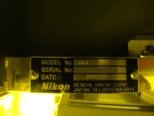

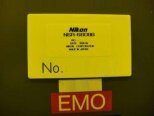

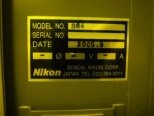

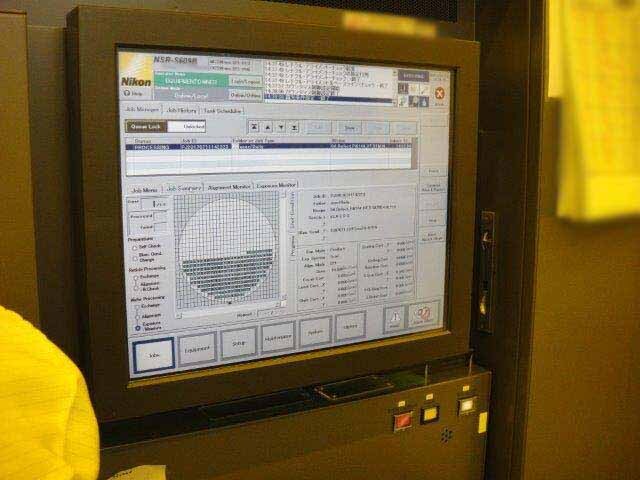

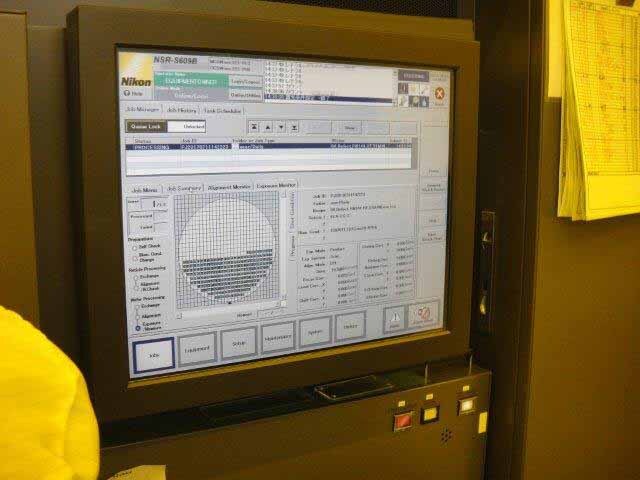

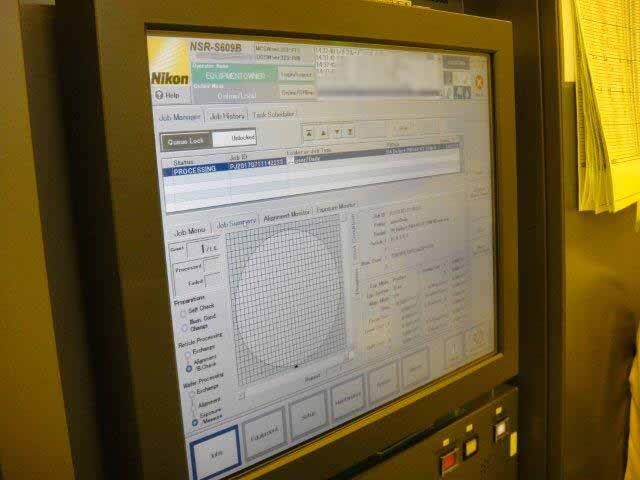

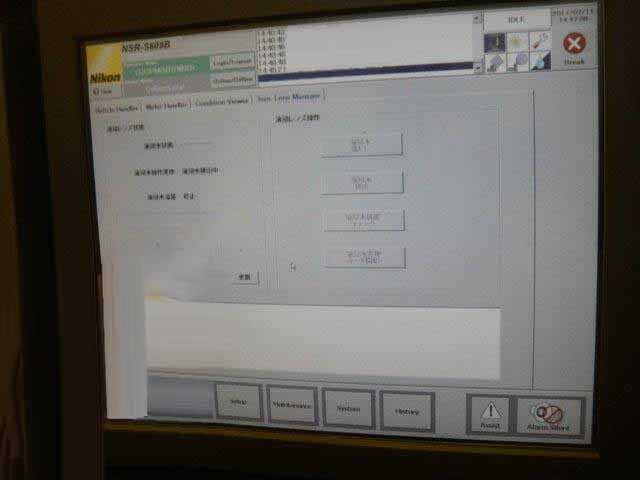

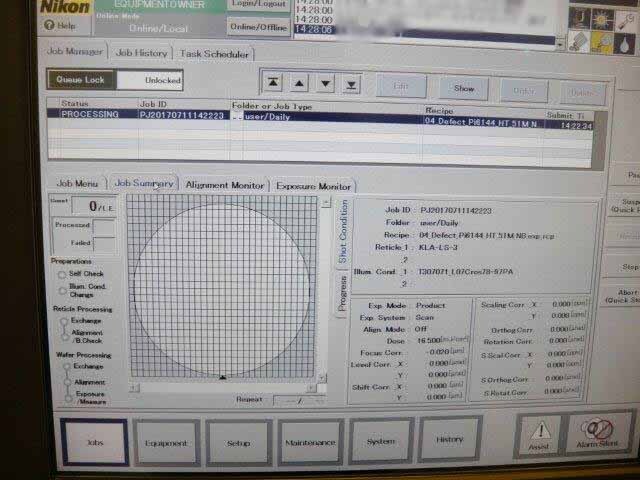

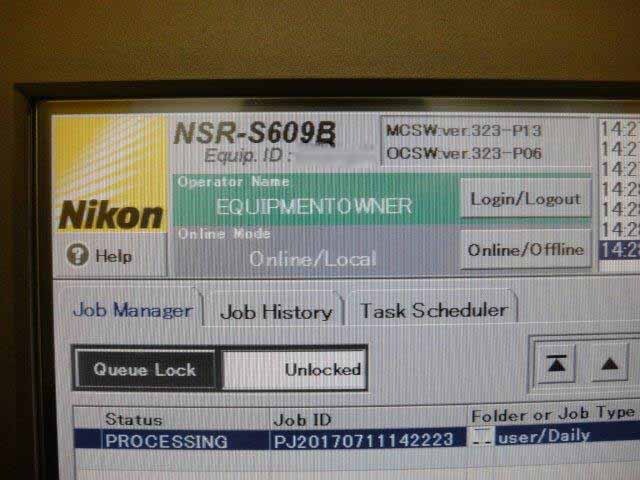

