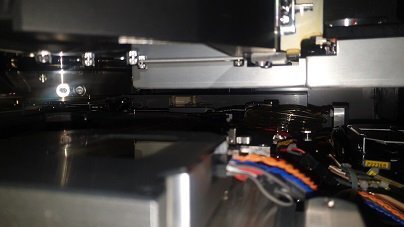

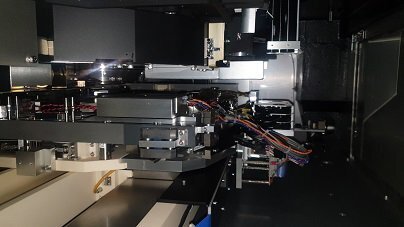

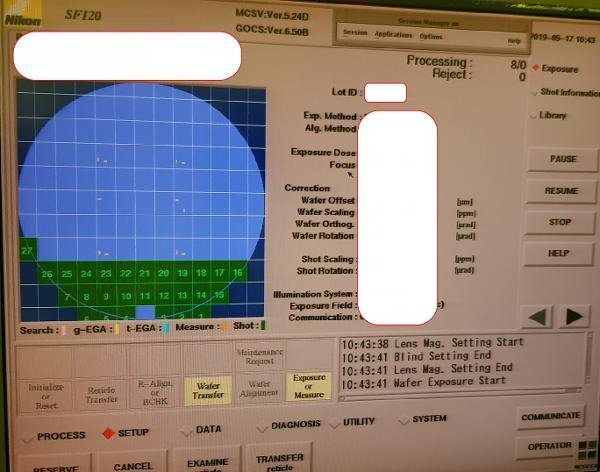

Used NIKON NSR SF120 #9207084 for sale

URL successfully copied!

Tap to zoom

ID: 9207084

Stepper, 12"

Front In-line FOUP / ACT12

(6) Reticles, 0.25"

Variable reticle microscope

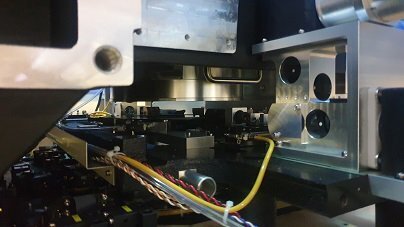

Main body:

