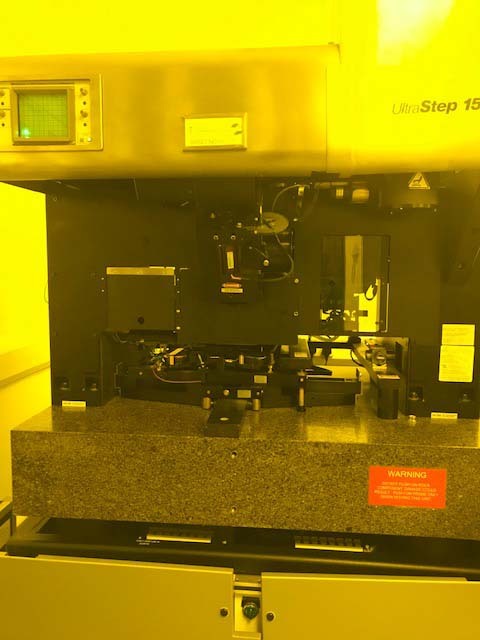

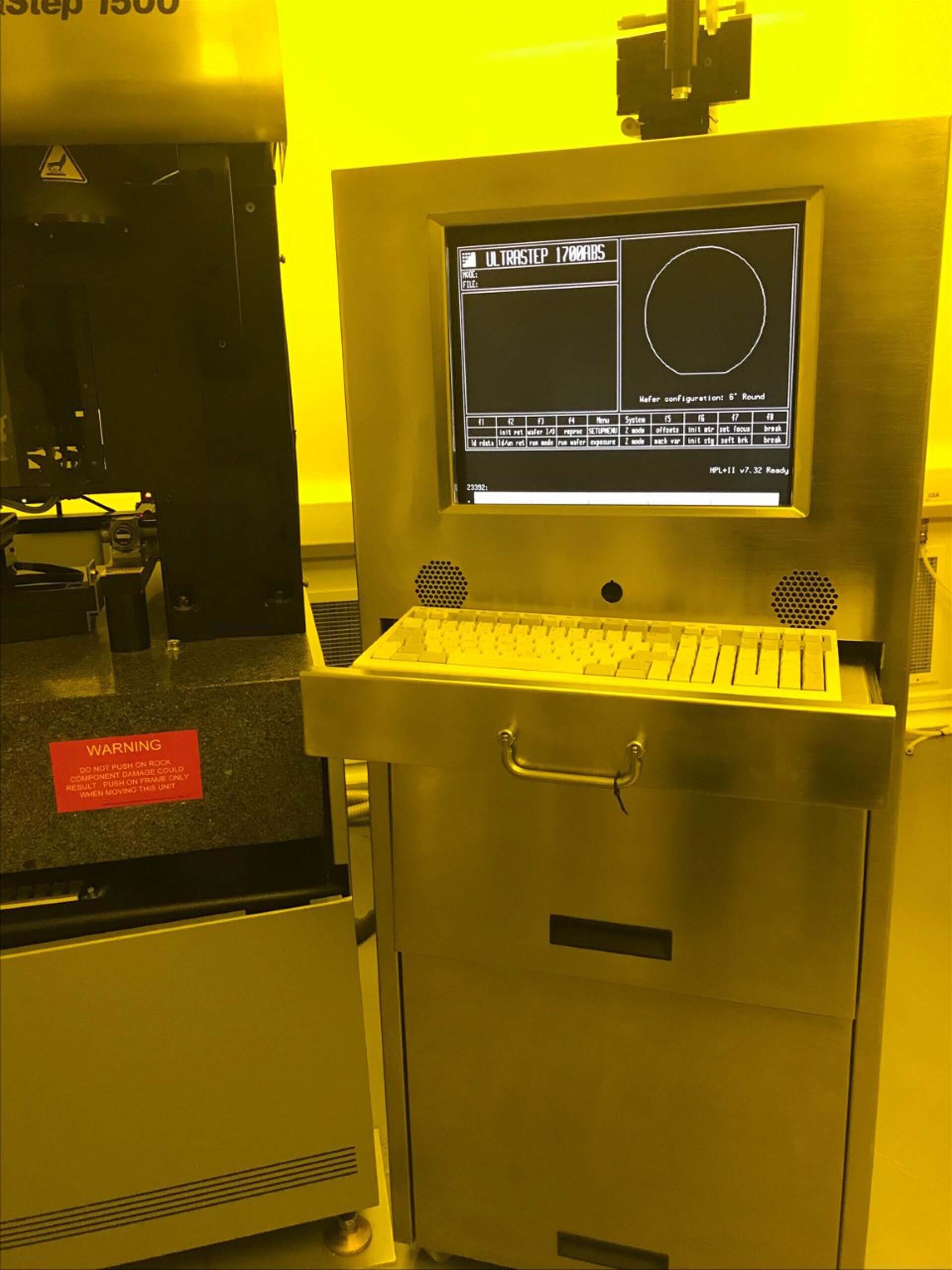