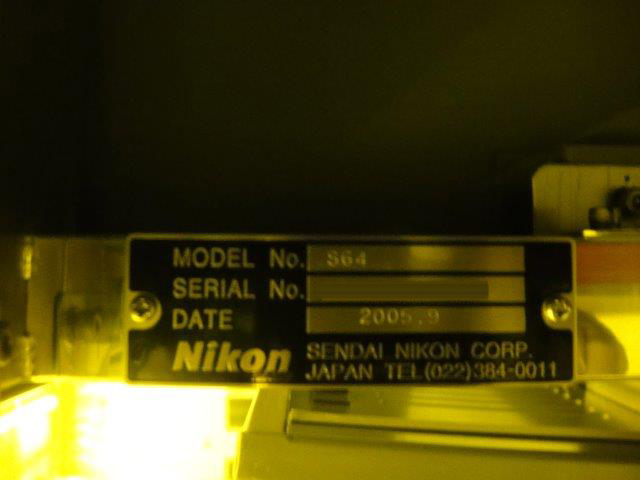

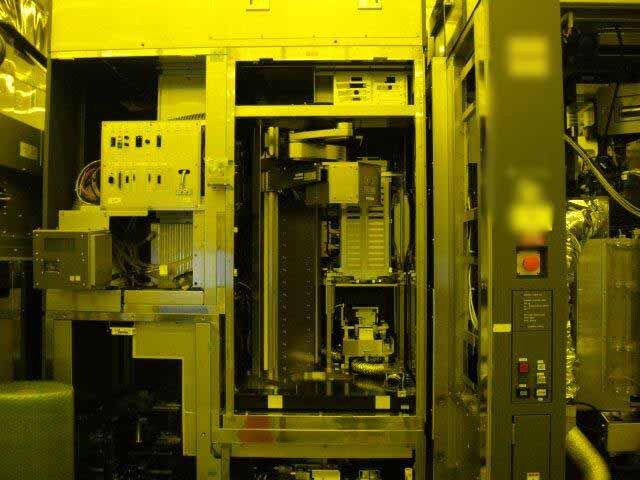

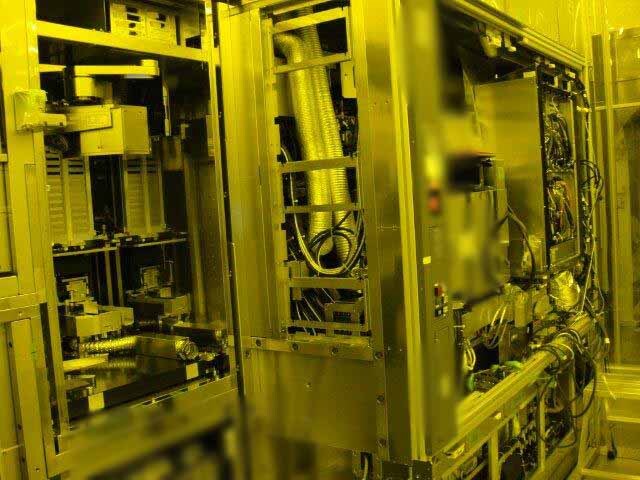

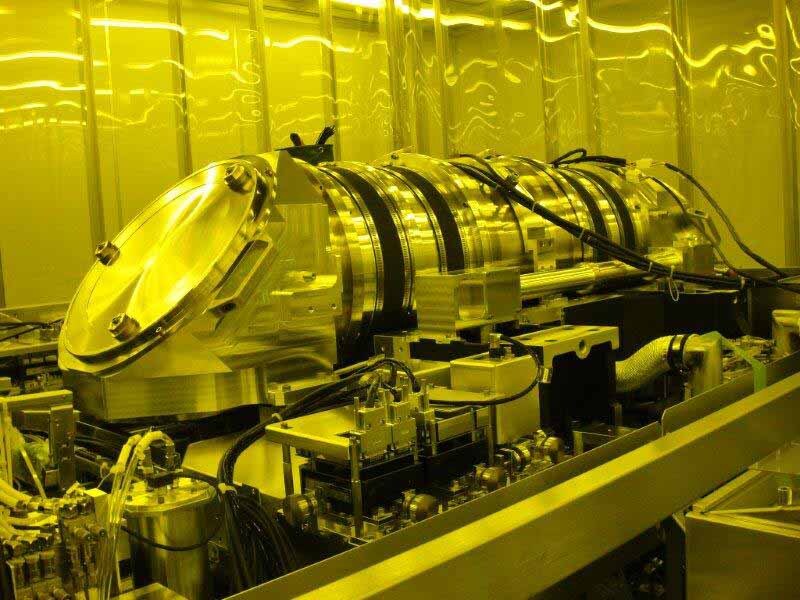

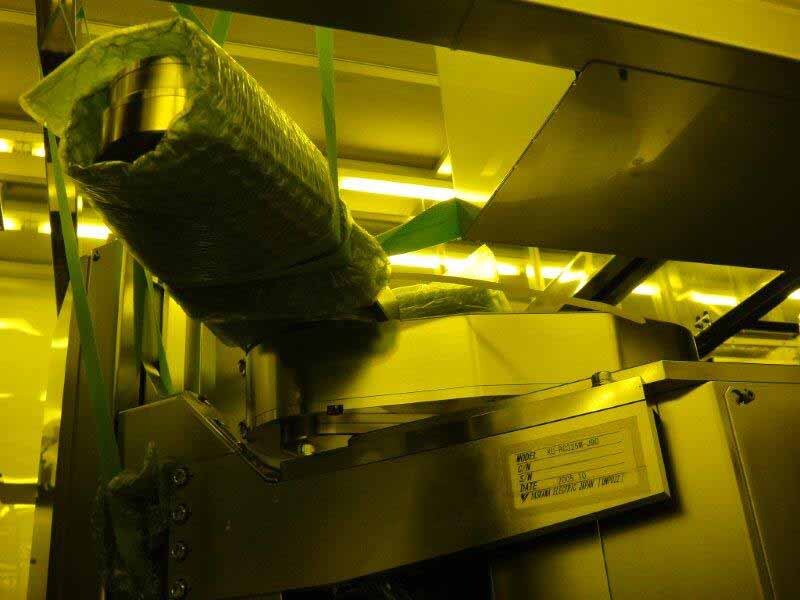

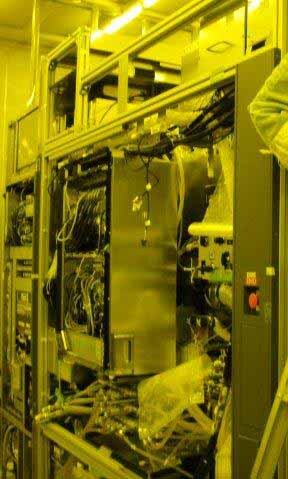

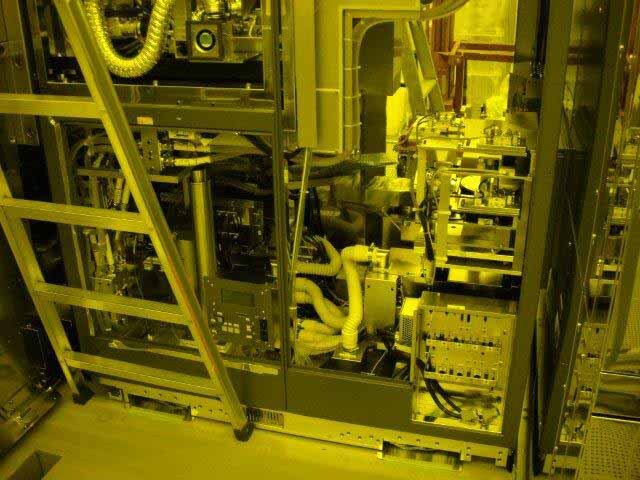

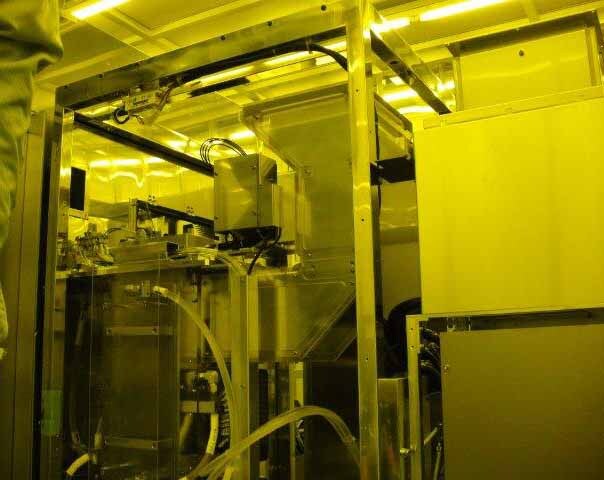

