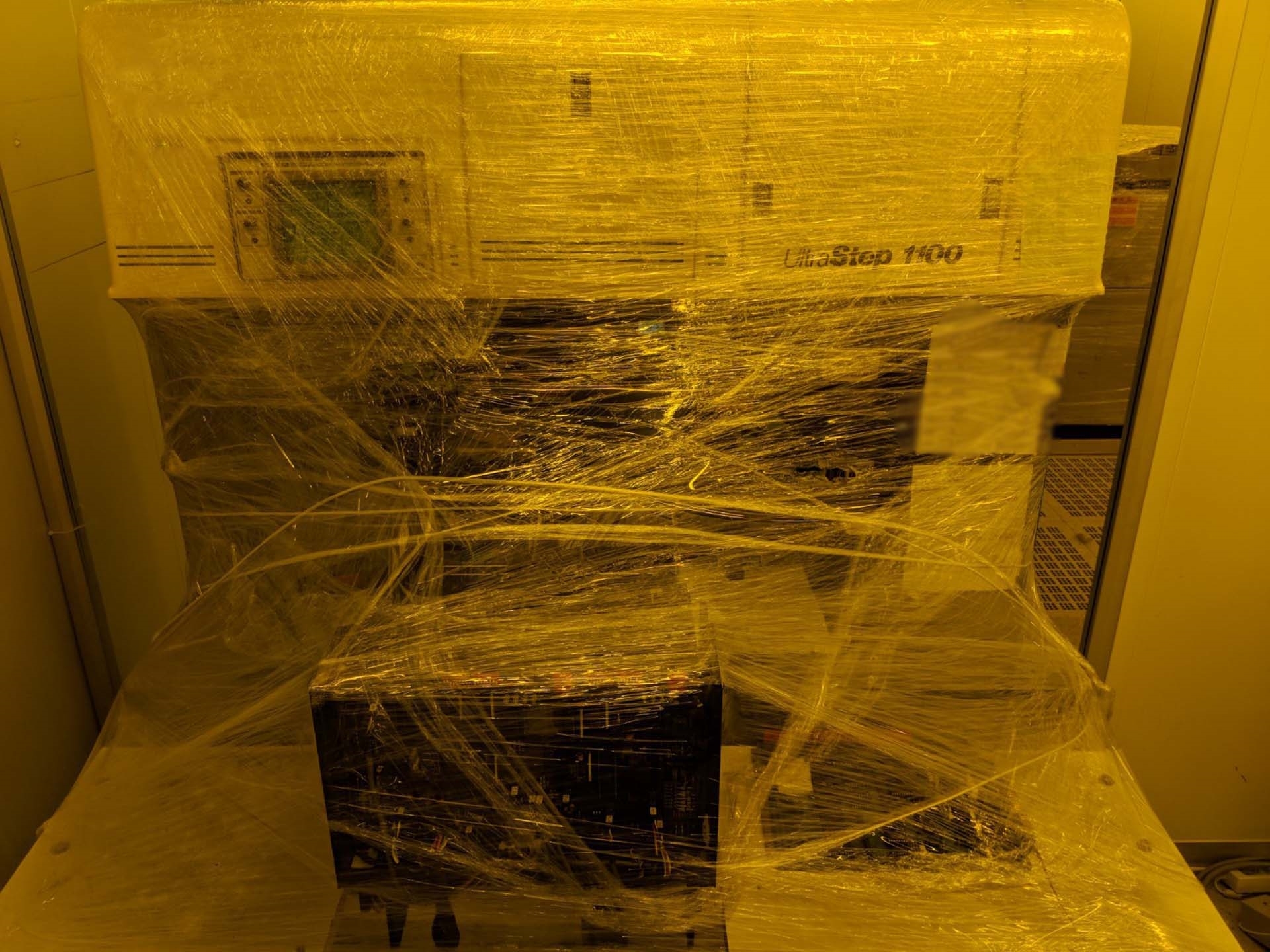

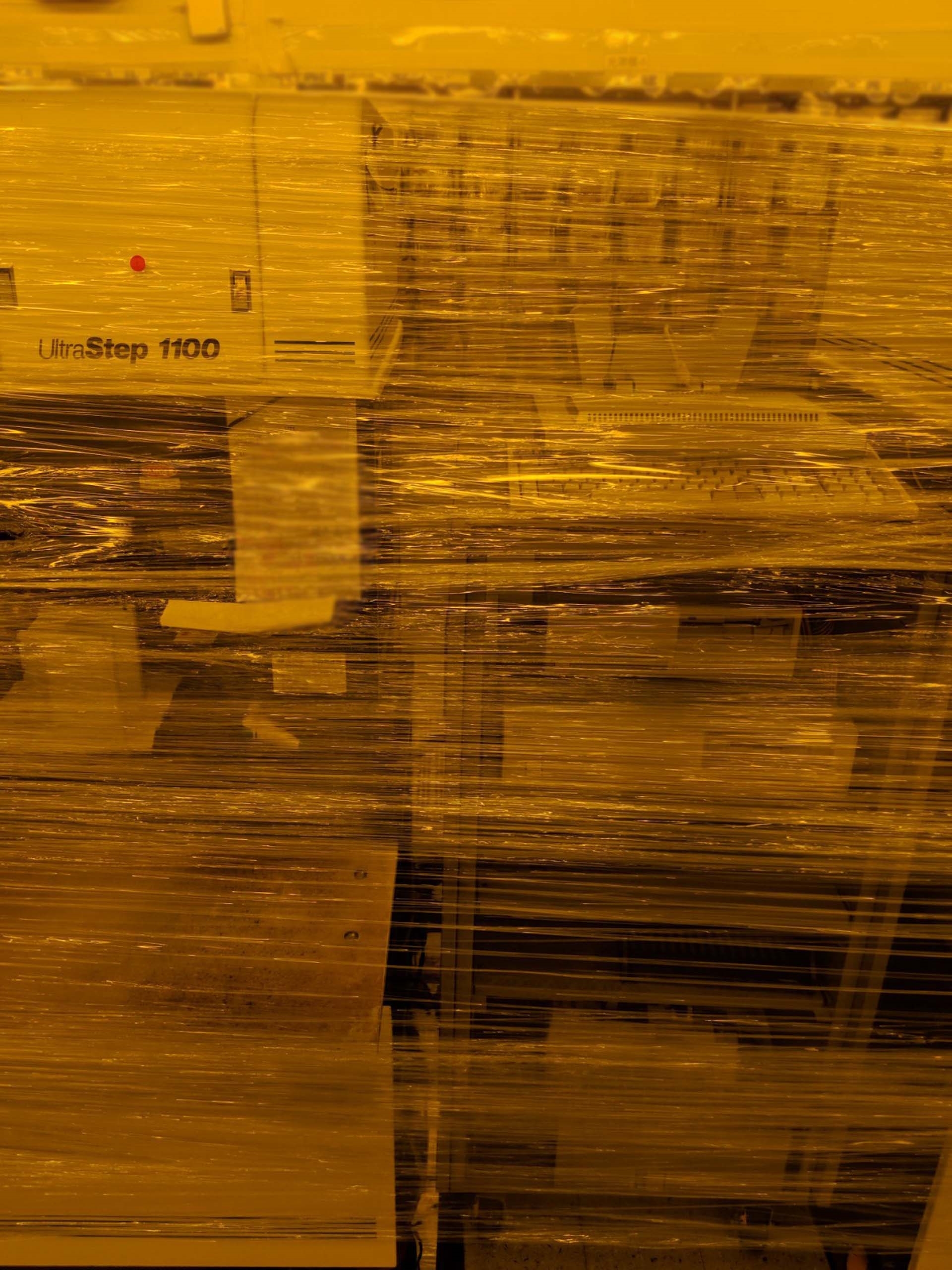

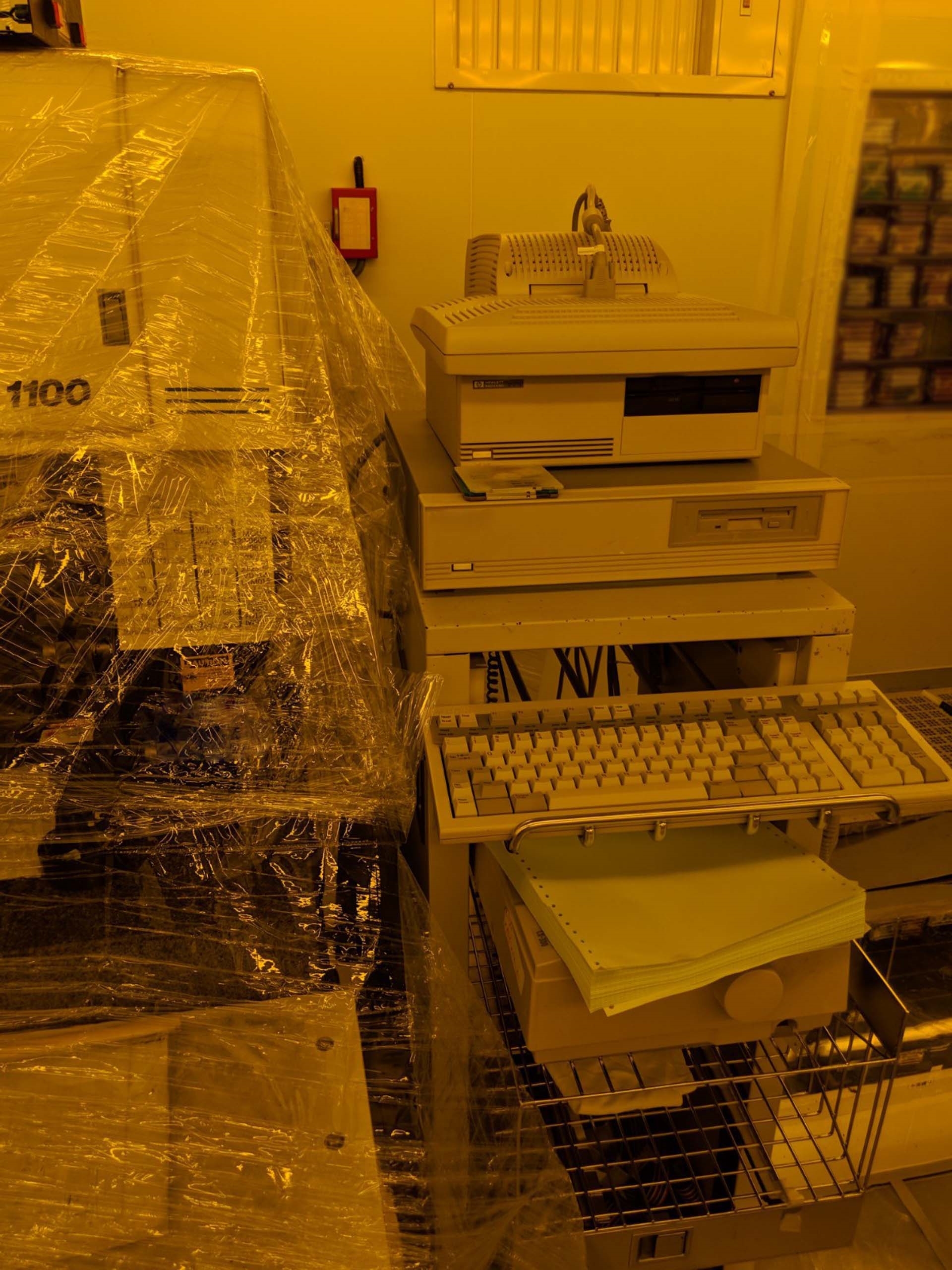

Used ULTRATECH 1100 #9227856 for sale

URL successfully copied!

Tap to zoom

ULTRATECH 1100 is a wafer stepper designed to help enhance the microelectronics industry by providing precise stepping of semiconductor wafers in order to produce integrated circuits. This powerful machine is capable of performing high-precision operations on 6-inch wafers due to its user-friendly operation, improved process control, and on-board diagnostics. This model of wafer stepper is designed with positioning accuracy of +/- 6 µm (AB) and Z-level accuracy of +/- 3 µm. It also features a temperature-controlled vacuum chuck, programmable focus, an advanced optical equipment, and a precise non-contact