Used NIKON NSR SF120 #293618791 for sale

URL successfully copied!

Tap to zoom

ID: 293618791

Wafer Size: 12"

Vintage: 2014

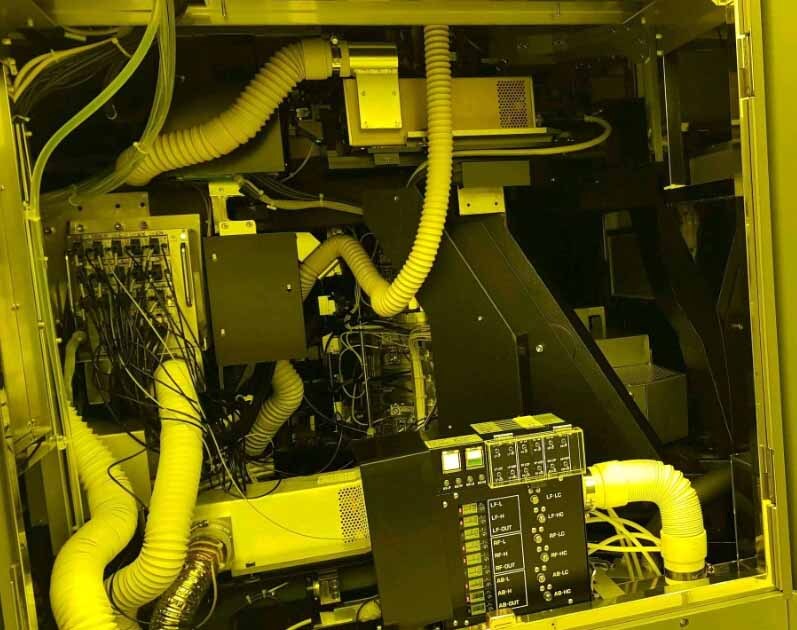

i-Line stepper, 12"

SMIF

No FOUP

SEMES KSPIN12 Track system

HP / HEWLETT-PACKARD DS10 Workstation

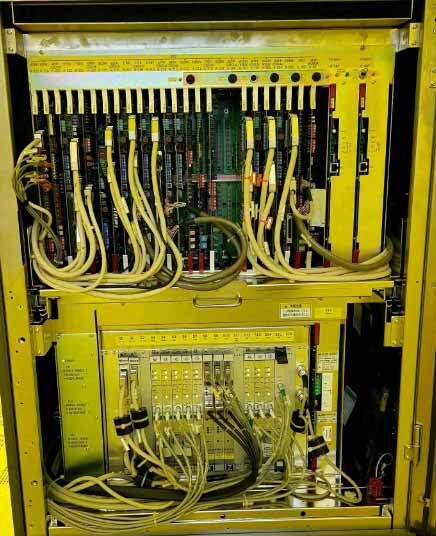

Module:

PM1: Light source

PM2: Alignment

PM3: Stage

Utility:

SR10MP 4IL2 Lens (NA: 0.50 ~ 0.62)

OSRAM HBO 5004 W/NIL Lamp for laser

Missing parts:

RL Buffer robot and controller

Morocco board

Piezo drive unit

FW Robot

(2) Blind Y

(2) Blind X

WL Box

DMCC UIP NSR Server workstation

Operating system: Windows

Hard Disk Drive (HDD) has been removed

2014 vintage.

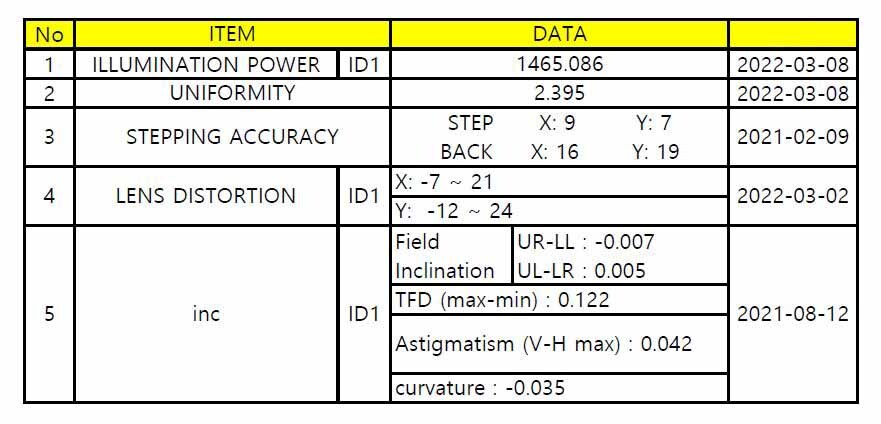

NIKON NSR SF120 is a wafer stepper used in semiconductor fabrication and chip manufacturing. It is an alignment stepper that processes up to 200mm wafers per hour. It combines NIKON highly acclaimed two-axis accuracy and superior imaging performance with advanced alignment algorithms for improved overlay accuracy. This semiconductor stepper is designed with advanced components to meet the needs of today's most demanding wafer fabrication environments. It is capable of mask-to-mask alignment and has a built-in alignment feature for single-position realignment. It offers high throughput at low levels of linearity error and overlay error - offering production stability. NIKON NSR-SF120 uses an imaging equipment with a 3-chip arrayed image-capturing system, aseismatically mounted within a reliable and stable chamber. This imaging unit has a high NA illumination machine, featuring a unique optical design of NIKON, and is capable of capturing high quality imaging of features without mask distortion. It also uses proprietary software to identify and align parts within the chamber efficiently and accurately. The superior design of NSR SF 120 enables it to be used in photolithography processes, such as photoresist patterning and high-accuracy overlay alignment. It is also capable of optical pattern check, gate and contacthole pattern delineation, scatterometry and mask alignment, due to its high-speed, high-accuracy features. NIKON NSR SF 120 is a robust and reliable wafer stepper ideal for a wide range of production needs. It is able to process loads of up to 4 inch for both 200mm or 300mm wafers, making it suitable for processing the most difficult production challenges. Furthermore, it offers advanced process control, providing excellent spot-to-spot stability and productivity. In terms of safety, NSR SF120 has a safe and stable operating environment, and a wide range of safety features. It is equipped with a multi-restraint clocking tool and a reliable beam stop baffle guard to ensure safe operation. Additionally, its advanced standby asset ensures low power dissipation when in idle mode. Overall, NSR-SF120 is a reliable and powerful semiconductor stepper designed for the most demanding fabrication operations. Its three-chip array imaging model and advanced alignment algorithms result in high throughput and exceptional overlay accuracy. It also offers a wide range of safety and process control features, making it a suitable choice for both small and large chip manufacturers.

There are no reviews yet