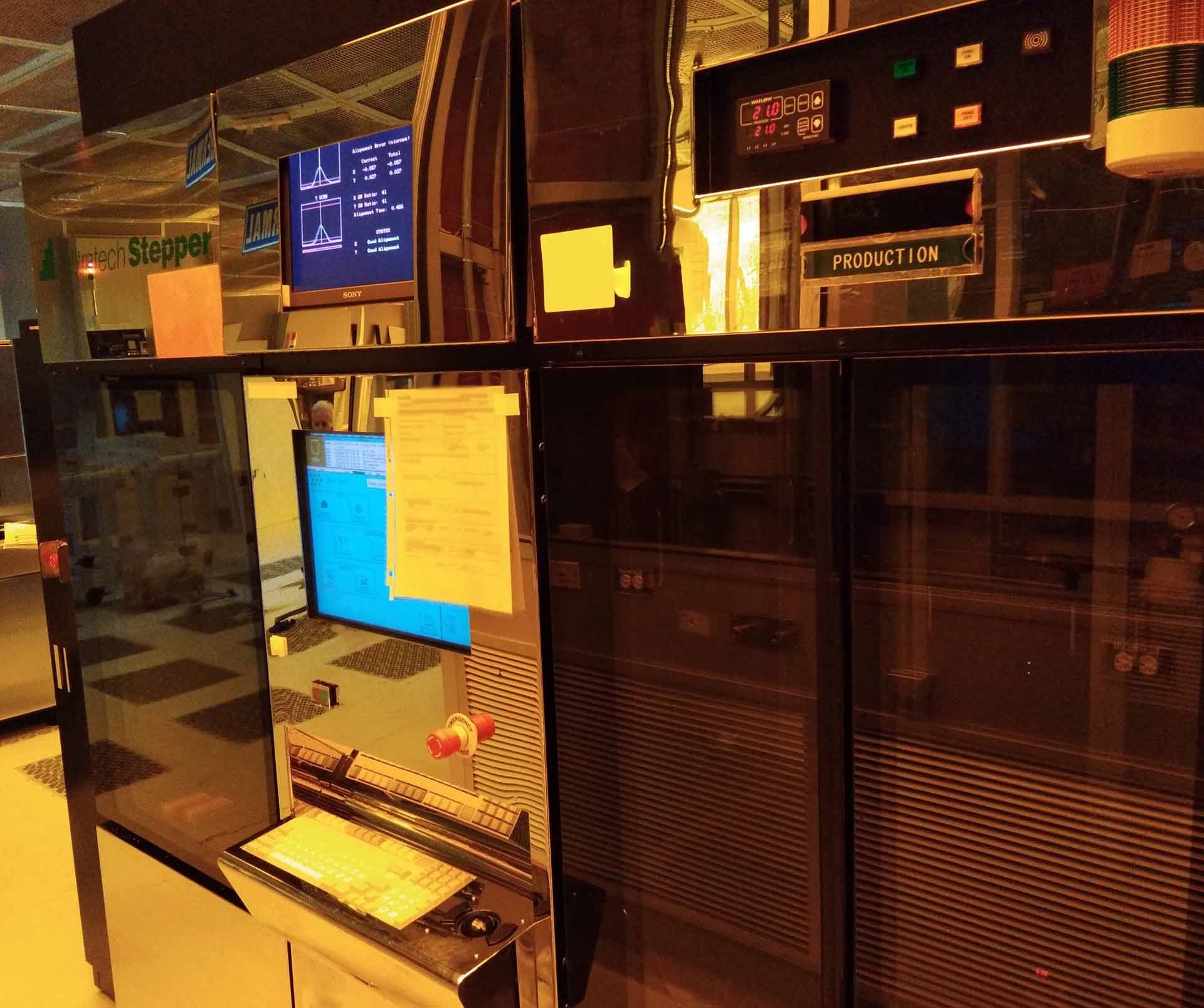

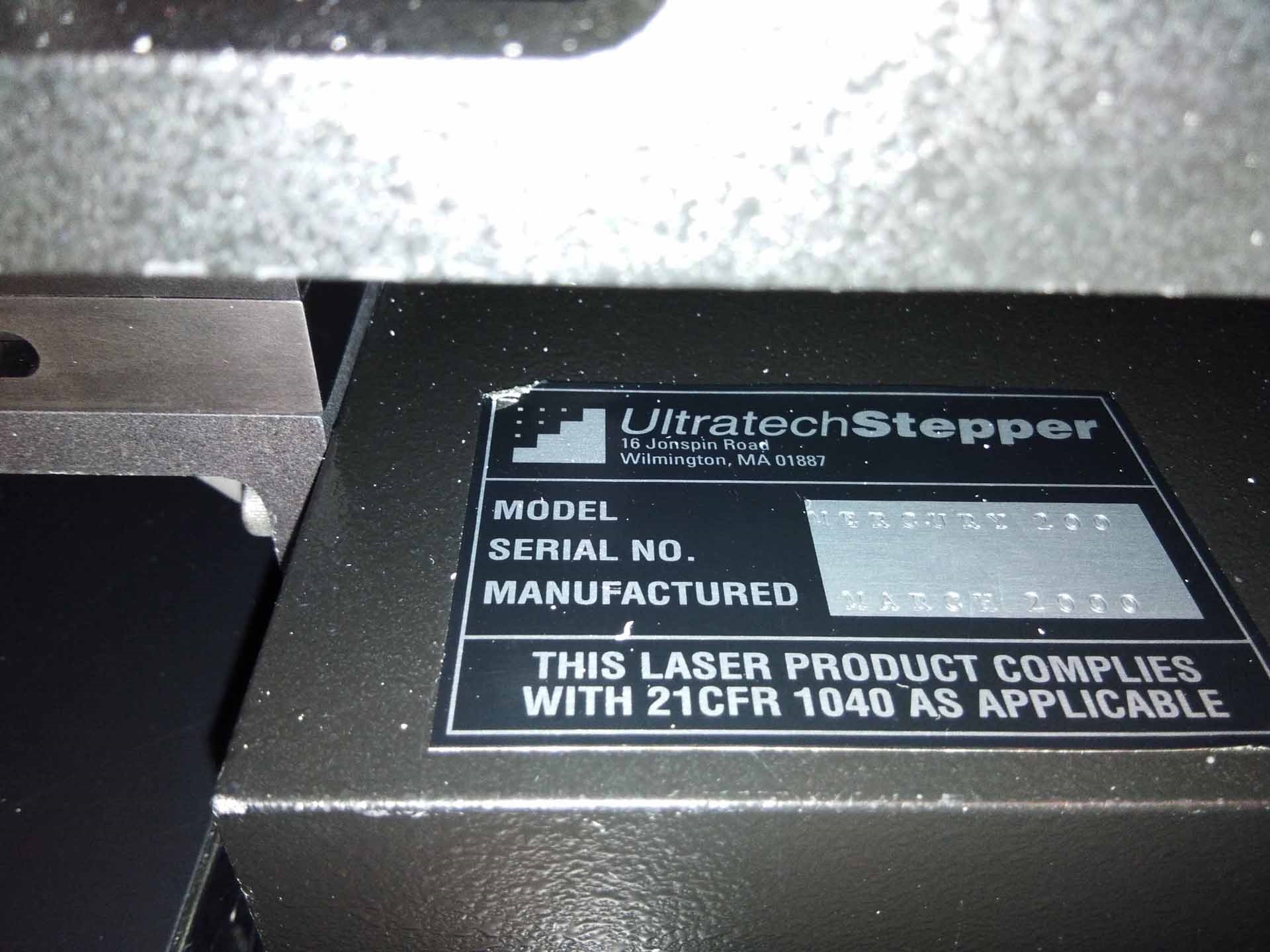

Used ULTRATECH Mercury XLS 200 #9228468 for sale

URL successfully copied!