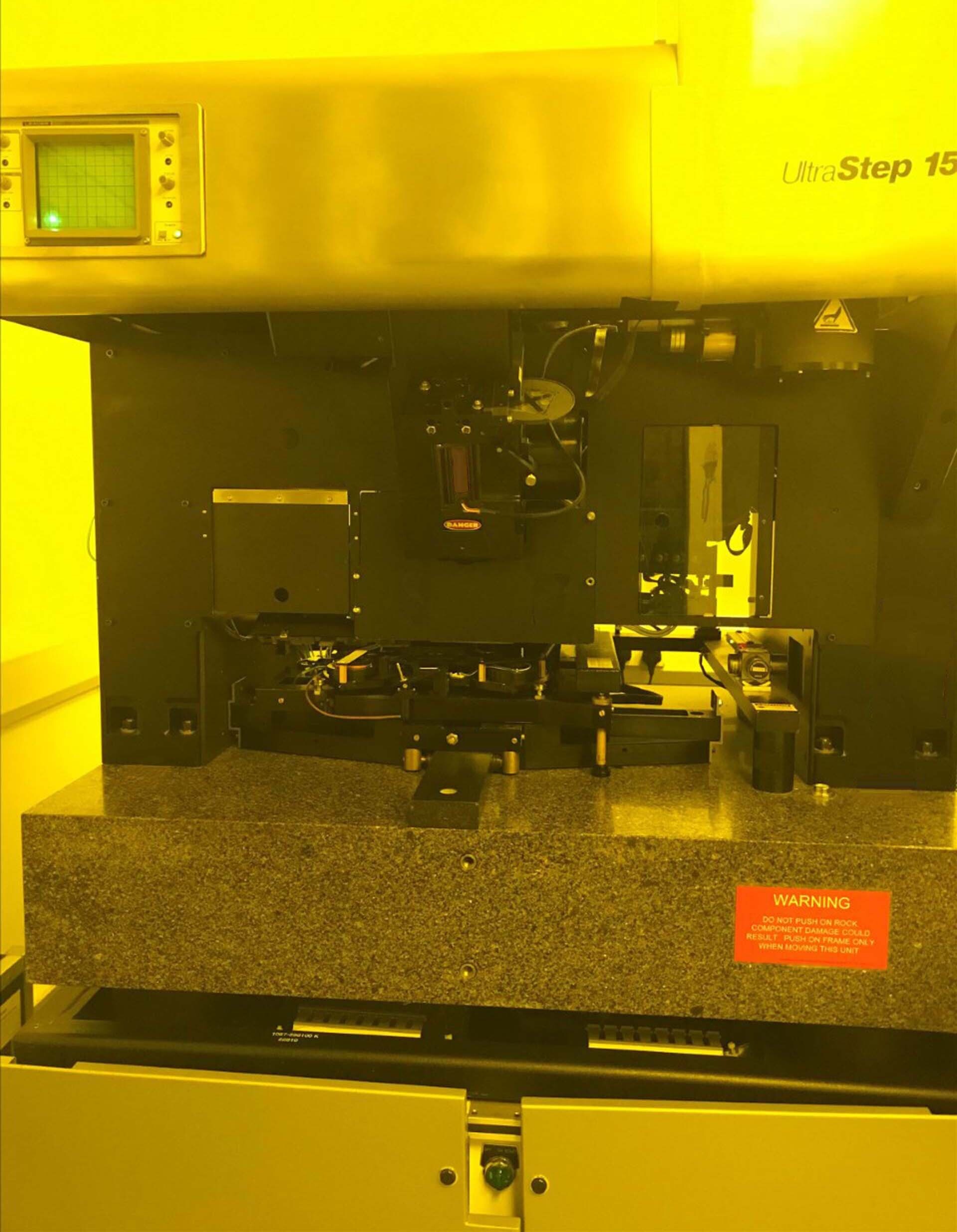

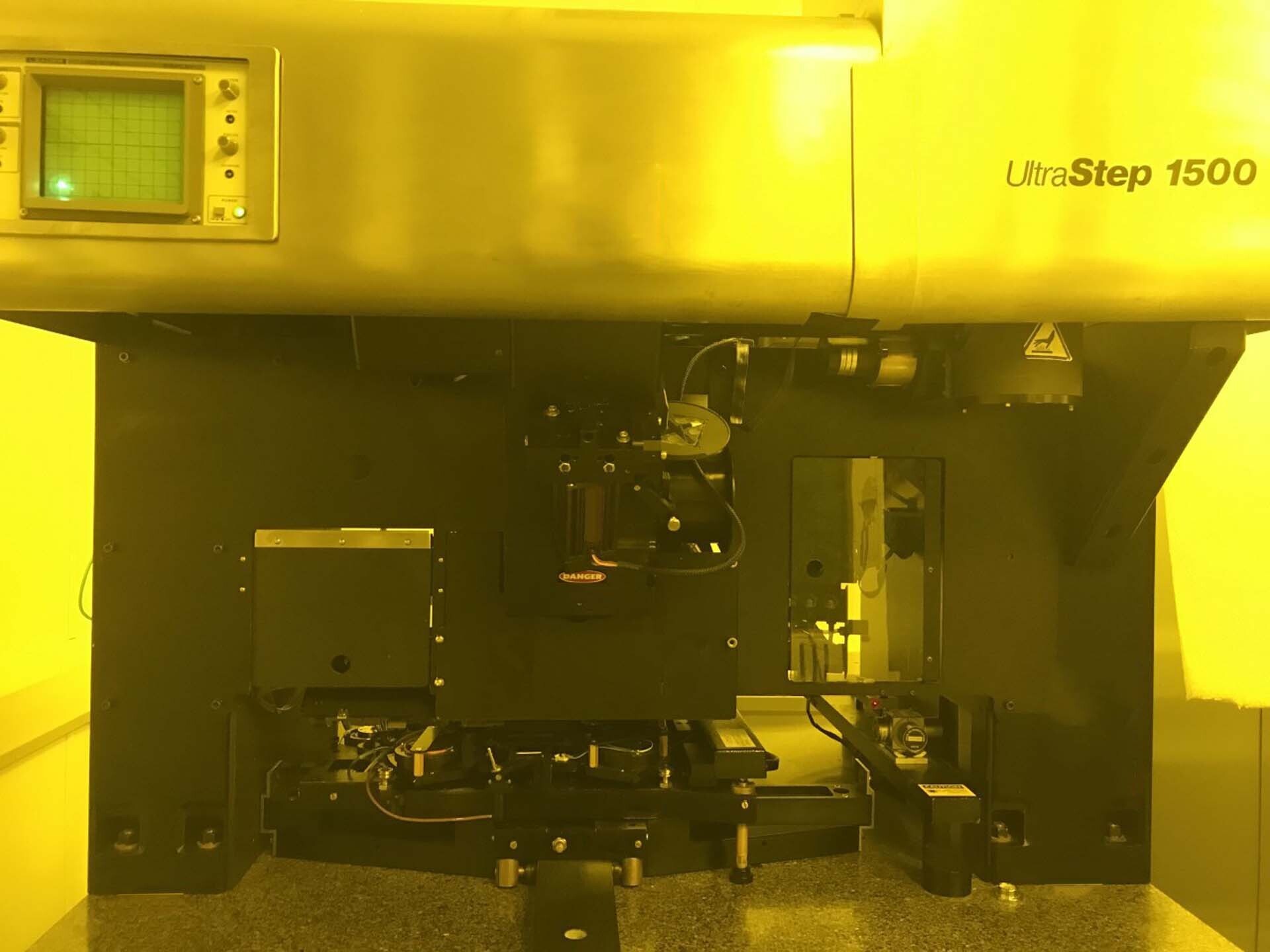