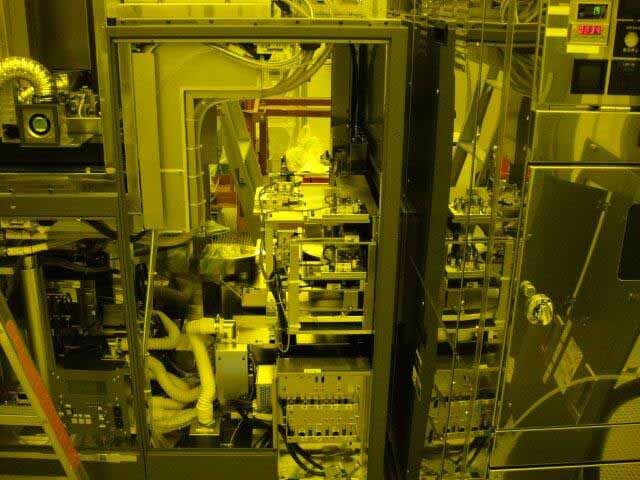

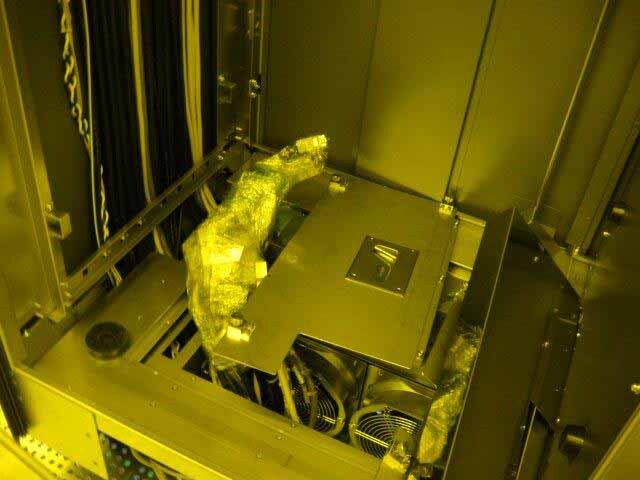

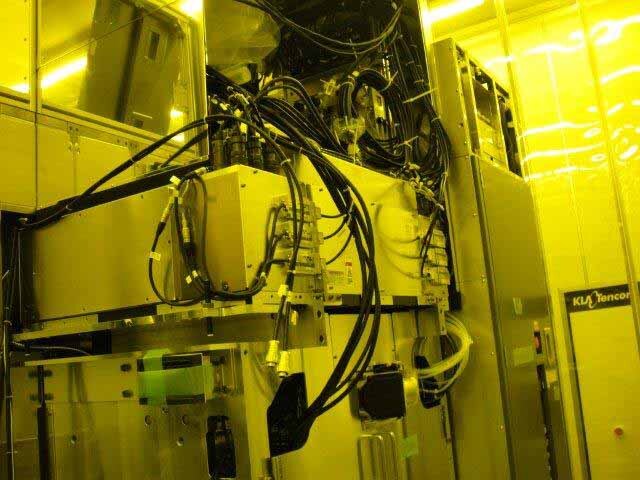

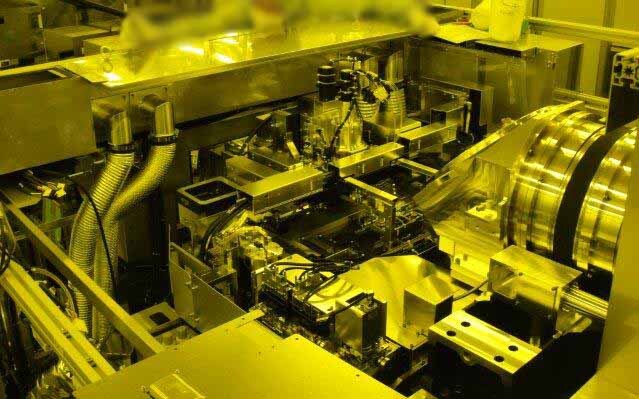

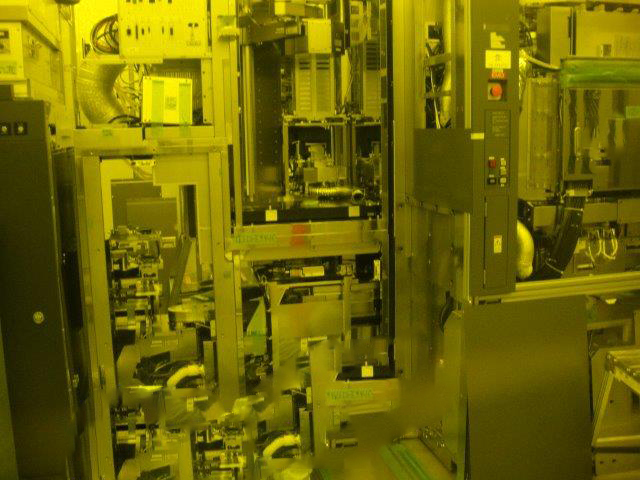

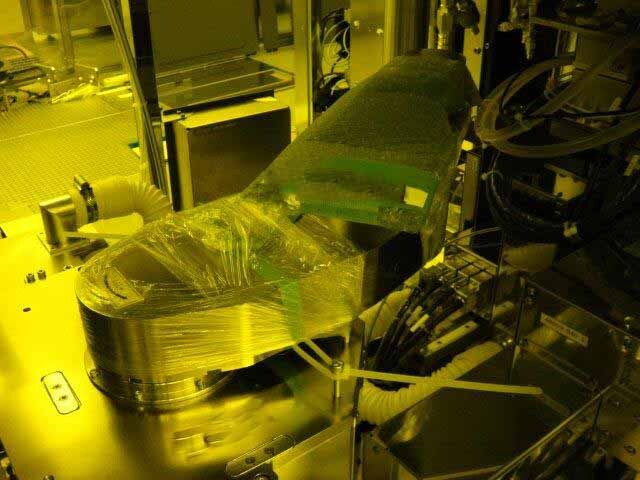

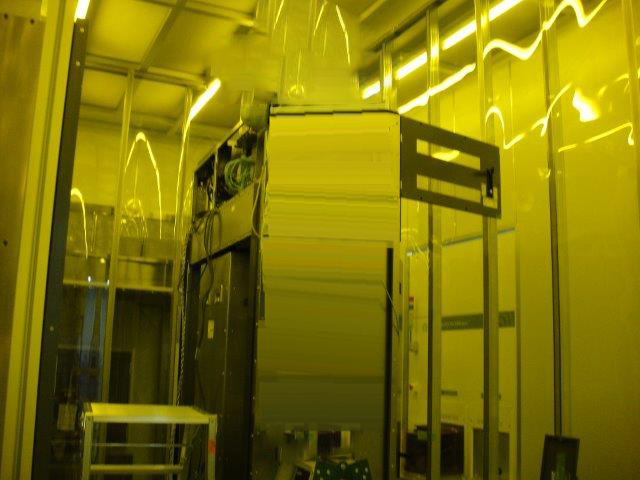

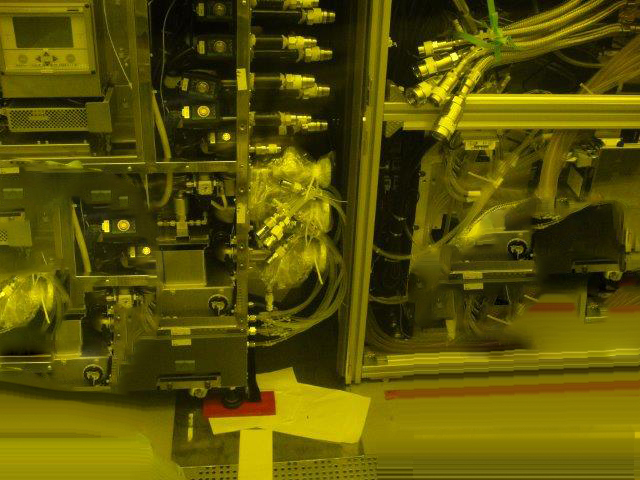

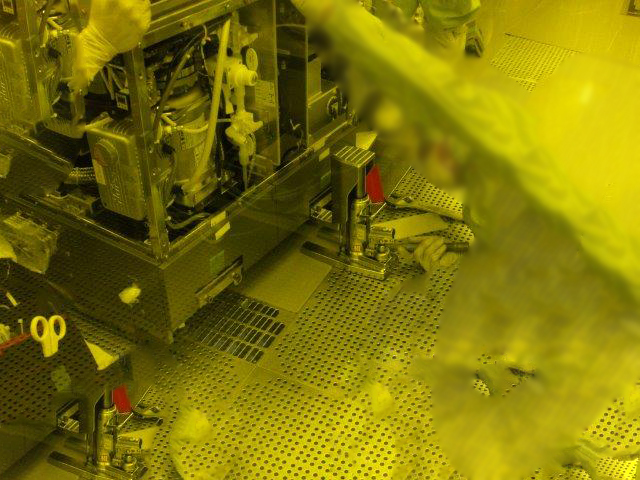

