Used NIKON NSR SF120 #9361374 for sale

URL successfully copied!

Tap to zoom

ID: 9361374

Wafer Size: 12"

Vintage: 2003

i-Line stepper, 12"

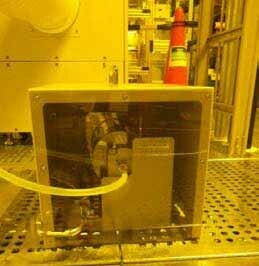

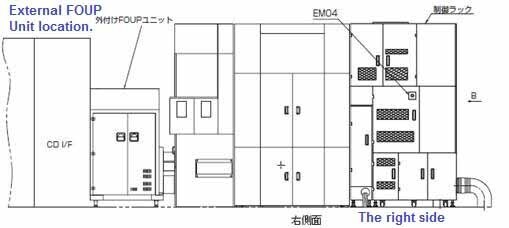

Main body

Loader chamber

Power supply box

Lamp house cooling unit

Exposing source: i-line

Wavelength: 365 nm

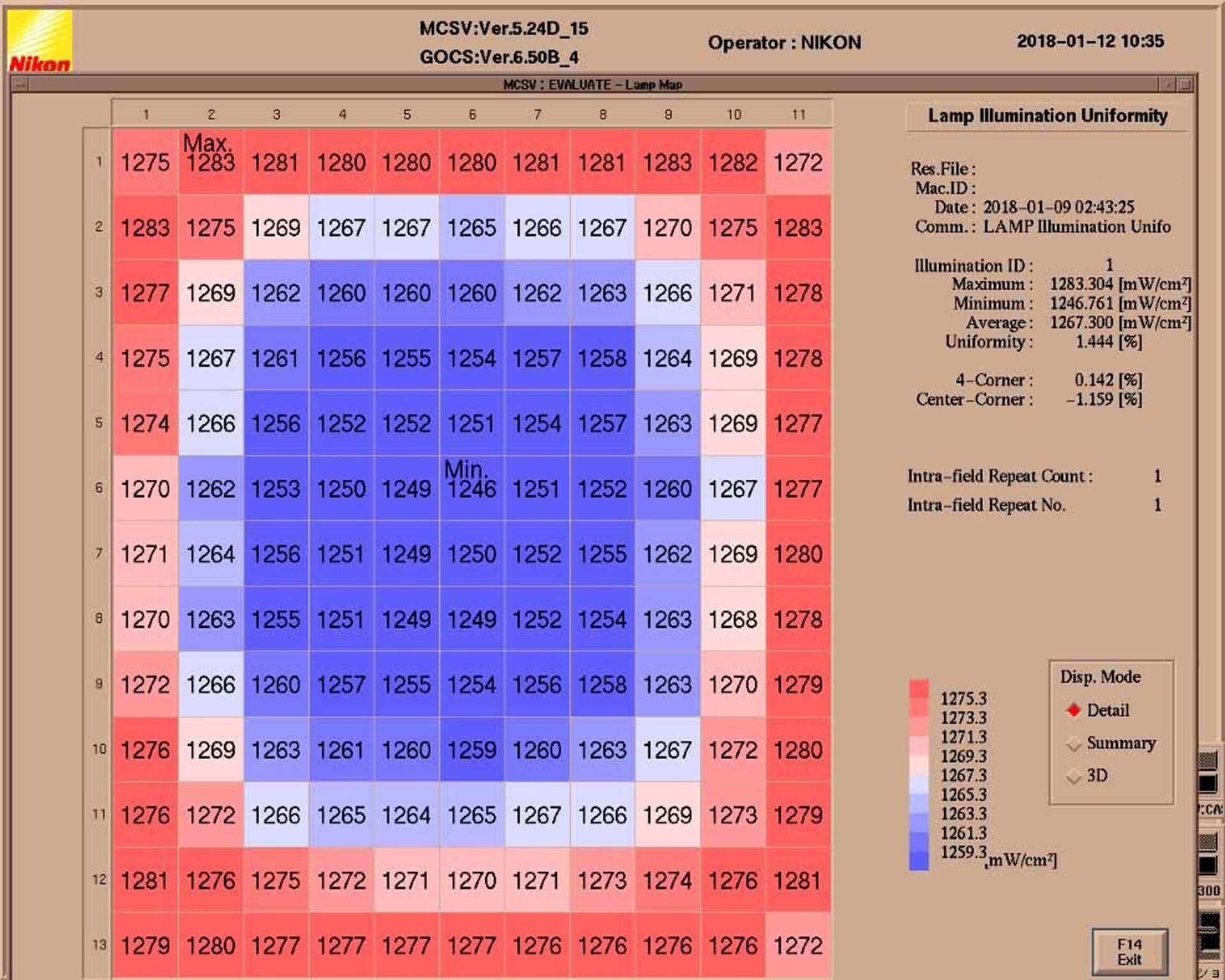

Surface illumination: 1000 mW / cm²

Reduction ratio: 1:4

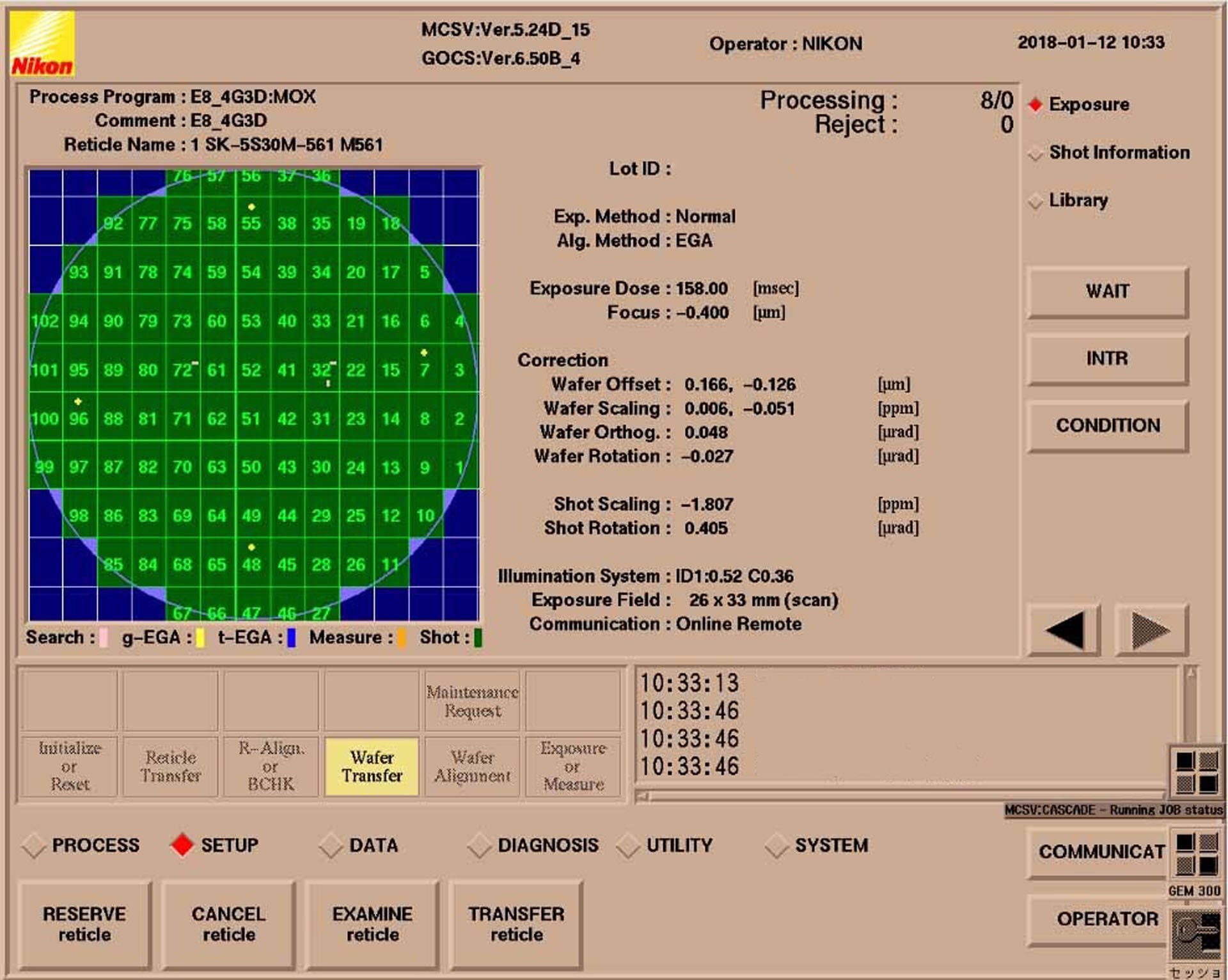

Wafer alignment: FIA / LSA

LC Control: 25x33 mm

Step pitch: 25 nm x 33 mm, 76-Shots, 12"

