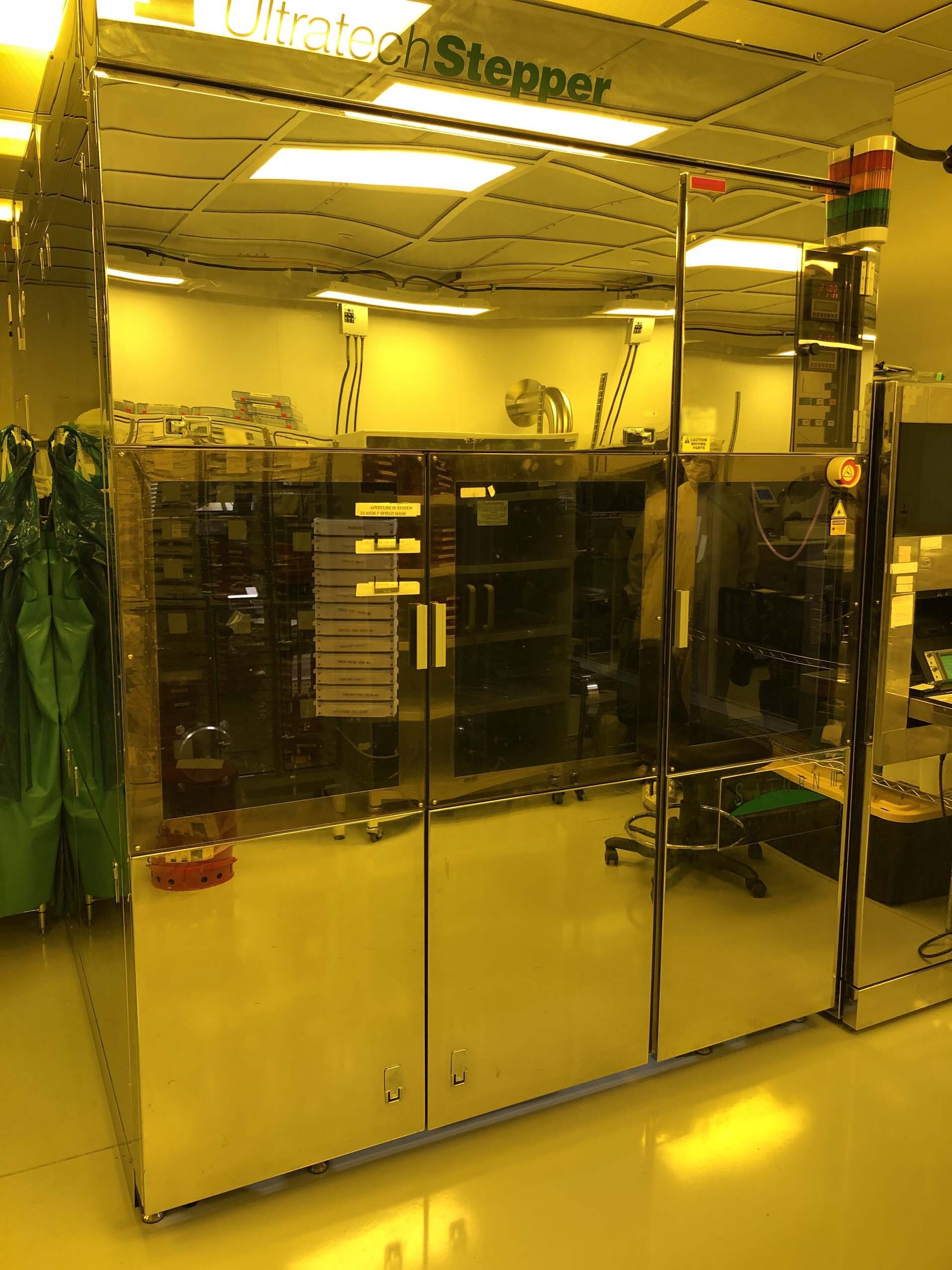

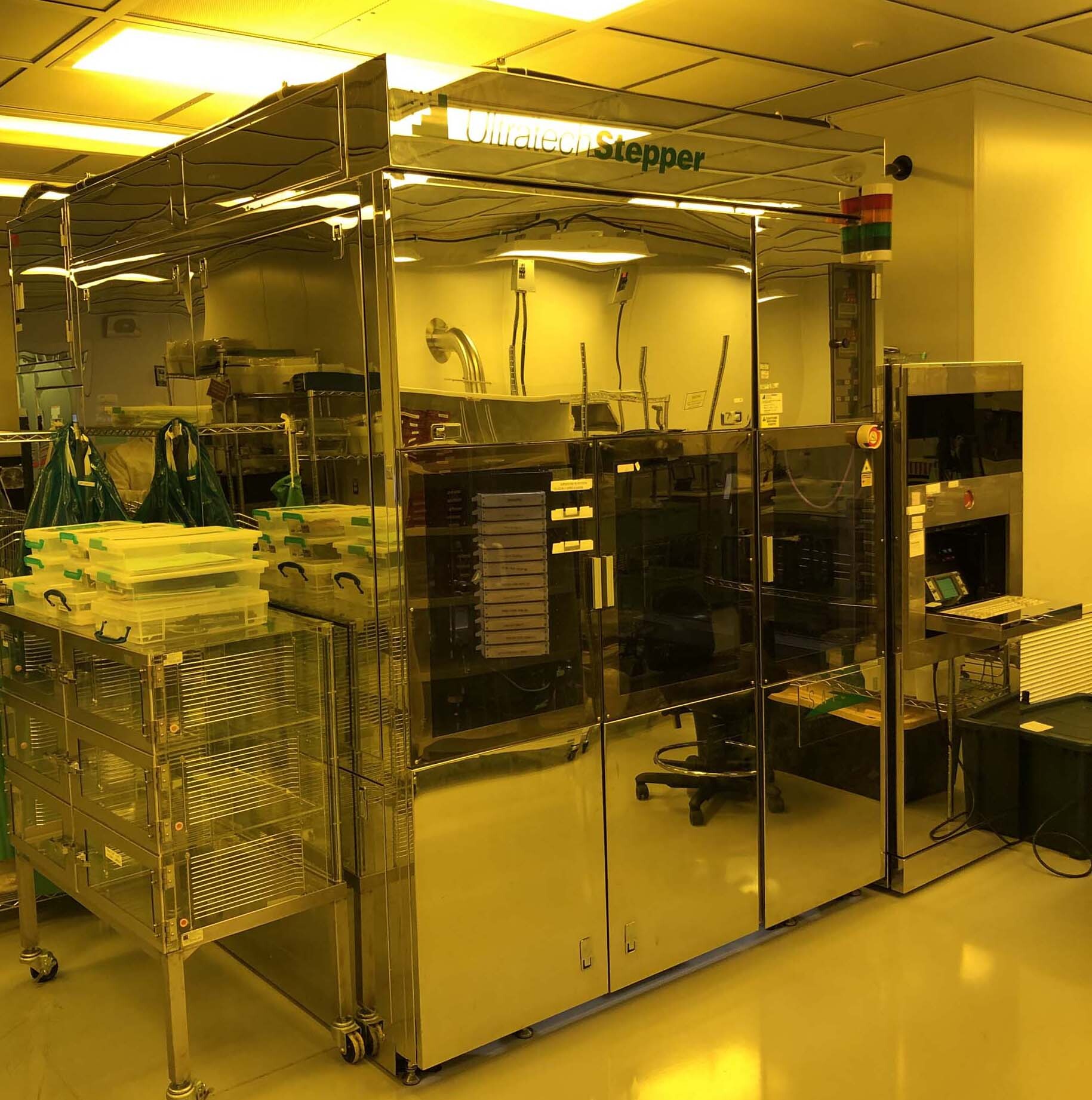

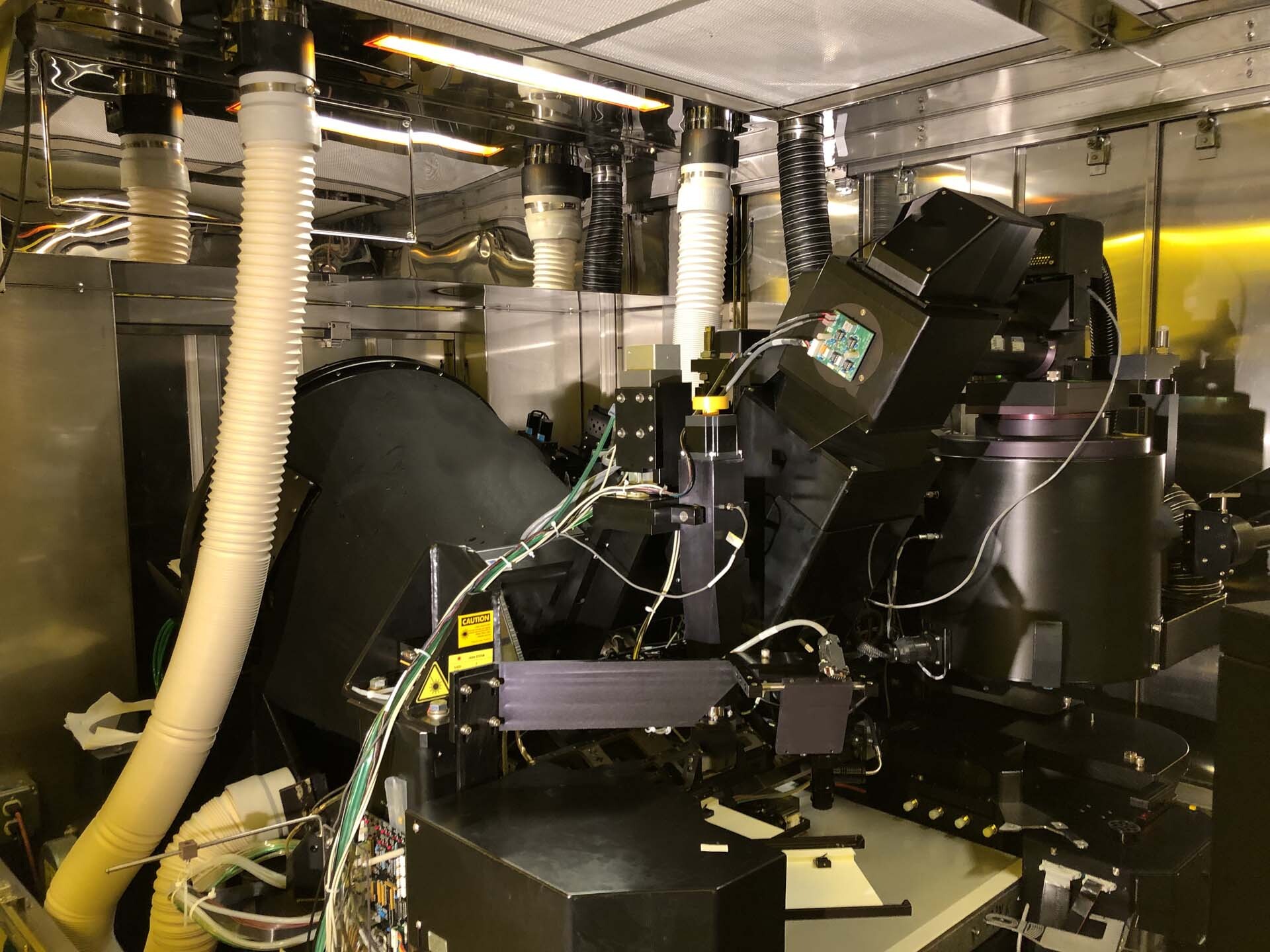

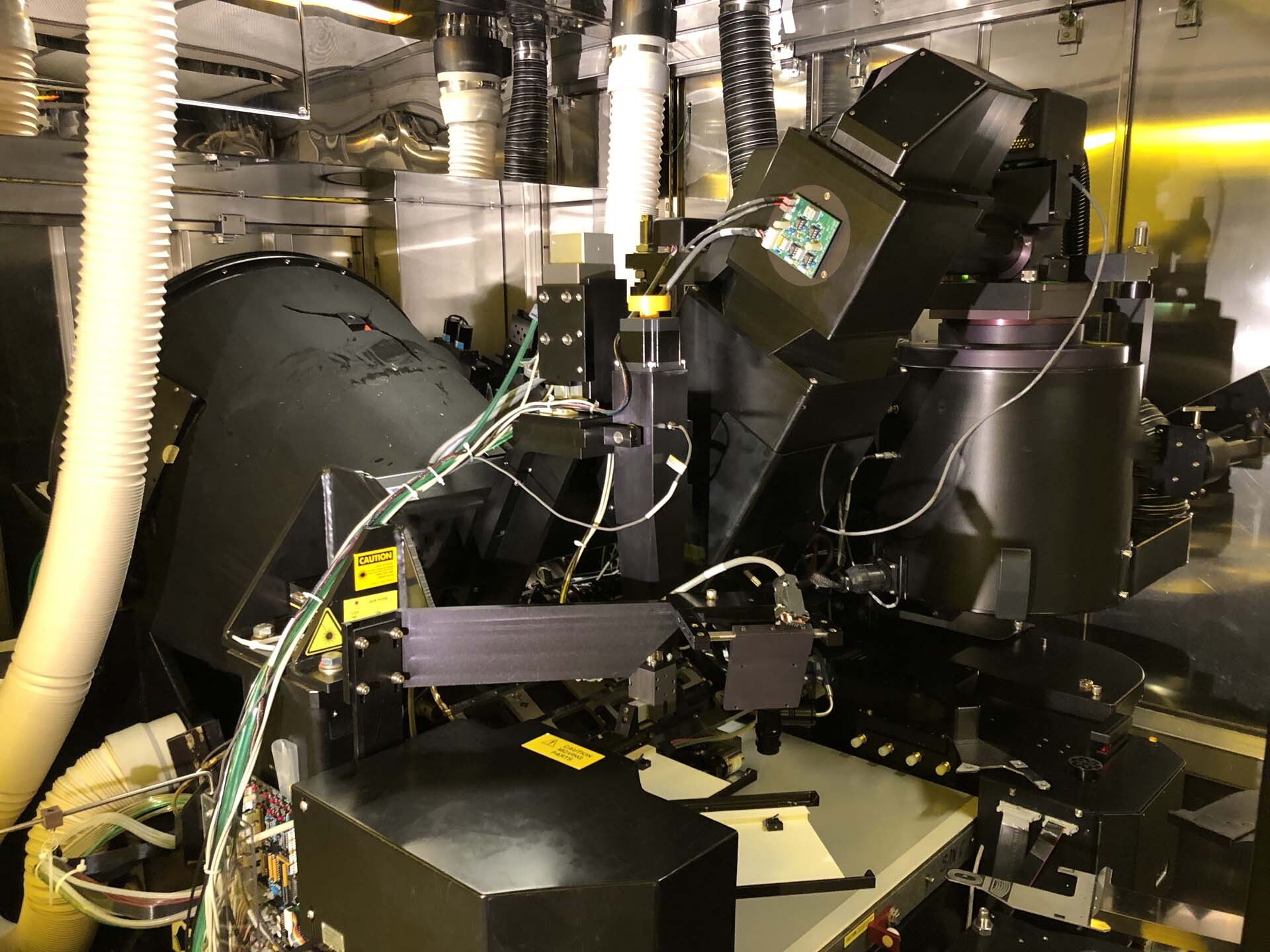

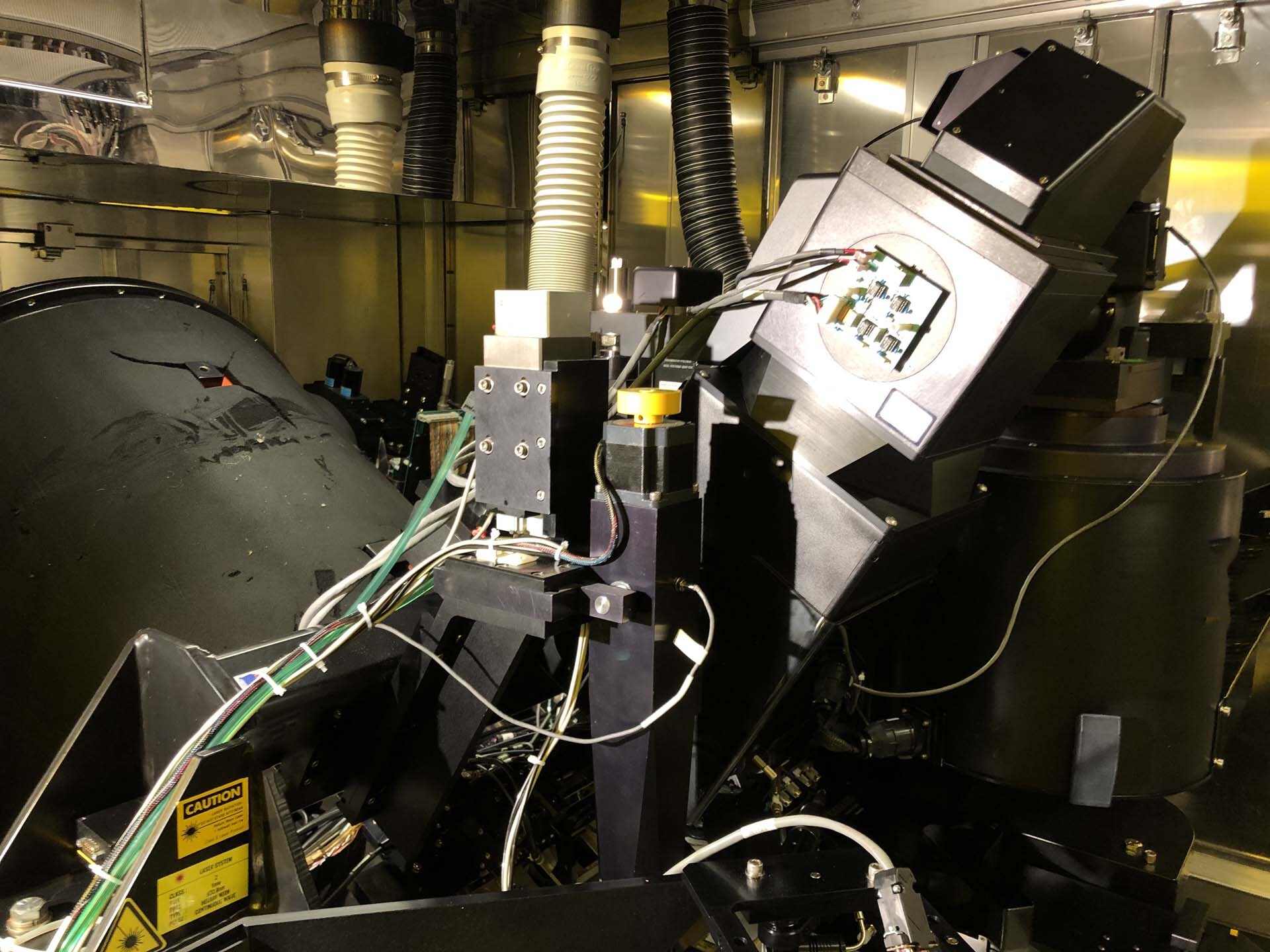

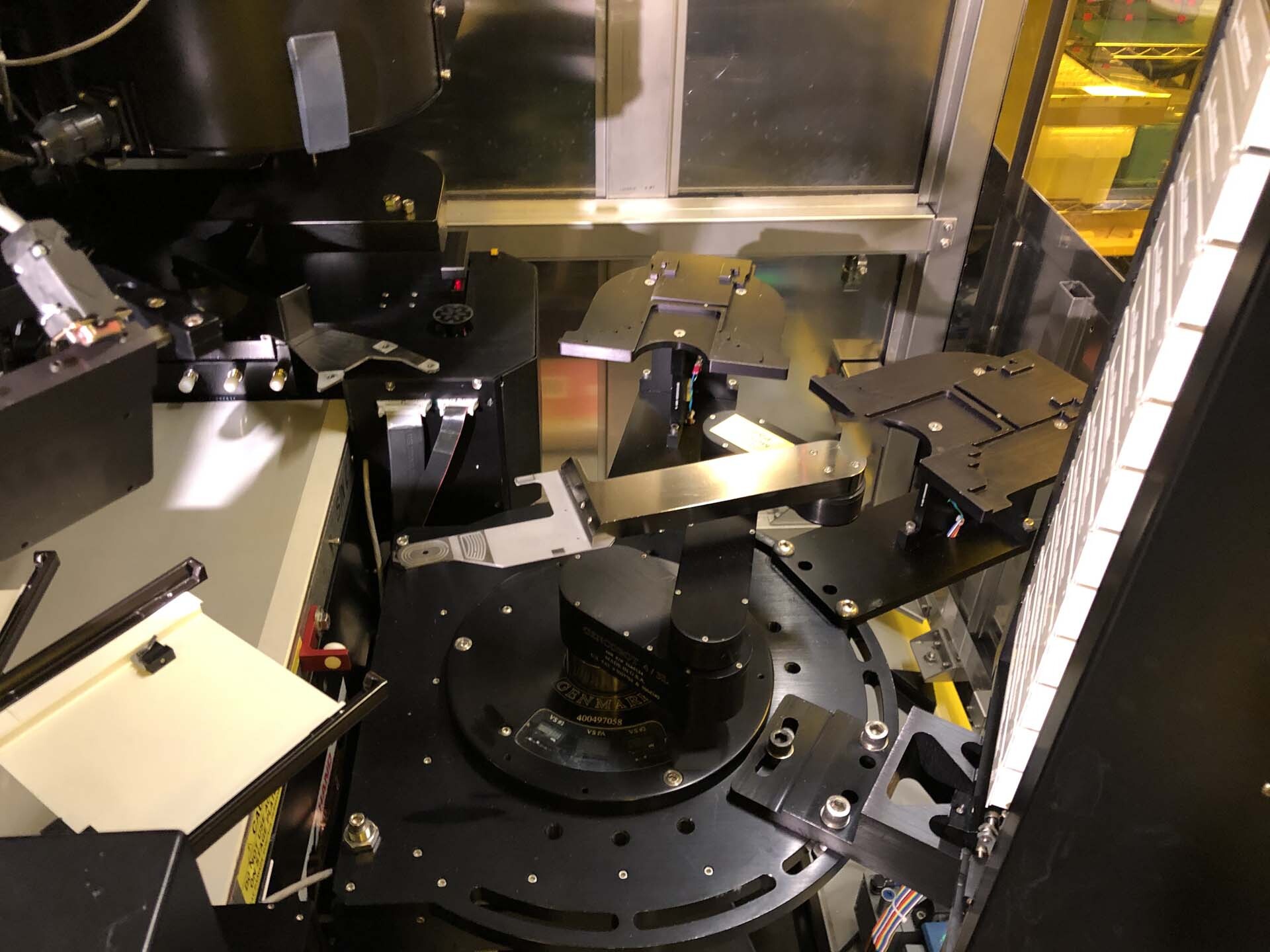

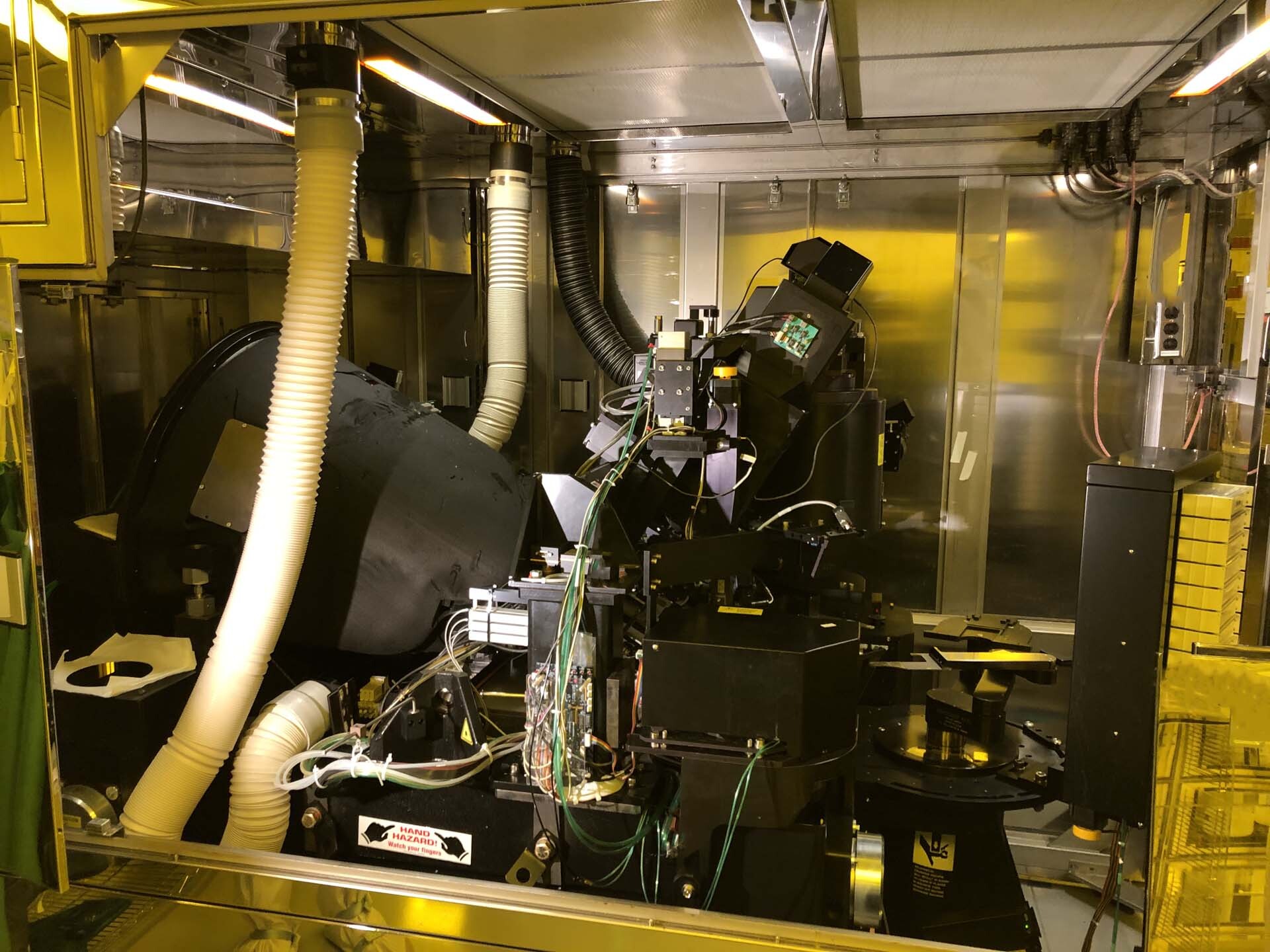