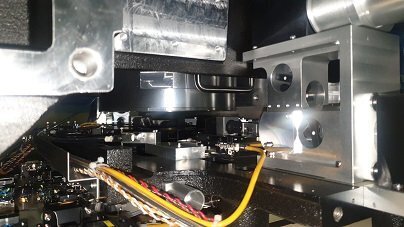

Magnification: 1/4 Reduction

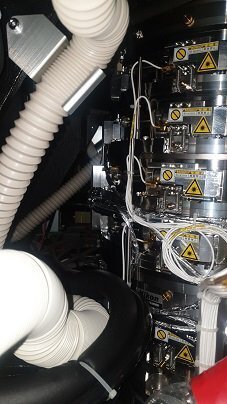

i-Line light-source, 365 nm

Resolution: 0.28um

NA Variable lens: 0.50 - 0.62

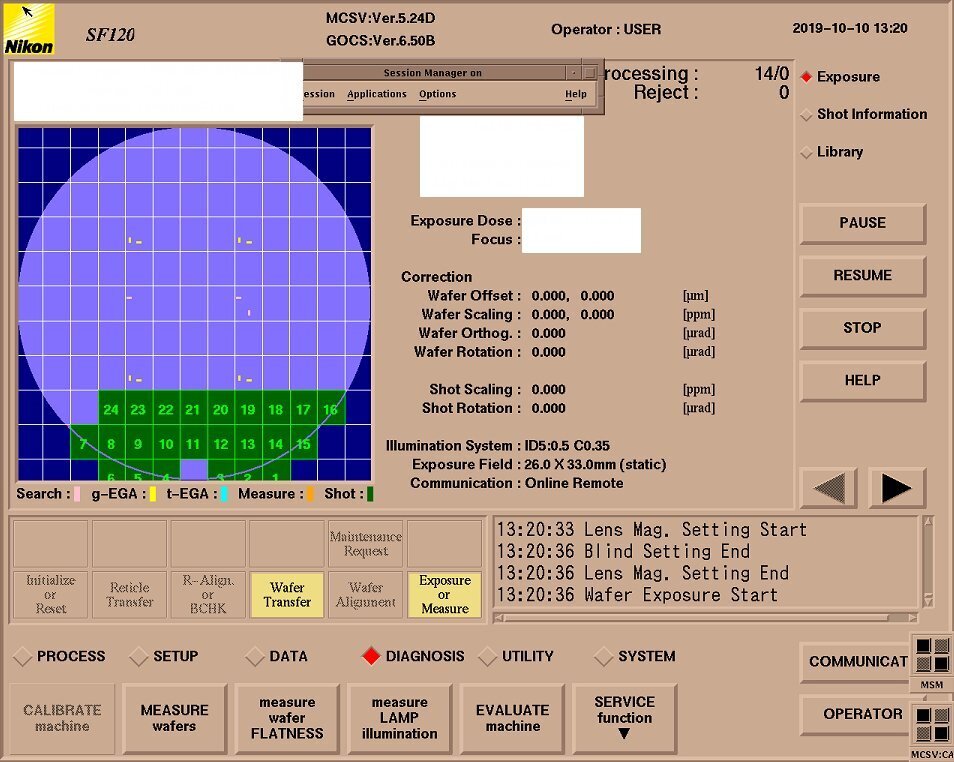

Exposure: 25 mm x 33 mm

3-Axis (5) PIEZO Lens adjust

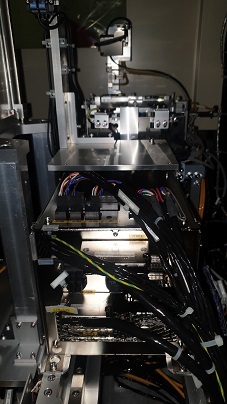

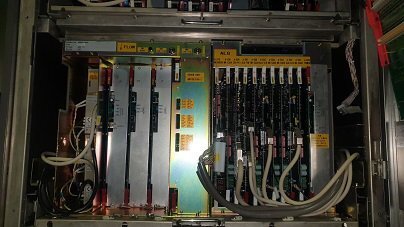

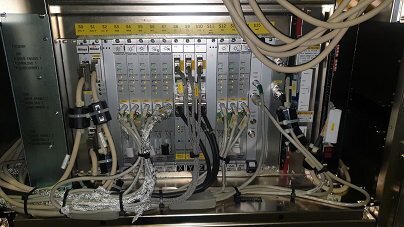

PC System hardware:

Type: DS10

UPS System

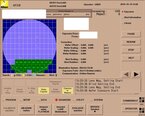

Alignment sensor:

LSA

FIA

AIS

No LIA

Interferometer system:

Wafer stage

Reticle stage

Mercury ARC lamp: 5.0 kW

Multi focus system

Table leveling system (VCM)

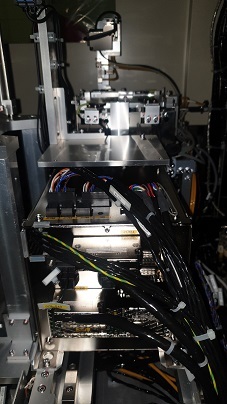

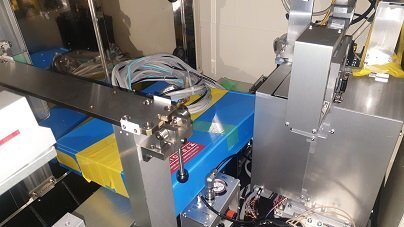

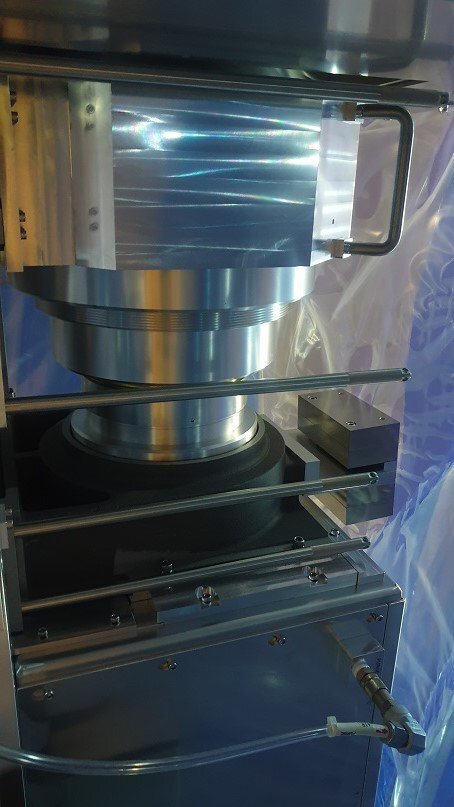

Wafer loader:

Type III

Wafer type: Notch

Front In-line FOUP + ACT12

Single wafer cassette

Wafer pre-align type: NC PRE2

Reticle loader:

SMIF Type (OHT)

(2) Indexes

Barcode reader

PPD3 Particle checker

Control rack:

Type: Normal (Right)

Cable length: Normal

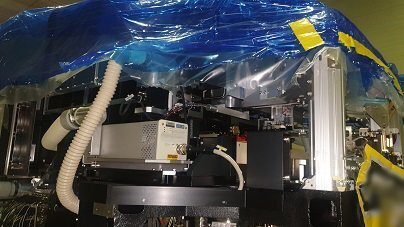

Chamber:

S52 Sendai chamber

CVCF NEMA (1,2)

BATC / CATC / LLTC: 23.0°

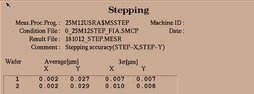

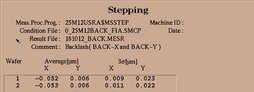

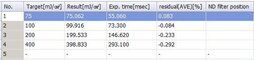

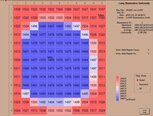

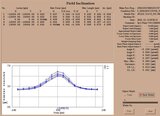

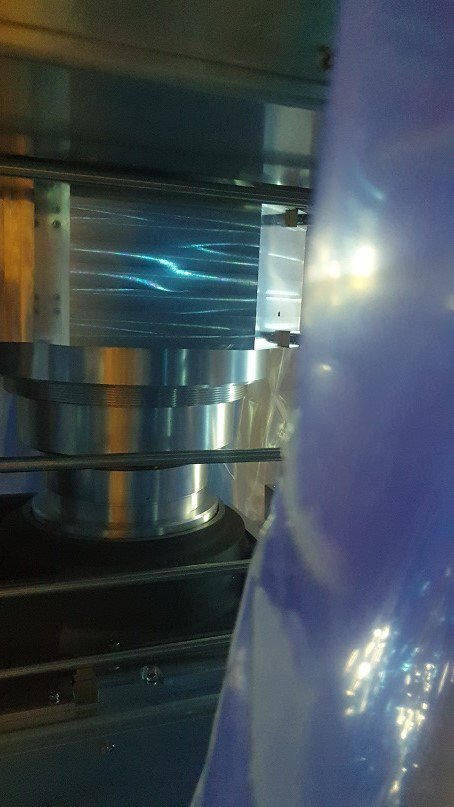

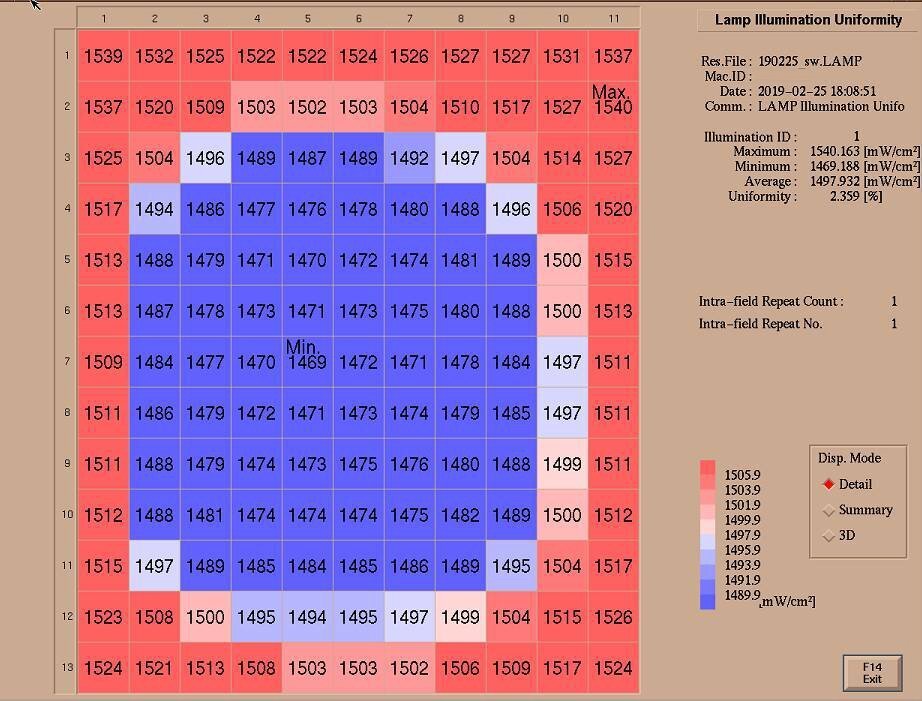

PM Data:

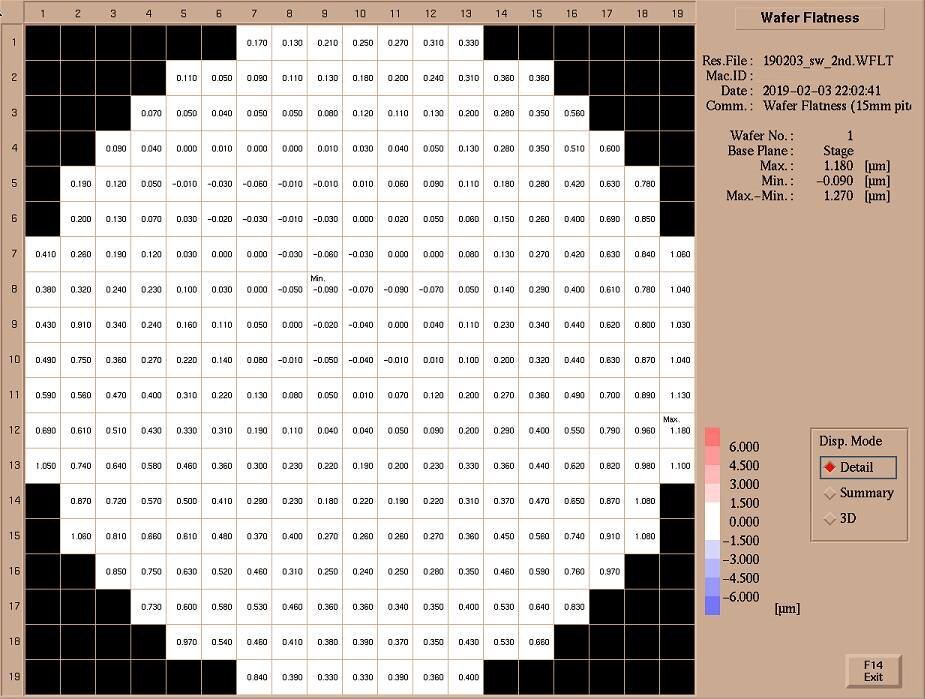

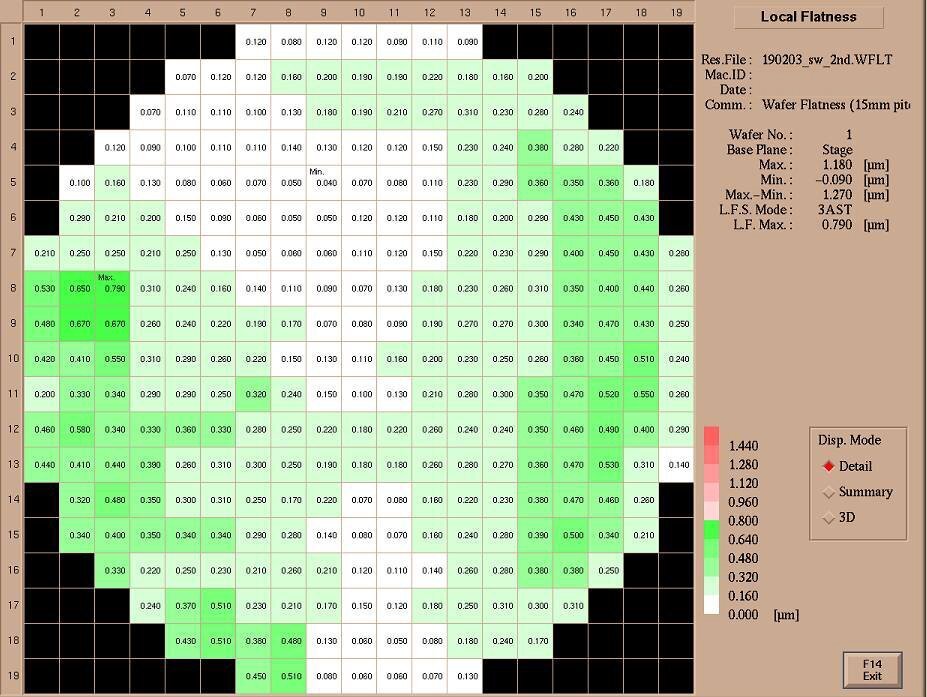

Wafer Flatness:

Maximum: 1.270 um

L.F Maximum: 0.790 um

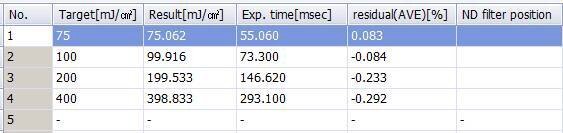

Lamp:

Power: 1497.932 mw/cm²

Uniformity: 2.359%

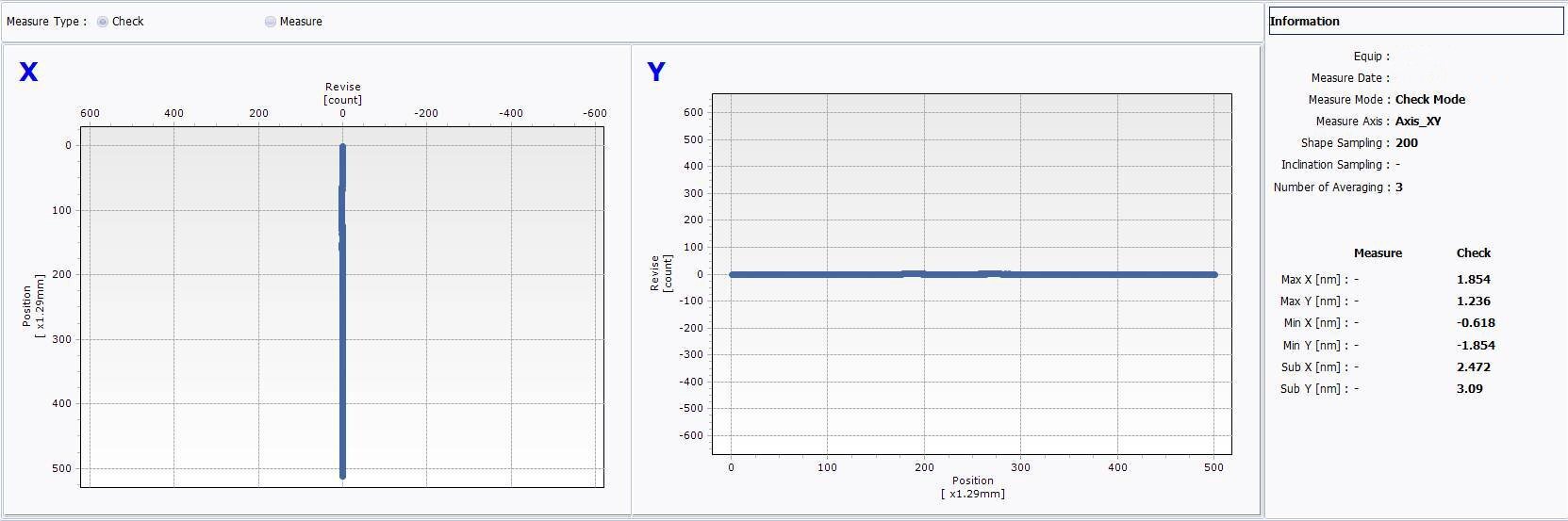

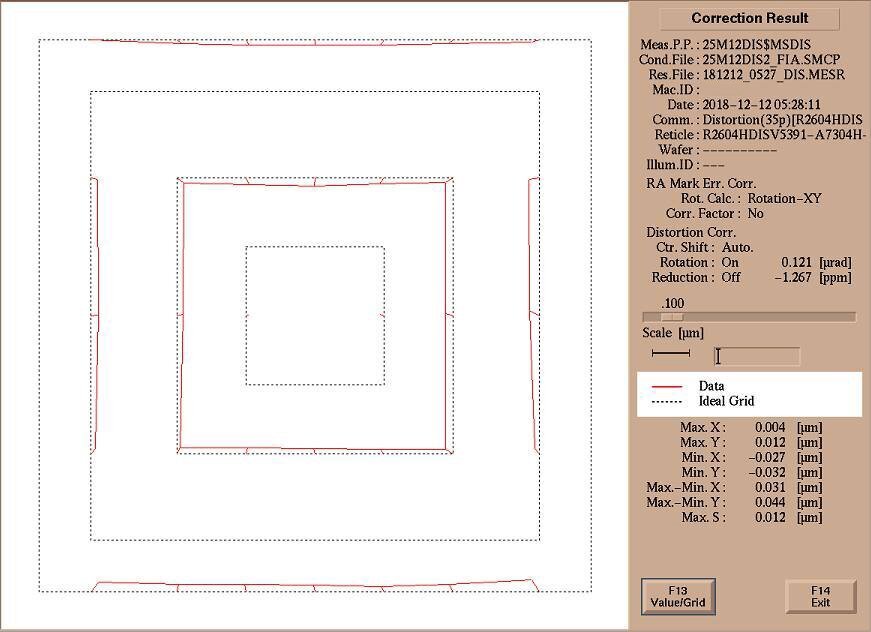

Lens distortion:

Maximum X: -0.012 - 0.013um