Exposure amount: 90 mJ / cm²

Reticle buffer: 14 Sheets (Maximum)

(2) Reticle load ports

Throughput:

FIA-EGA: 100 Wafer / Hour

(2) LSA-EGA: 90 Wafer / Hour

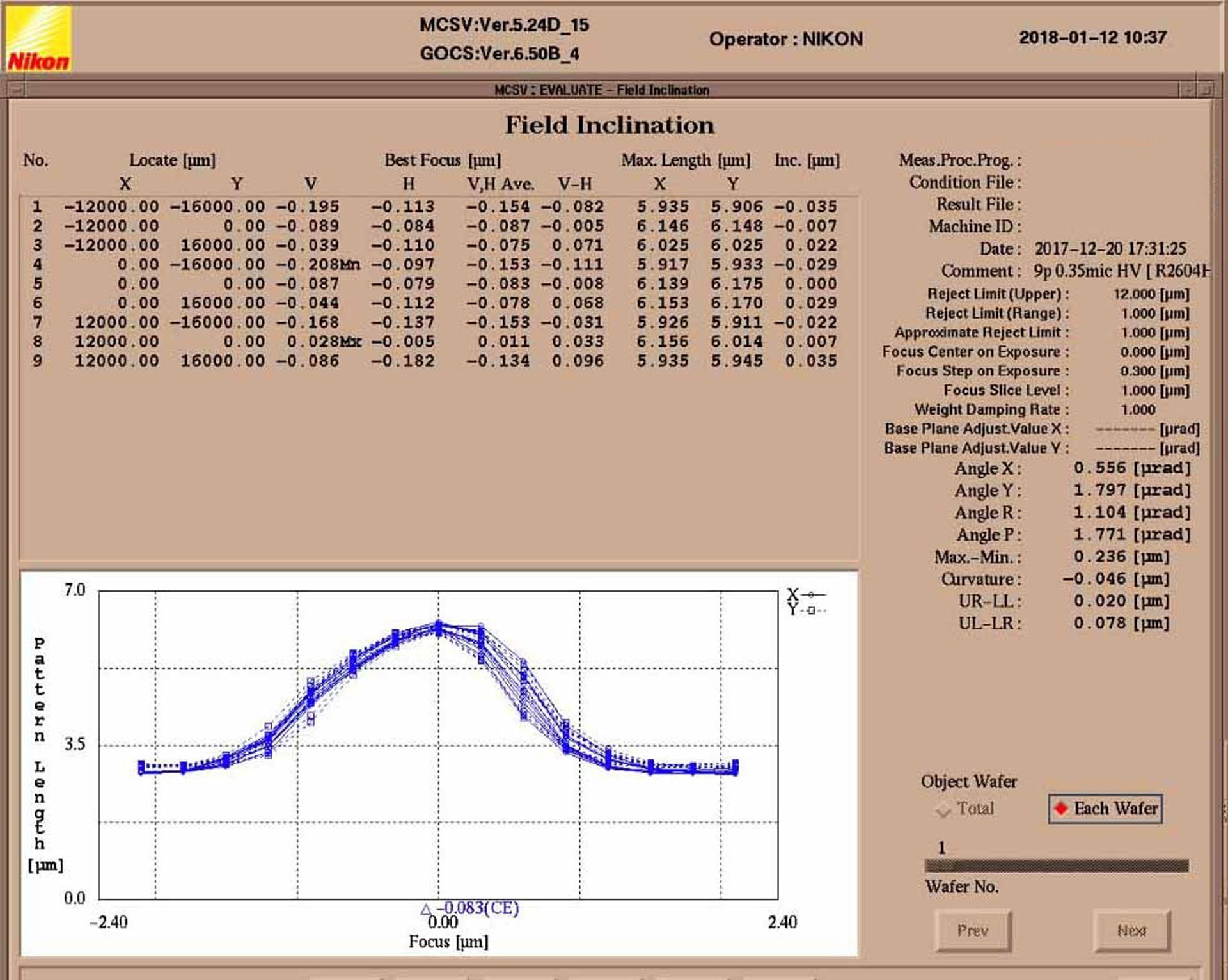

Resolution: <280 nm

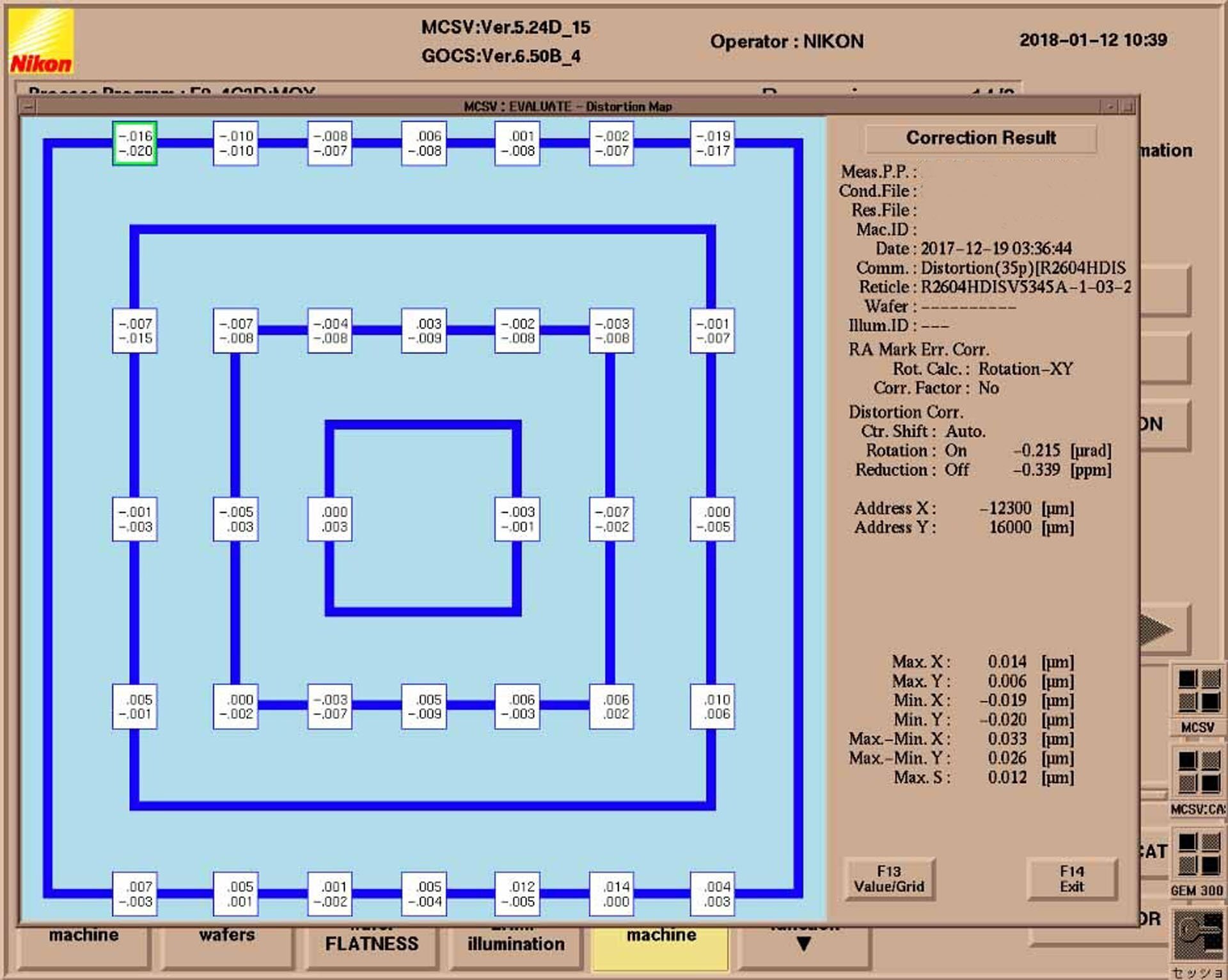

Alignment accuracy: <35 nm (M+3σ)