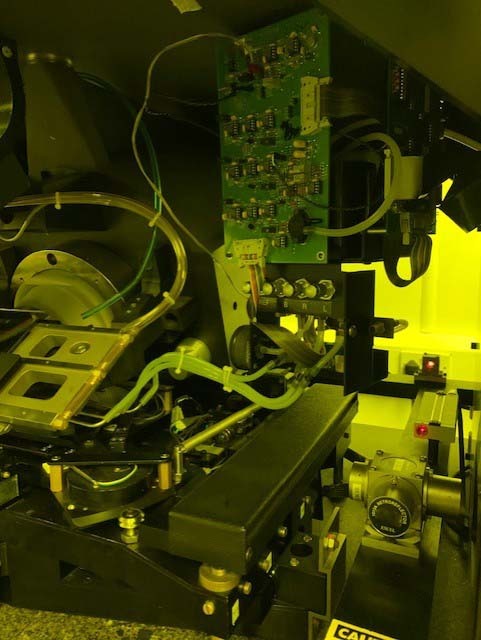

Used ULTRATECH 1500 WAS #9293282 for sale

URL successfully copied!

Tap to zoom

ID: 9293282

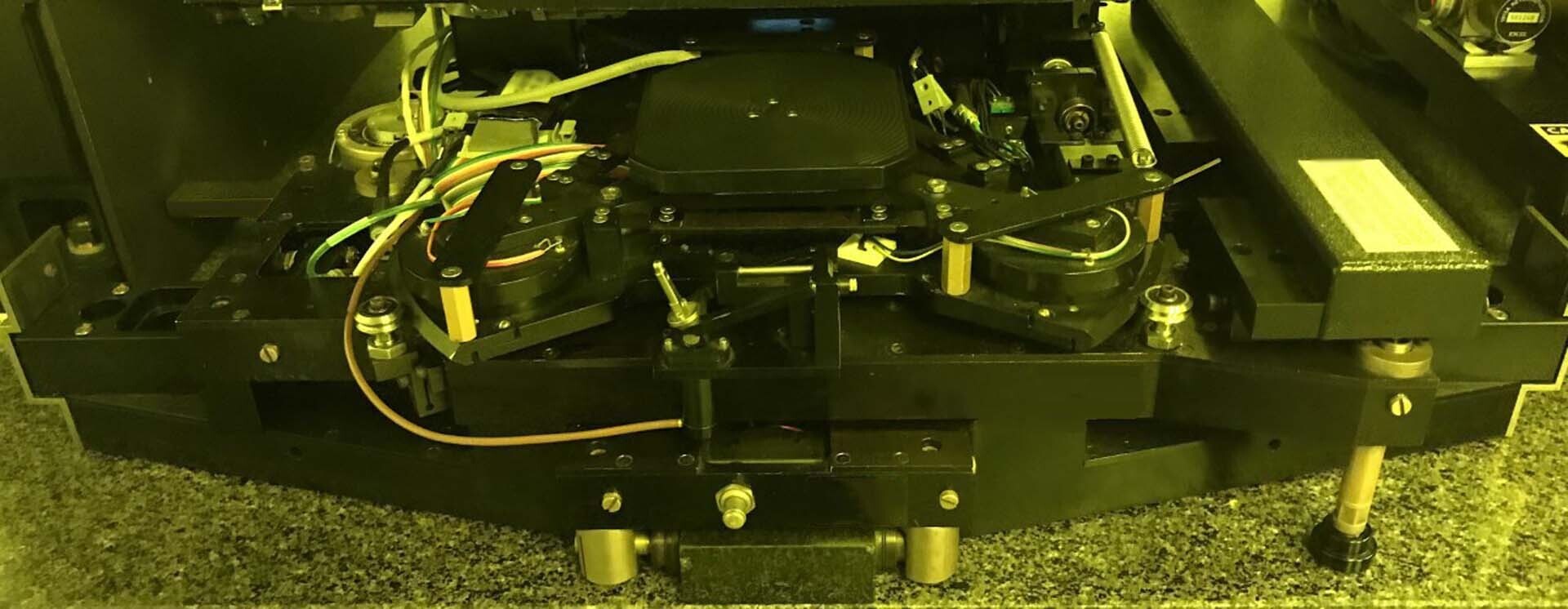

Wafer Size: 6"