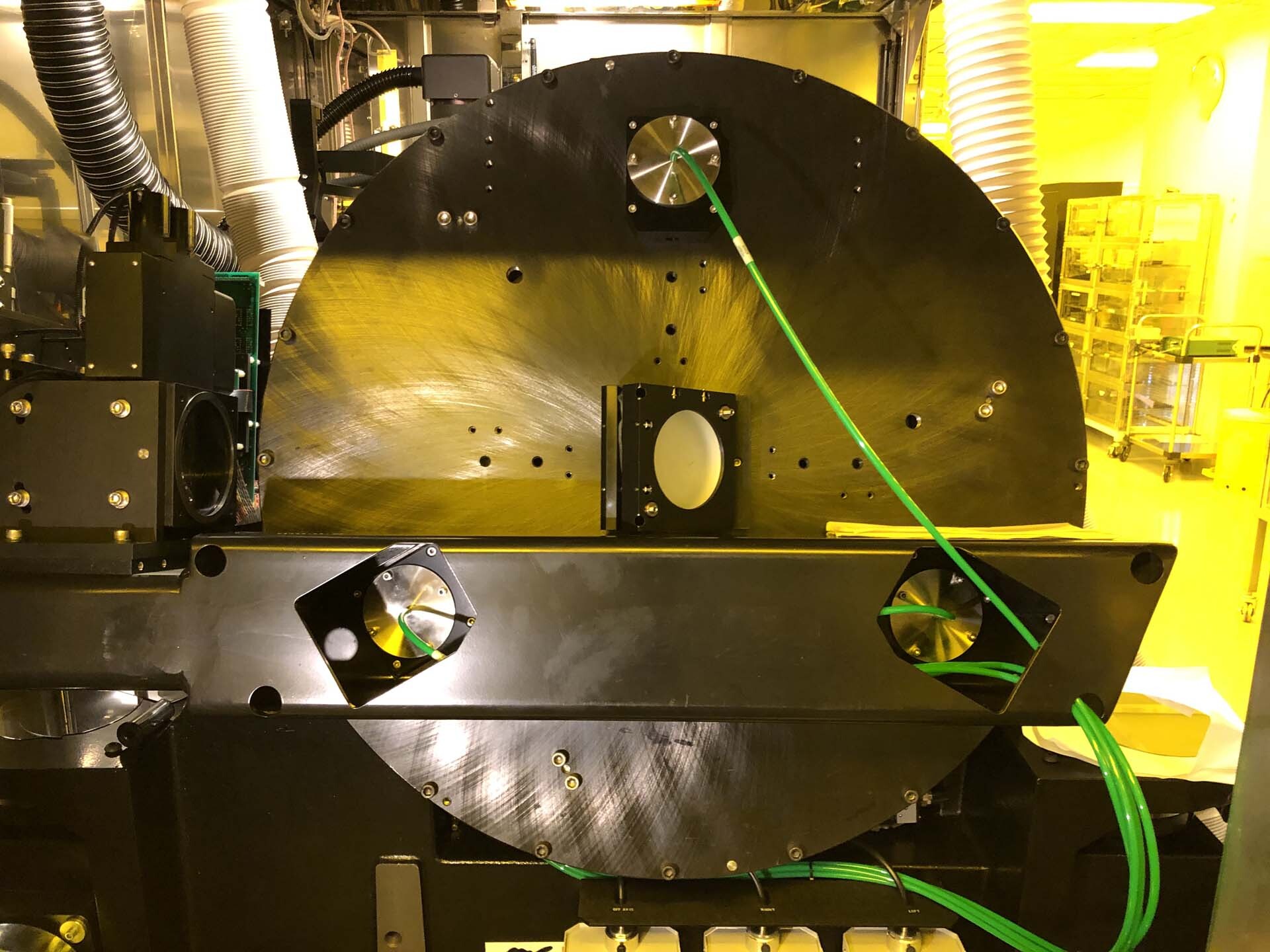

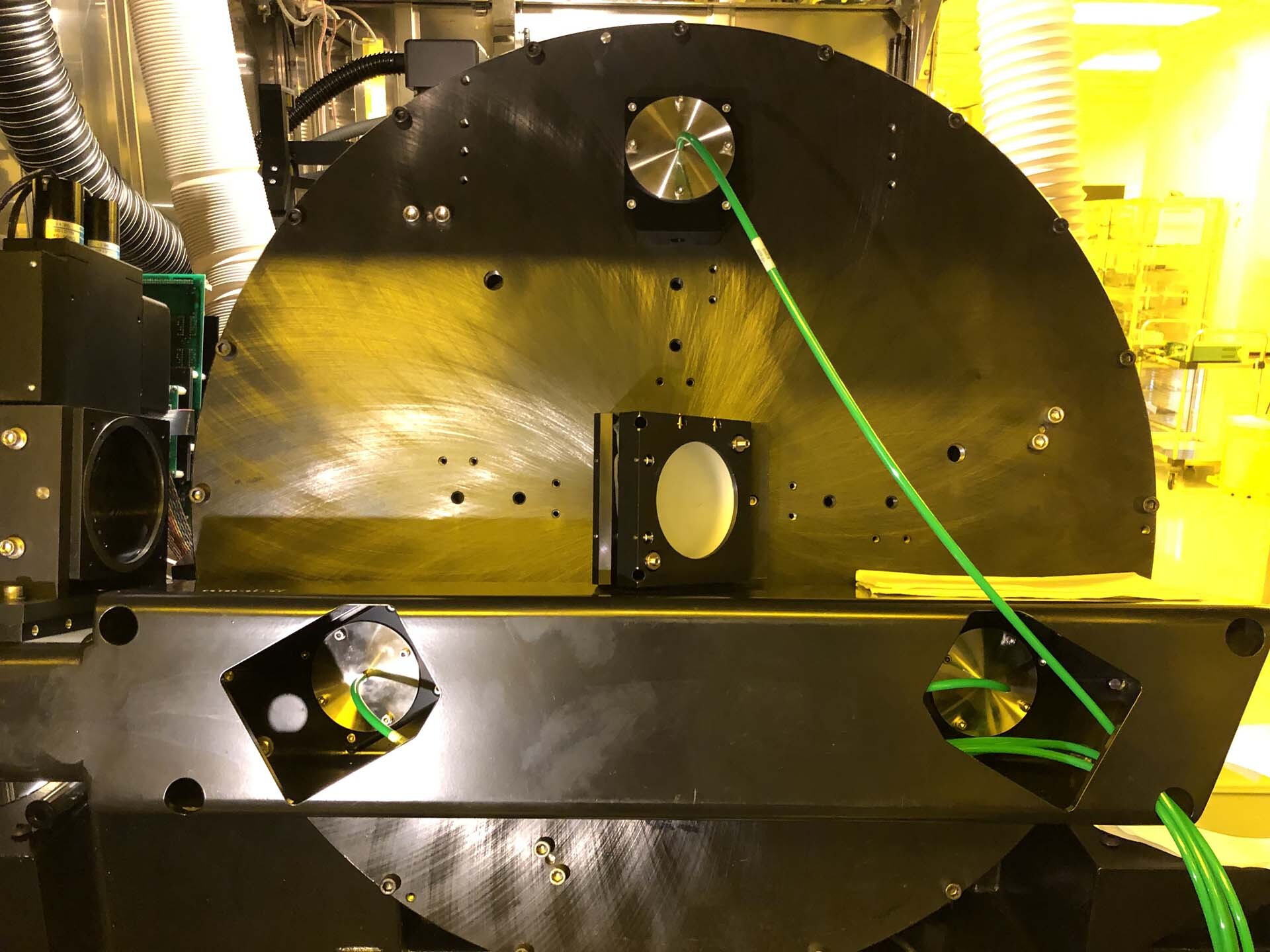

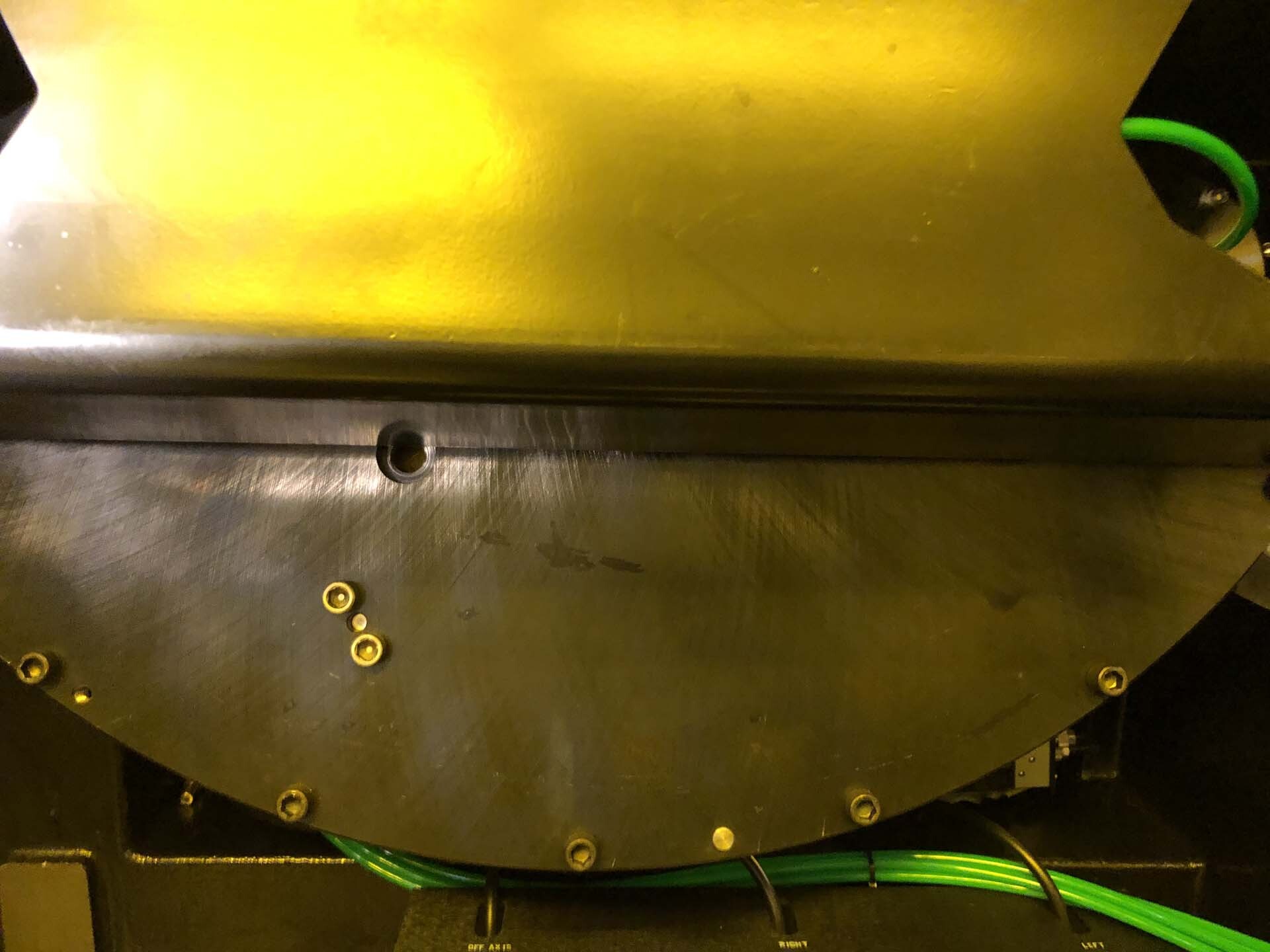

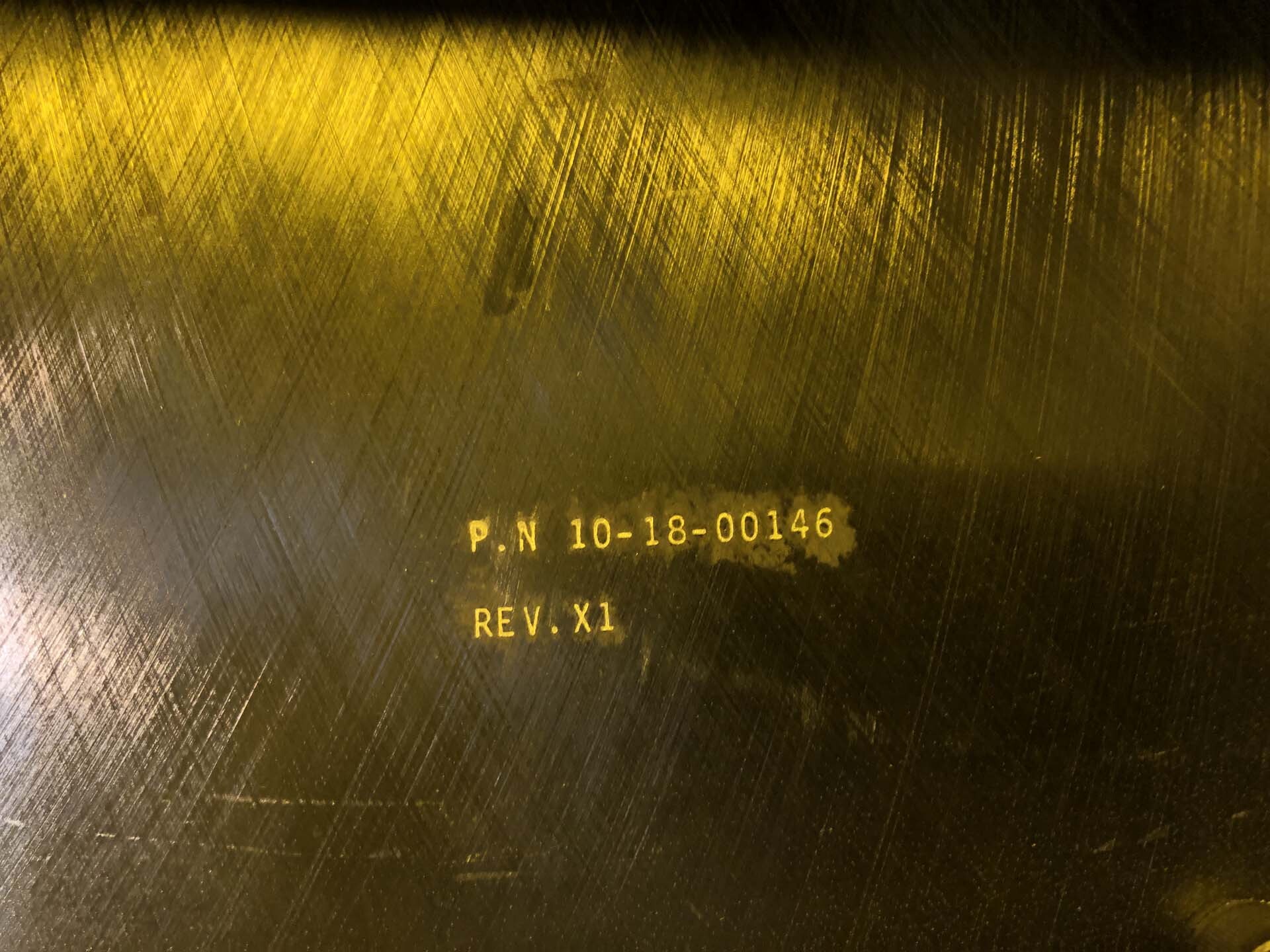

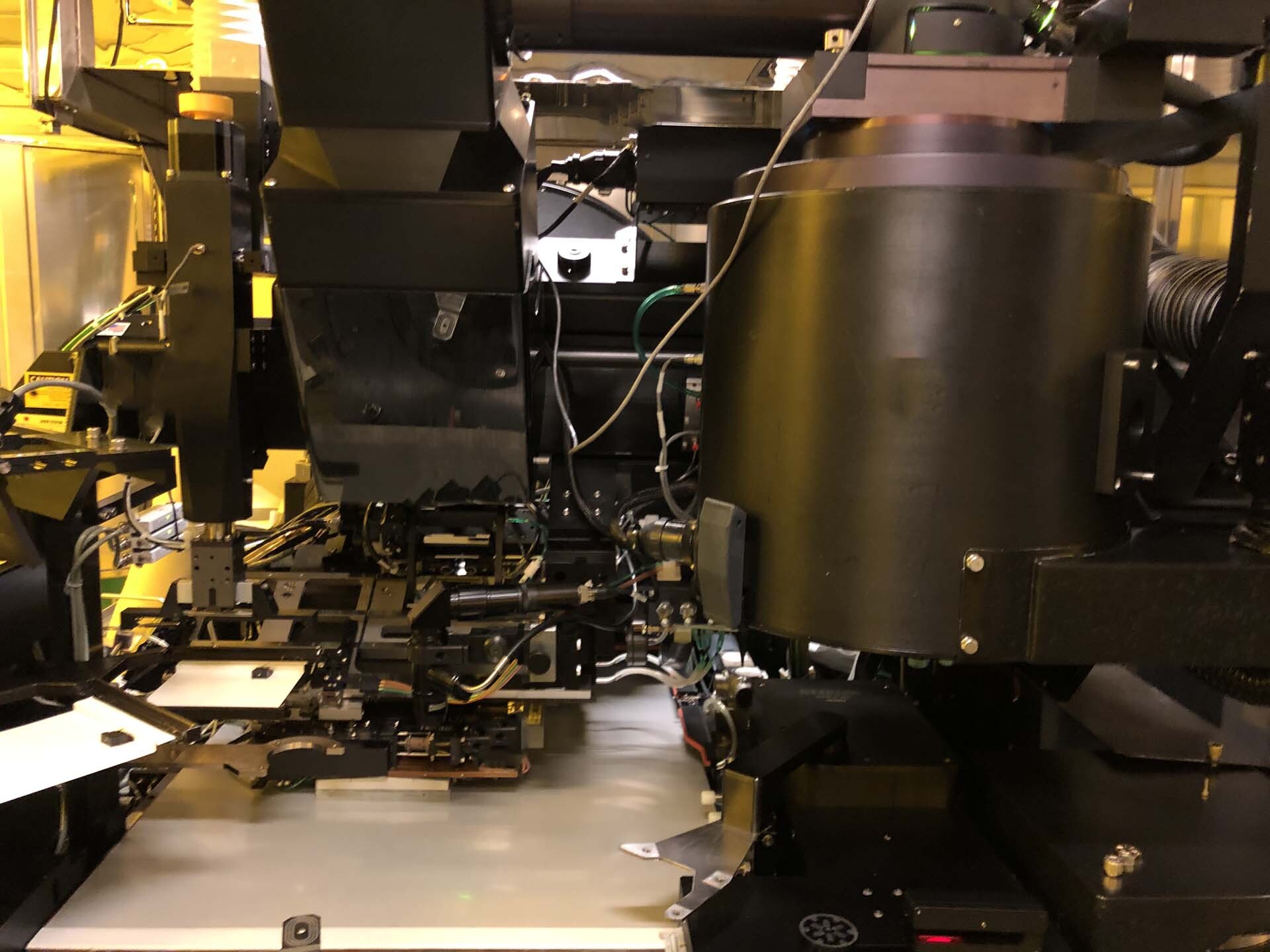

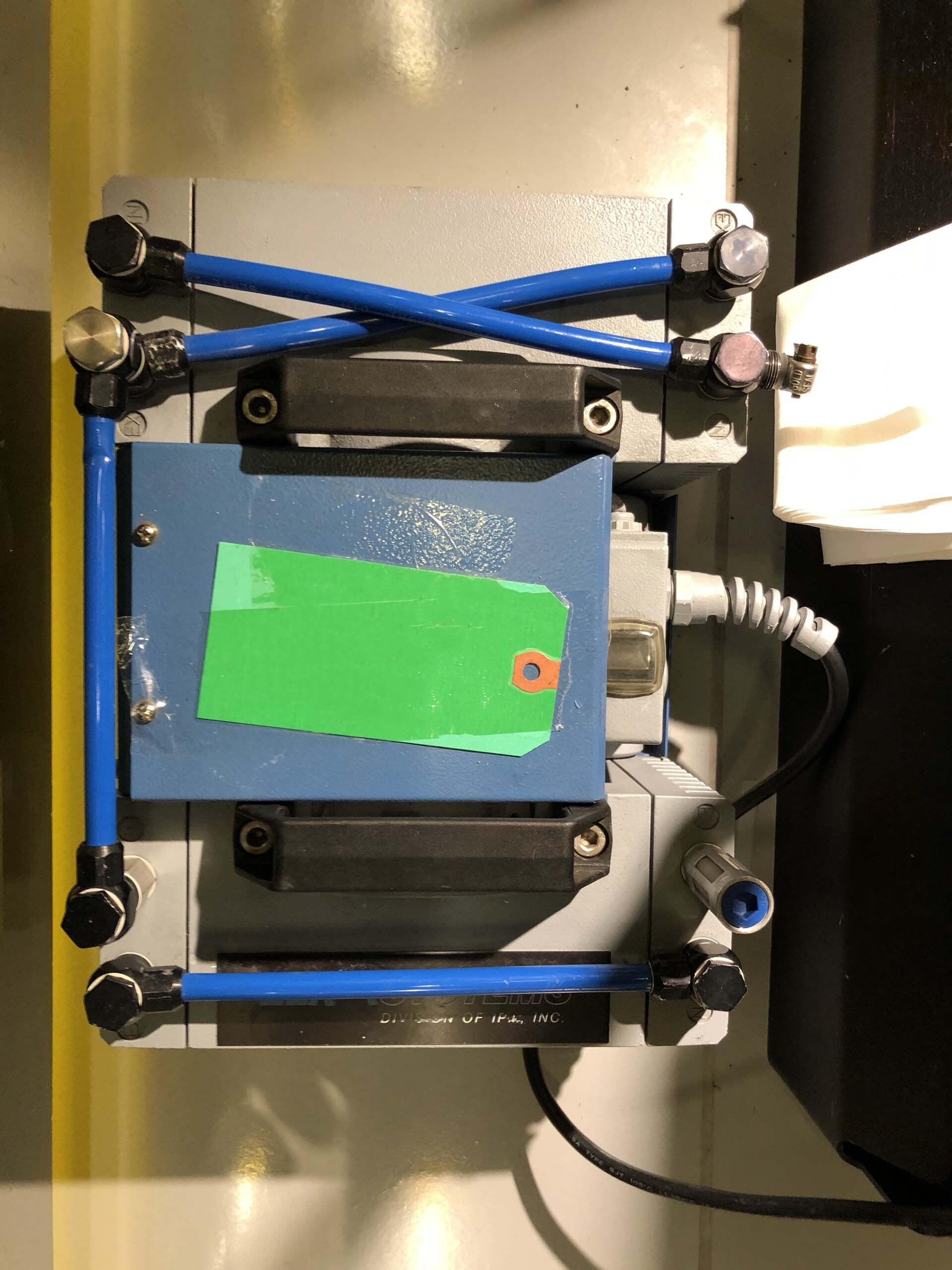

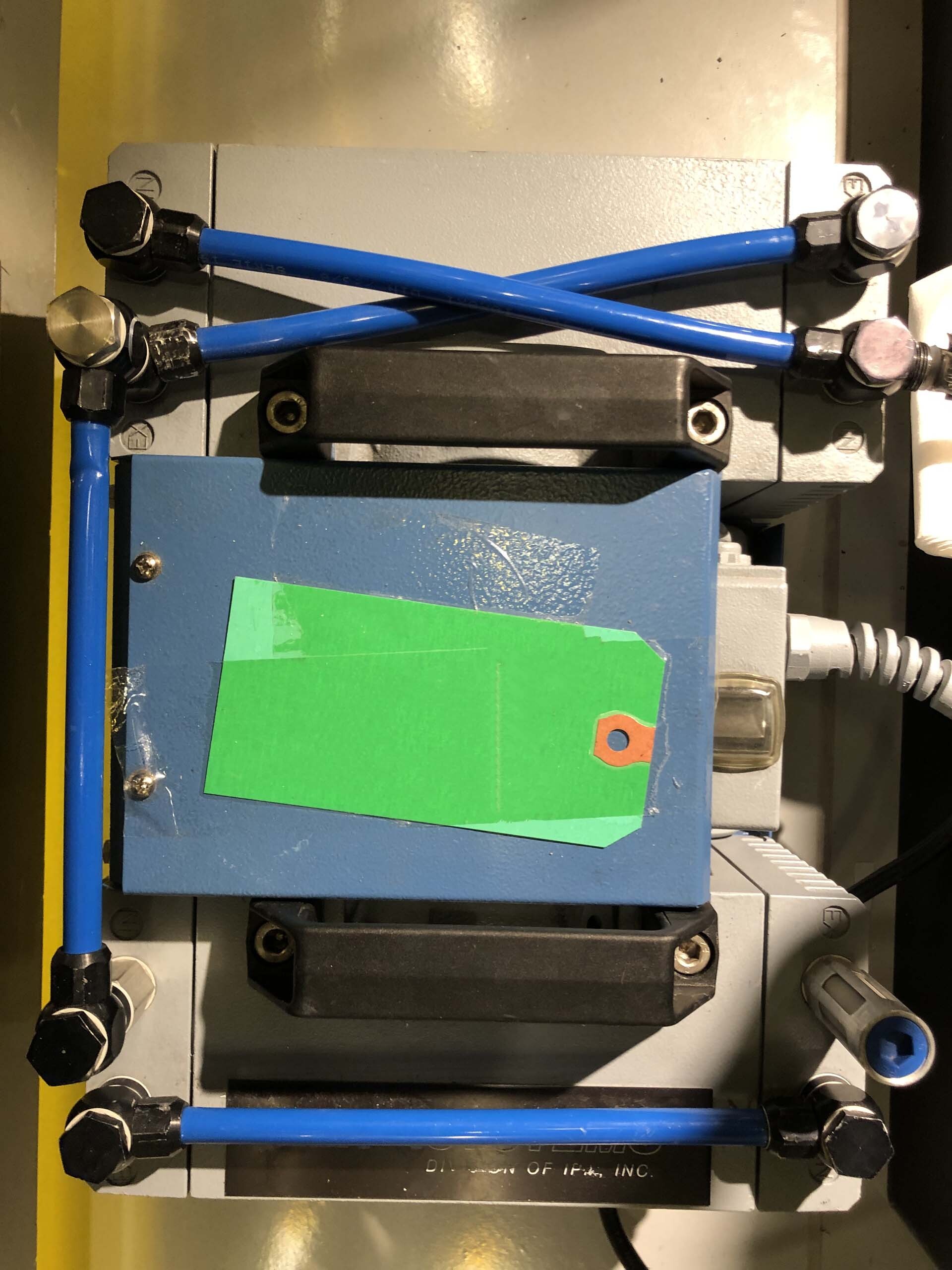

