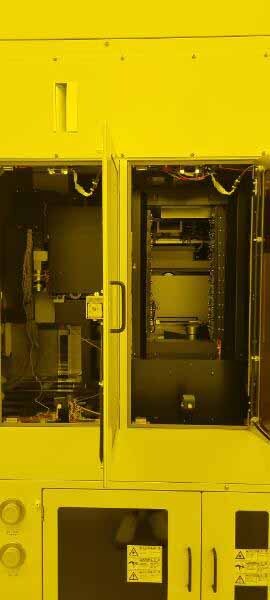

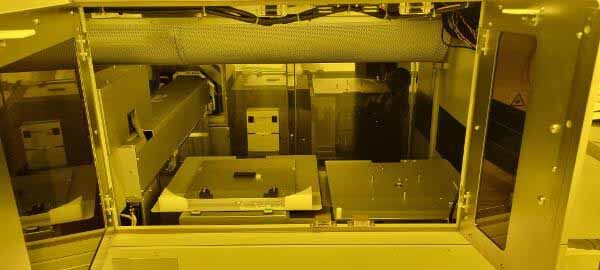

Used NIKON NSR S204B #293627299 for sale

URL successfully copied!

Tap to zoom

ID: 293627299

DUV Scanner

CYMER ELS 6400

Exposure power: 900 mW/cm²

Illumination uniformity: ±2%

Wafer flatness: 3.0 µm

Recticle accuracy: 0.4 - 0.8 mm

Reticle rotation: |x| + 3σ, 0.02 µm

Stepping precision: 3σ, 0.025 µm

Backlash precision: 3σ, 0.025 µm

Distortion: ≤ ±0.025 µm

LSA Overlay: 3δ ≤ 0.045 µm

FIA Overlay: 3δ ≤ 0.045 µm

Inclination: ≤ 0.2 µm

Wafer pre-alignment: ≤ 15 µm.

NIKON NSR S204B is a high-performance, step-and-repeat wafer stepper equipment designed for the production of photomasks, reticles, flat panel displays, and high-resolution inspection substrates. It features one of the most precise resolution of 0.37nm with a maximum pattern size of 12mm x 12mm. The machine is capable of handling multiple reticules simultaneously, making it suitable for production of large volumes of photomasks, reticles, and flat panel displays. NIKON NSR-S204B is equipped with a 3-mirror projection alignment system, optimized scan algorithms, without any image split or overlap, and advanced alignment protection. The precise alignment accuracy achieved with this unit ensures integrity and outstandingly easy alignment with the photomask placement stage. To achieve the utmost throughput and productivity, the S204B speeds up the exposure process and features a high-speed rotation stage for additional wafers in the field area, enabling multiple reticles to be exposed simultaneously. This enables a dramatic increase in efficiency and stability in production. The machine also benefits from a ten-fold internal magnification reduction as well as an extended depth of focus to allow over 0.75 �m of step height without any image loss of detection. In addition, a chromatic aberration correction tool allows coarse and fine adjustments. The S204B also provides advanced edge representation technology, ensuring greater accuracy in the inspection process. The SNR Technology measures edge information and shape distortions, taking into account any non-linearities, and provides more accurate results than that of a traditional step-and-repeat stepper. To protect the operator from errors, the S204B features inbuilt error detection and prevention systems, allowing for proper handling of any unexpected interference or malfunction during production. The asset also features inbuilt intelligent alignment, allowing for accurate resolution and quick positioning. In conclusion, NSR S 204 B is a high performing, multifunctional wafer stepper model designed for the production of photomasks, reticles, flat panel displays, and high-resolution inspection substrates. By offering an advanced mirror alignment equipment, enhanced scanning capabilities, increased speed and heightened inspection accuracy, the S204B is a powerful tool essential to any production process. This system provides the highest level of accuracy and throughput without compromising image integrity.

There are no reviews yet