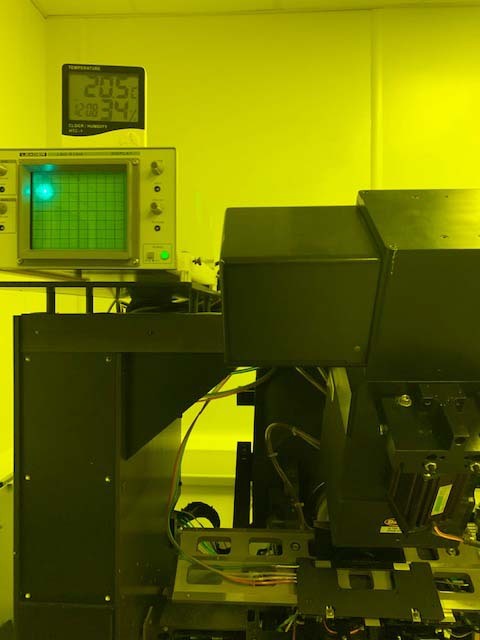

Vintage: 2007

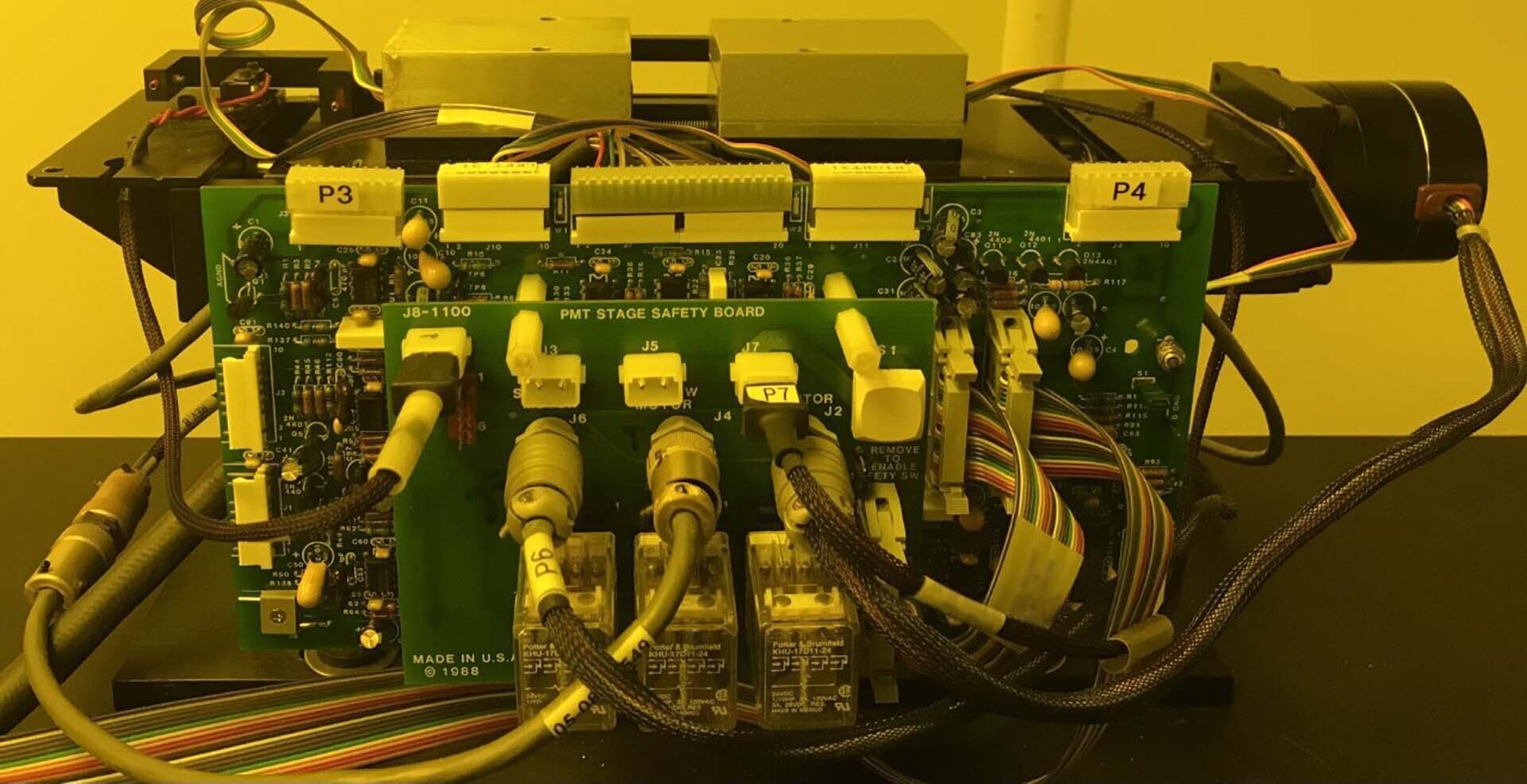

Stepper, 6"