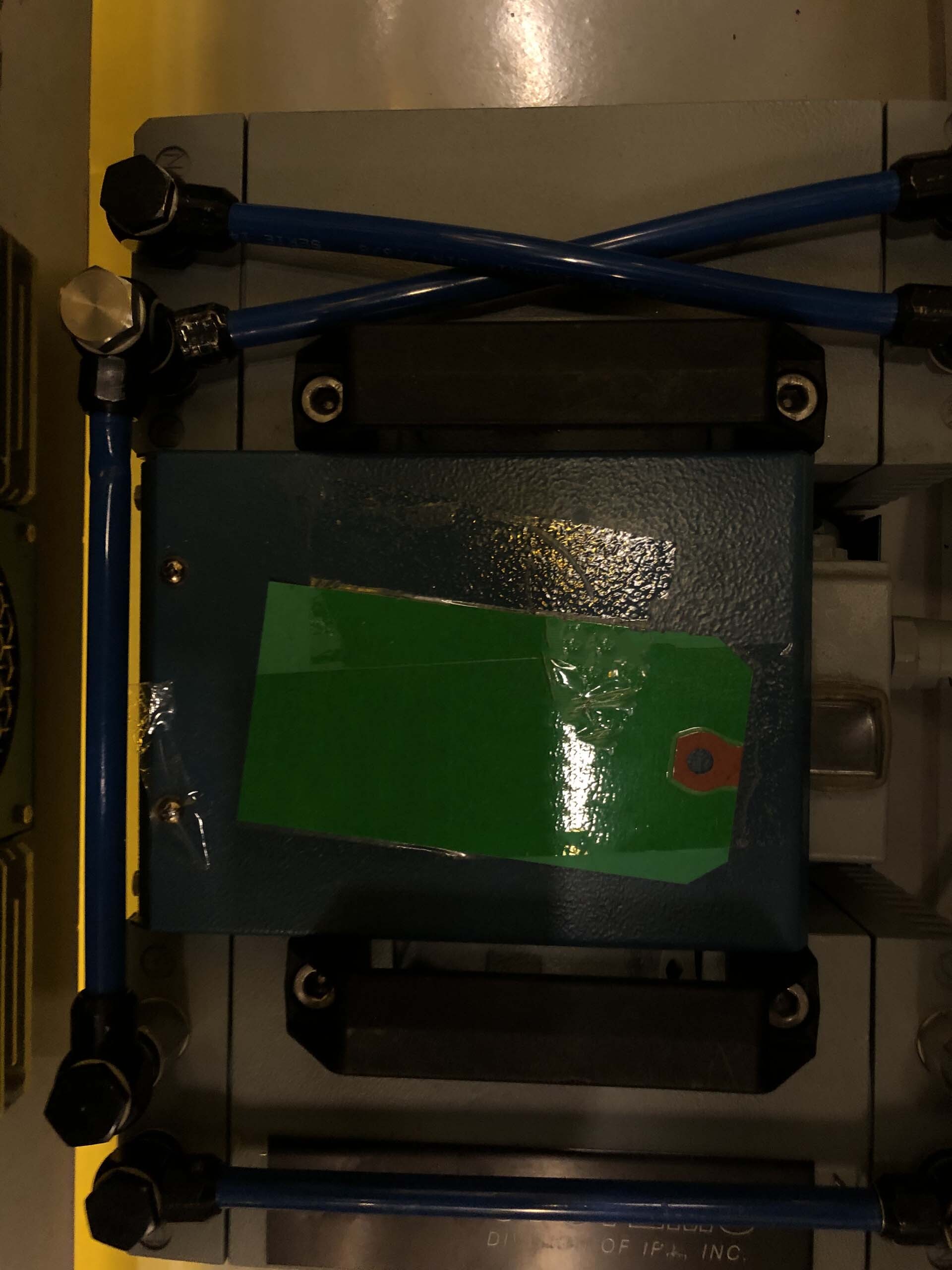

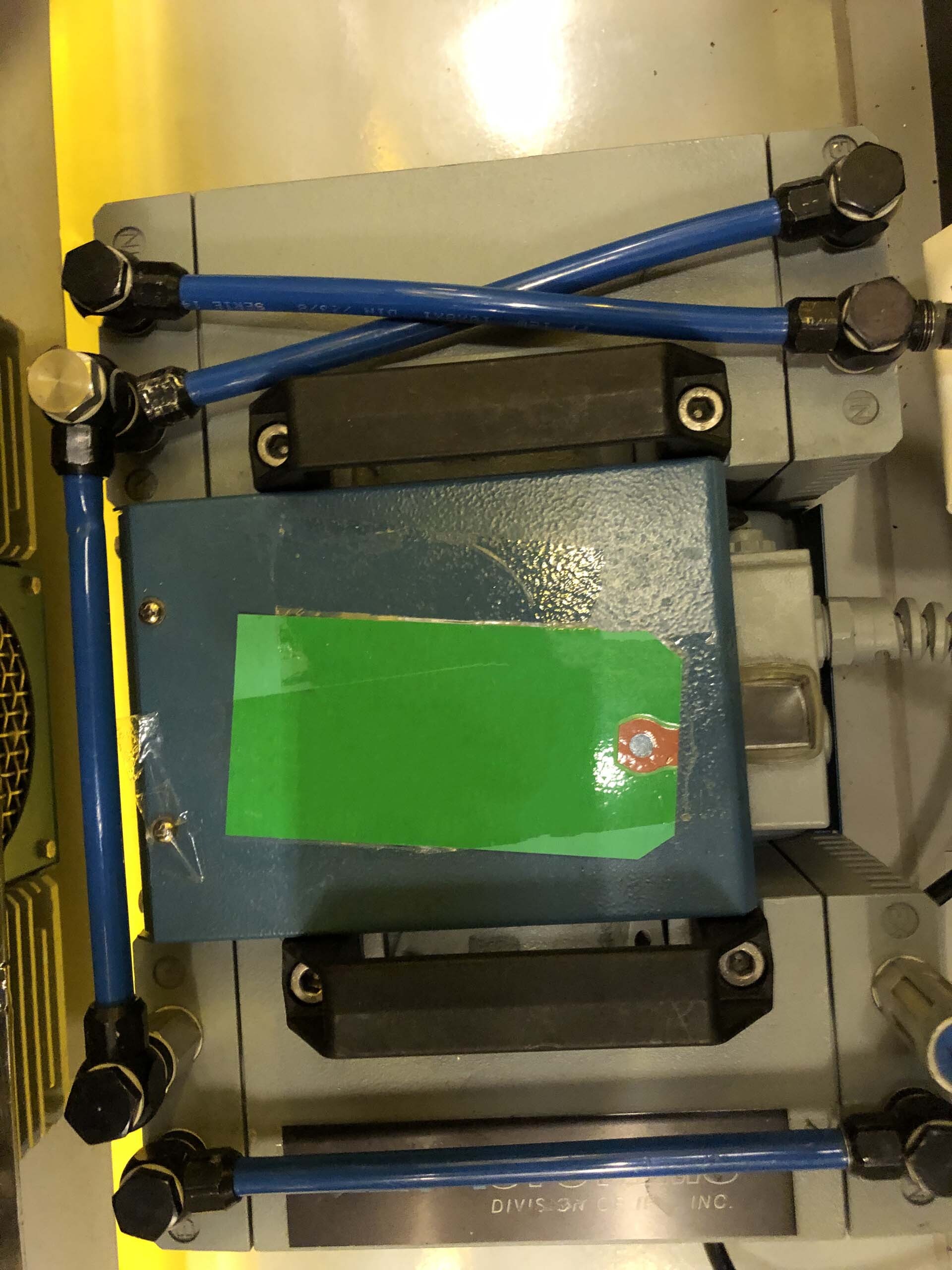

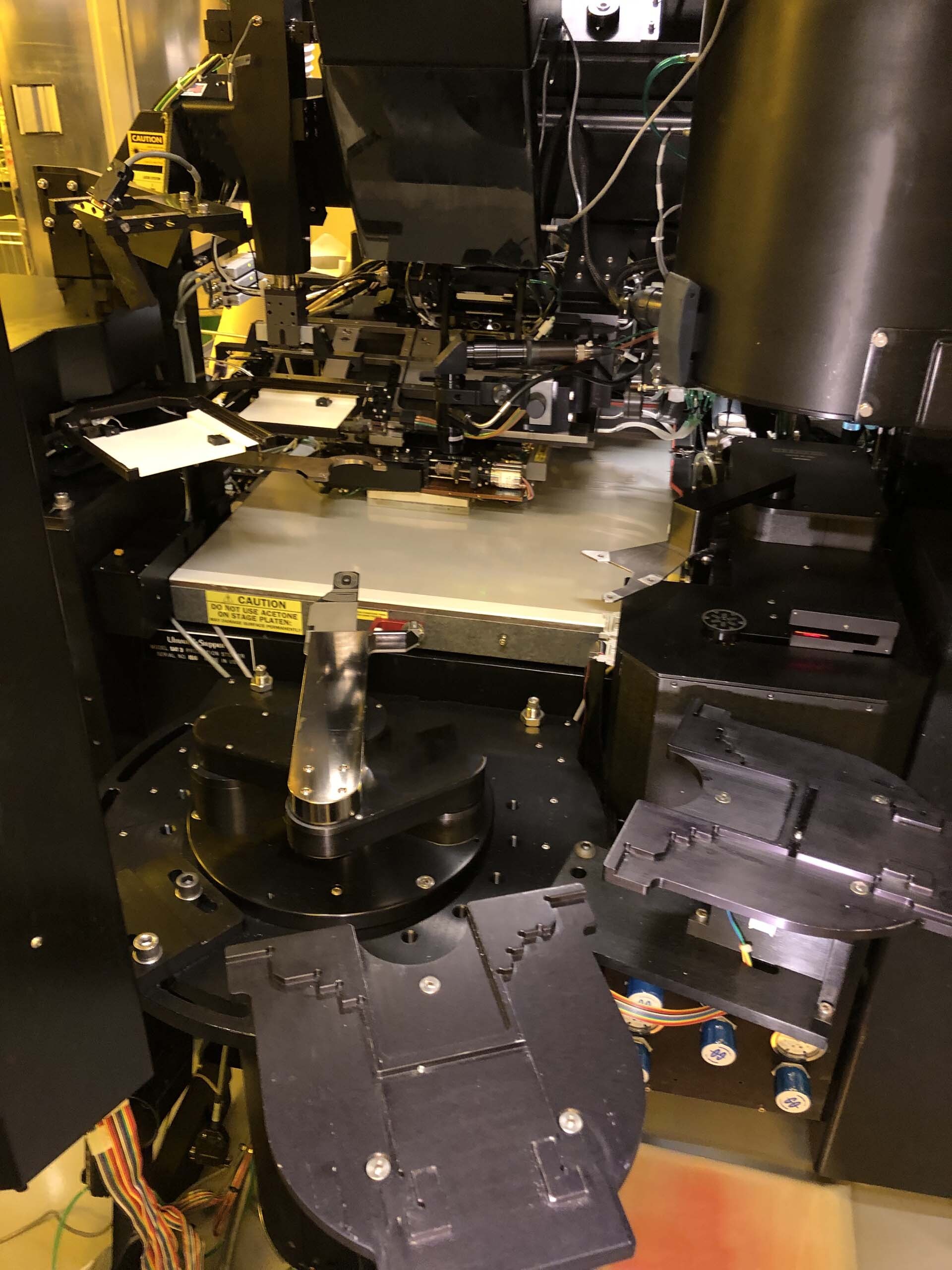

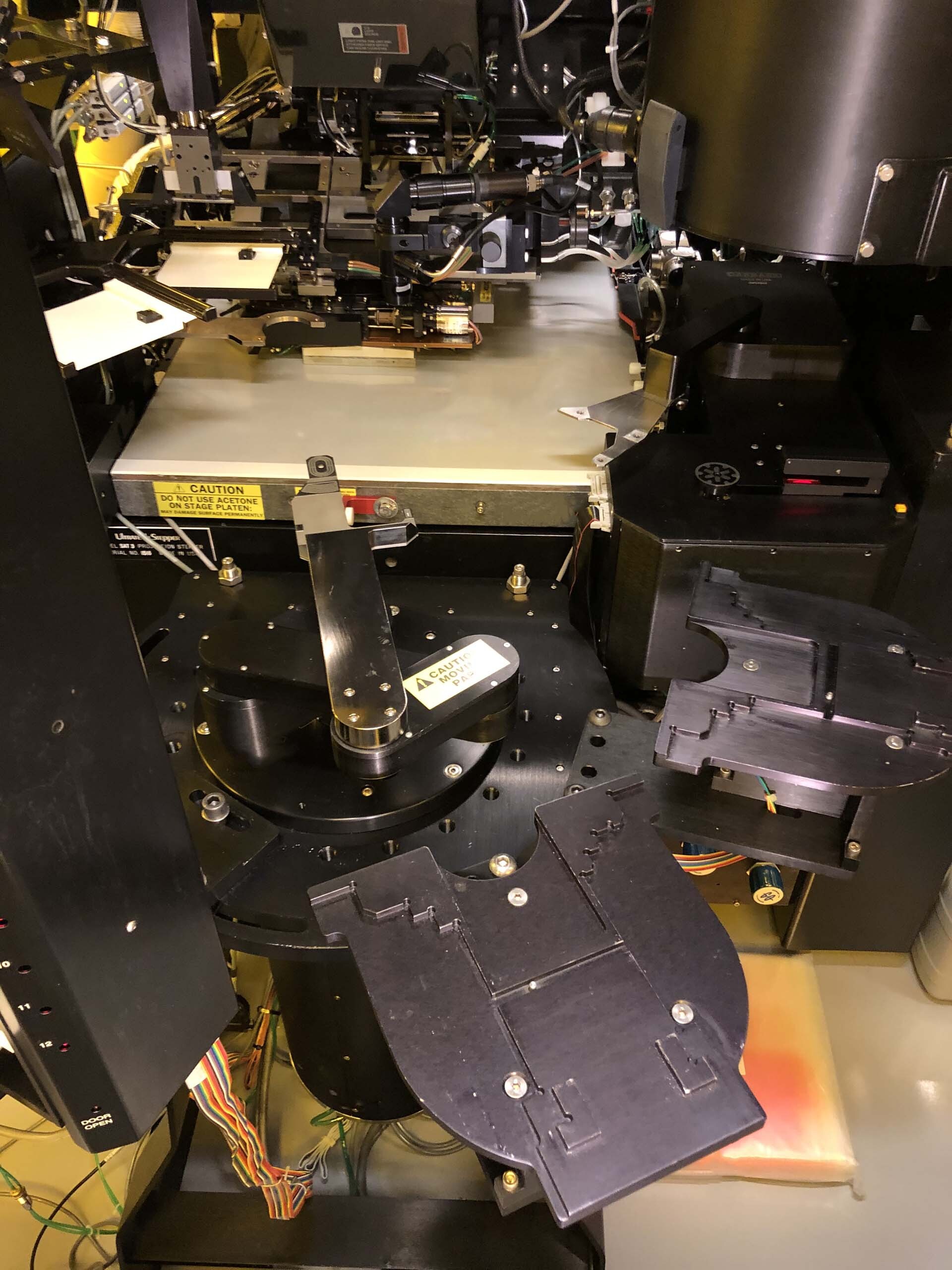

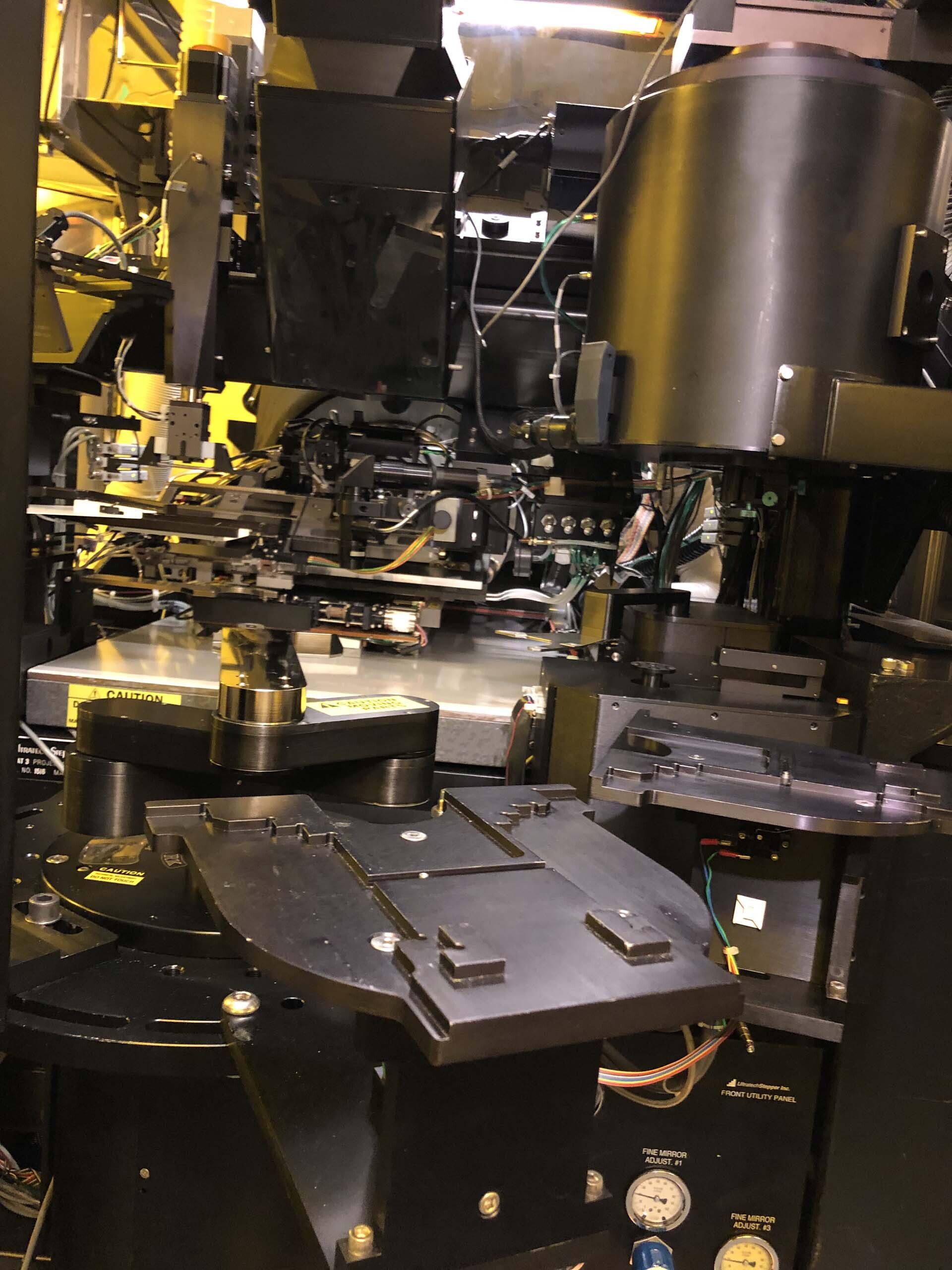

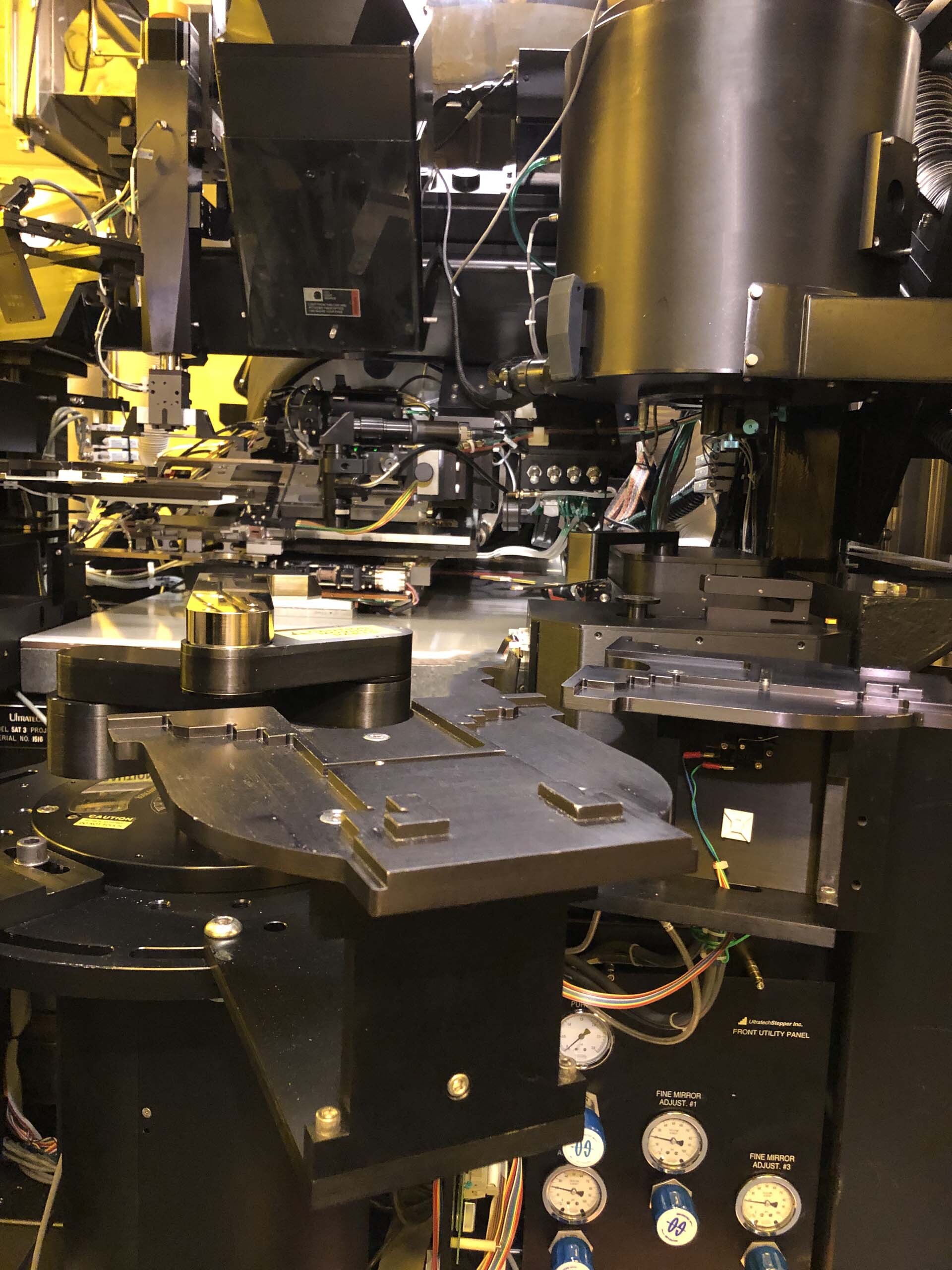