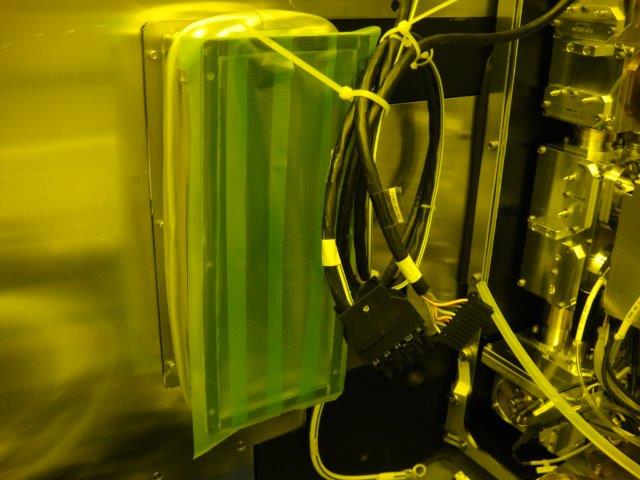

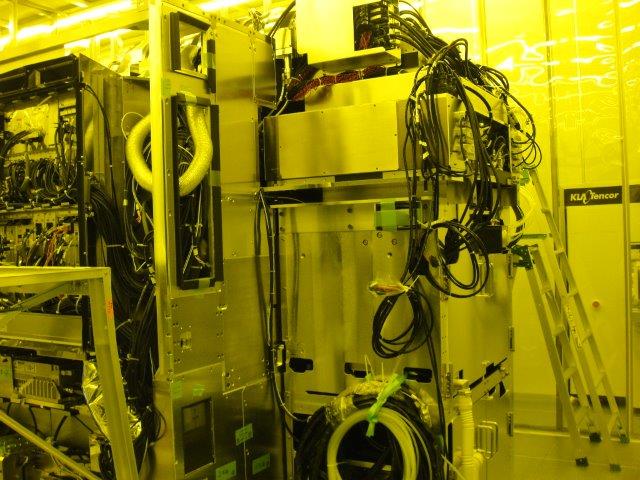

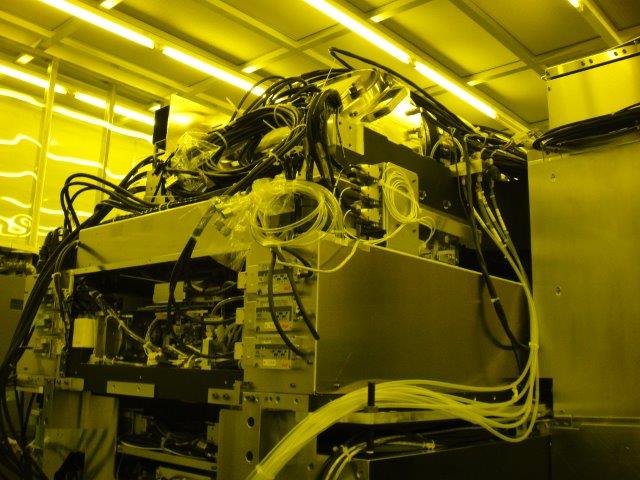

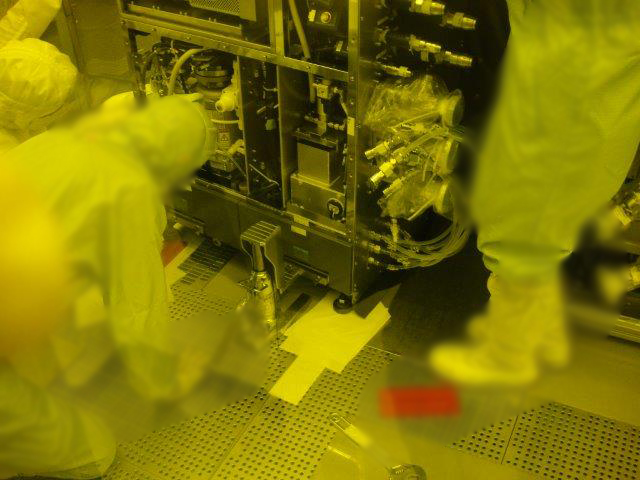

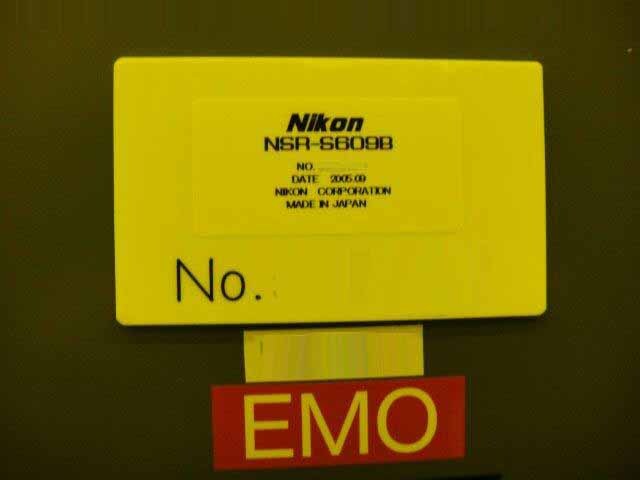

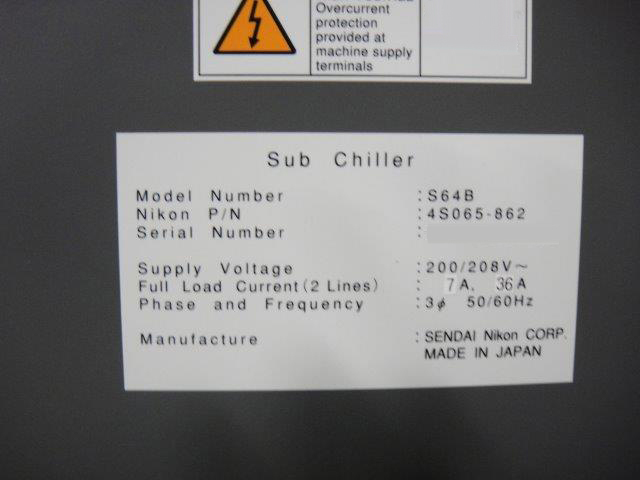

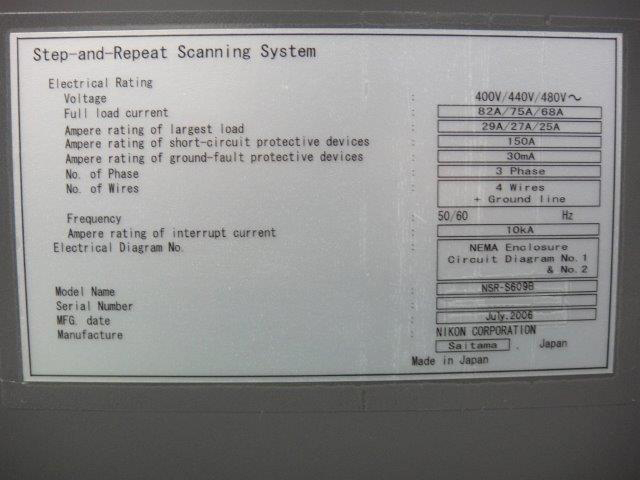

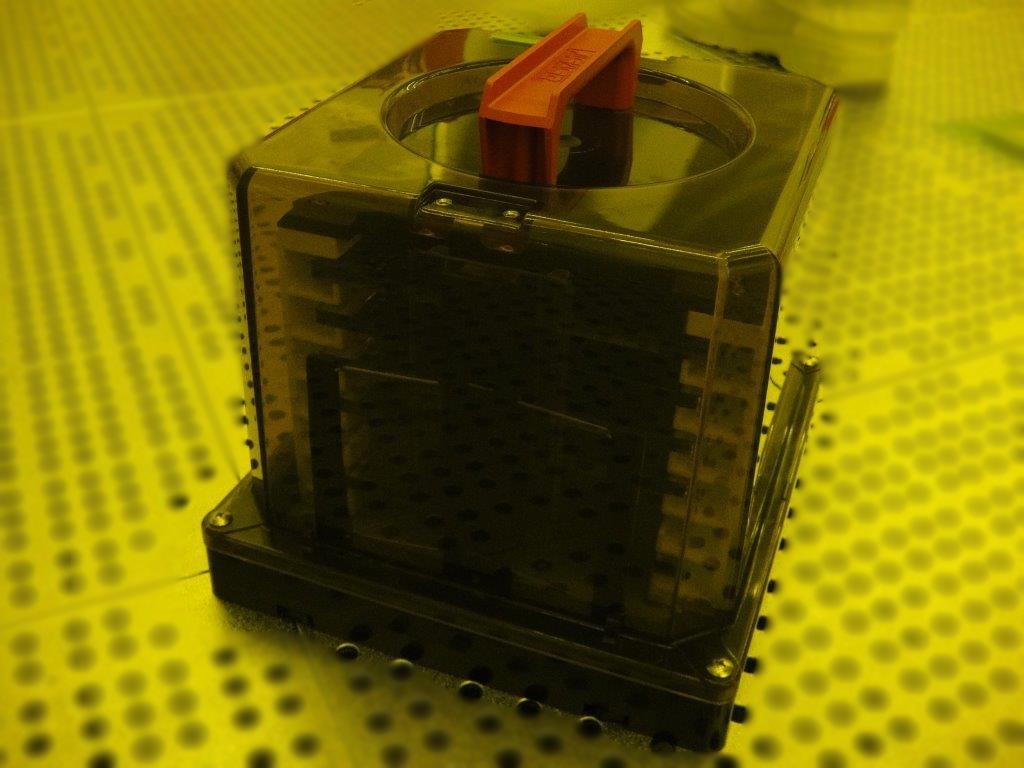

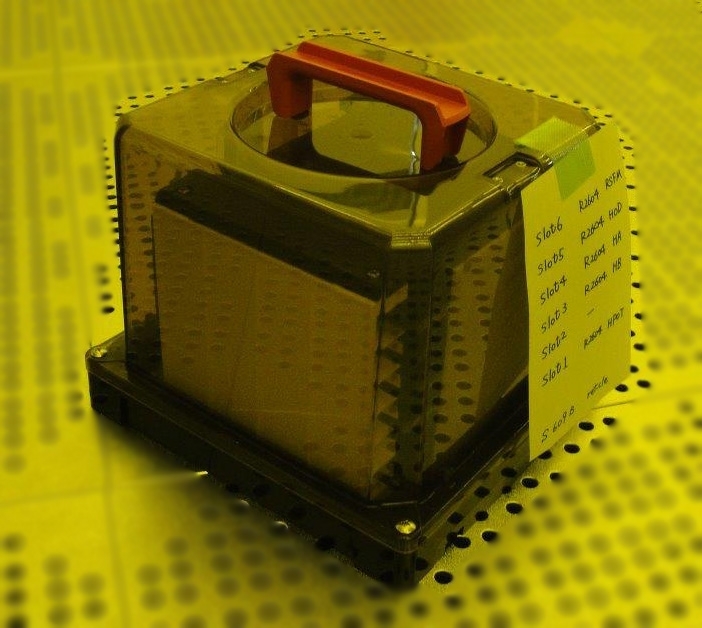