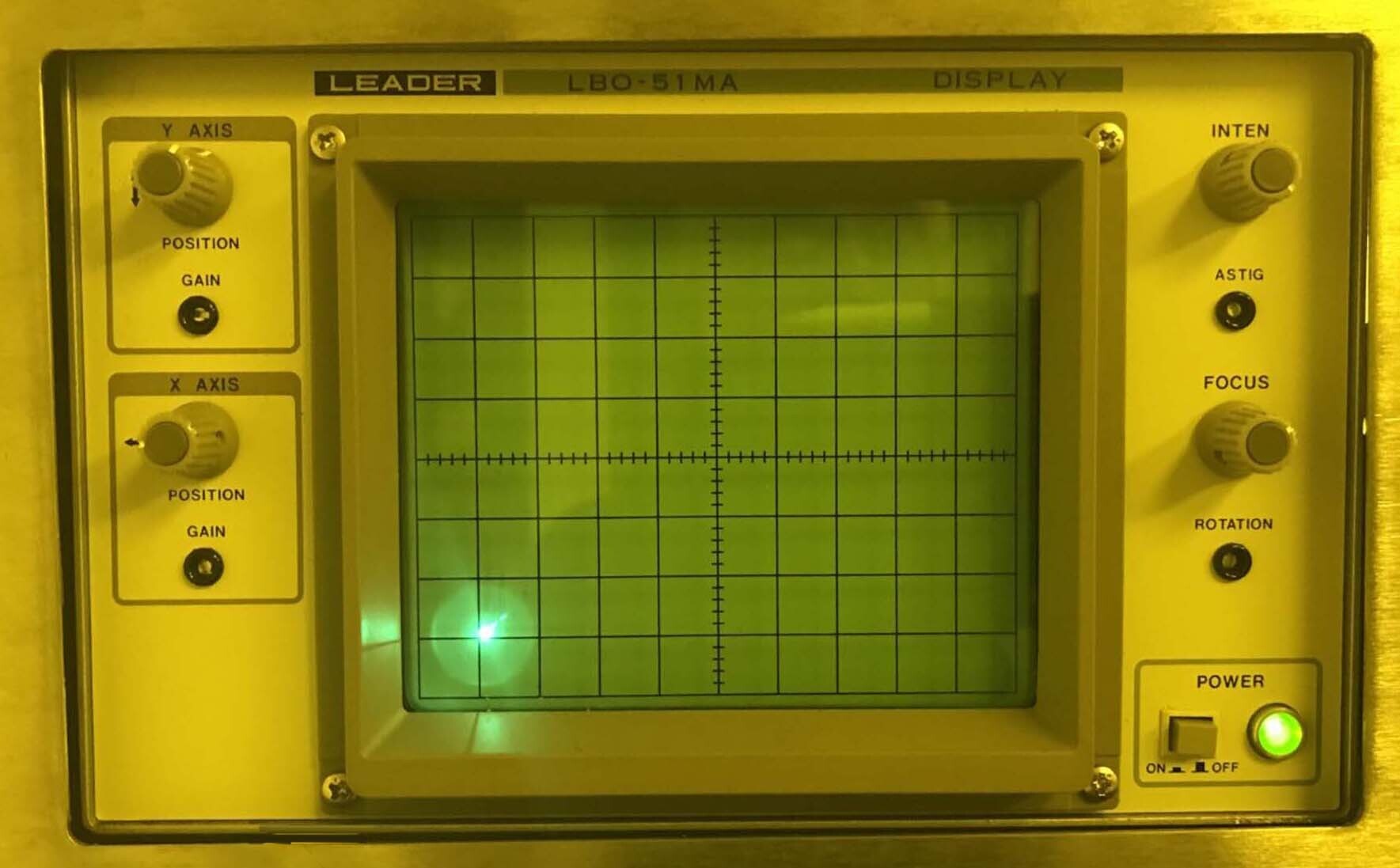

WAS Alignment can be upgrade to MVS

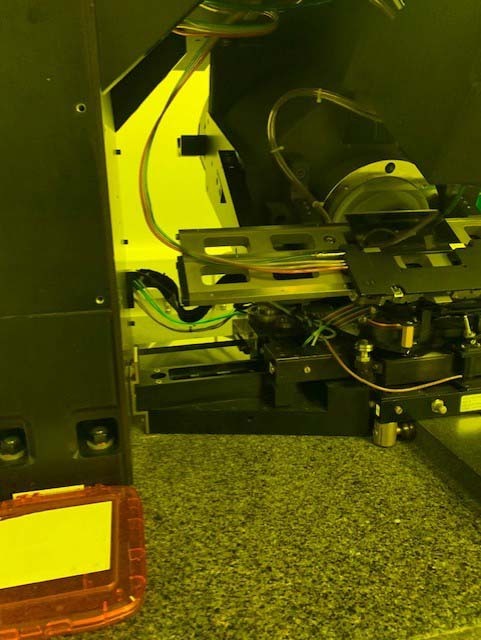

Wafer autoloader can be upgraded to TAZMO Loader

Reticle: 3x5 converted to 5x5

2007 vintage.

