unit

WL Unit

LSA Laser head: 3225H-PCN

Interferometer laser head: 5517C

Reticle indexer: Indexer R150

IU Power: 439 mW/cm³

Uniformity: 4.67%

TTL-FC2: 19 nm

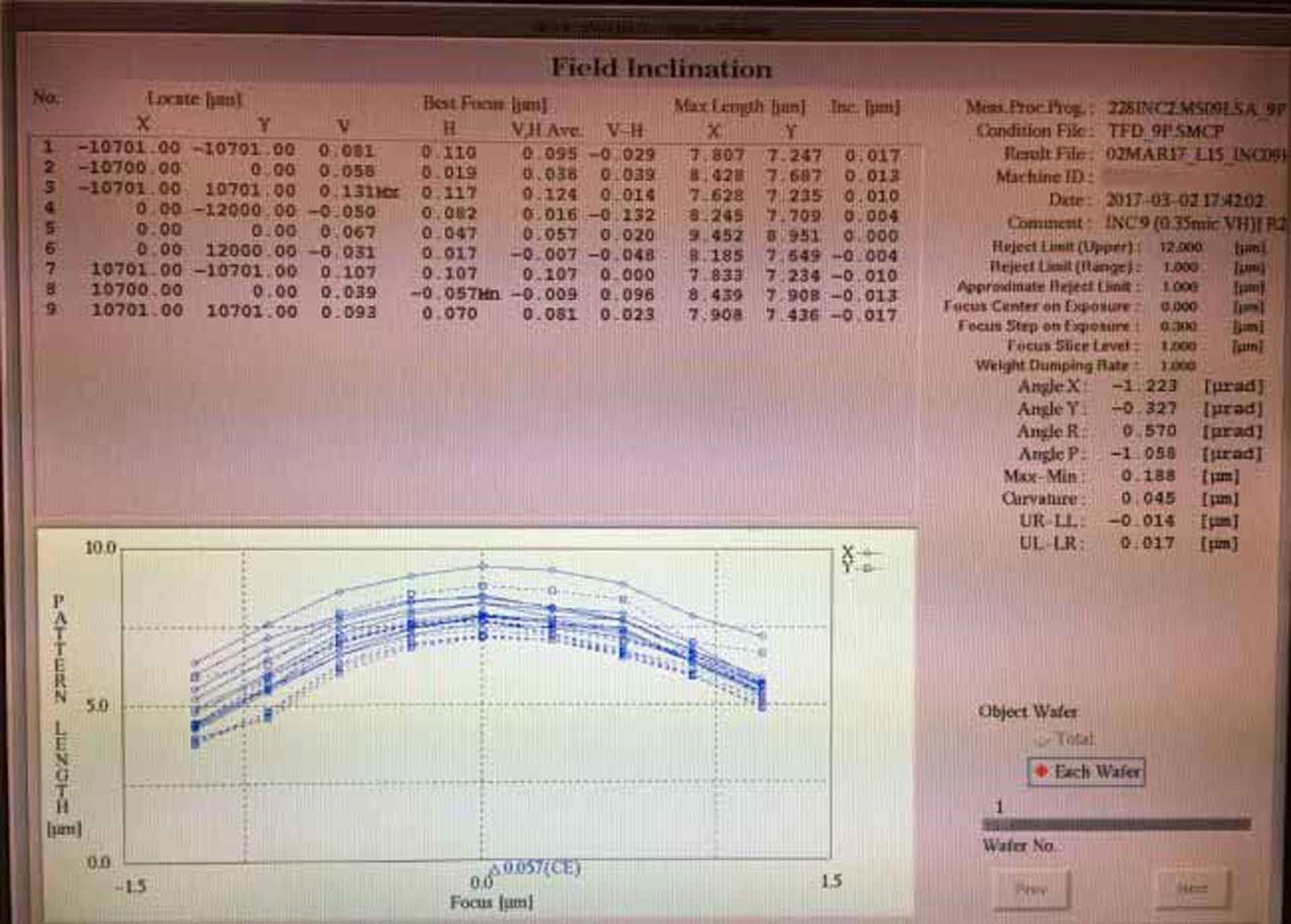

Focus: 51 nm

TFD: 188 nm

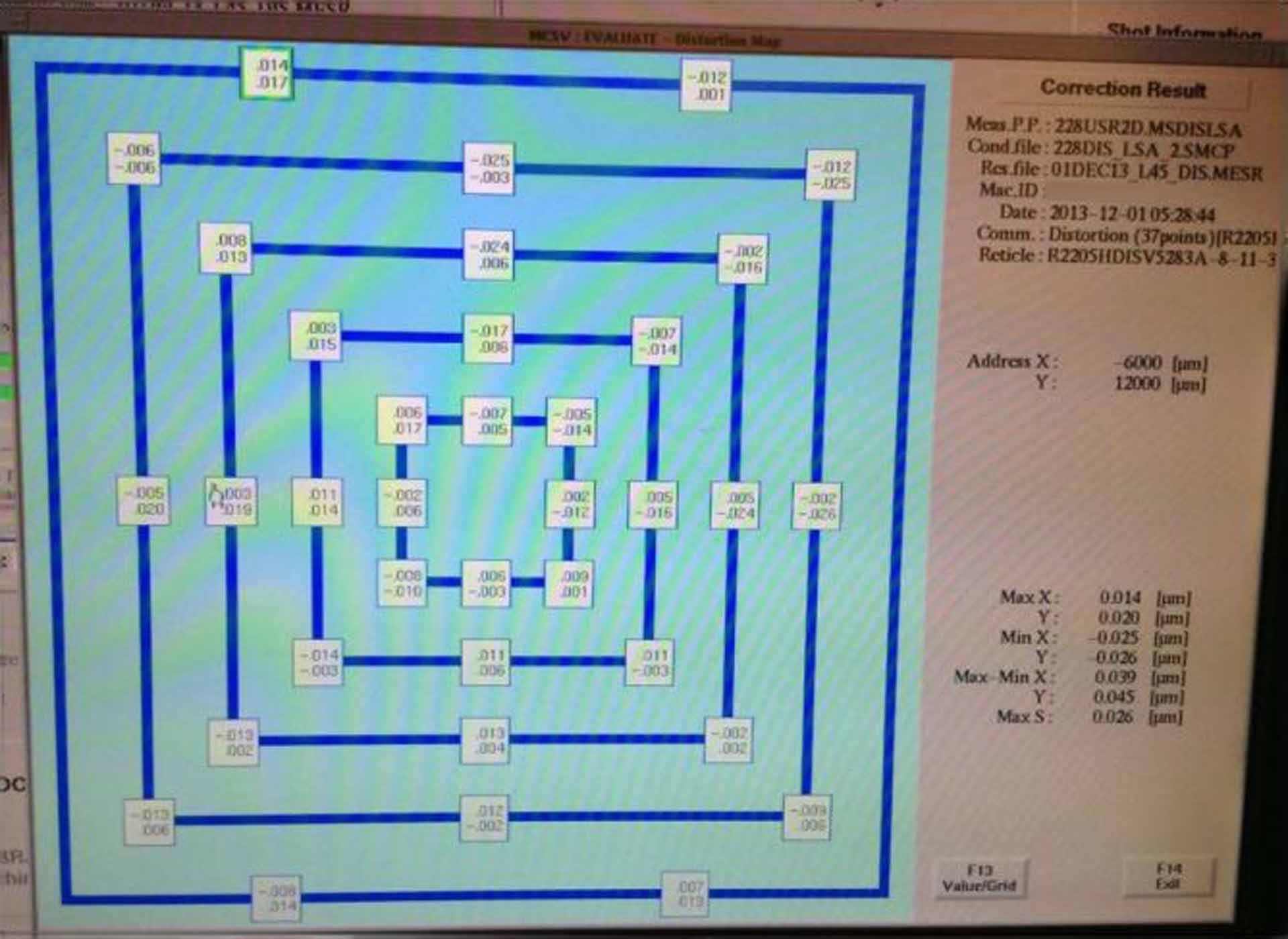

Distortion maximum (X/Y): 14 / 20 nm

Distortion minimum (X/Y): -25 / -26 nm

Wafer flatness: 0.8 um

Local flatness: 0.3 um

LSA Translation:

X: -8 nm

Y: 5 nm

LSA 3sigma:

X: 55 nm

Y: 58 nm

FIA Translation:

X: -10 nm

Y: 1 nm

FIA 3sigma:

X: 55 nm

Y: 56 nm

Shot magnification: 0.39 ppm

Shot rotation: -0.376 urad

CIM Linked.

NIKON NSR 2205 i14E is a high-precision wafer stepper designed for production of photomasks. Photomasks are used in the manufacture of integrated circuits and contain graphic elements that need precise positioning and alignment. This stepper is equipped with two independent optical lenses and a digital camera that enables high-precision imaging of individual wafer fields. NIKON NSR-2205I14E provides 14 inches of wafer scanning area. Its dual lithography options make it capable of handling alternating wavelengths ranging from 365 nm to 248 nm. Its two imported SEM LF ISI aspheres deliver uniform resolution and depth of focus. High-speed image capturing allows high-precision imaging of the entire wafer field and minimizes pattern alignment errors with its new computer-aided algorithm. The stepper's integrated glass and debris removal system prevents device deterioration and contamination. This ensures accurate device formation and prevents costly wafer reprocessing. The stepper also includes specially designed features that reduce the height difference of the field by as much as 1 µm, ensuring uniform focus over the entire stepper field. NSR 2205 i14E is designed to maximize yields while minimizing costs. Its flexible correction and overlay functions make it easy to adjust parts to corresponding component systems. It's durable and reliable design, coupled with long-term maintenance capabilities, allow this stepper to operate up to 444 hours without significant service or maintenance. Designed and manufactured with the latest industry standards, NSR-2205I14E offers unsurpassed levels of wafer fabrication efficiency. It's advanced imaging capabilities, fast image capturing, robust performance, and affordability make it an ideal choice for any semiconductor production facility.

There are no reviews yet