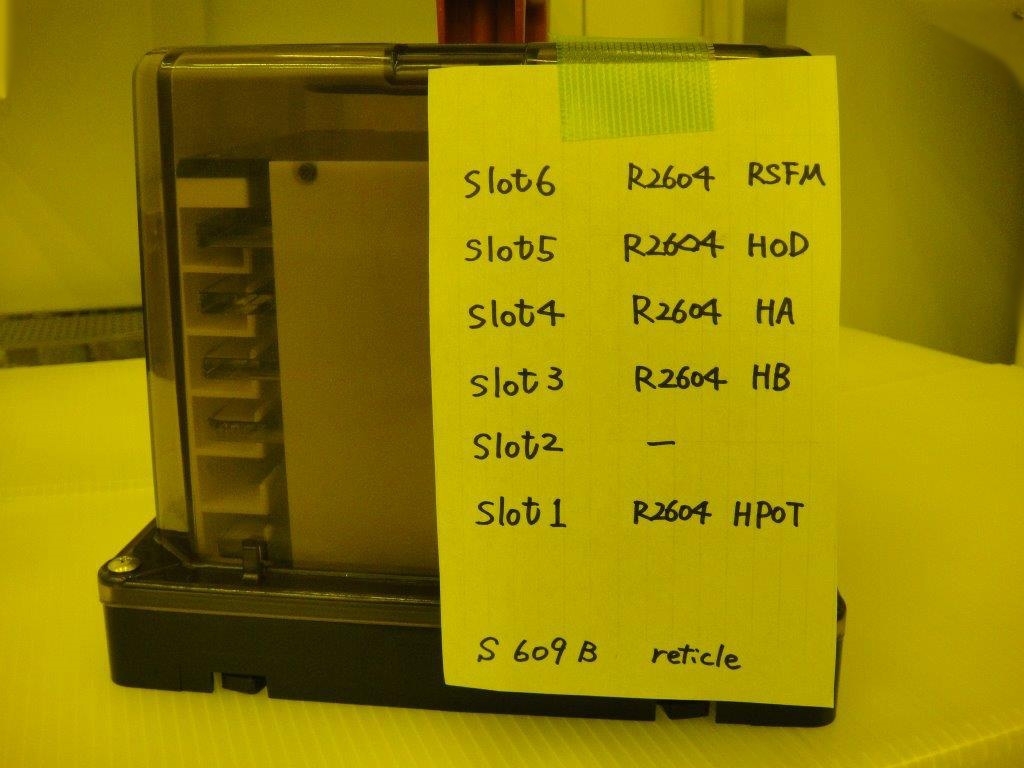

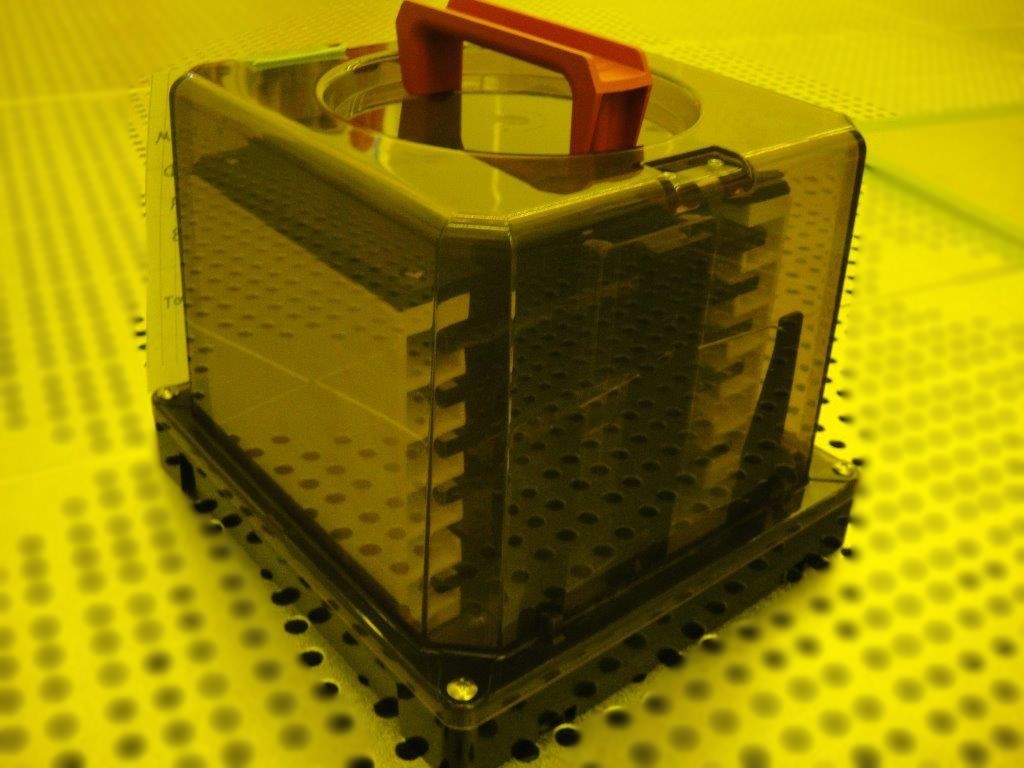

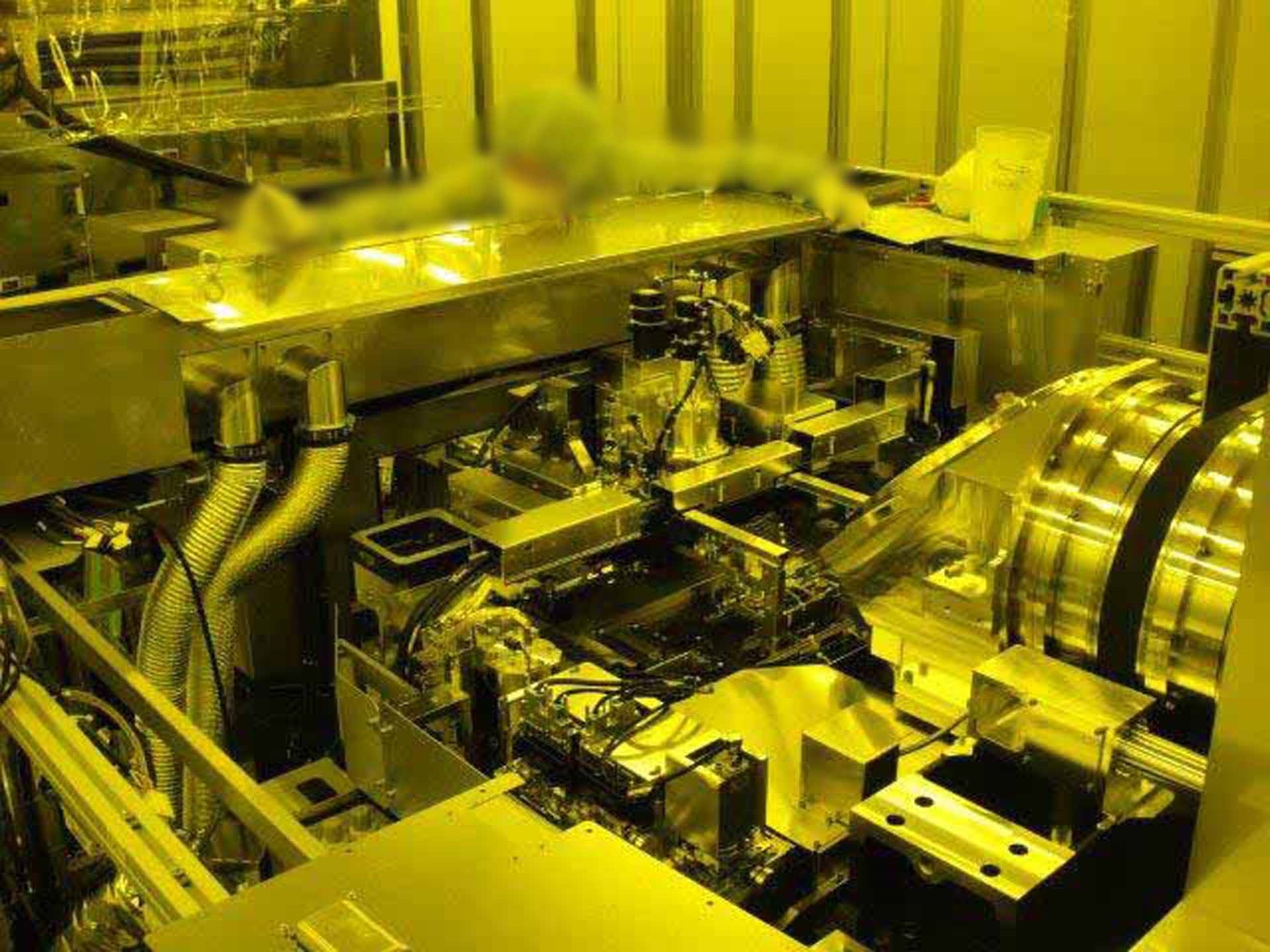

Used NIKON NSR S609B #9188831 for sale

URL successfully copied!

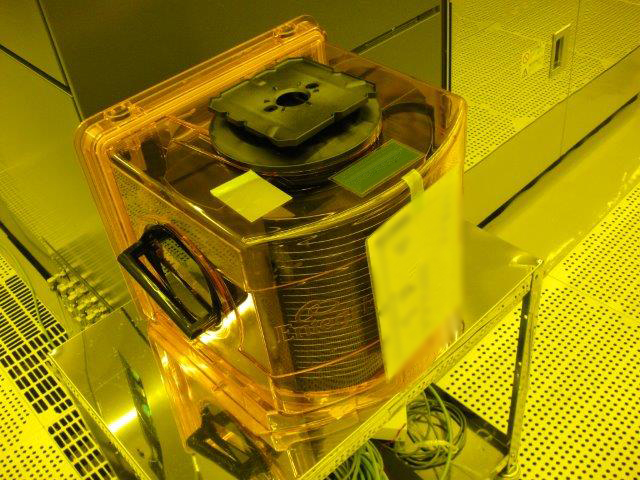

Tap to zoom

ID: 9188831

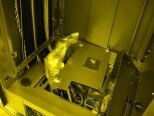

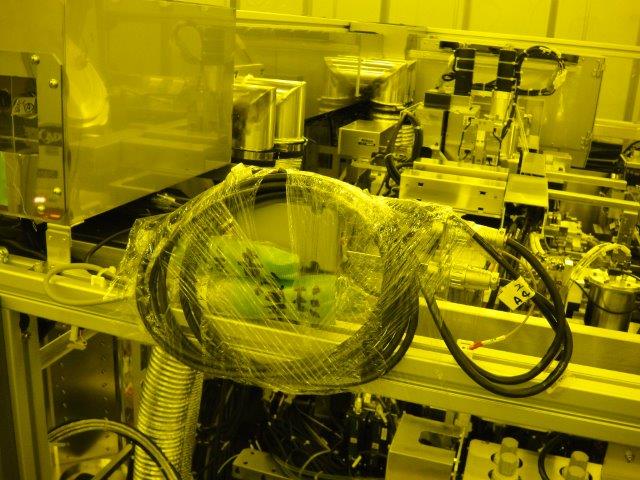

Wafer Size: 12"