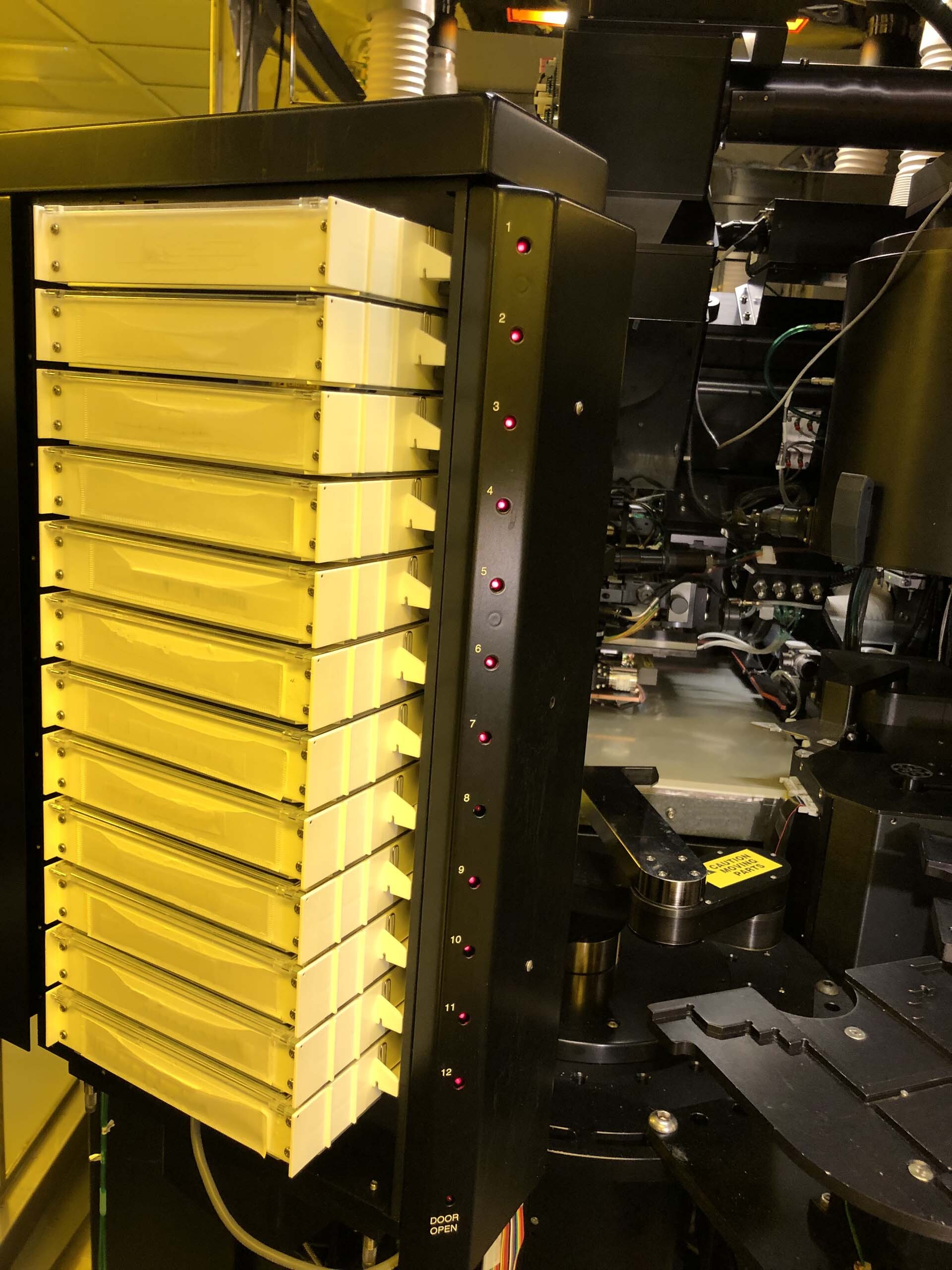

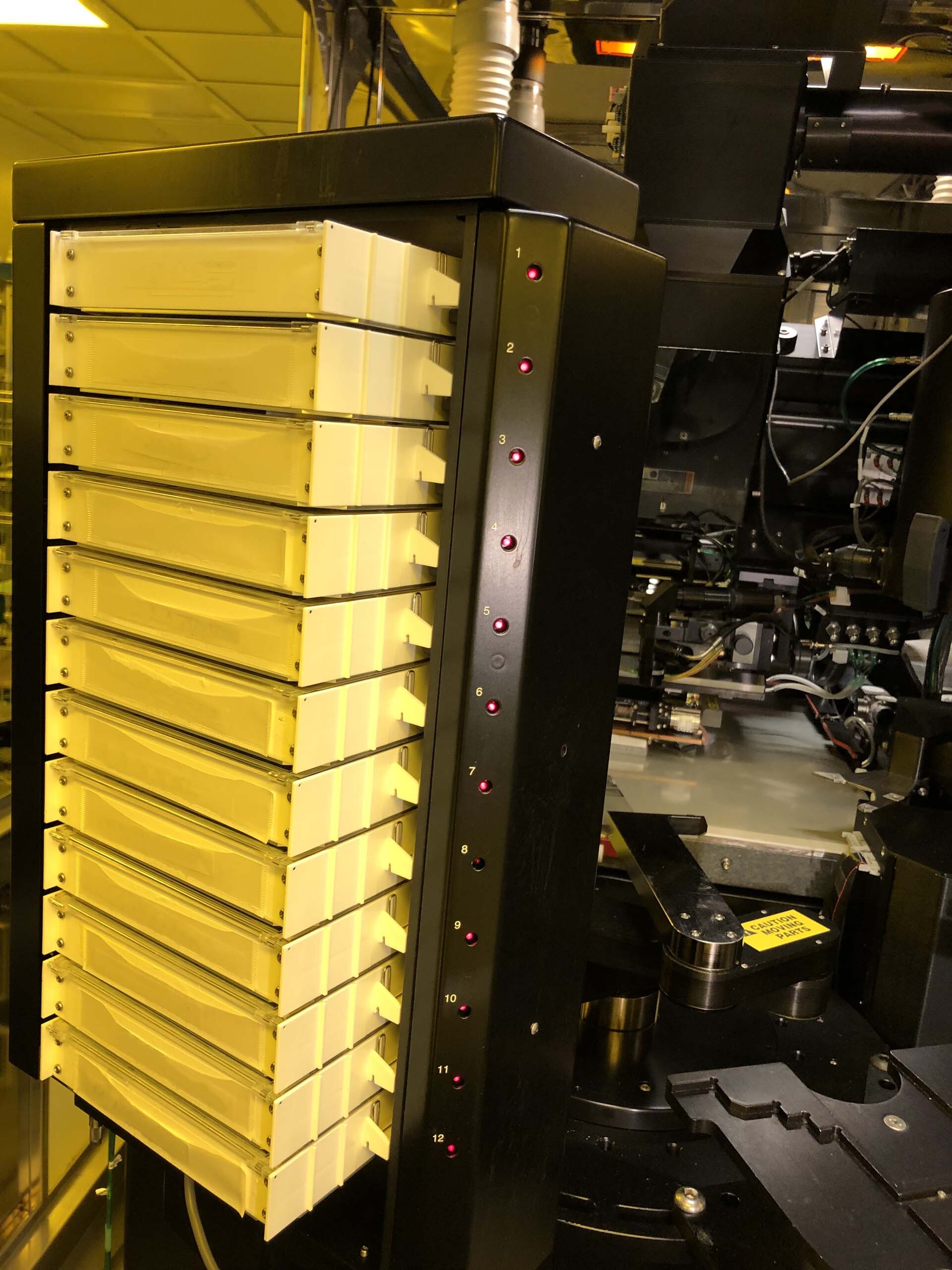

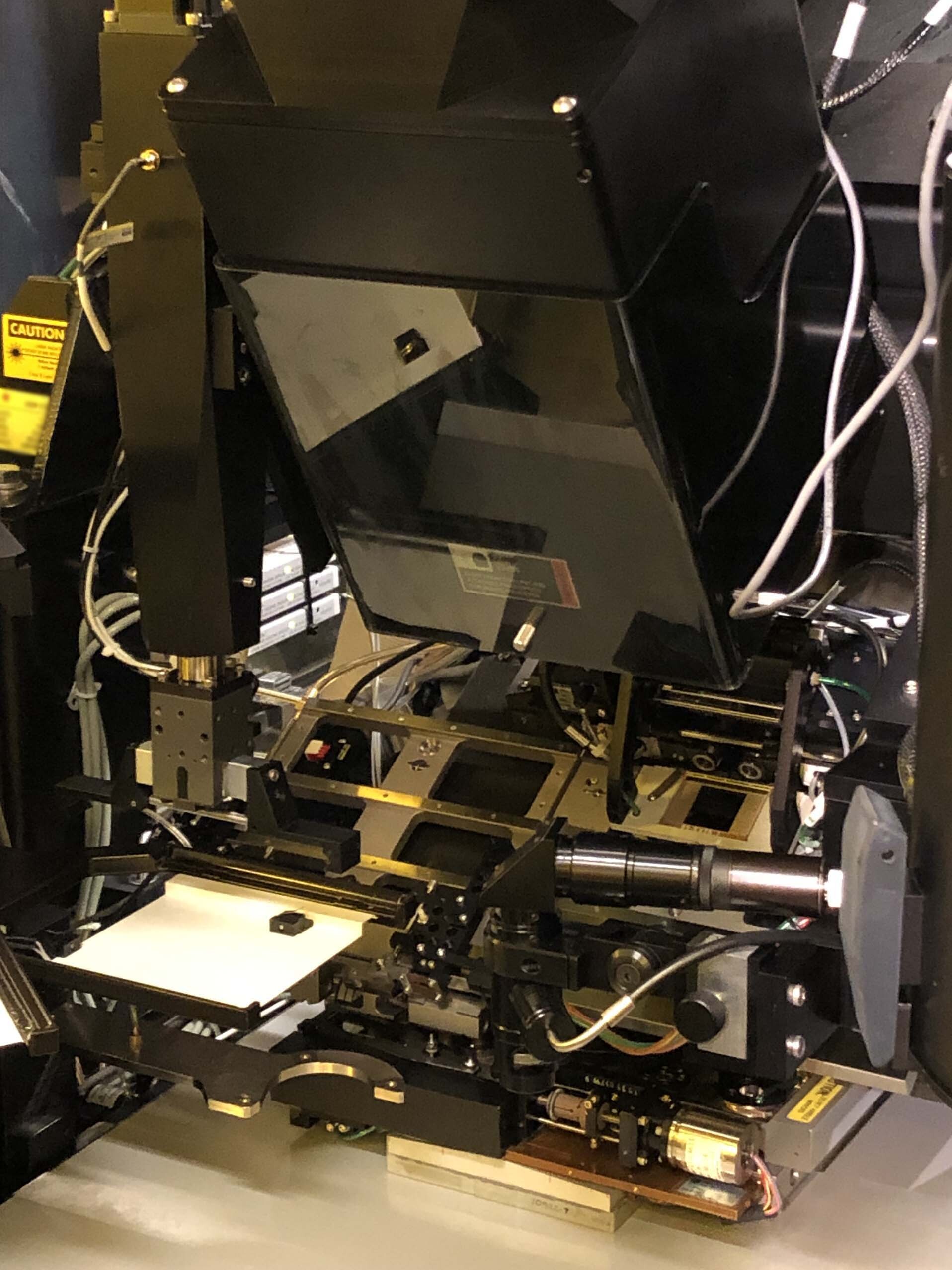

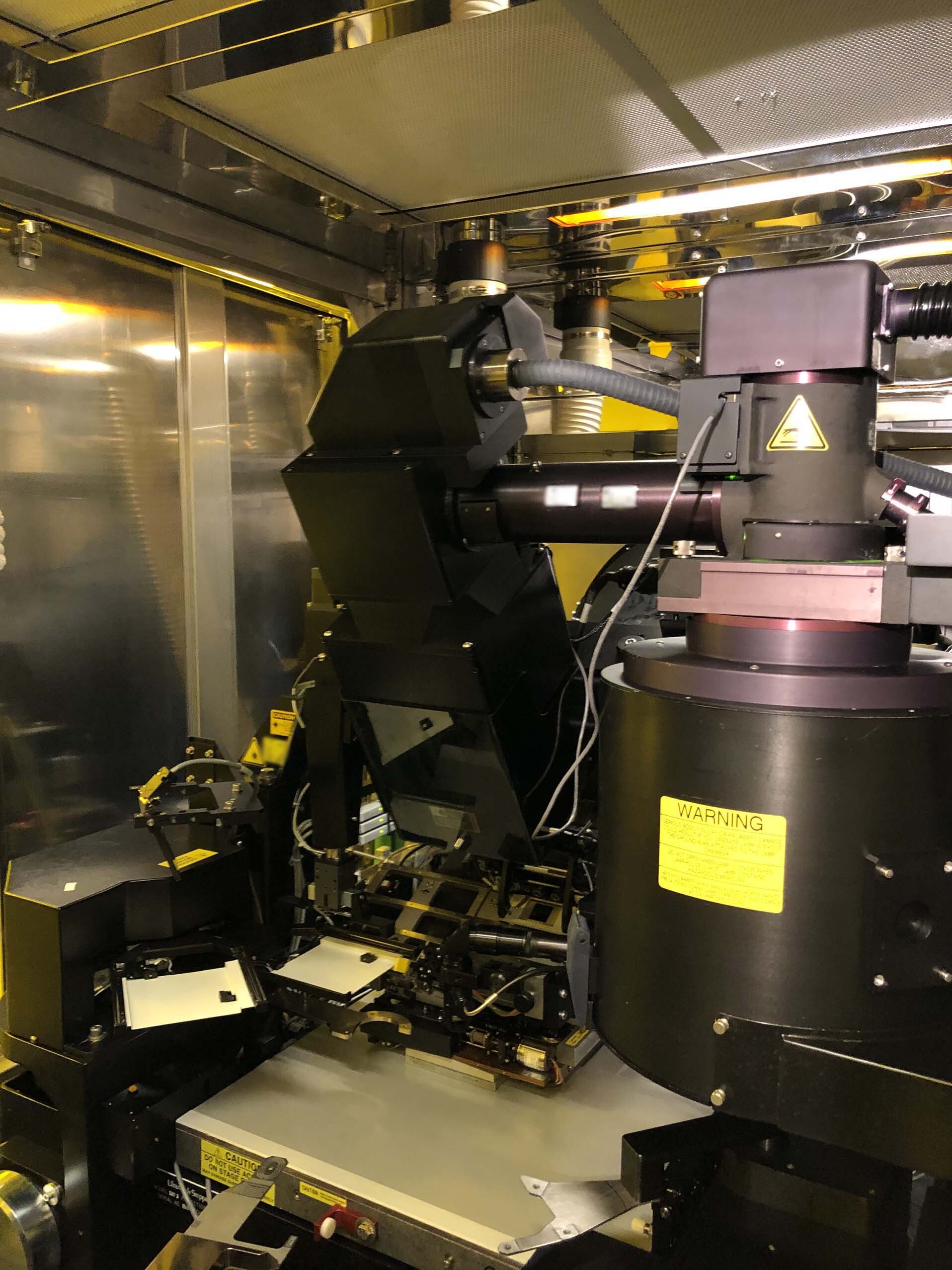

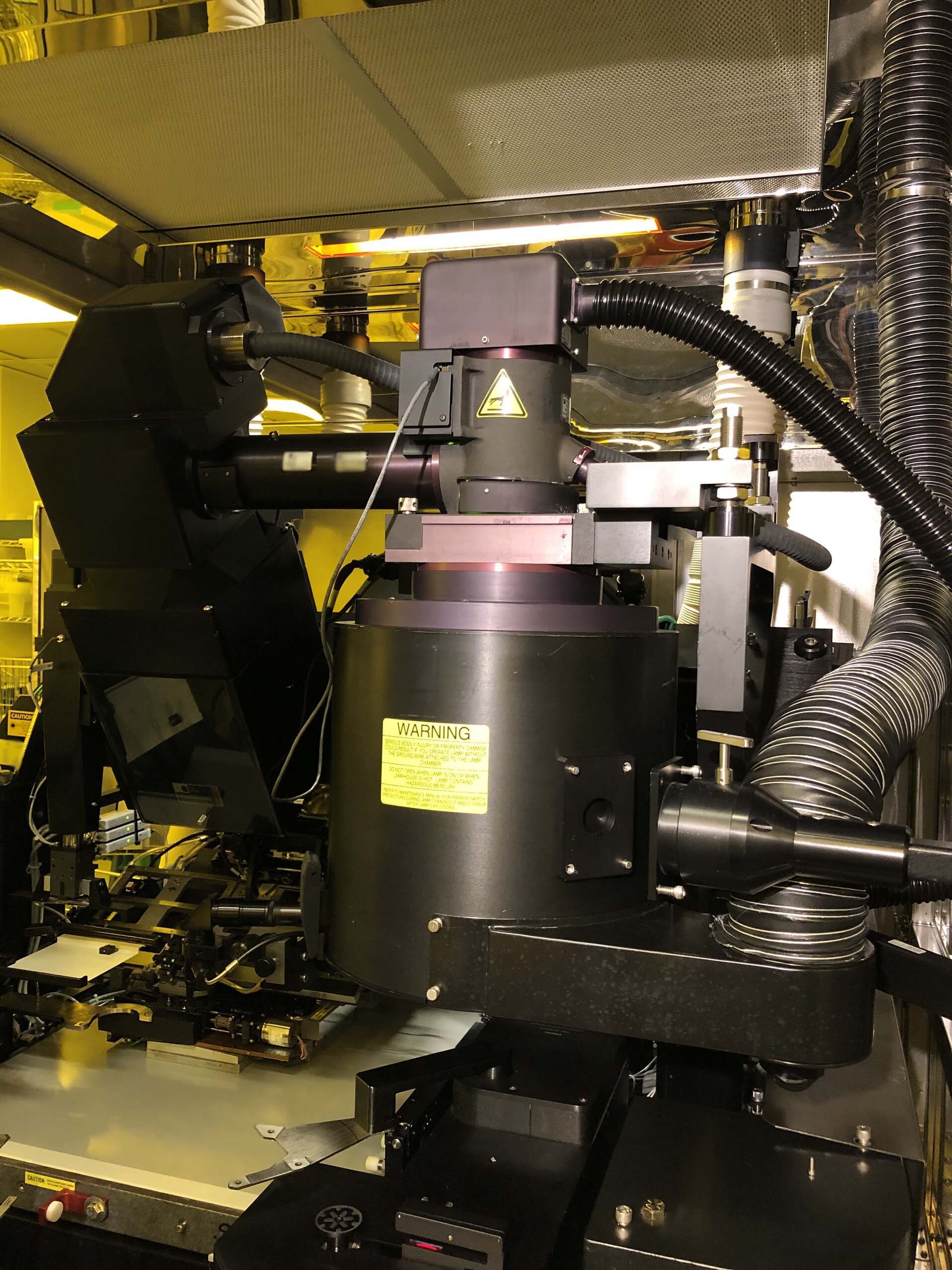

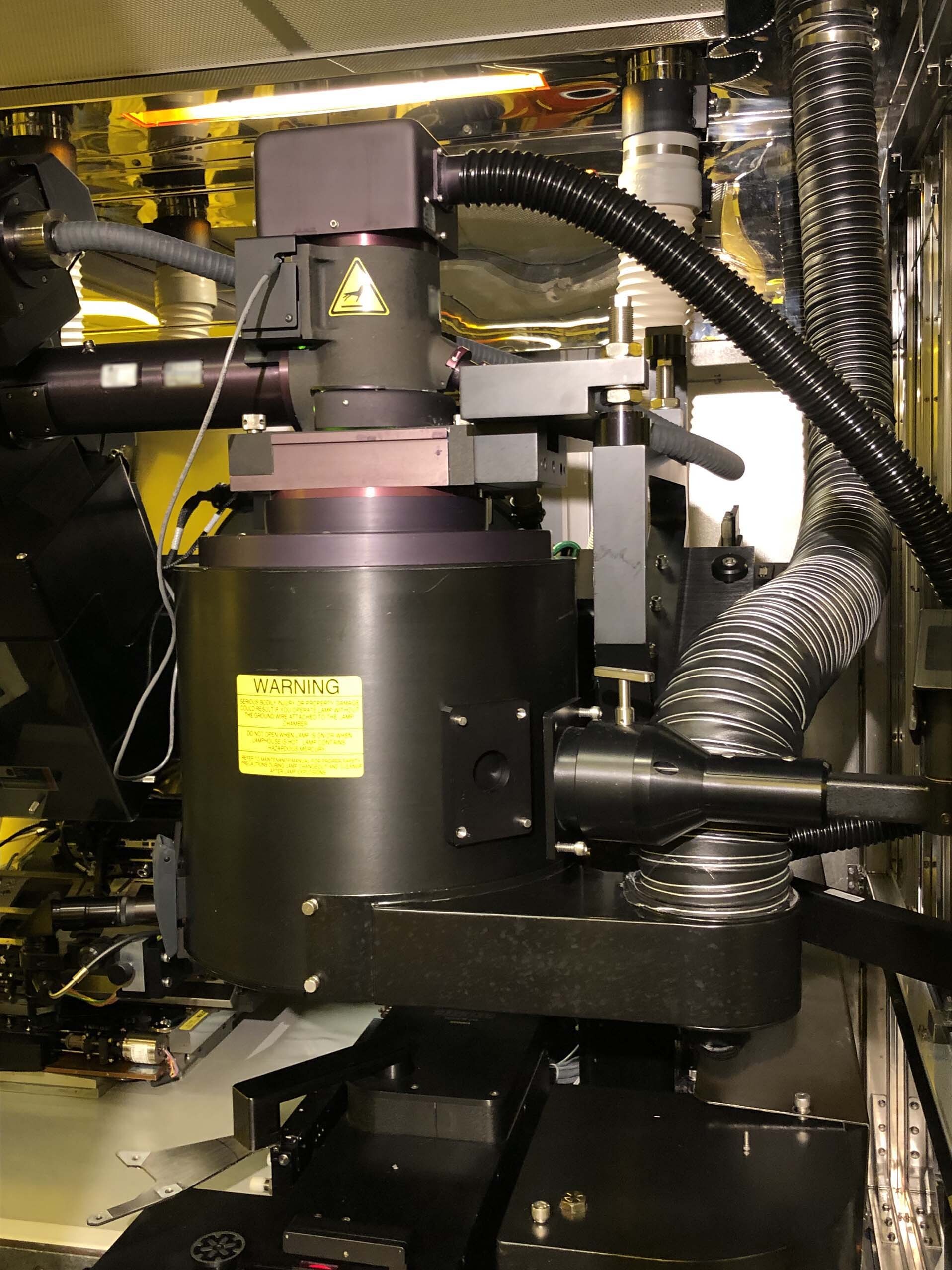

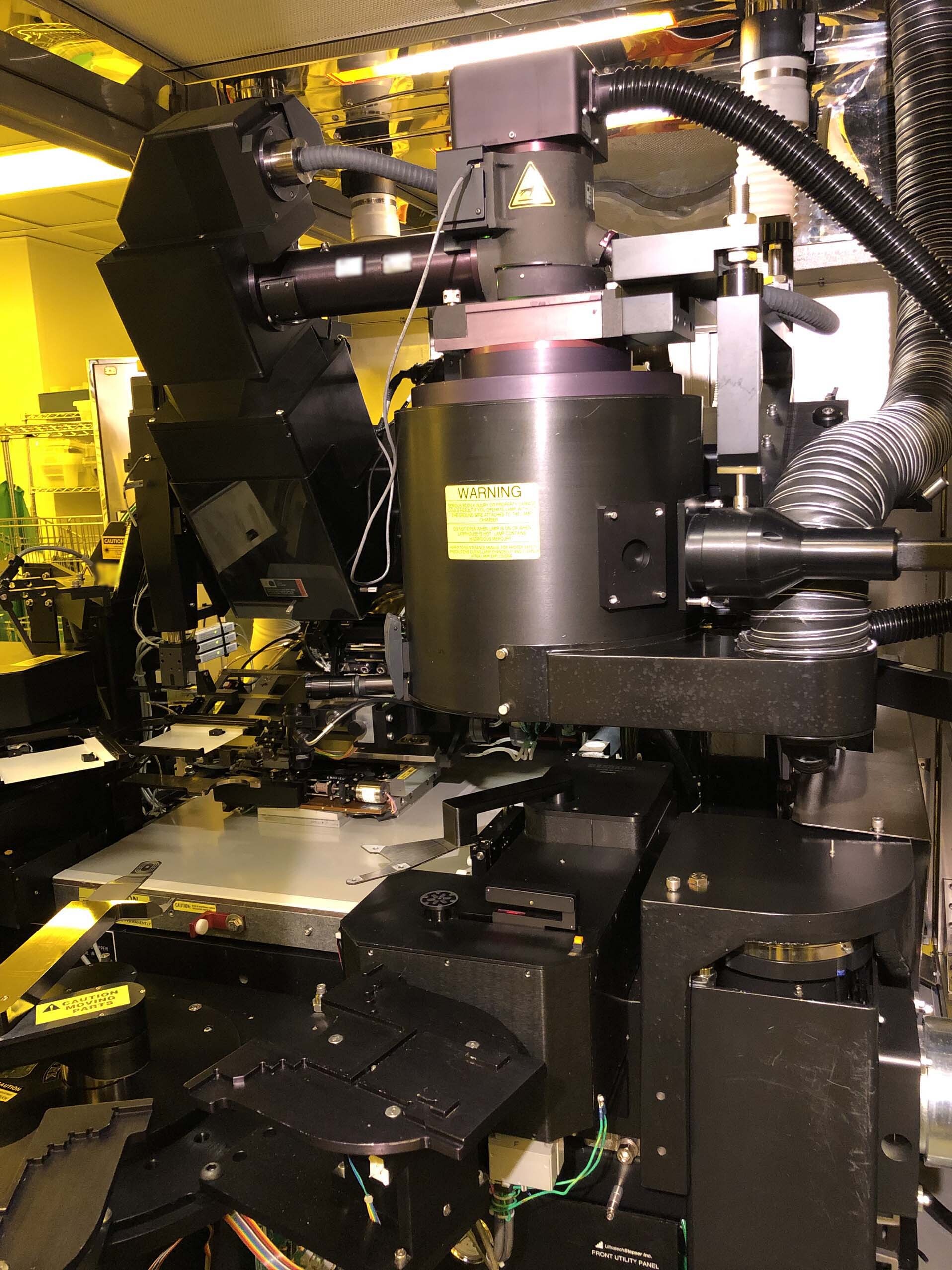