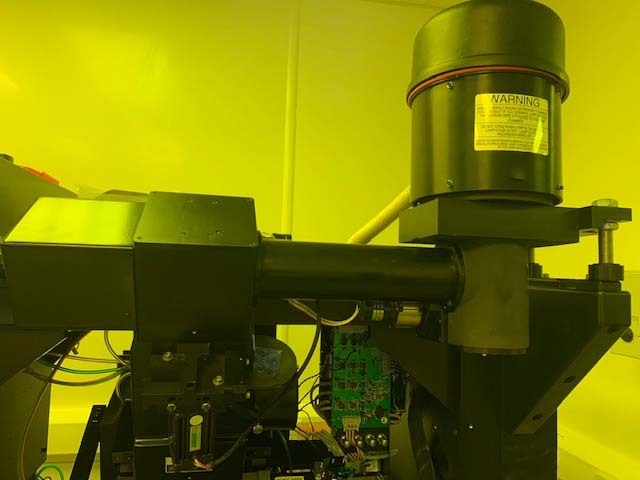

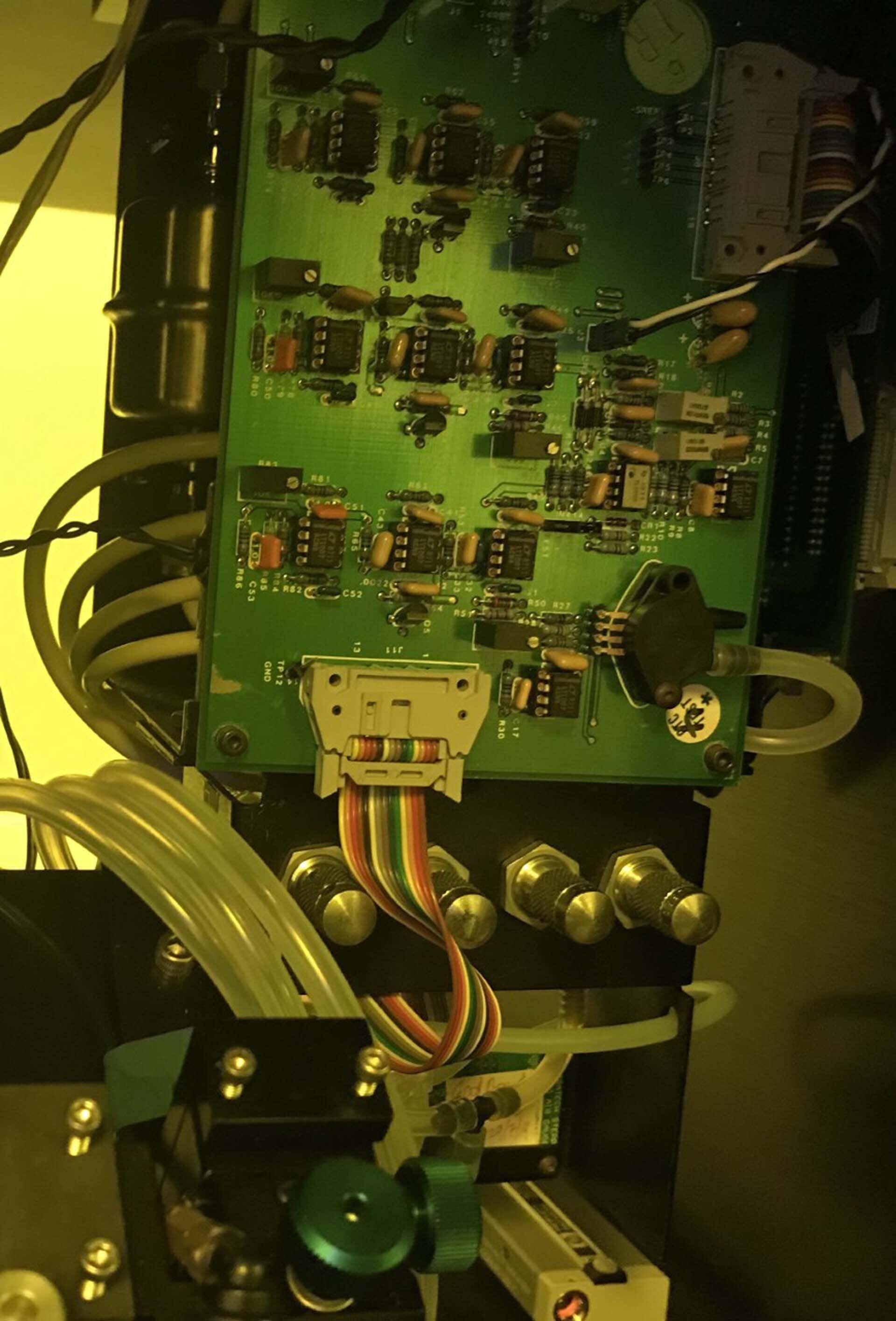

ULTRATECH 1500 WAS is an advanced wafer stepper designed for high-performance semiconductor integration processes. This wafer stepper offers an automated method for accurately and quickly patterning multiple semiconductor layers with nanometer resolution. Its patented technology utilizes integrated Direct Scanning Technology (DST) to produce semiconductor chips with extremely precise features and minimal space waste. 1500 WAS features a high-resolution automated patterning equipment capable of processing patterns with 0.6 μm pitch and beyond. It is equipped with a high-resolution optical system with adjustable zoom that allows for auto-focusing and magnification up to twenty times. The stepper is capable of constant trajectory scanning and multiple exposures. This ensures that the resulting pattern is accurately duplicated across chips with small size variations. It also allows for faster process times, and eliminates the need for costly adjustments or costly retools. ULTRATECH 1500 WAS is highly adjustable, and its high-speed logic architecture is adjustable for coarse and fine motions. Its data input architecture is automated, allowing for faster and more accurate data input to improve process throughput. This advanced stepper scans pattern data with nanometer-level accuracy, resulting in superior process performance. 1500 WAS also boasts an advanced cooling unit that maintains the optimal temperature necessary for wafer processing. The machine is also equipped with a vibration isolation platform that provides users with a low-noise process environment. This tool also houses advanced diagnostic tools to troubleshoot any issues experienced during the process. ULTRATECH 1500 WAS is capable of operating in the full range of integrated process options, including photolithography, hard etching, and wafer inspection. It is also capable of integrating other process technologies, such as jump wire bonding and a variety of lithographic front-end equipment. These integrated process options, along with its advanced features, make 1500 WAS an ideal solution for high-end semiconductor integration processes.

There are no reviews yet