Vintage: 2006

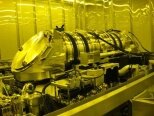

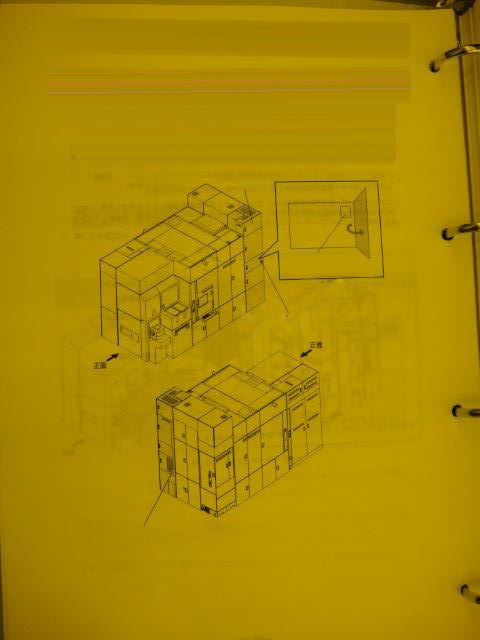

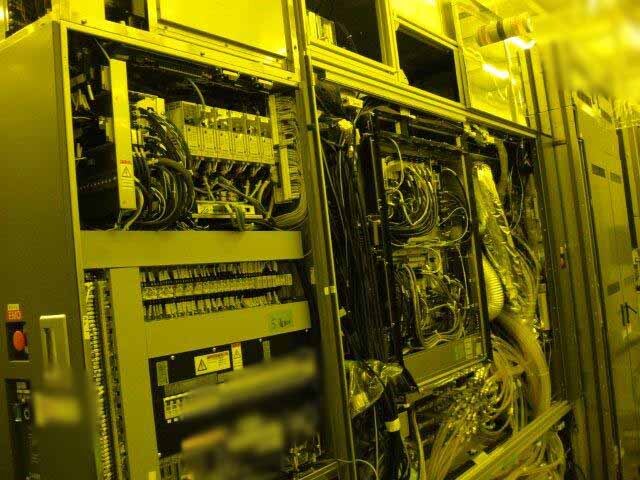

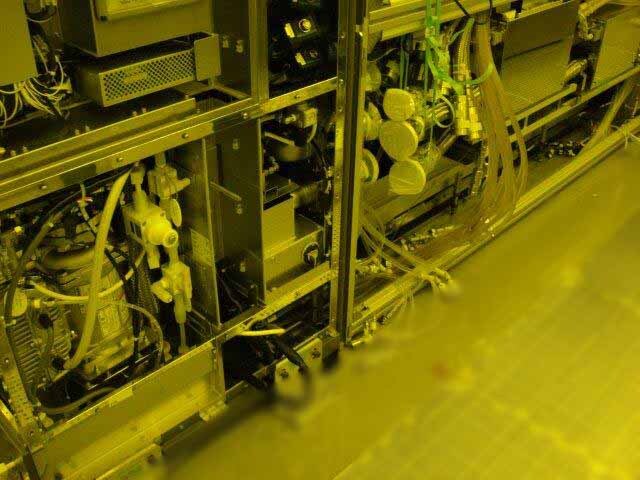

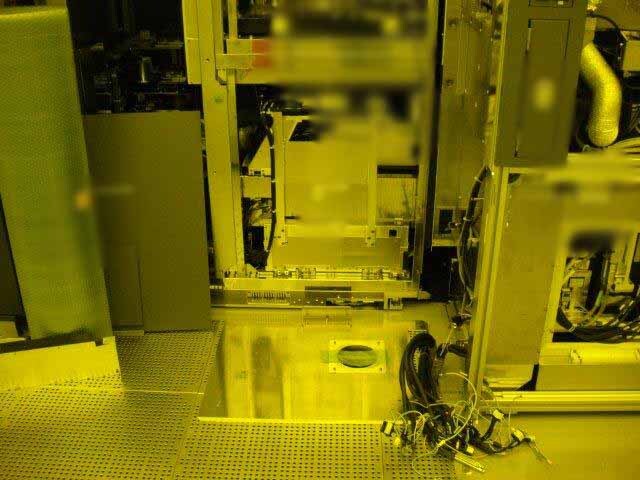

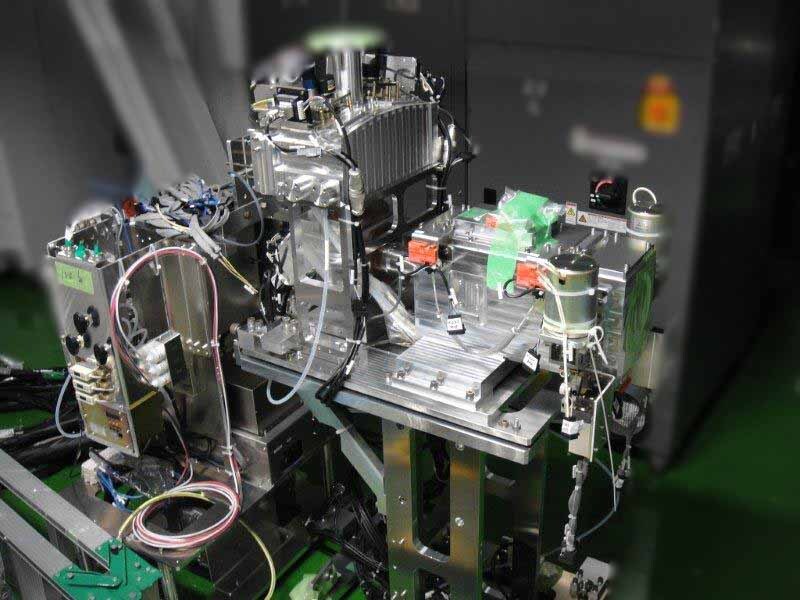

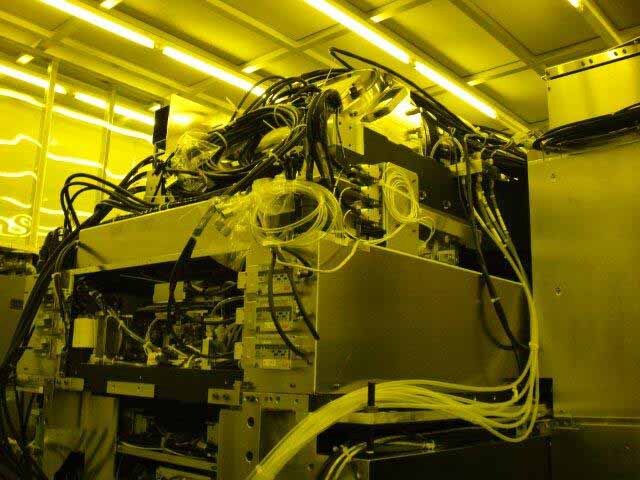

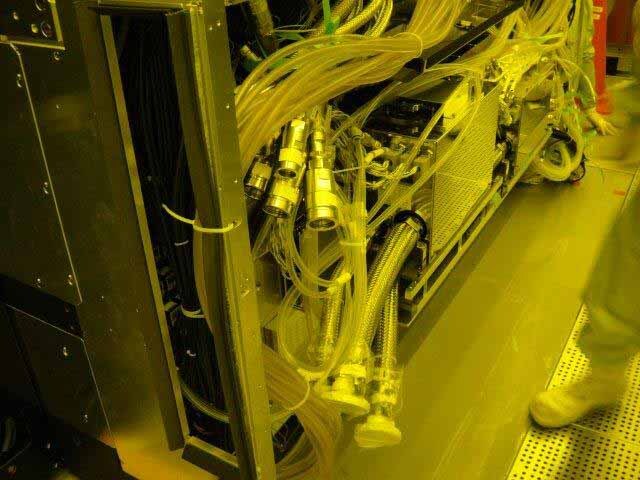

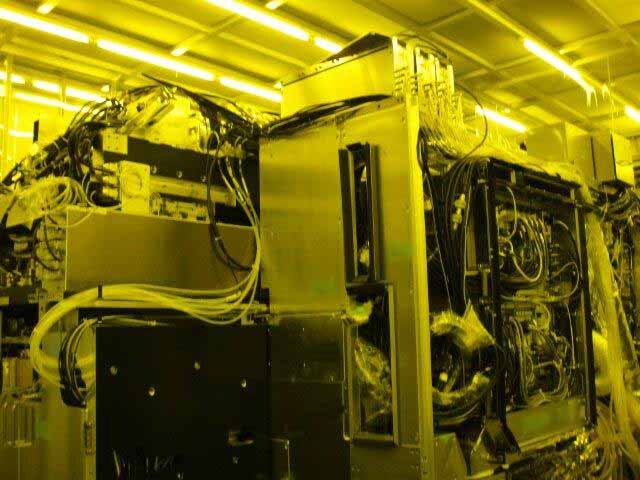

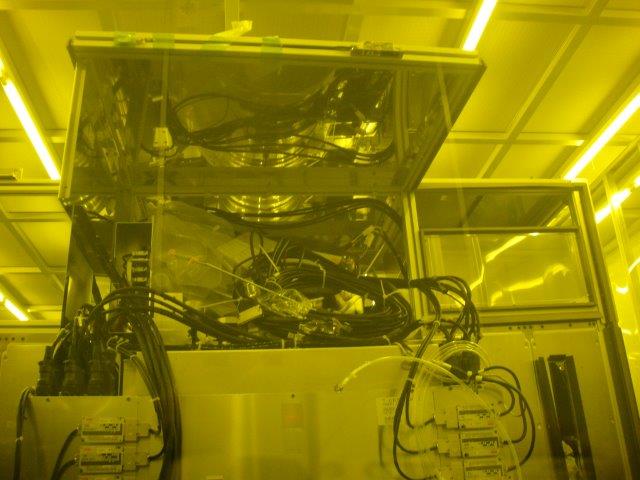

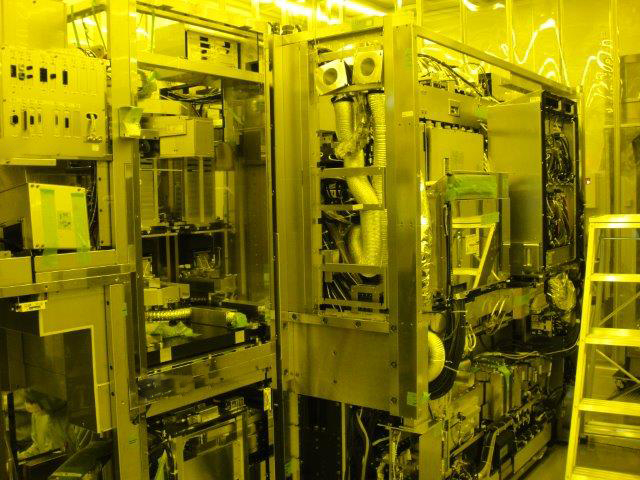

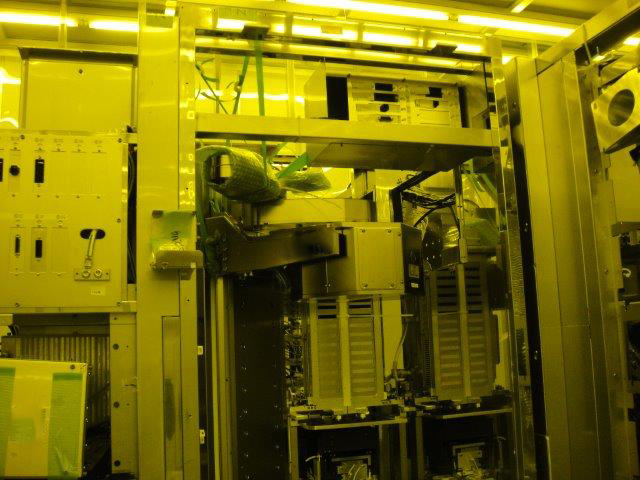

Wafer stepper, 12"

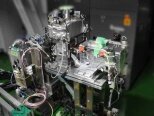

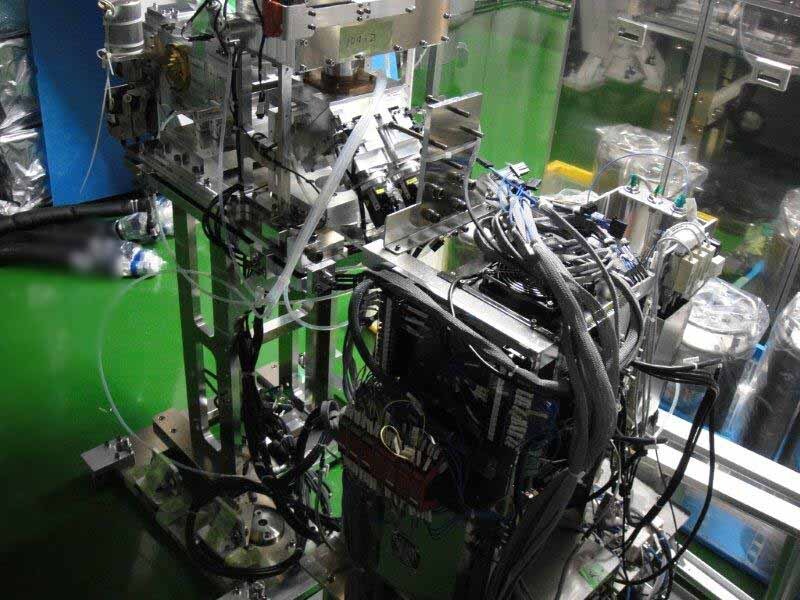

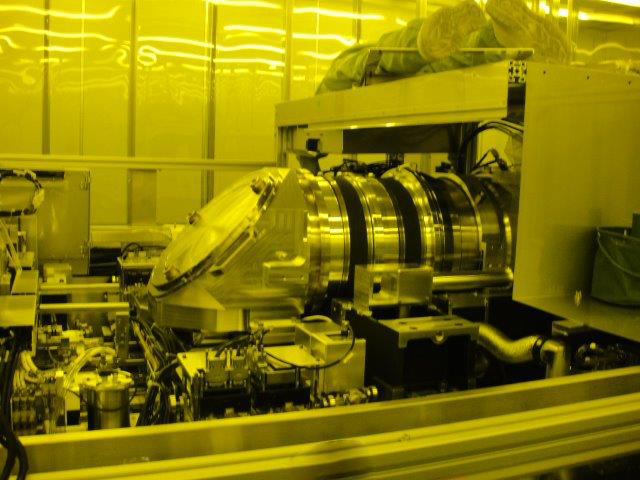

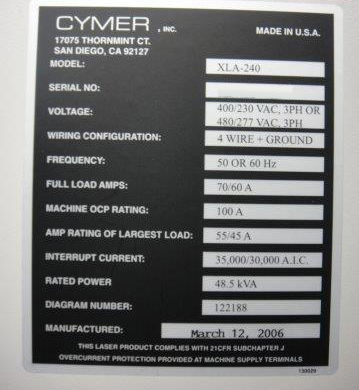

CYMER XLA 240 Laser

Resolution: ≦ 55 nm

NA: 1.07

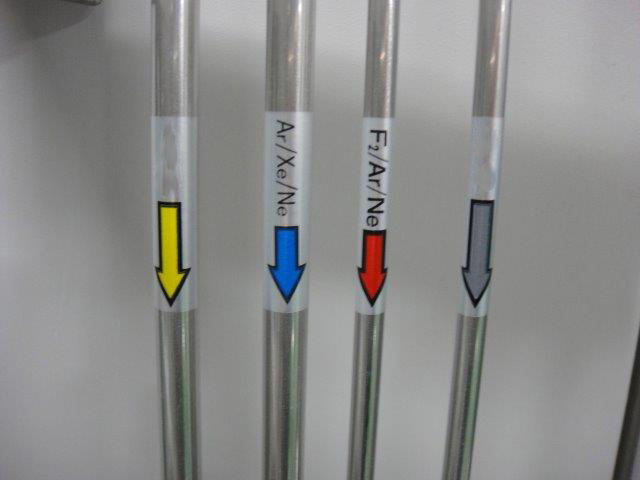