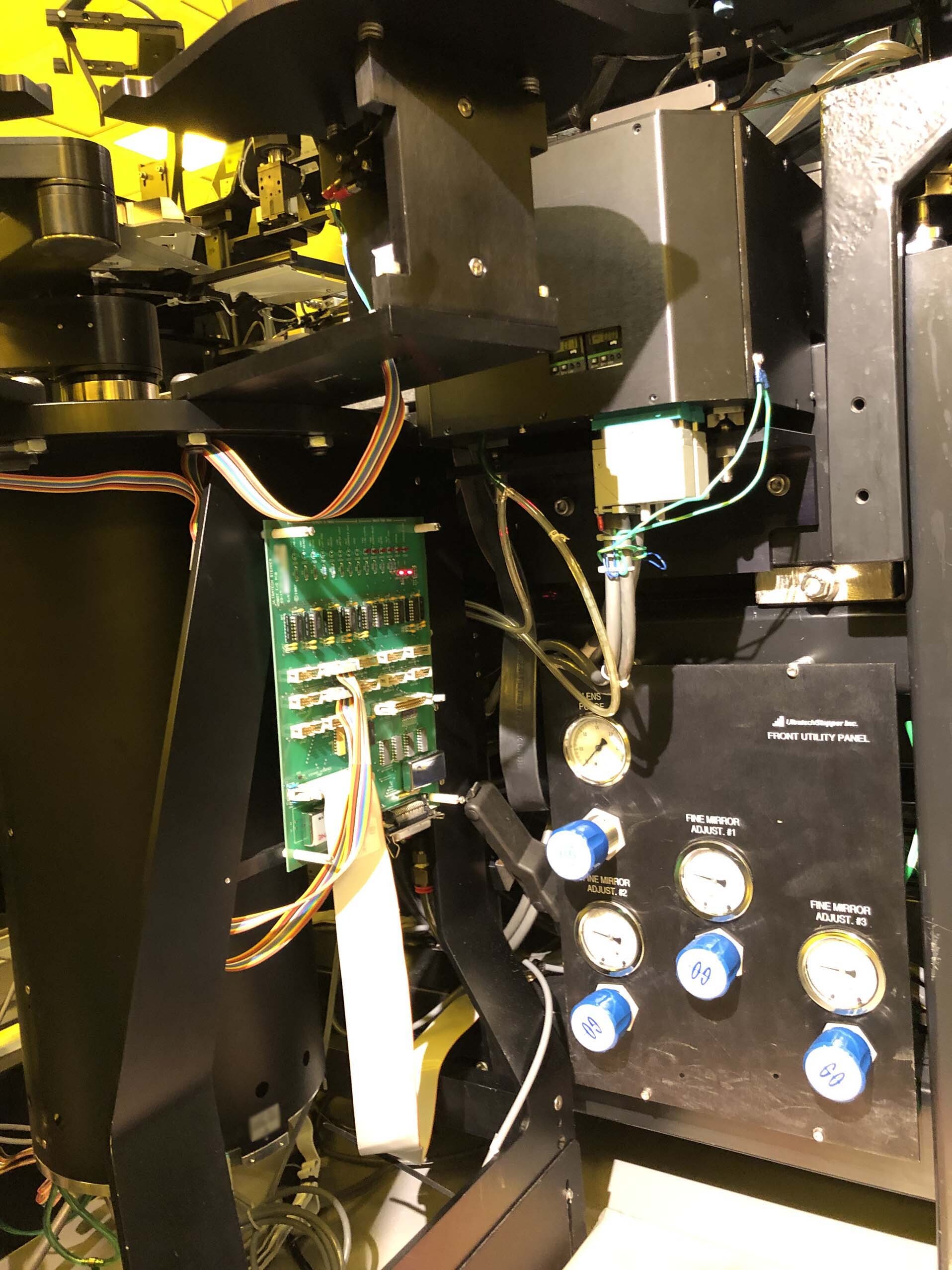

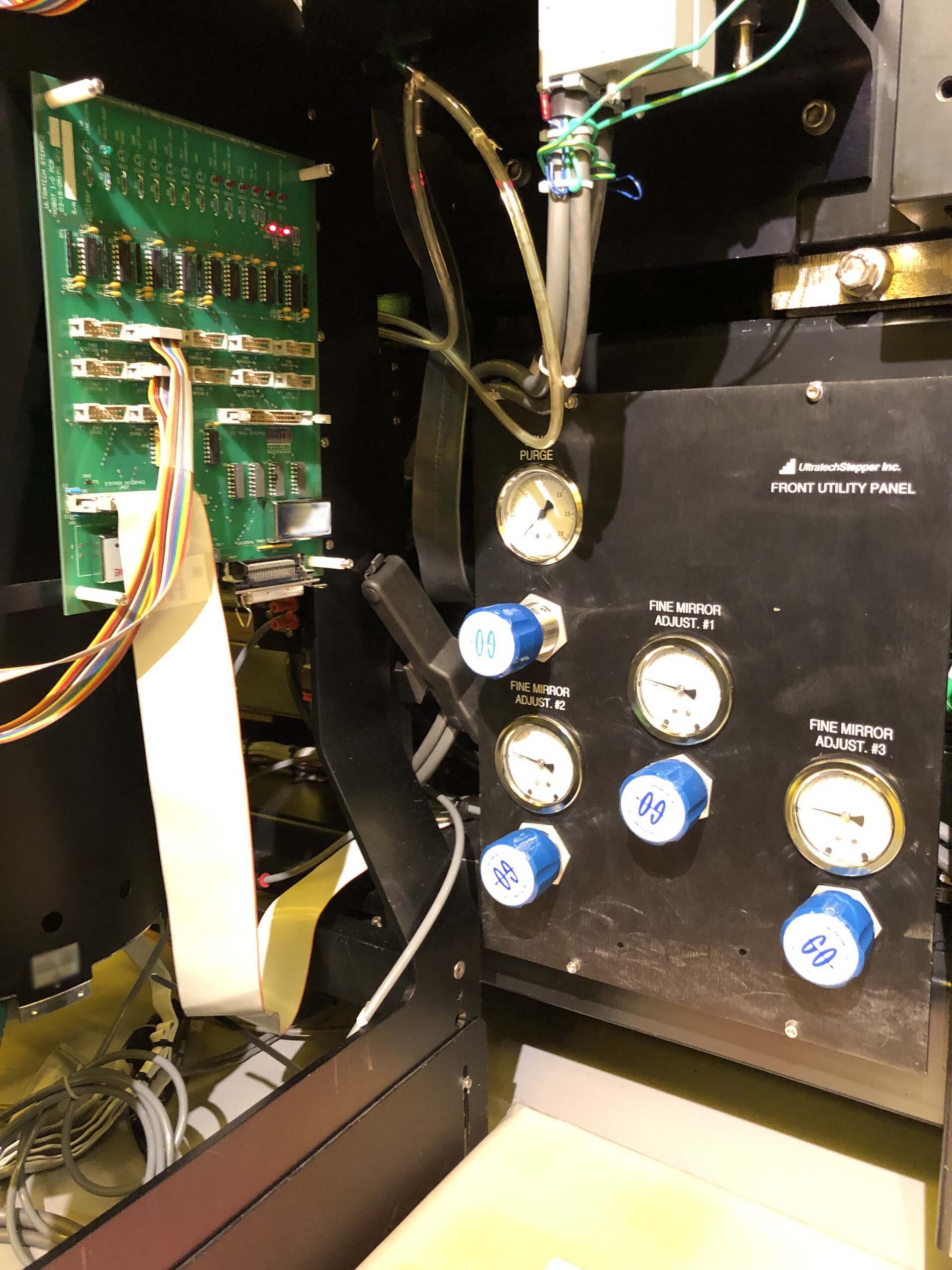

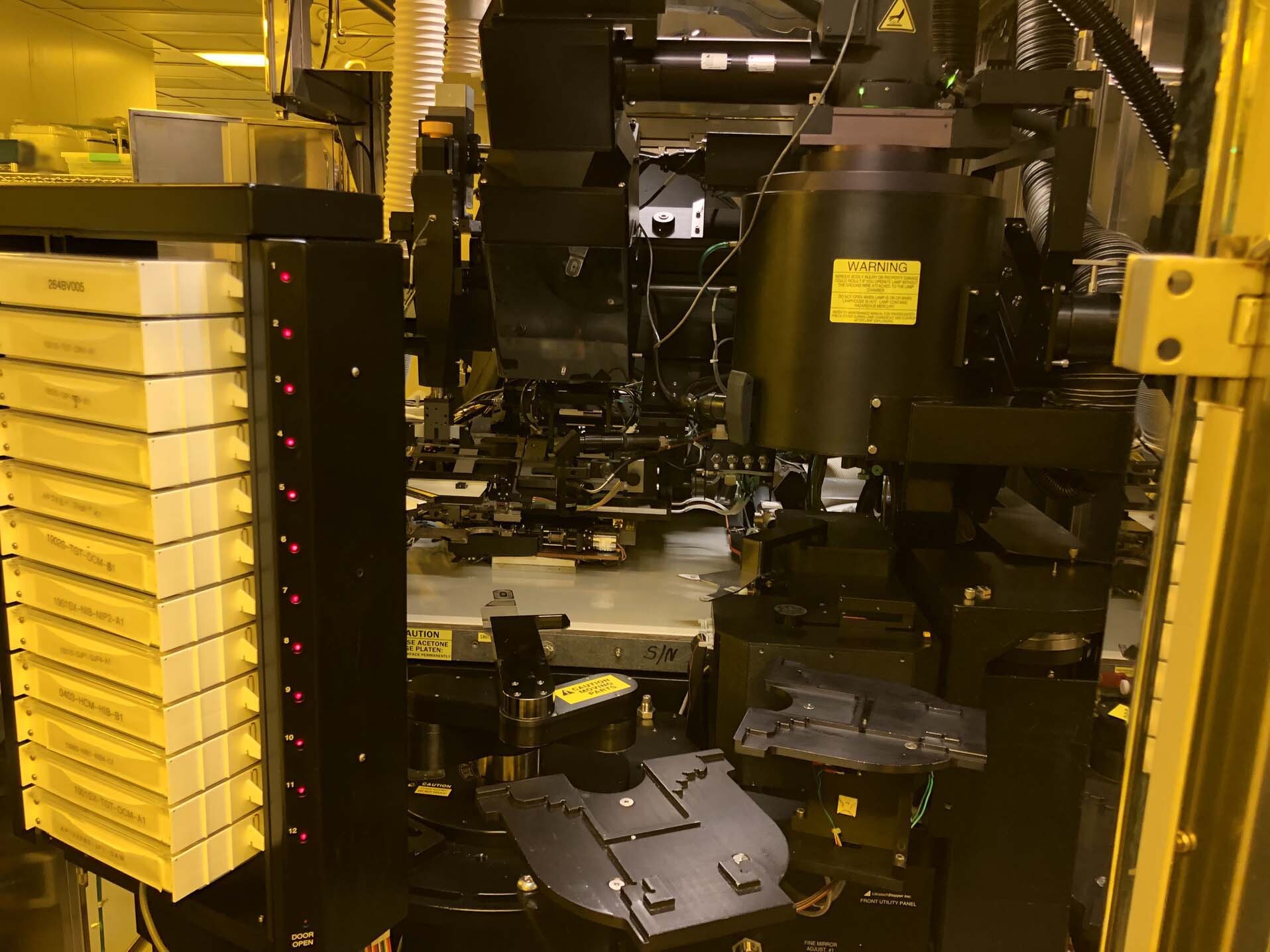

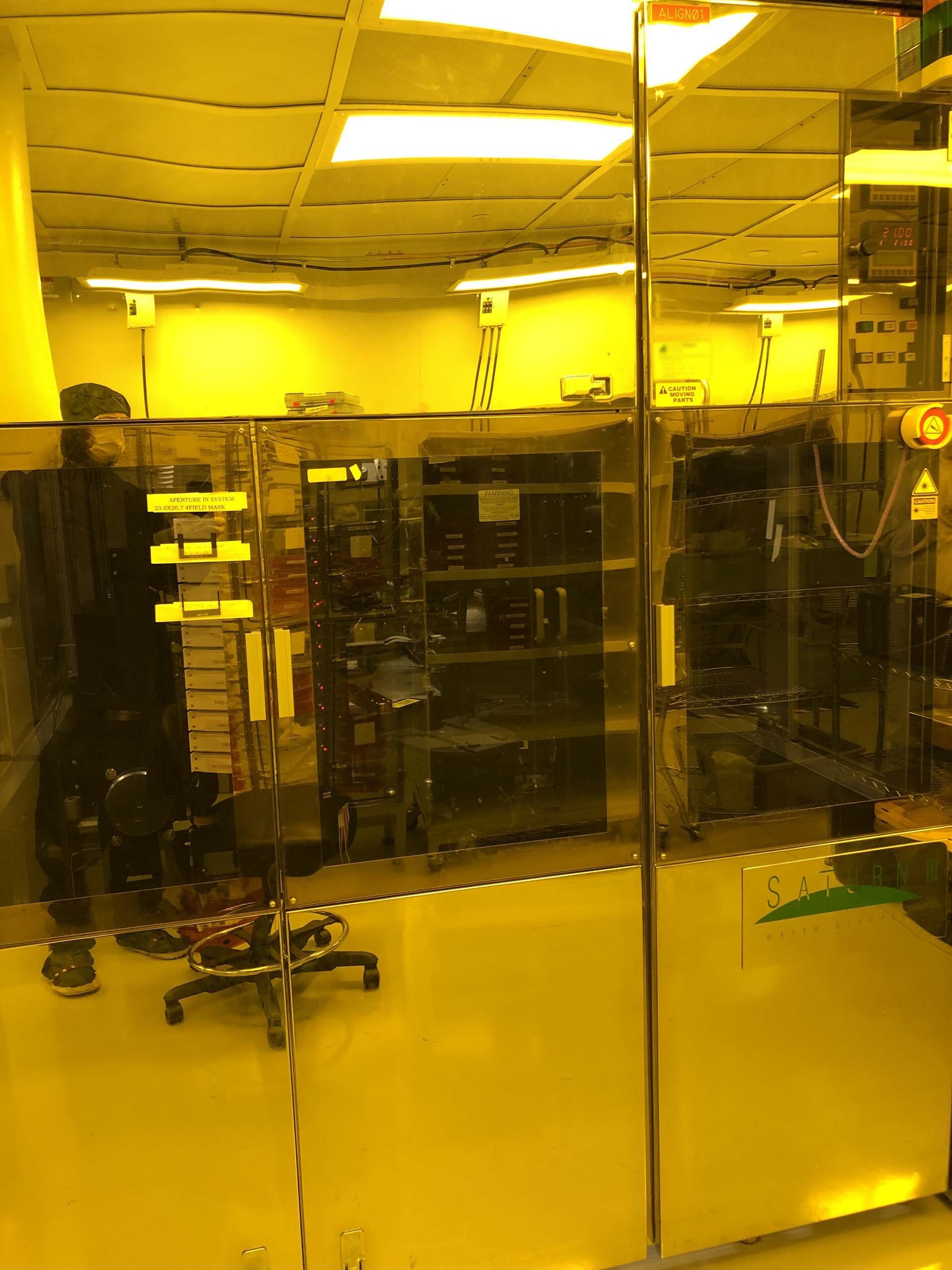

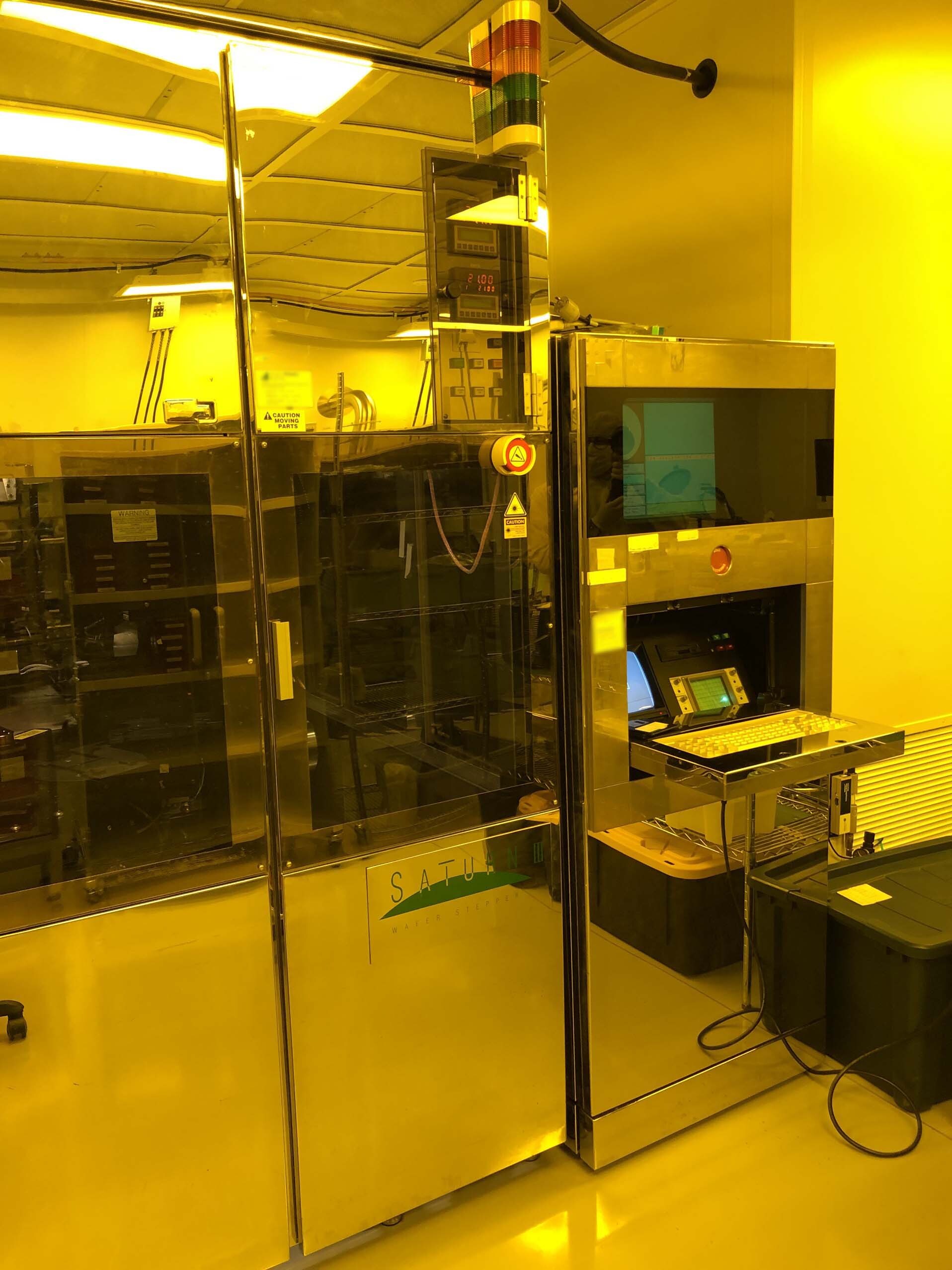

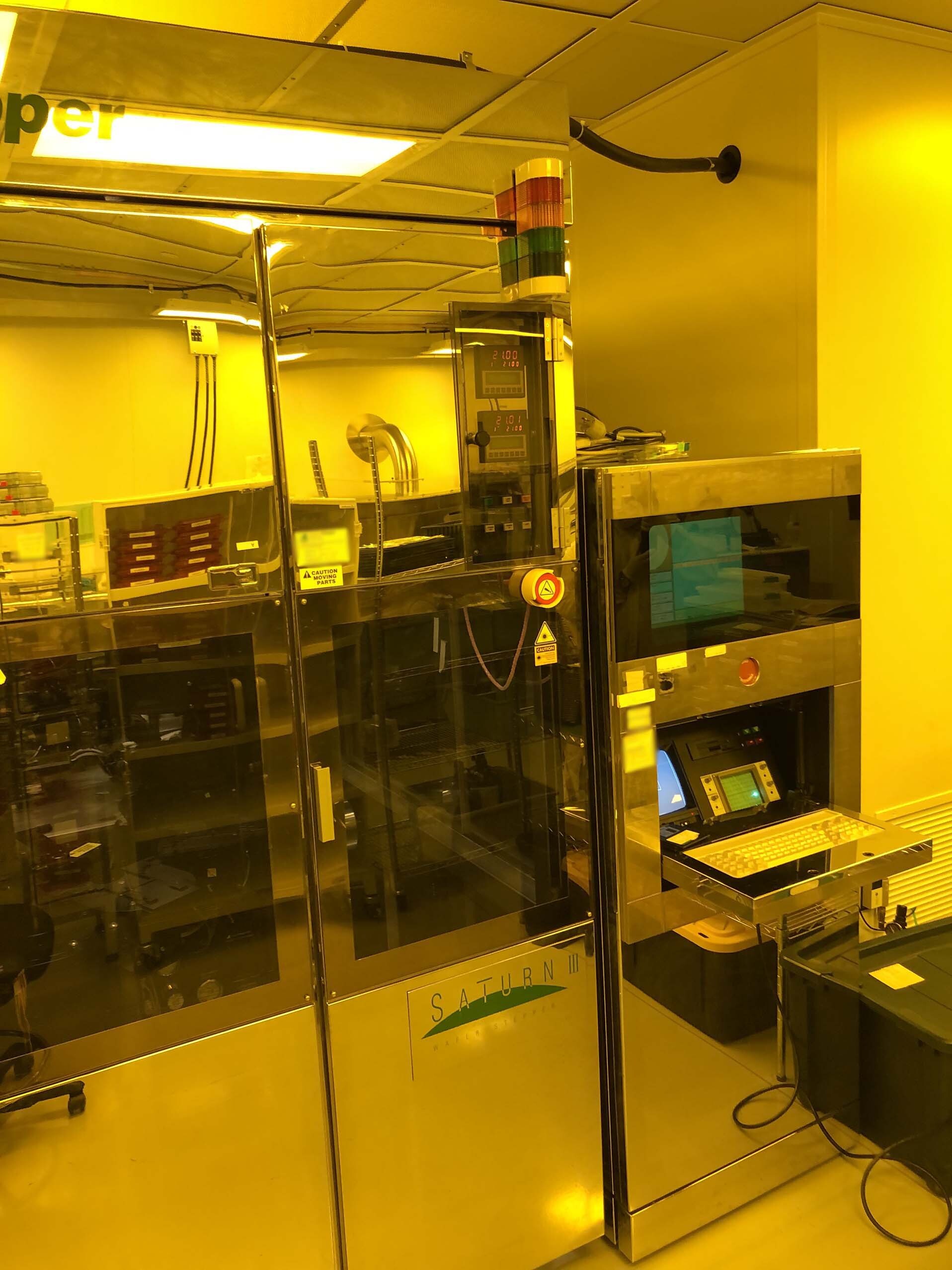

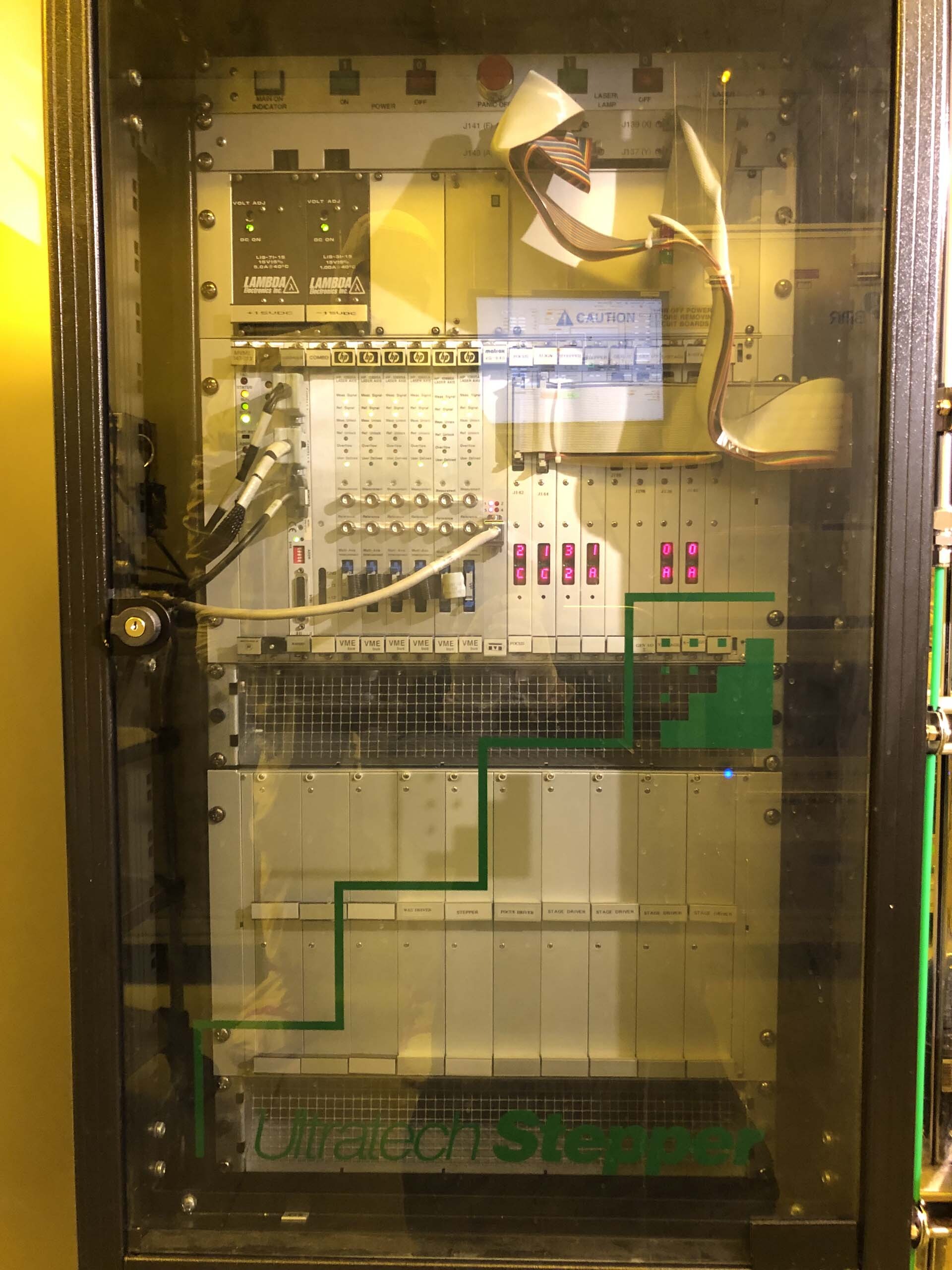