Tap to zoom

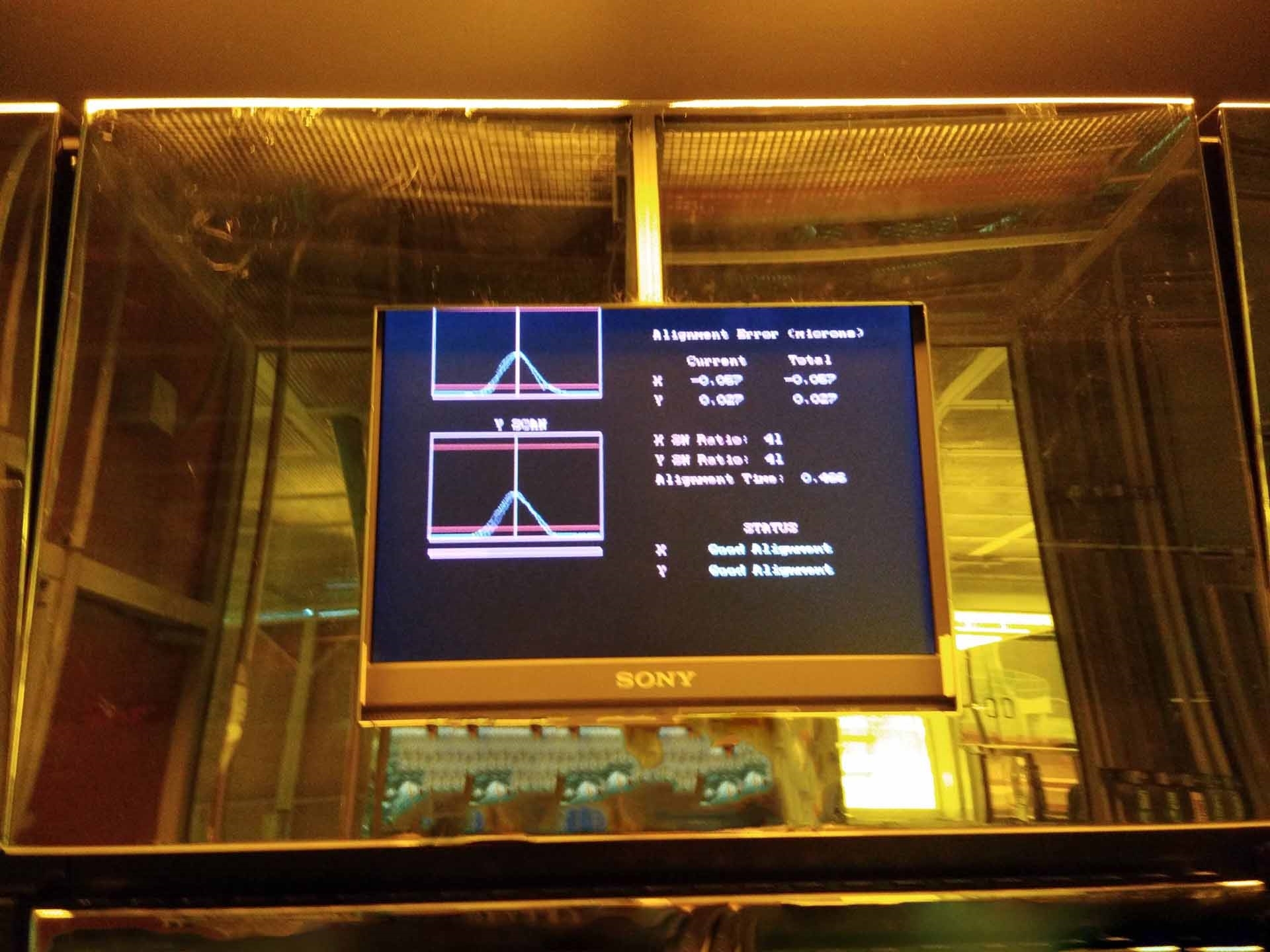

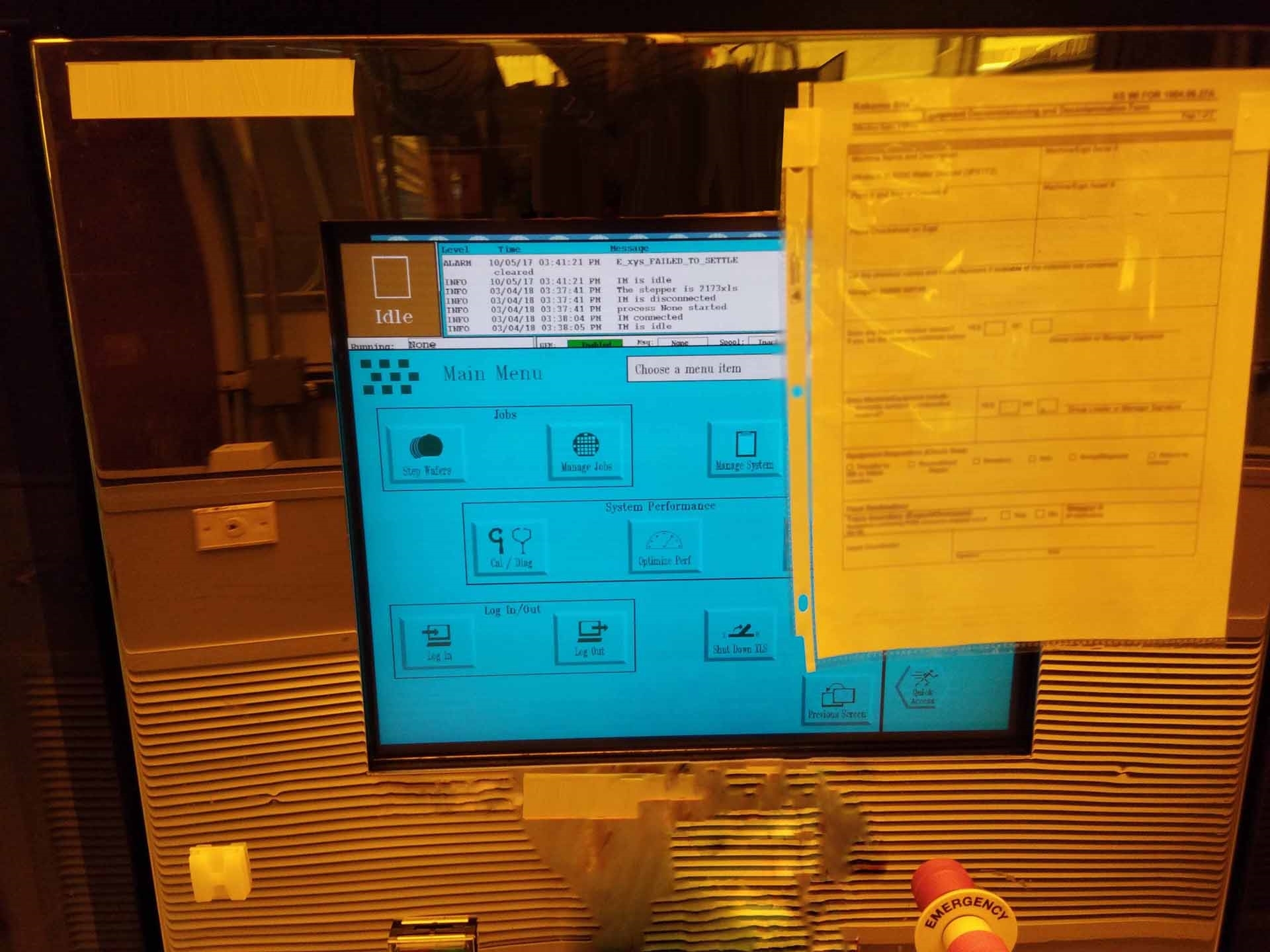

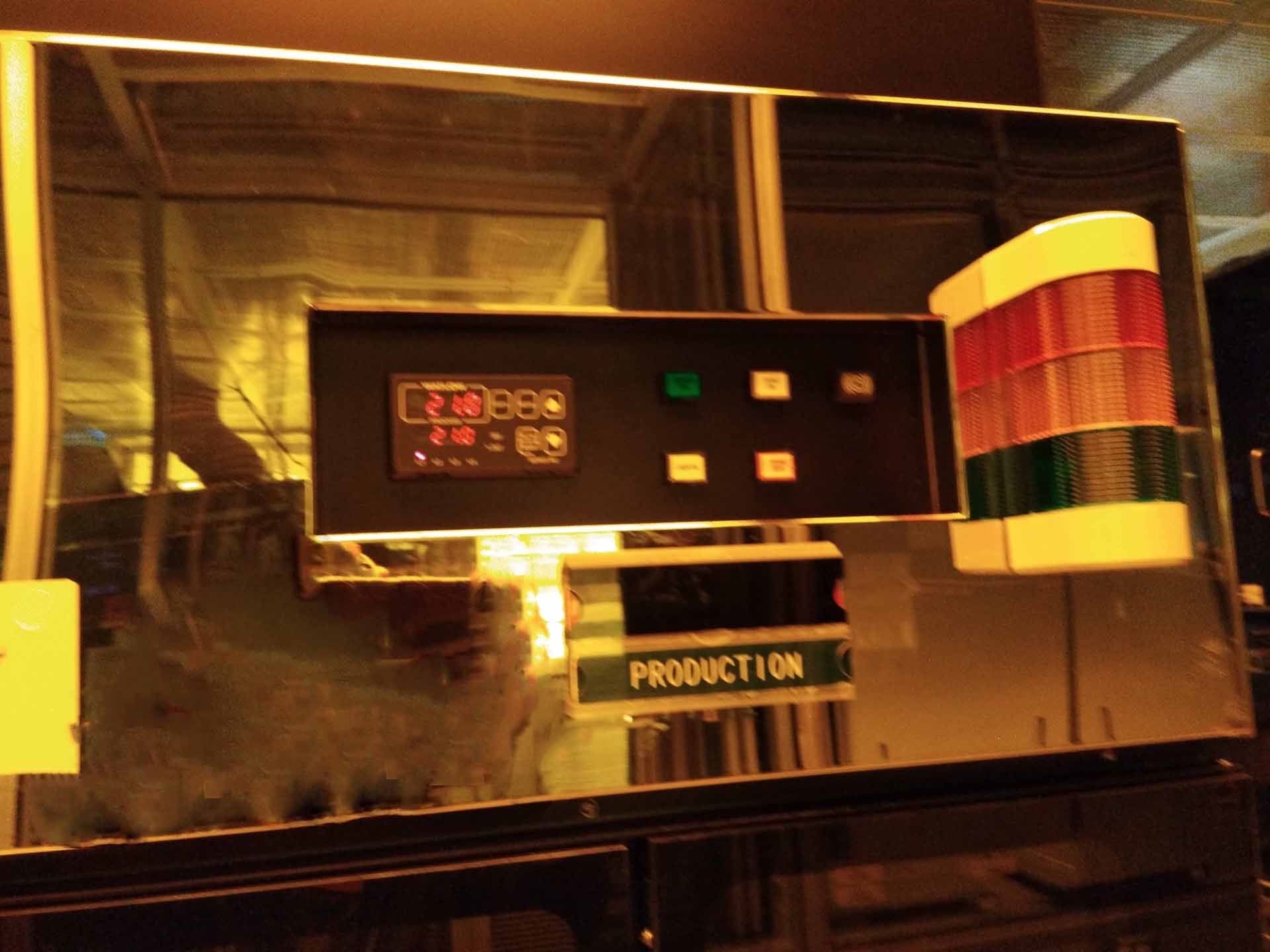

ULTRATECH Mercury XLS 200 Wafer Stepper is a high-performance lithography tool that allows manufacturers to create high-precision chip patterns for advanced semiconductor fabrication processes. The XLS 200 incorporates advanced features that allow it to deliver superior pattern printing accuracy and high throughput. The equipment is built on ULTRATECH advanced imaging technology, including its FiestoLVDS multi-level imaging platform and Beamblanker electronic shutter. These technologies result in precise imaging and improved beam-exposure stability. The system also features thermally stable imaging optics for optimal performance and pattern placement accuracy. This advanced technology allows the XLS 200 to produce images with high resolution, low line widths, and high overlay accuracy. The XLS 200 uses a dual-beam architecture with separate, independently controlled columns for exposing. This modular design enables higher throughput and improved performance. Additionally, the platform includes a 5-axis stage for accurate alignment of masks and wafers during the exposure process. The XLS 200 also features a flexible and expandable architecture providing the ability to integrate advanced processes and options. This includes optional lithography features such as SmartSource, Focal-Depth, Multi-Level, Multi-Patterning, Polarity, and Low Dynamics. This allows the user to customize their processes and achieve higher yields with fewer iterations. The XLS 200 is designed to reduce development costs by streamlining the unit calibration process. It includes quick-to-measure laser height and focus systems that save time and reduce operator intervention. Additionally, the machine includes a removable calibrator board for automated calibration. Incorporating leading-edge technologies, Mercury XLS 200 Wafer Stepper is an ideal solution for advanced semiconductor manufacturing applications. It delivers superior performance, improved yield production, and cost savings through streamlined calibration and improved throughput.

There are no reviews yet