Exposed light source: ArF Excimer laser

Wavelength: 193 nm

Reduction ratio: 1:4

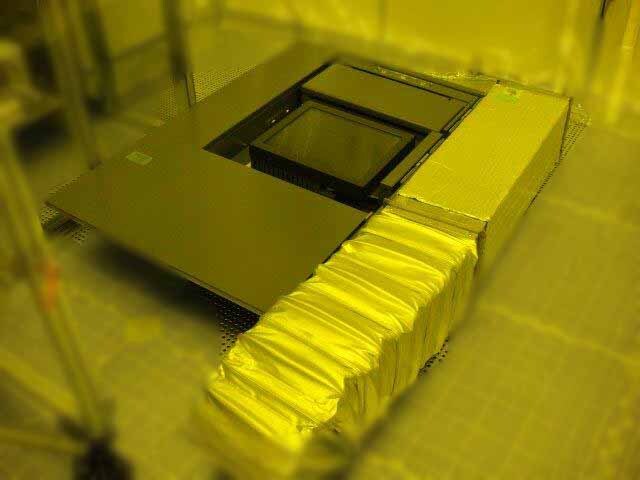

Maximum exposing range: 26 x 33 mm

Overlap accuracy: ≦ 7 nm

Throughput: ≧ 130 wafers/hour (76-Shots)

Exposure power conversion: 4800,952 (mW/cm²)

Illumination uniformity conversion: 0.205% (Dynamic)

Wafer holder flatness, Hip flatness: 2.018 μm

Reduction magnification: 1:4

Measurement of moving mirror measuring:

Residual WX: 1.201 nm

Residual WY: 1.271 nm

Exposure of light moving stage mirror measuring:

Residual WX: 1.028 nm

Residual WY: 0.533 nm

Lens distortion:

Max X: 6.2 nm Y: 3.9 nm

Max X: -6.3 nm Y: -2.4 nm

Stepping precision (Step):

SX1: 3σ = 5.8 nm

SX2: 3σ = 6.9 nm

SX3: 3σ = 6.6 nm

SY1: 3σ = 4.0 nm

SY2: 3σ = 4.2 nm

SY3: 3σ = 4.2 nm

2006 vintage.

