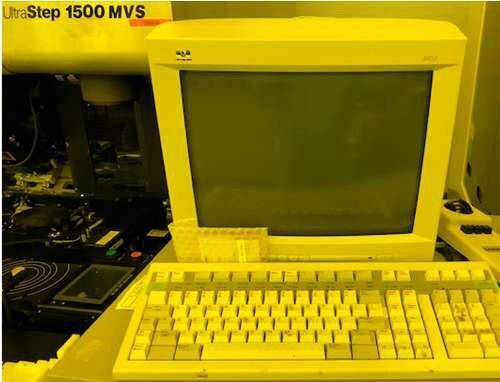

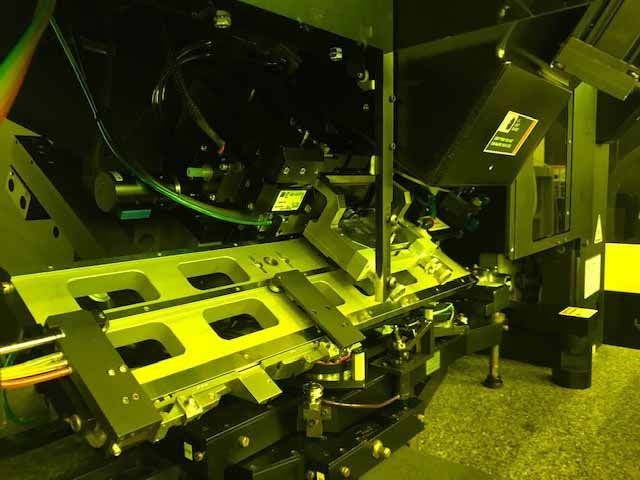

Used ULTRATECH 1500 MVS #9293528 for sale

URL successfully copied!

Tap to zoom

ID: 9293528

Wafer Size: 6"

Vintage: 2000

Stepper, 6"

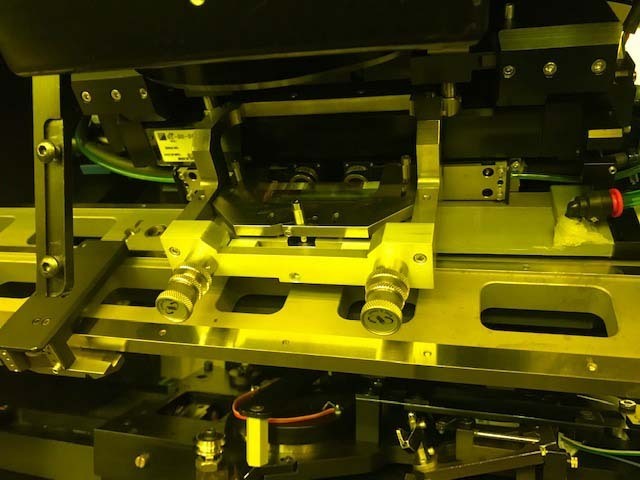

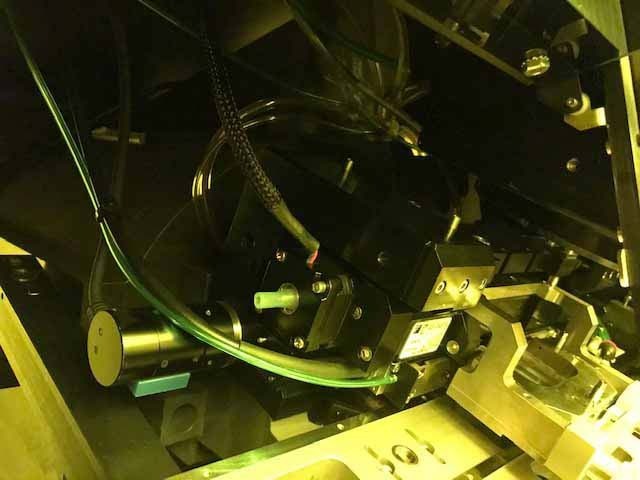

Stage type:

SERVO Driven X and Y

Stepper motor driven in theta

Multi-axis air bearings

Laser metered

Laser resolution: 40 nm

Vibration control: Isolated granite table

Computer:

HP 362 Controller

Graphics monitor

Enclosed impact printer

Wafer handling:

Cassette to cassette autoloader

Manual loader / Robotic loader

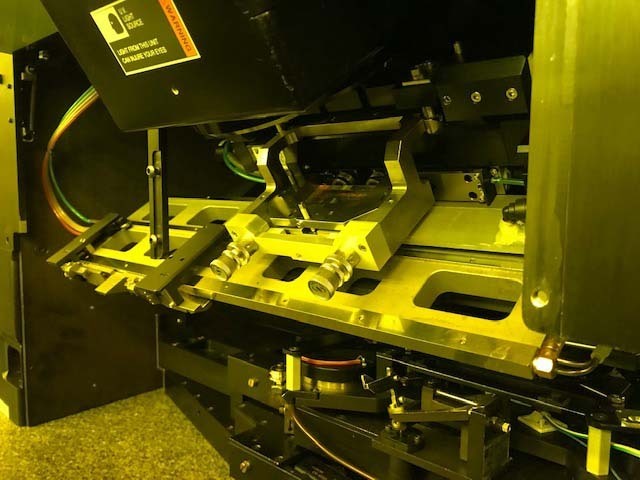

Imaging and lens (1.0 µm):

Resolution: 1.0 µm

CD Control: 0.9 ≤ CD ≤ 1.1 µm

DOF: > 3.0 µm

Lens distortion: ≤ 160 nm, 100%

Lens matching (A-B): ≤ 180 nm, 100%

Maximum image area: 34.2 x 13.6 mm

Longest rectangle: 39.0 x 11.4 mm

Largest square: 18.0 x 18.0 mm

Exposure spectrum: 390-450 nm

Imaging and lens (0.8 µm):

Resolution: 0.8 µm

CD Control: 0.72 ≤ CD ≤ 0.88 µm

DOF: > 2.0 µm

Lens distortion: ≤ 110 nm, 100%

Lens matching (A-B): ≤ 130 nm, 100%

Maximum image area: 31.80 x 11.5 mm

Longest rectangle: 34.0 x 10.0 mm

Largest square: 15.5 x 15.5 mm

Exposure spectrum: 390-450 nm

Exposure (1.0 µm and 0.8 µm):

Uniformity: 3.0%, 2.5%

Wafer plan irradience: ≥1000 wM/cm²

2000 vintage.

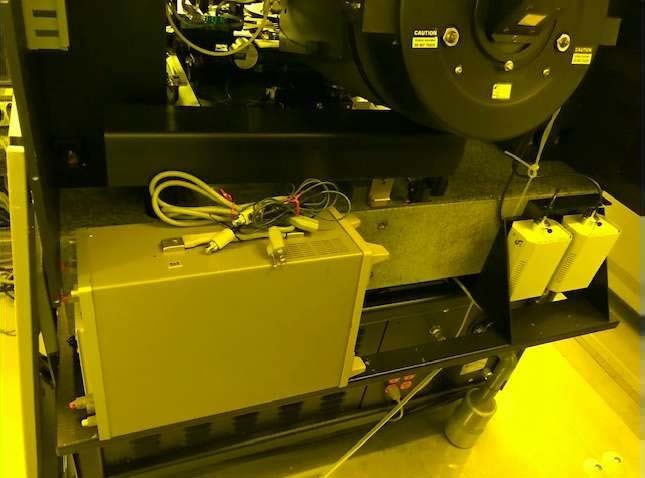

ULTRATECH 1500 MVS (Micro-atmosphere Vacuum Stepper) is a high performing wafer stepper designed for photoresist applications. This advanced equipment is designed to provide precise alignment and placement of high-resolution photoresists and features advanced imaging and alignment capabilities. It is suitable for advanced lithography applications, including deep-UV and EUV resists. 1500 MVS operating environment is isolated from the outside atmosphere by a series of sealed chambers. Its temperature, pressure, and humidity within the chambers are preset to the optimal lithography conditions. This vacuum environment ensures the highest level of exposure precision while reducing unwanted defects such as scorch marks and streaks. ULTRATECH 1500 MVS features an Advancers Guide System (AGS), which provides automatic focusing, registration, and alignment control. This unit supports wafer alignment errors as small as 0.7 microns and precise depth-of-focus control. It also includes a Built-in Light-Curve Detection Gaussian measurement machine to ensure the best image quality and lithography results. 1500 MVS features a Prodigy Controllers Tool and TrueMVS Advanced Acquisition software. This software is designed for fast and flexible integration of imaging and optical data into the asset. It supports up to four layers, a variety of imaging methods, and almost any step and repeat procedure. It also supports the ability to review and compare results from different scans and exposure processes, providing a quick overview of exposure effects. ULTRATECH 1500 MVS is designed to handle any wafer sizes up to 8 inches. This stepper has a maximum scanning speed of 40 mm/s, ensuring high productivity in both production and research applications. An automated beam-size recognition feature is also included to automatically adjust the exposure parameters for optimal imaging. 1500 MVS is a top of the line, advanced wafer stepper designed to provide the highest resolution images for lithography processes. It is equipped with advanced stepper features, sophisticated control and image-processing capabilities, and extremely precise alignment and stability. It is the perfect choice for production and research facilities that need precise, consistent exposure results.

There are no reviews yet