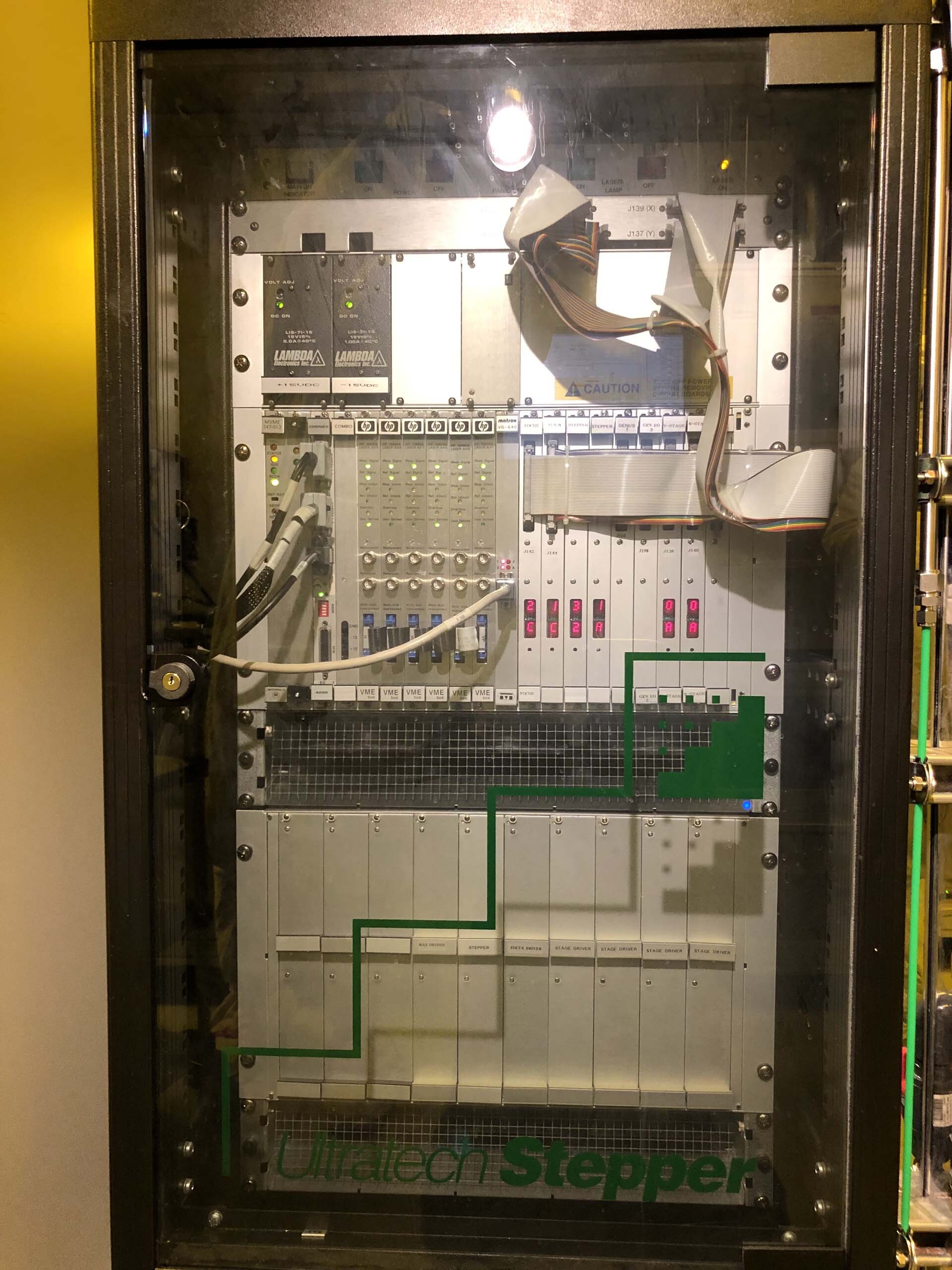

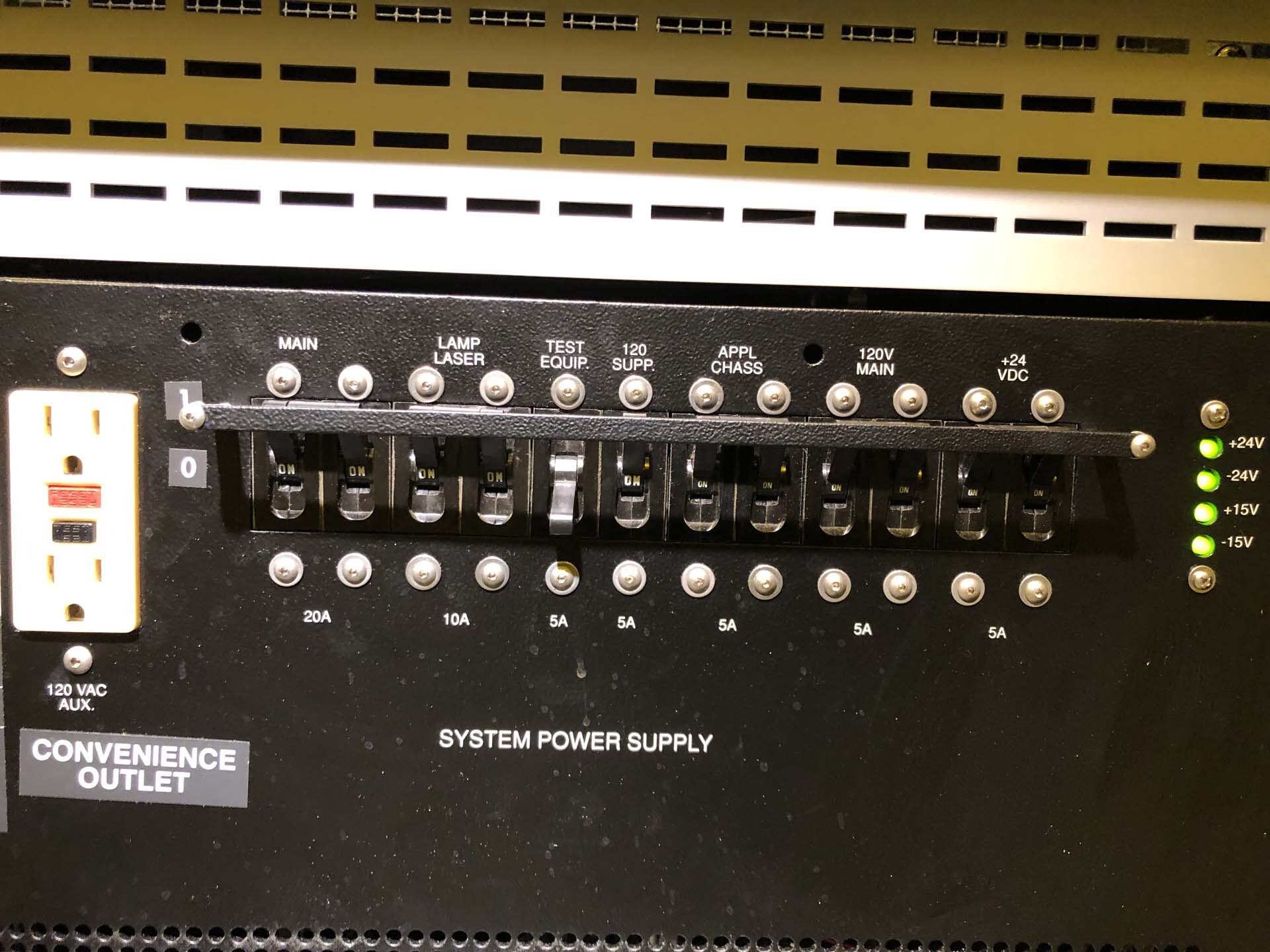

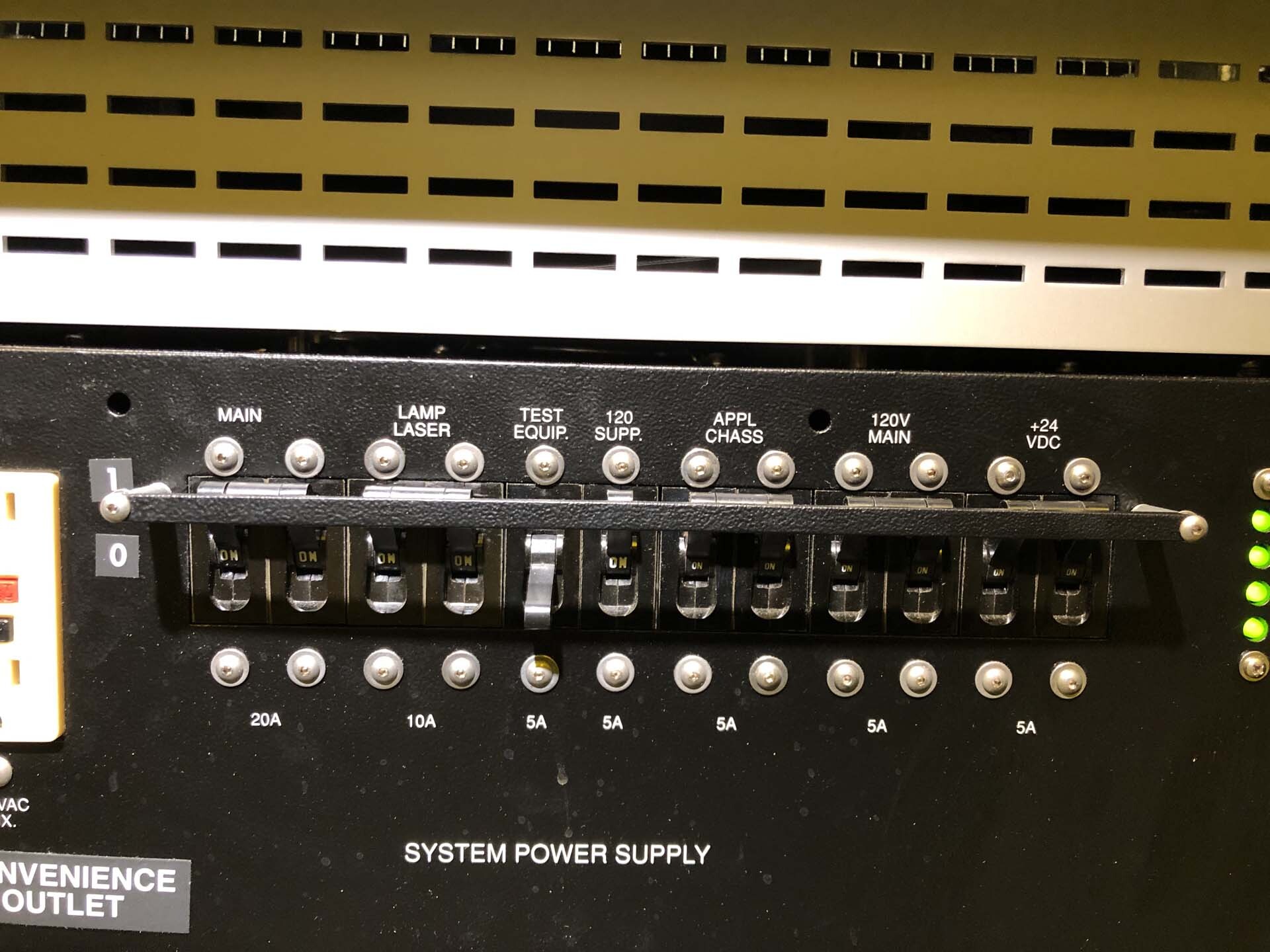

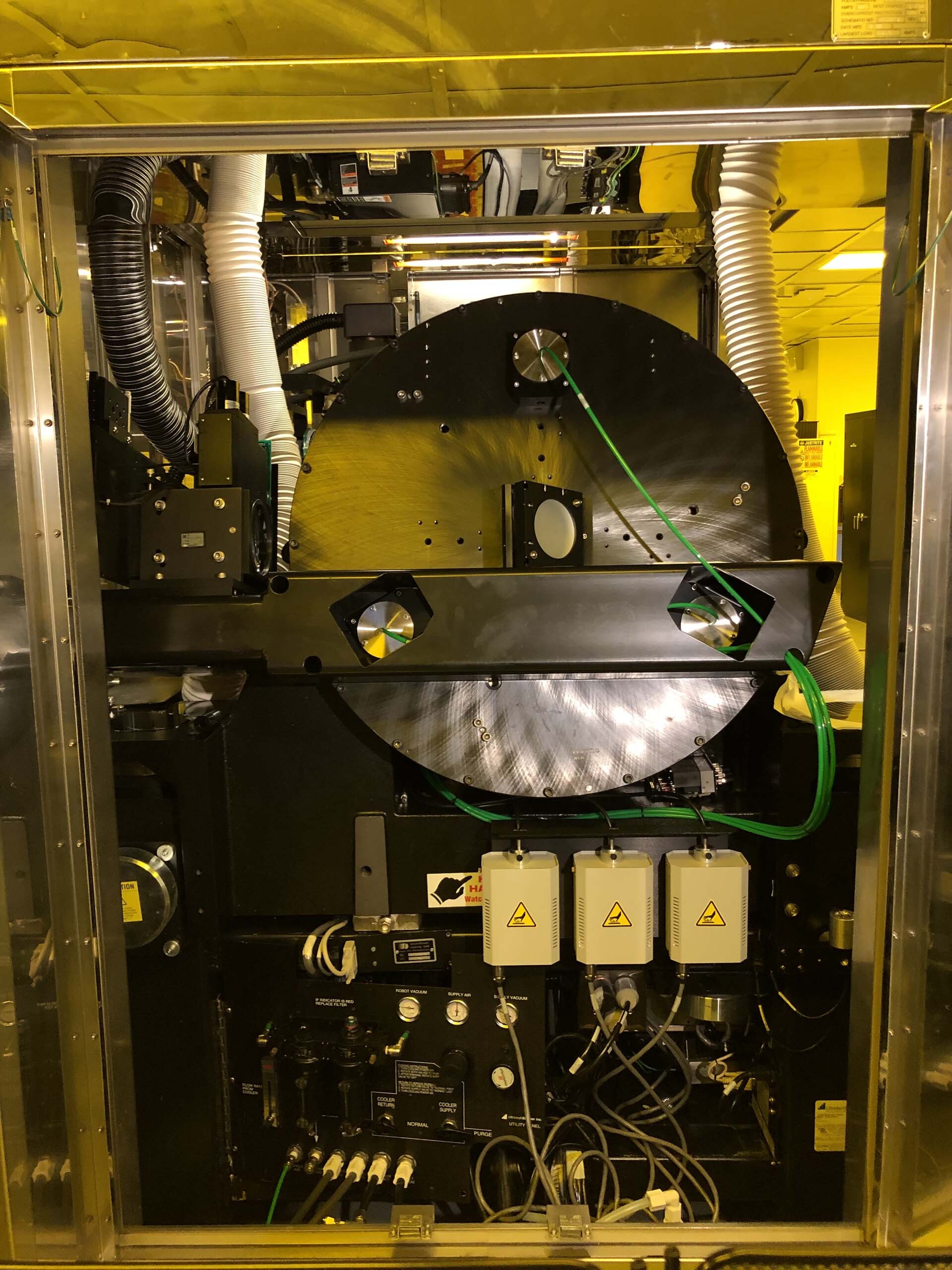

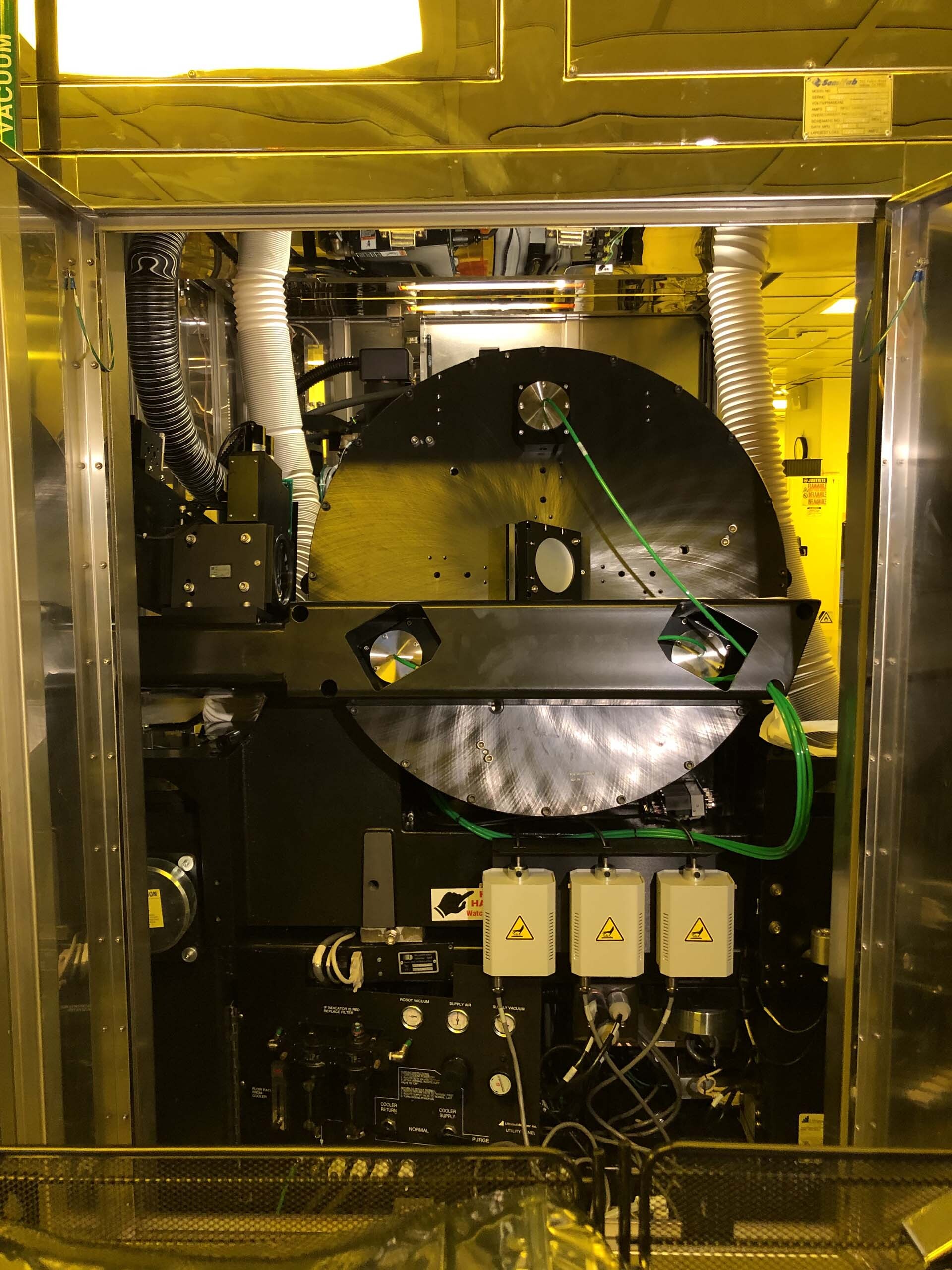

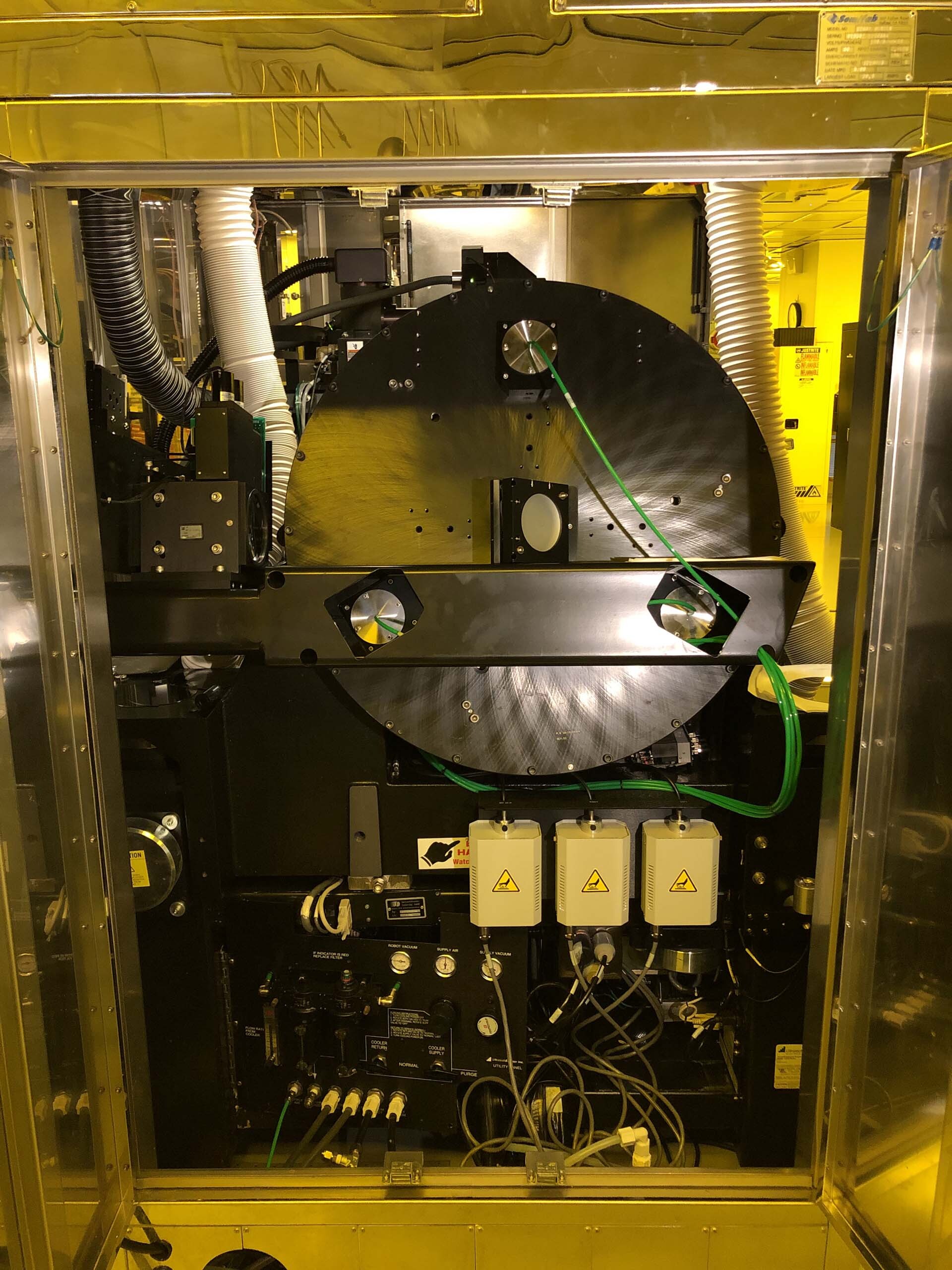

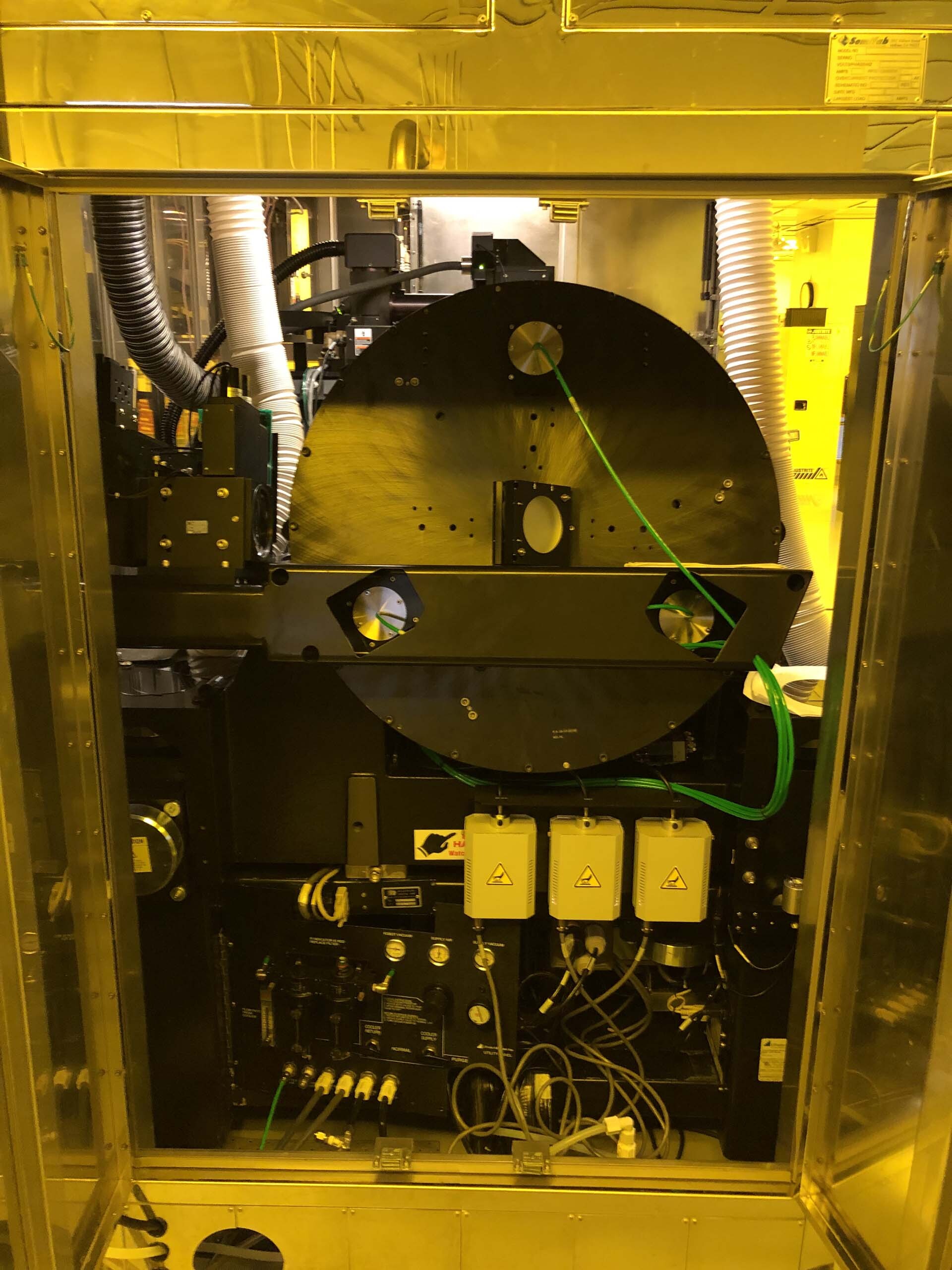