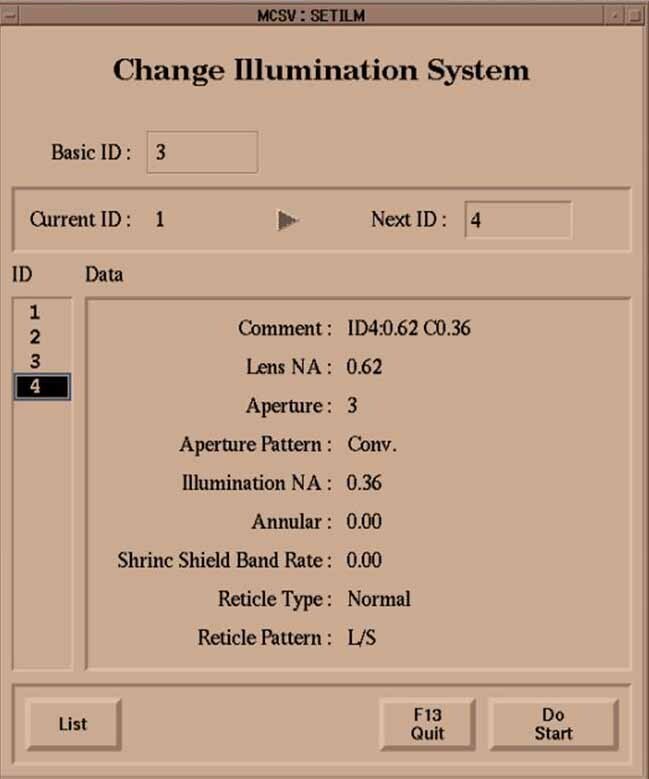

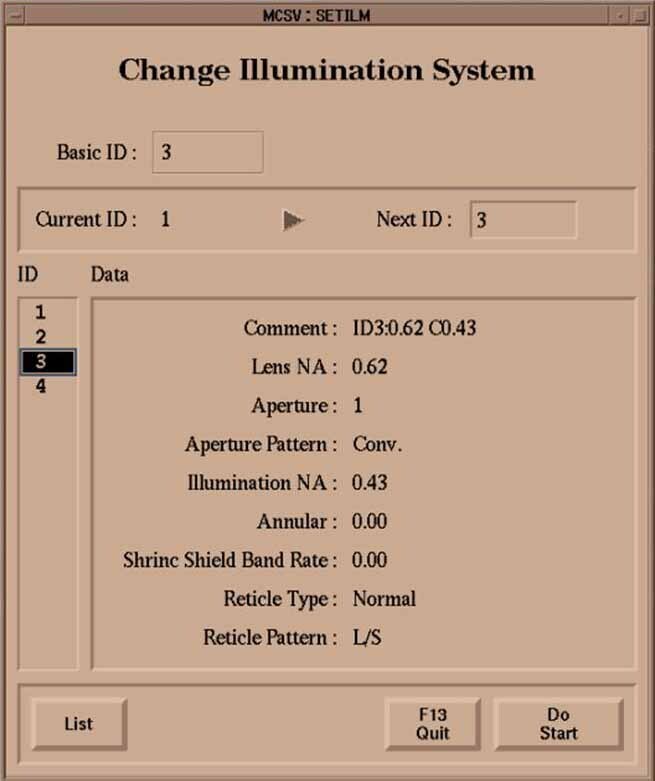

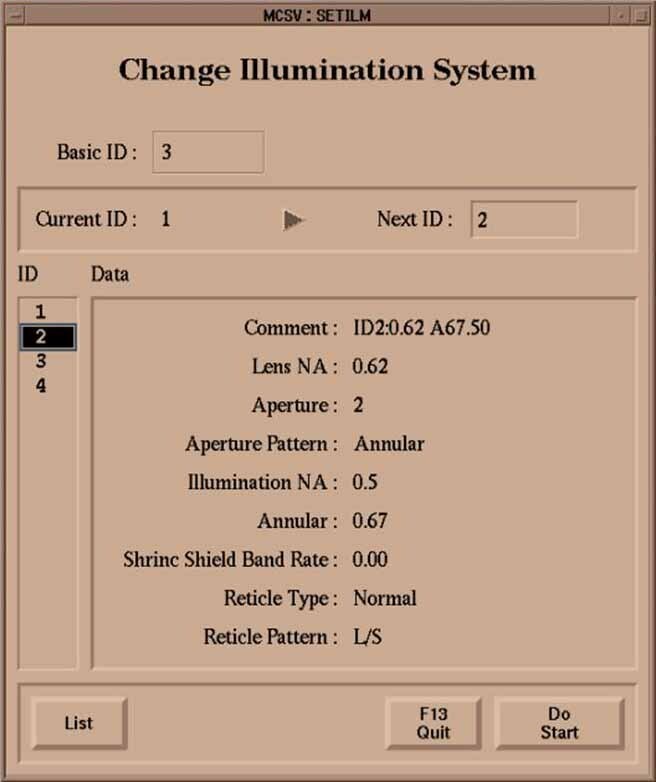

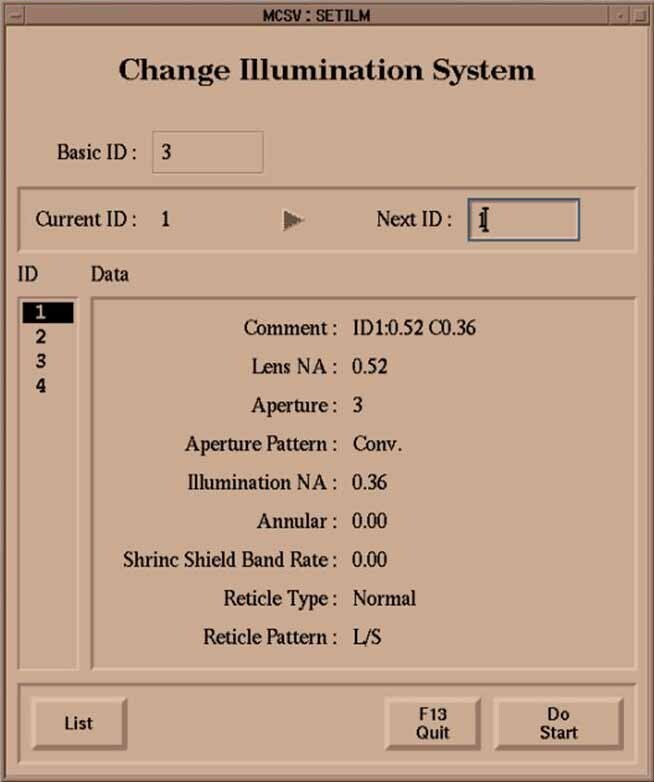

Projection lens NA: 0.50~0.62

Lighting NA with squeezing:

I-NA: 0.43 CONV

I-NA: 0.36 CONV

I-NA: 0.50 2/3Ann

(2) VRA Angle exposure range (Scan field):

26x33 mm

25x33 mm

Options:

PPD

Particle inspection device

2D Barcode

WL Front in-line

Relay FOUP unit

2003 vintage.