external Z-axis measurement system. It has several automated functions such as a wafer-to-reticle alignment, a wafer-to-reticle fetching routine, and an auto-focus routine. Additionally, it offers a user interface for cluster jobs, a computer-controlled lighting unit, and provides automated process control with on-board process monitoring. 1100 wafer stepper utilizes multiple lithographic techniques such as contact lithography, laser lithography, and Deep-UV (DUV) lithography. This allows the user to set the parameters and configurations according to their specific needs. It also uses a multi-dimensional calibration machine to ensure accuracy and repeatability, and has an exposure time of 0.2 - 10 seconds. The integrated camera tool allows the user to view the wafer in various angles and magnifications. This versatile wafer stepper has a wide range of applications in semiconductor processing and testing, including testing for chip failure, wafer thinning, the production of integrated circuits, and semiconductor device fabrication. It can also be used for laser trimming of components and for inspection and analysis. ULTRATECH 1100 runs on a powerful 3.8GHz Intel processor, and offers amazing speeds of operation with 300 MHz internal clock speed. 1100 is designed with a minimum size and weight, making it easy to integrate into a variety of settings. Its easy-to-use interface and advanced functions make it an ideal tool for those looking to produce accurate and reliable microelectronic components. With it, users can produce electrical and electronic components with precision and accuracy.

There are no reviews yet