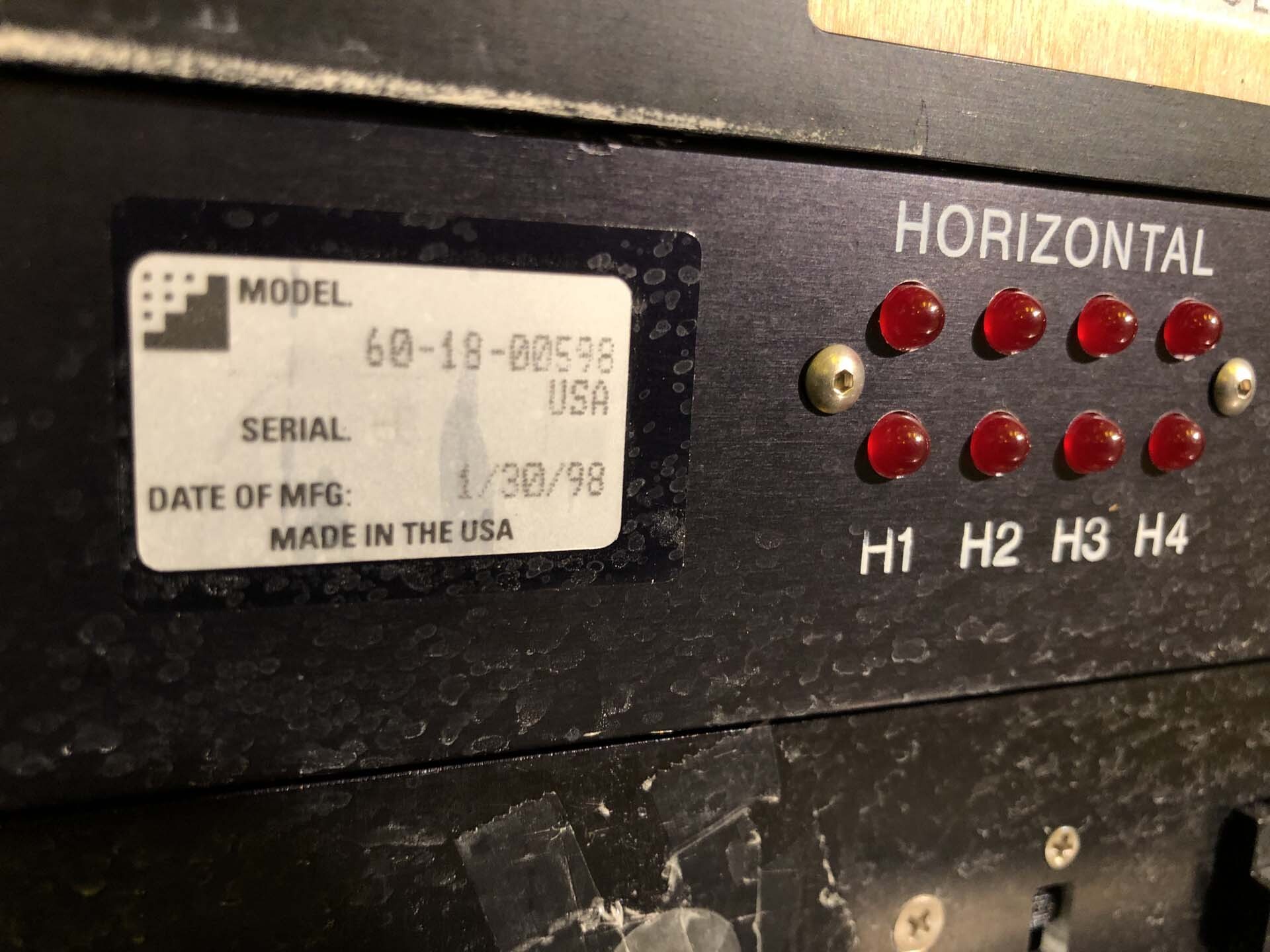

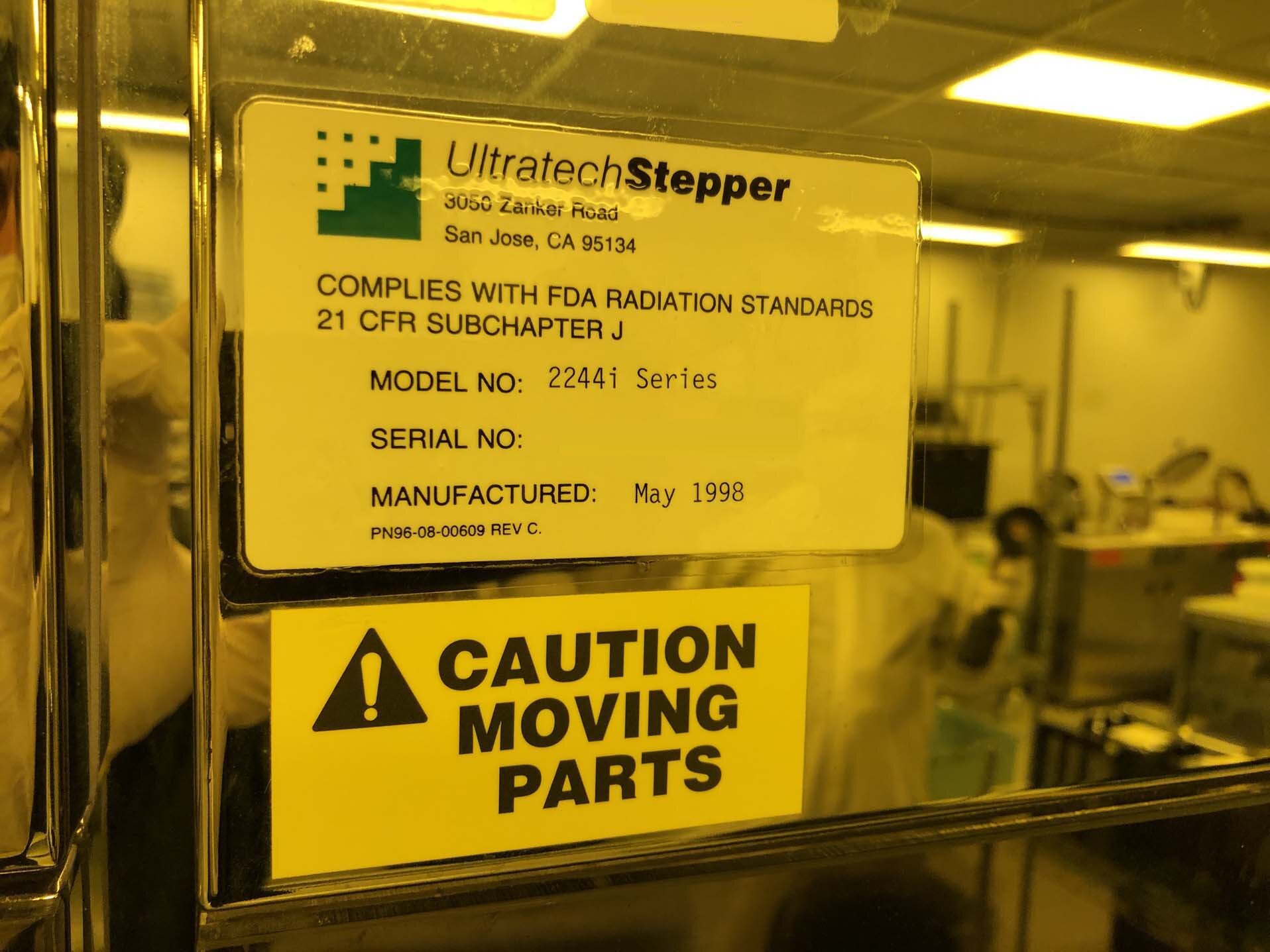

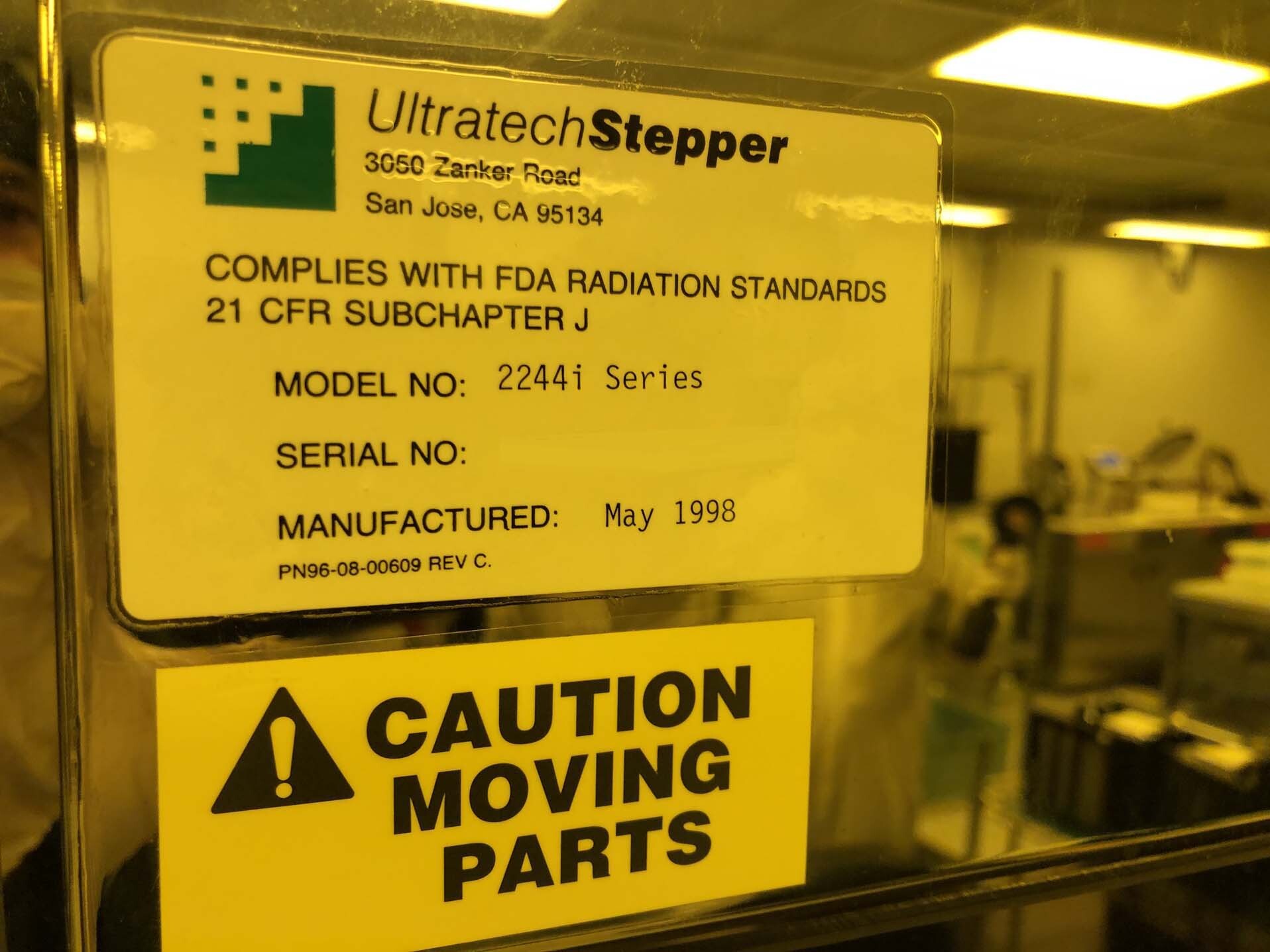

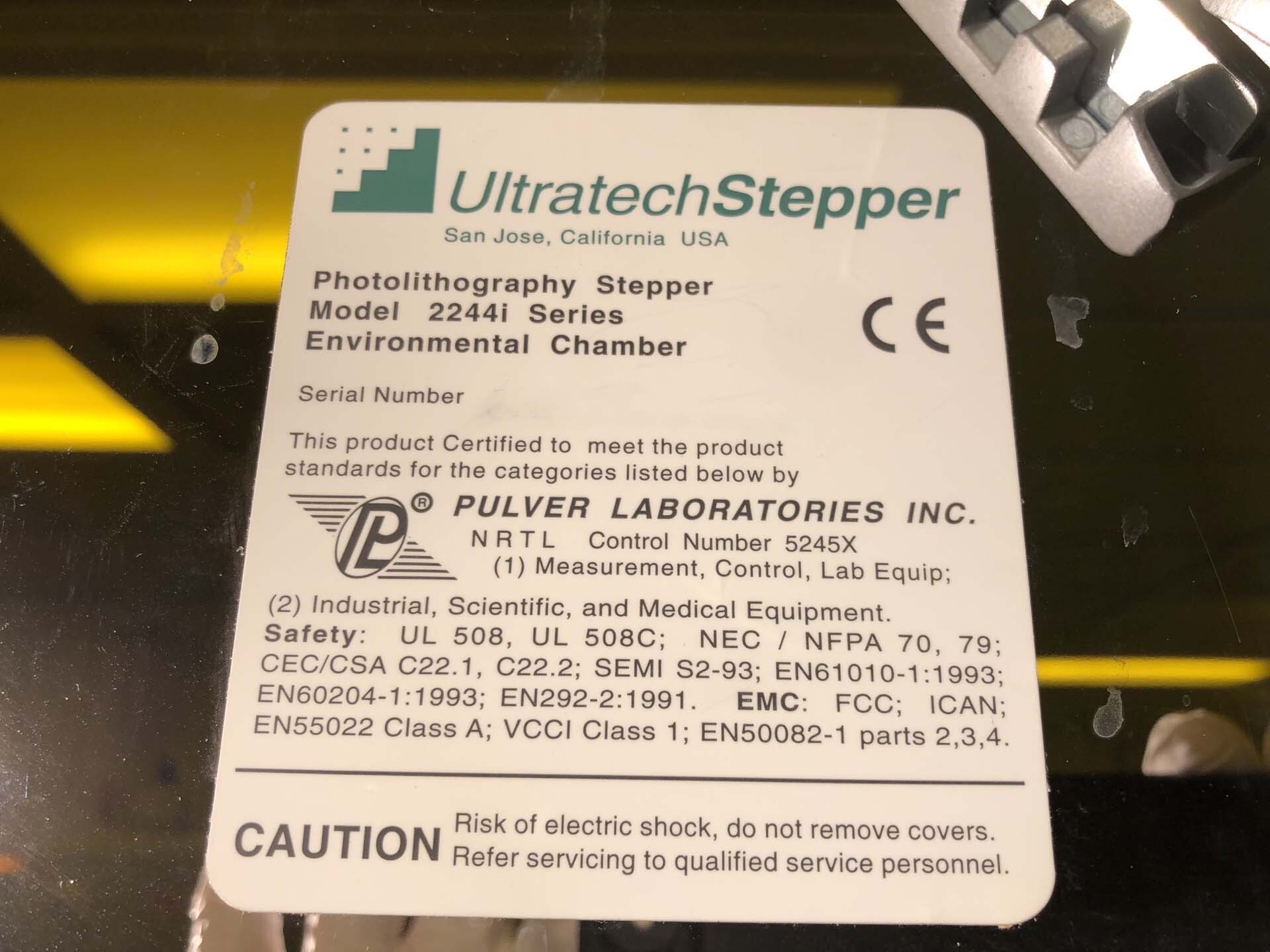

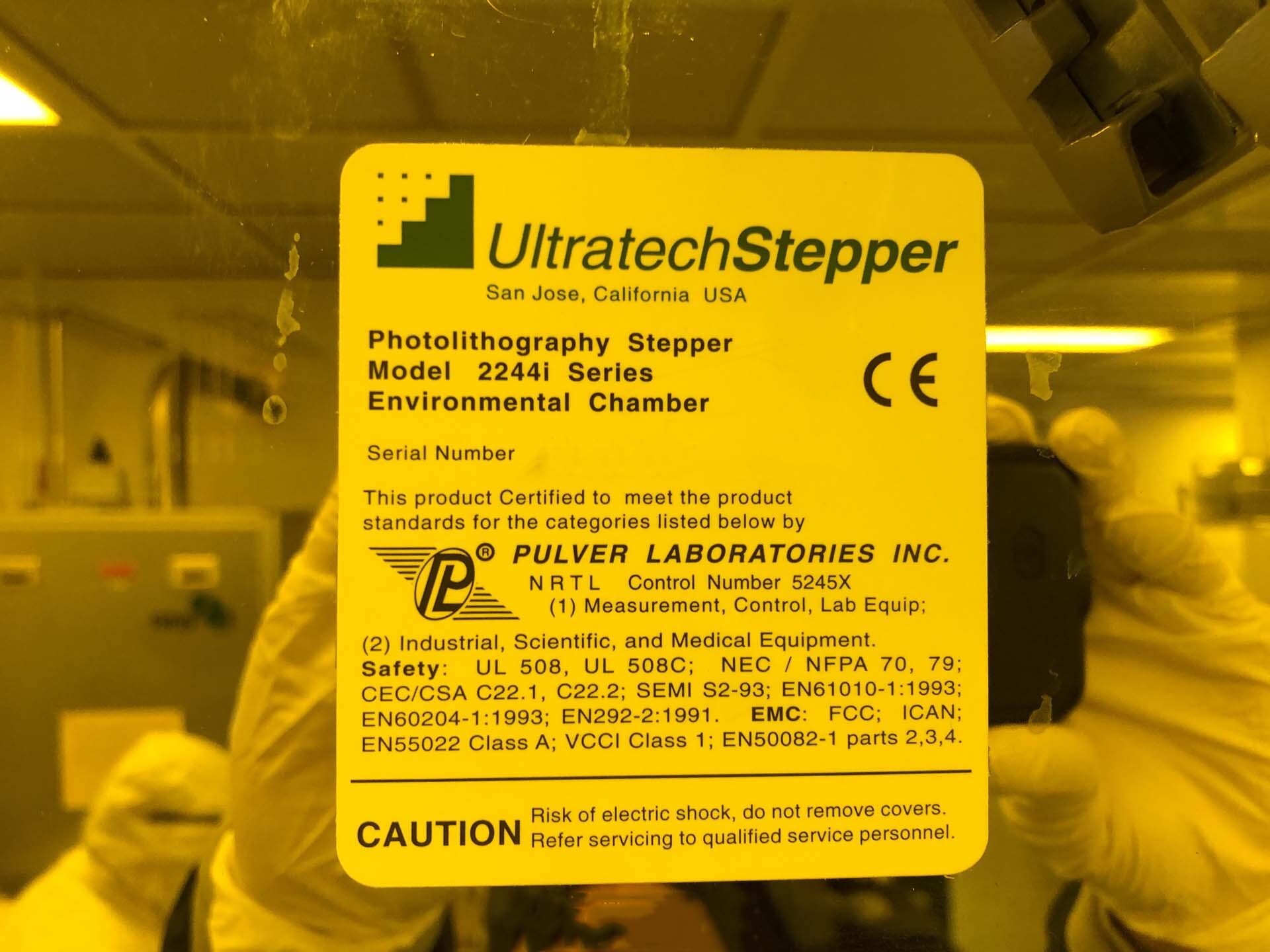

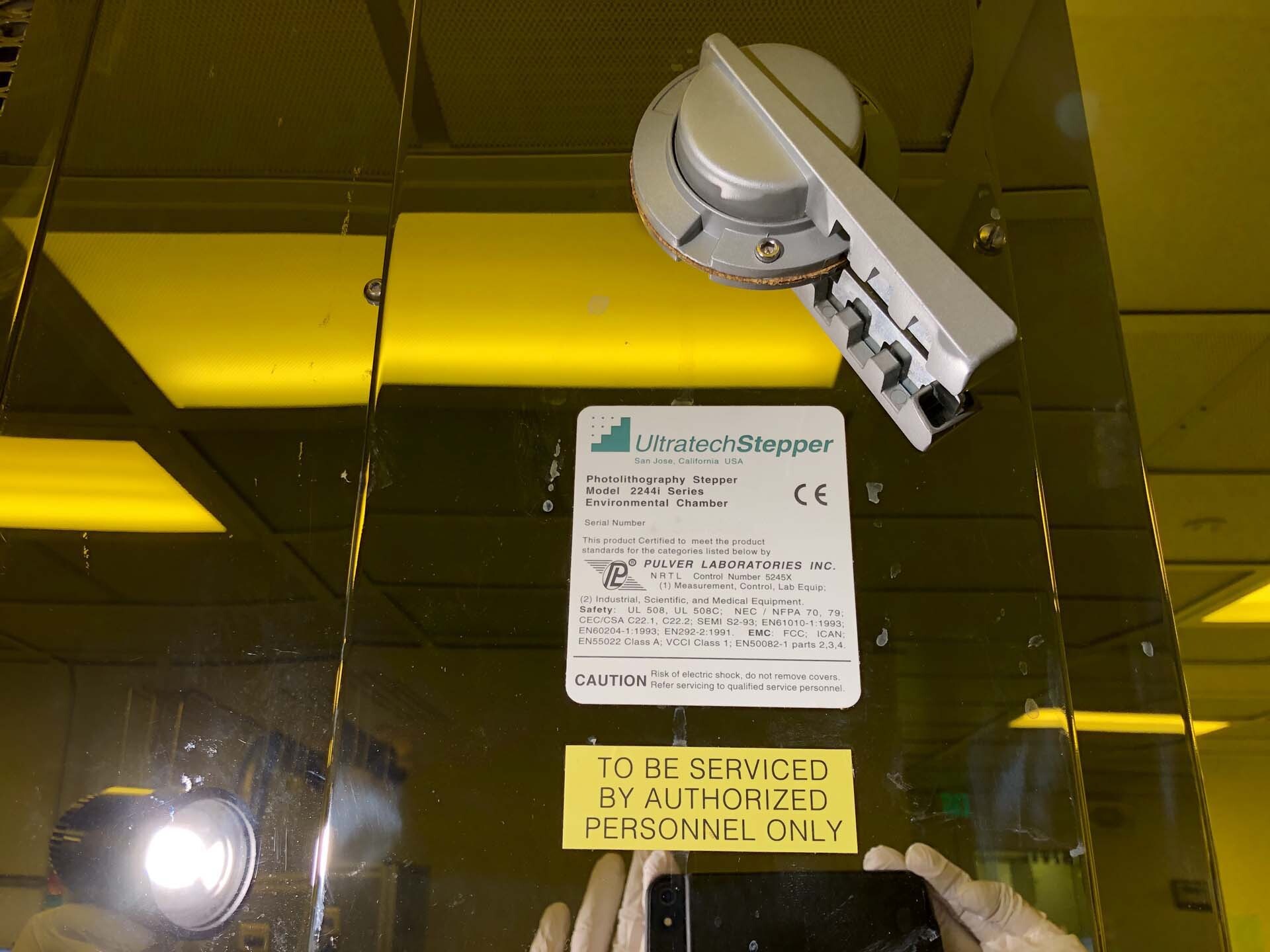