Maximum Y: -0.017 ~ 0.016um

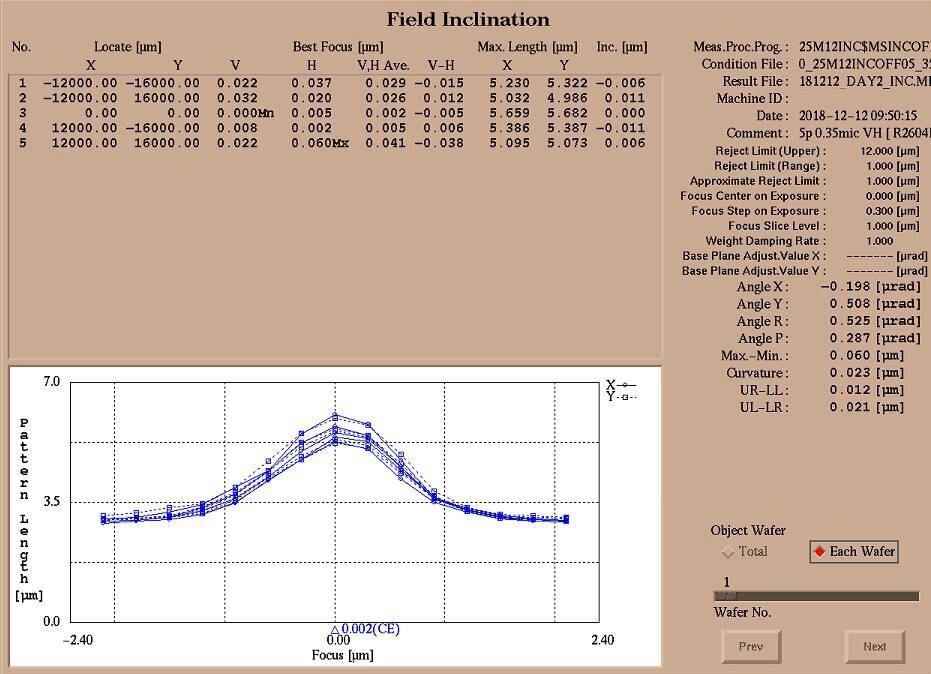

Lens inclination:

Maximum: 0.060 um

Curvature: 0.023 um

AST(V-H): 0.051 um

UR-LL: 0.012 um

UL-LR: 0.021

Illumination system:

ID1(L-NA/I-NA): ConV 0.52/0.36

ID2(L-NA/I-NA): ANN 0.62/0.5

ID3(L-NA/I-NA): ConV 0.62/0.43

ID4(L-NA/I-NA): ConV 0.62/0.36

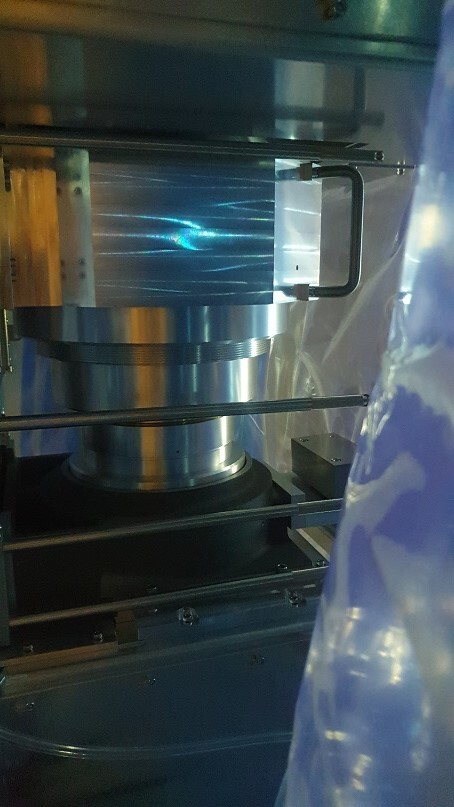

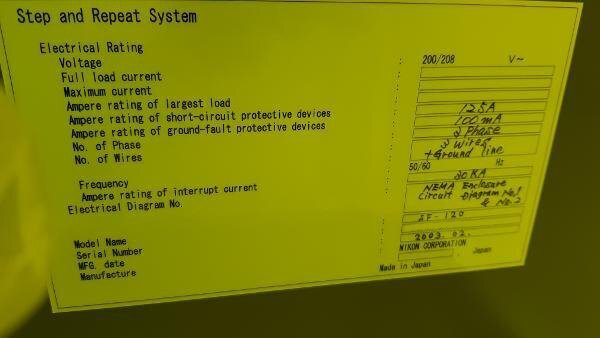

Power supply: 208 V, 3-Phase, 60 Hz

2003 vintage.

NIKON NSR SF120 is a high-precision wafer and mask aligner equipment that features NIKON proprietary "Resonant Scanned Stepper" (RSS) technology. It is able to achieve high throughputs and high accuracies for a range of demanding stepper applications. It is suitable for both mask and wafer processing. The system employs a high-speed 6-axis stage to obtain 1-nm positioning resolution. The stage has a maximum acceleration of 30 m/s2, enabling shorter cycle times with fewer retouched frames. The wafer steper is capable of exposure and alignment of wide range of photomasks. It has a non-contact alignment light source with 9-wavelengths (including i-line, g-line, and u-line) to provide high-accurate alignments for wafers and photomasks. The unit also features a programmable alignment algorithm for further accuracy improvement. In addition, the high-accuracy alignment and registration repeatability (1.5 sigma) is assured by the introduction of the proprietary two-dimensional registration marker. NIKON NSR-SF120 is designed with an intuitive user interface and optimized recipe generation tools to reduce setup time. NIKON proprietary optical axis correction function is used to maintain verticality of the optical axis (on-axis verticality) for wide range of applications. The wafer stepper is equipped with multiple options for speed and accuracy. It uses a patented auto-sensor machine for detecting residual materials. The default auto-sensors can detect any object from 0.1 microns up to 10mm in dimension. The machine also offers a registration search mode to register the wafer and the mask quickly and accurately. NSR SF 120 is also designed with a comprehensive set of safety functions. It features an in-situ protection tool to protect the user from exposure to hazardous substances. It also has an absolute-position monitor which can detect problems quickly if any change is detected to the asset's status. NSR-SF120 is a fully-high precision wafer stepper that meets the high demands of production-level applications. Its capability and advanced technologies allow it to provide outstanding alignment accuracies and throughputs. It offers a cost-effective solution for applications that require high-precision alignment and registration of wafers and photomasks.

There are no reviews yet