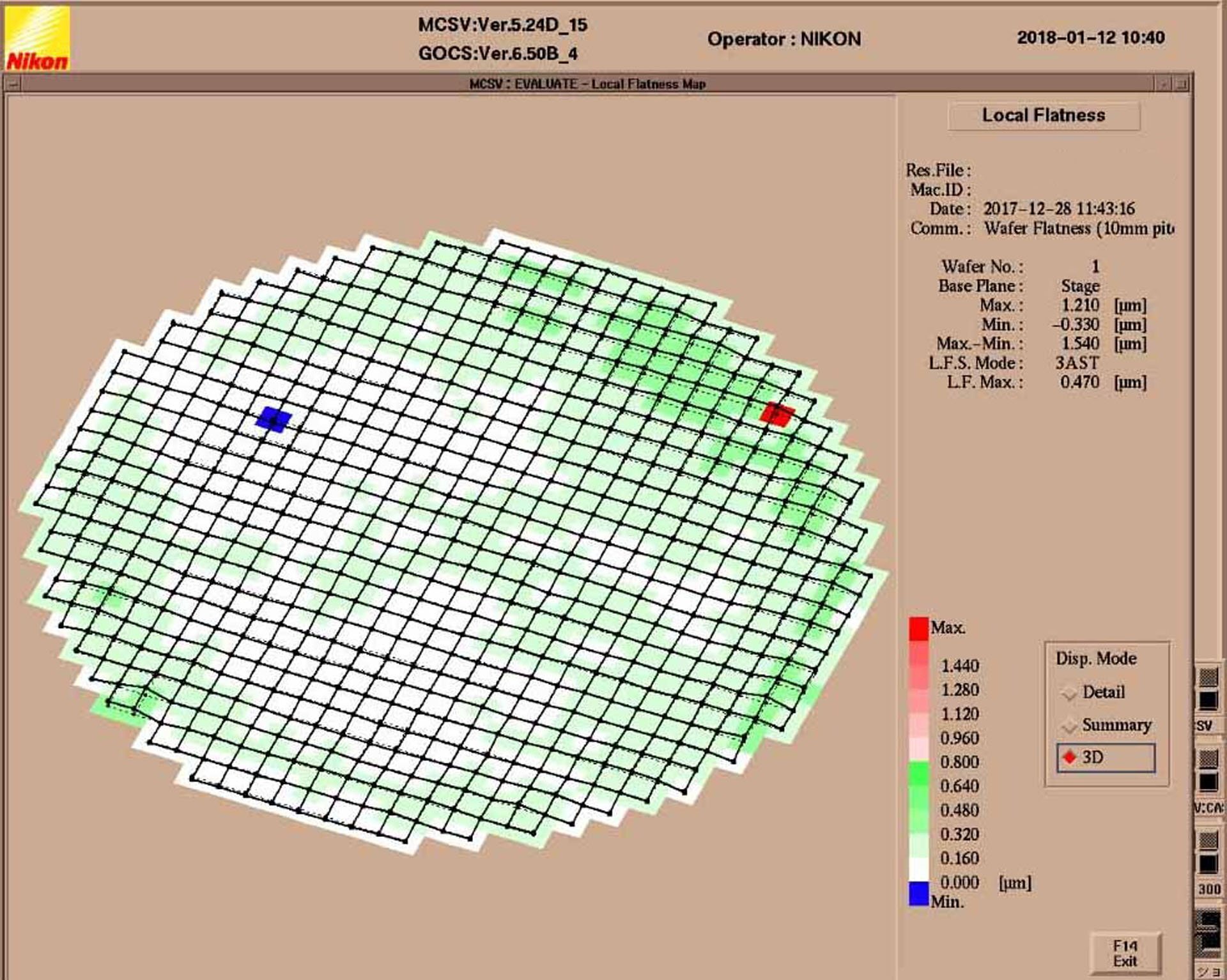

NIKON NSR SF120 is a fully automated wafer stepper, designed specifically for sophisticated wafer processing needs. This stepper offers a wide range of features, such as a superior pattern alignment equipment that ensures accurate overlay accuracy across multiple wafer levels. The 5-axis motion system also ensures precise wafer movements with a minimum of vibration for greater stability. NIKON NSR-SF120 also provides a high-precision lens unit that produces excellent wafer surface fidelity and improved performance. Advanced software and optics for a bright field imaging also guarantee excellent edge detection and sharpness. NSR SF 120 features a large 6-inch field of view that can accommodate most wafer shapes and sizes. Its high-resolution 10-megapixel camera gives outstanding imaging capabilities for accurate, repeatable wafer deposition process over the entire wafer surface. An automatic wafer calibration machine helps to reduce user input by setting the optimal exposure parameters for each product. This helps to ensure that all deposition processes are carried out with optimal precision and without any need for manual control. This stepper is also equipped with a host of features to enhance wafer processing, including substrate misalignment compensation, defect pattern identification, and wafer-level overlay preview for improving the quality and repeatability of the stepper. NSR SF120 also features ideal temperature control to maintain the best conditions for wafer processing. It employs a high-precision pressure chamber, which helps to control temperature drift, humidity, and contamination levels on the wafer surface. Air-jet stage cooling technology is also used during depo

There are no reviews yet