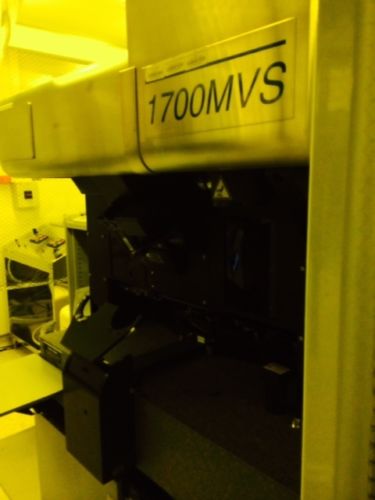

Used ULTRATECH 1700 MVS #9131885 for sale

URL successfully copied!

Tap to zoom

ULTRATECH 1700 MVS, manufactured by ULTRATECH, is a high-performance wafer stepper designed for the production of advanced semiconductor devices. It is targeted at a wide range of users—from chip manufacturers to packaging engineers. 1700 MVS incorporates many advanced features, such as advanced CCD (Charge Coupled Device) patterning, motion control, digital imaging, and automated alignment, in order to deliver superior optical performance. ULTRATECH 1700 MVS is equipped with an inertial equipment for motion control and digital imaging that allows for accurate and precise alignment of devices under test on the wafer. For greater control and accuracy, the system offers sub-micron silicon wafer positioning and a dual-axis tilt for improved optical accuracy. The unit's pattern alignment accuracy is high enough to achieve alignment of production IC features. In addition to providing accurate pattern alignment, 1700 MVS also features advanced CCD-based imaging and patterning techniques. This includes automatic feature and edge recognition, as well as overlay optimization. The machine can also be used for photo-aligning of wafer edges, which is particularly useful for wafer-to-wafer processing. In terms of workflow, ULTRATECH 1700 MVS is designed to reduce machine set-up time and maximize tool throughput. The asset offers fast wafer loading times, with advanced wafer clamping routines and multiple wafer sizes and configurations. It also provides automated, manual, or combined mode loading and unloading. For further efficiency, the model provides a built-in vision-controlled manual override, plus an intuitive visual display for 3-PI scanning. In summary, 1700 MVS is a powerful and versatile wafer stepper designed for production of advanced IC devices. It combines advanced motion control, CCD imaging and patterning, together with workflow automation, allowing users to achieve superior performance levels and fast throughput. Its range of features and configuration options make the equipment suitable for use in a variety of applications, from automation to packaging.

There are no reviews yet