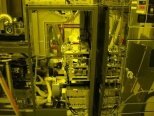

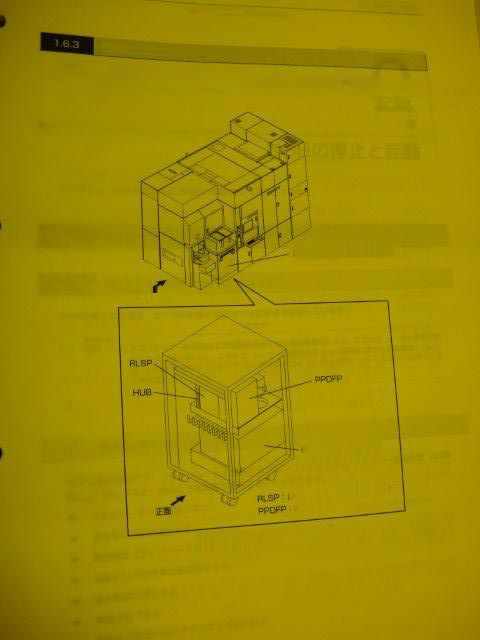

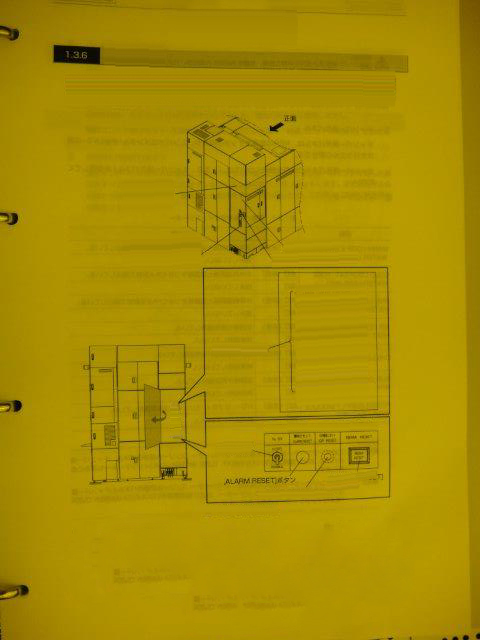

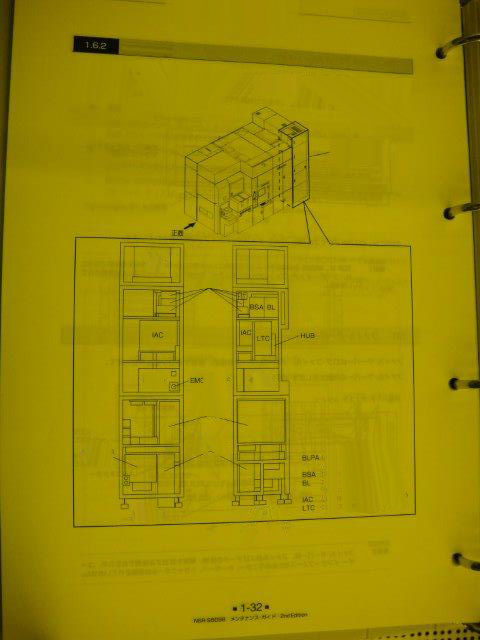

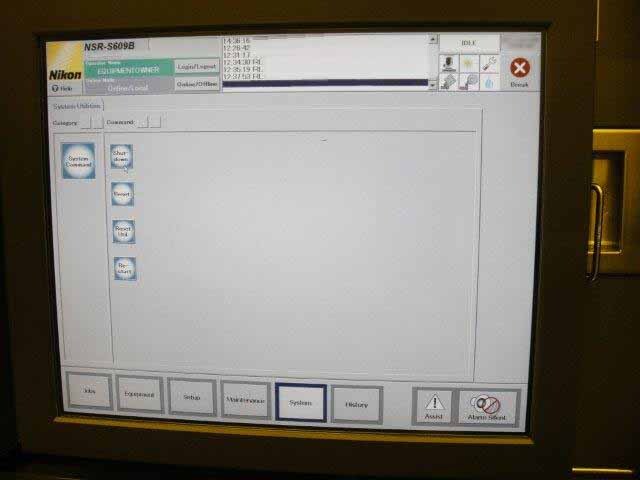

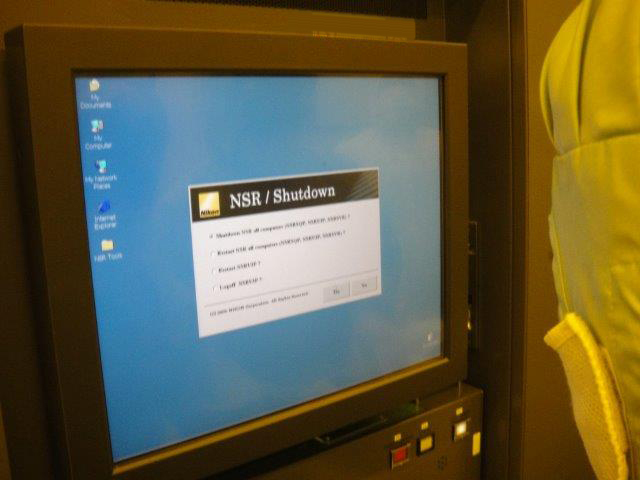

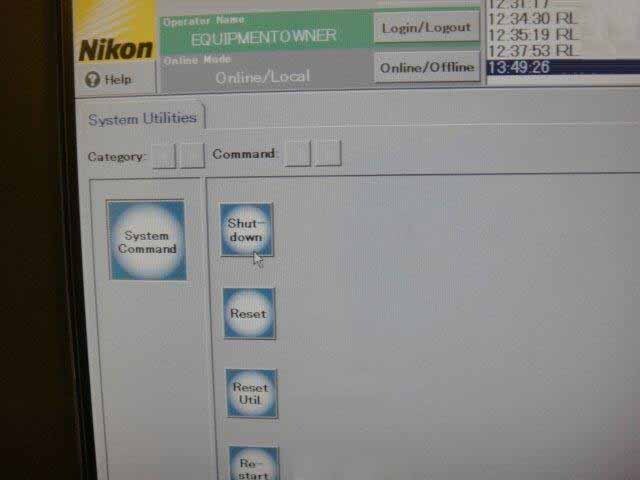

NIKON NSR S609B is a high-precision wafer stepper that is capable of producing state-of-the-art semiconductor wafers of excellent quality with the use of a variety of reticles such as stepper lens, optical microscope, and darkfield lens. It is a highly versatile lithography tool designed for production of large scale integrated circuits (LSIs), DRAMs, and other advanced memory products. NSR S609B is a scanning aligner wafer stepper, which is capable of enhancing the speed and accuracy of stepper operations. This equipment is equipped with a high-end scanner, a laser-based alignment system, and a communication unit that allows users to control and monitor the machine's operations from a single terminal. The unit's advanced electron beam optics and high resolution stepper lens maximize the precision of patterns created on its wafers. The highlighting feature of NIKON NSR S609B is its advanced AutoVisionTM software which is capable of compensating for misalignments in a masking process, and also allows users to apply batch corrections across a wide range of exposure angles, angles of incident light, and wafer sizes. The tool features a built-in wafer monitoring asset which can be used to inspect the integrity of wafer surfaces during the stepper operation. NSR S609B boasts of an extensive array of user-friendly features and technologies such as the remote service support, fault tolerances up to 0.2um, high speed scanning which enables users to take advantage of reduced exposure time, and is capable of processing up to five wafers at the same time. The stepper also comes with an auto-correction model that can detect and analyze irregularities in pattern placement and placement accuracy, powerful program-based alignment which helps to minimize image distortion, and a pattern analysis equipment to ensure that the stepper operates at the optimum overall performance. To ensure that its users maximize their productivity, the unit is fitted with a 200-wafer unloader and a 200-wafer loader, which are designed to reduce the unnecessary time and energy spent in manual handling of wafer assemblies. This system also comes with a number of protective measures that prevent dust and dirt from getting into the chamber, which effectively helps to prolong the life of its components and reduce maintenance costs. All in all, NIKON NSR S609B is a reliable and powerful wafer stepper that is highly recommended for production of advanced memory products, LSIs, and DRAMs. With its high precision, advanced features, and easy-to-use controls, NSR S609B is certainly an impressive choice for those looking for a versatile and accurate wafer stepper.

There are no reviews yet