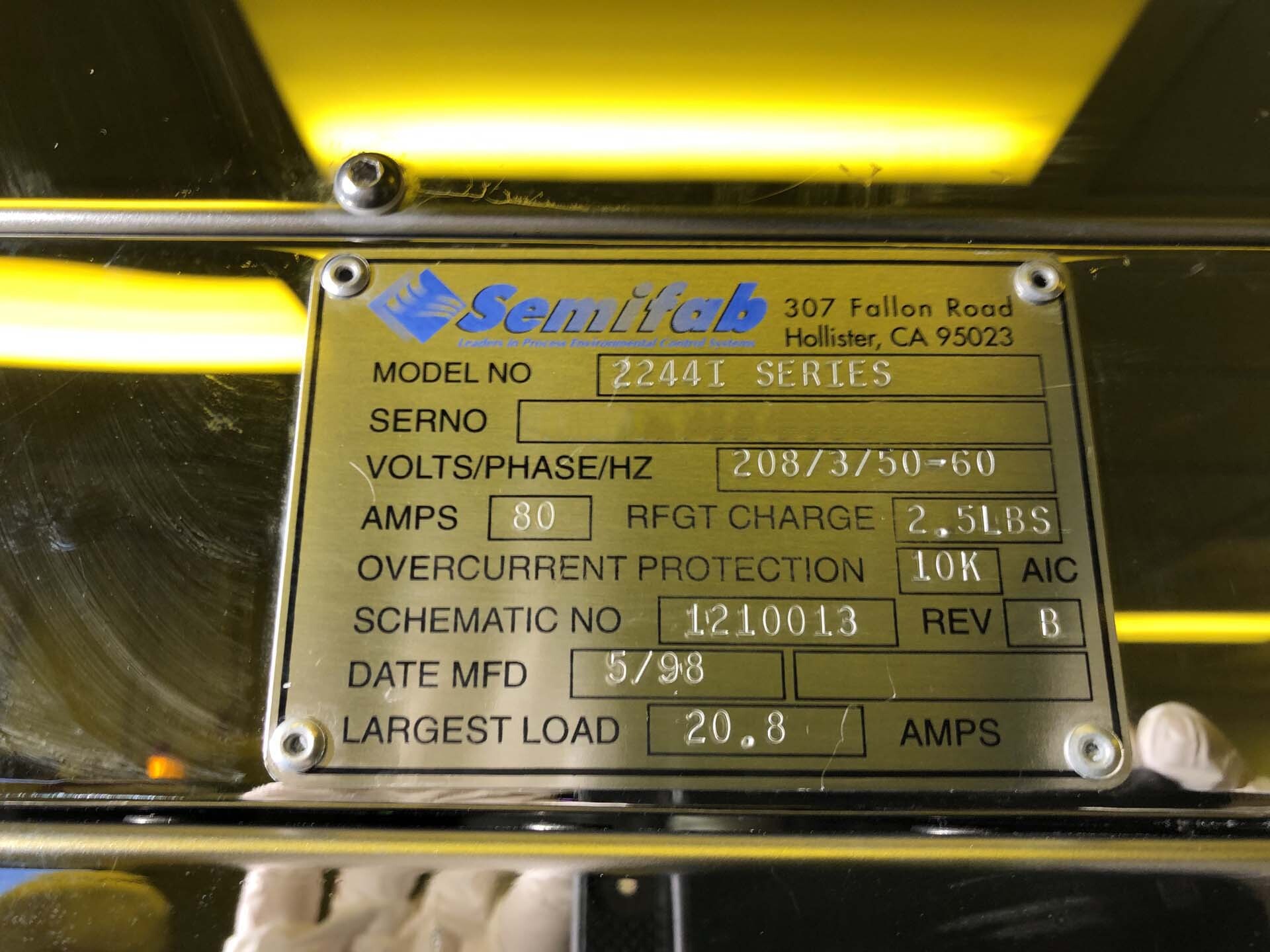

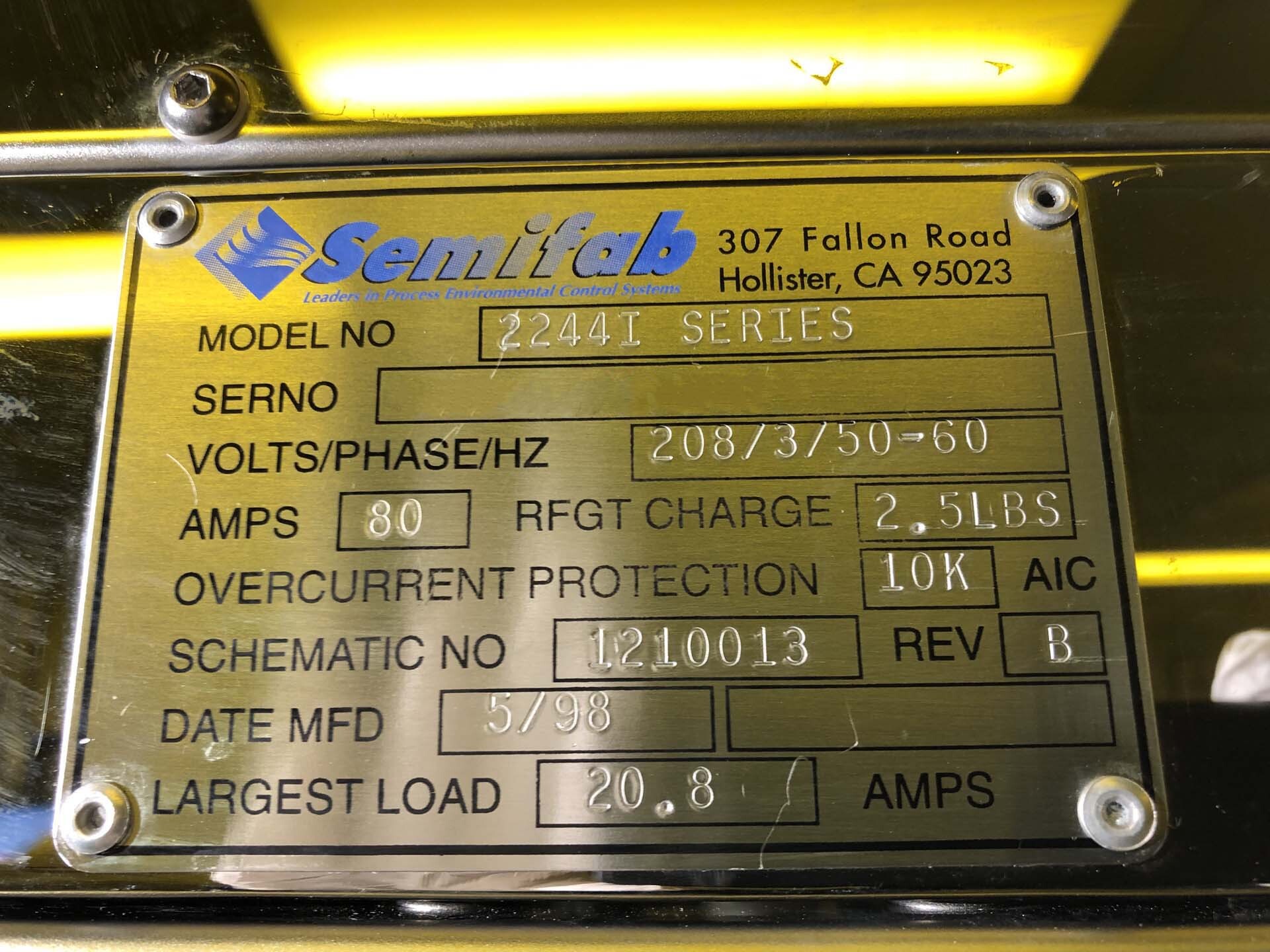

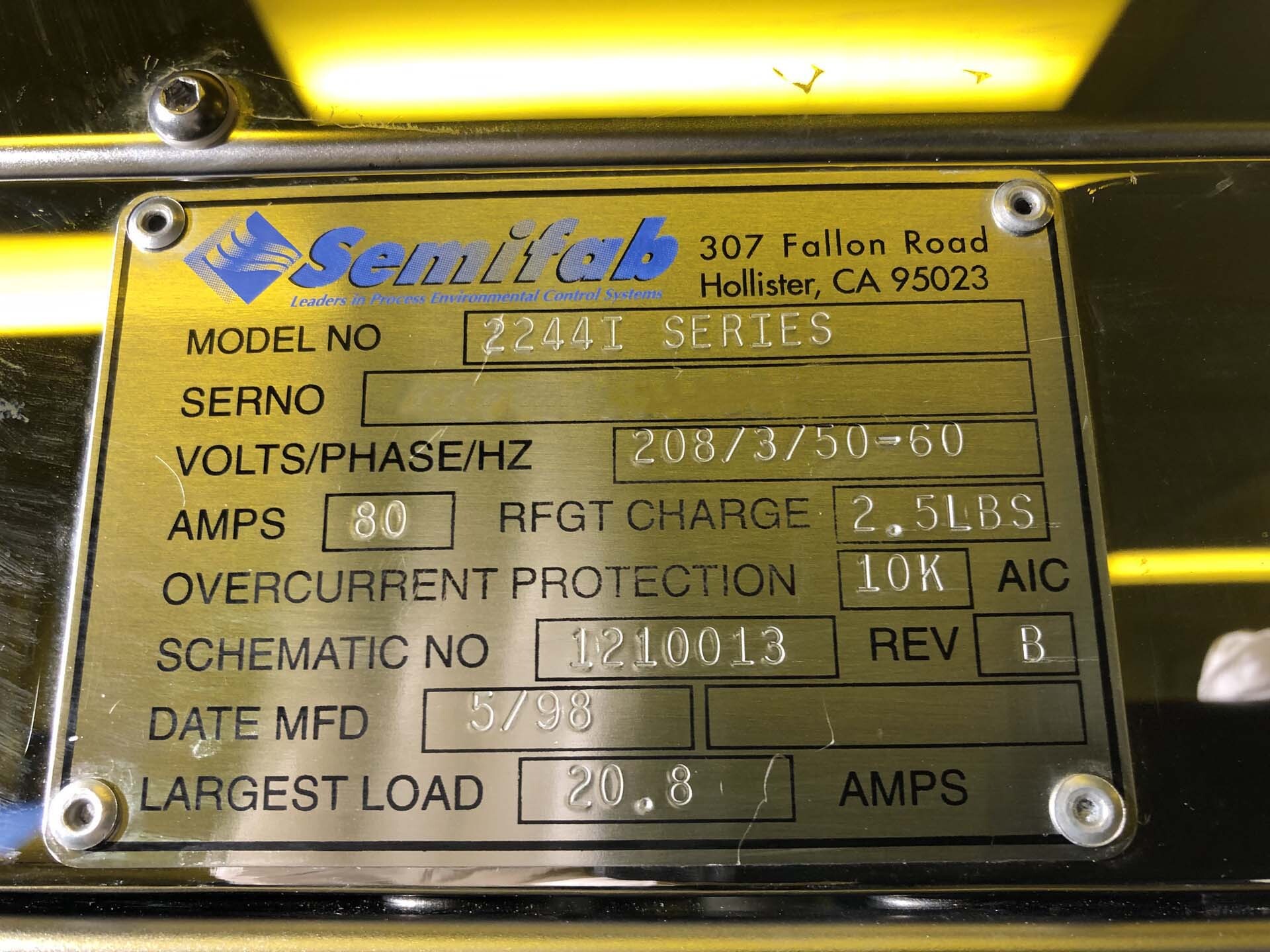

Used ULTRATECH Saturn III 6700 #293651574 for sale

URL successfully copied!

Tap to zoom

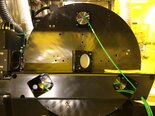

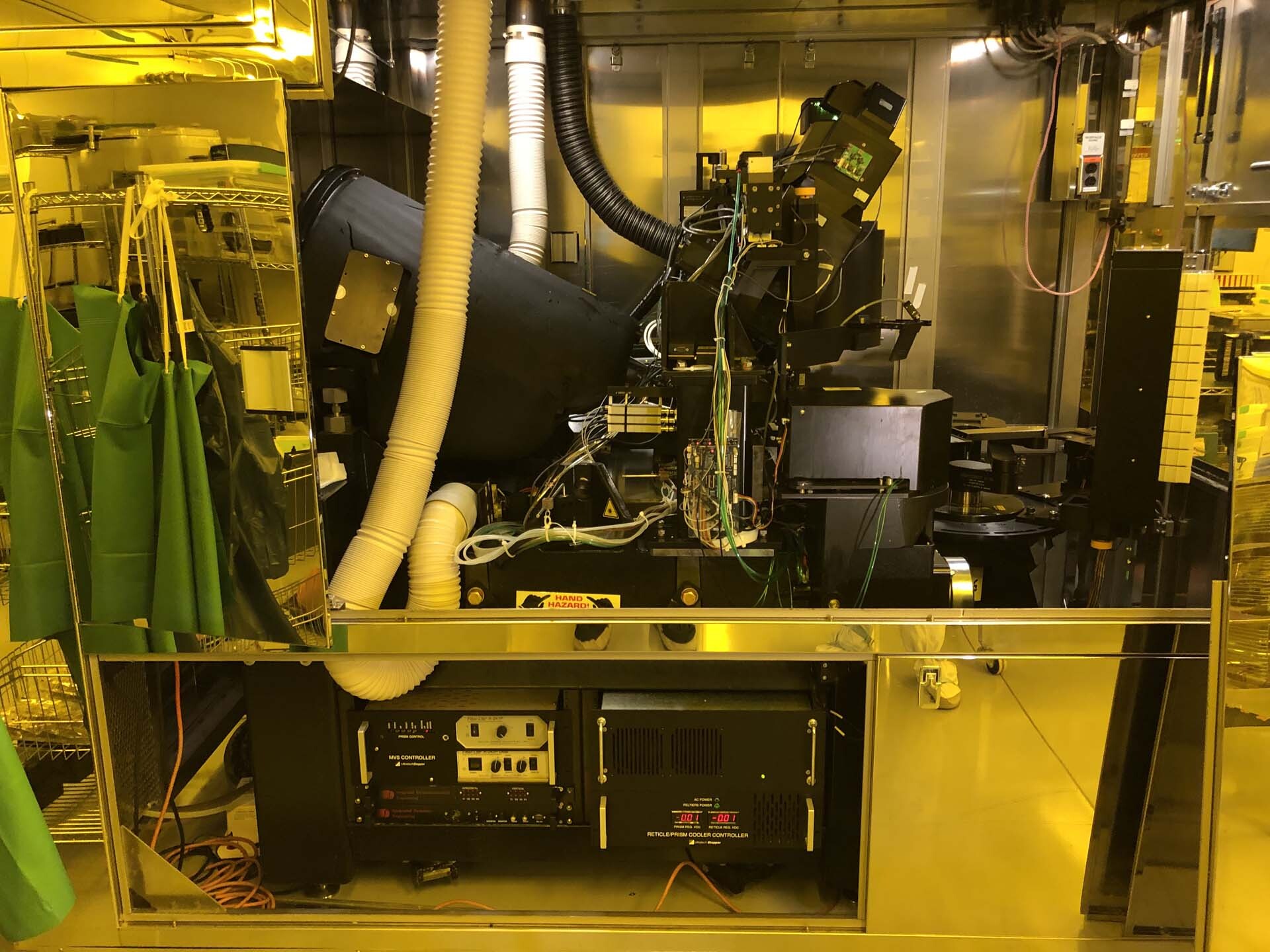

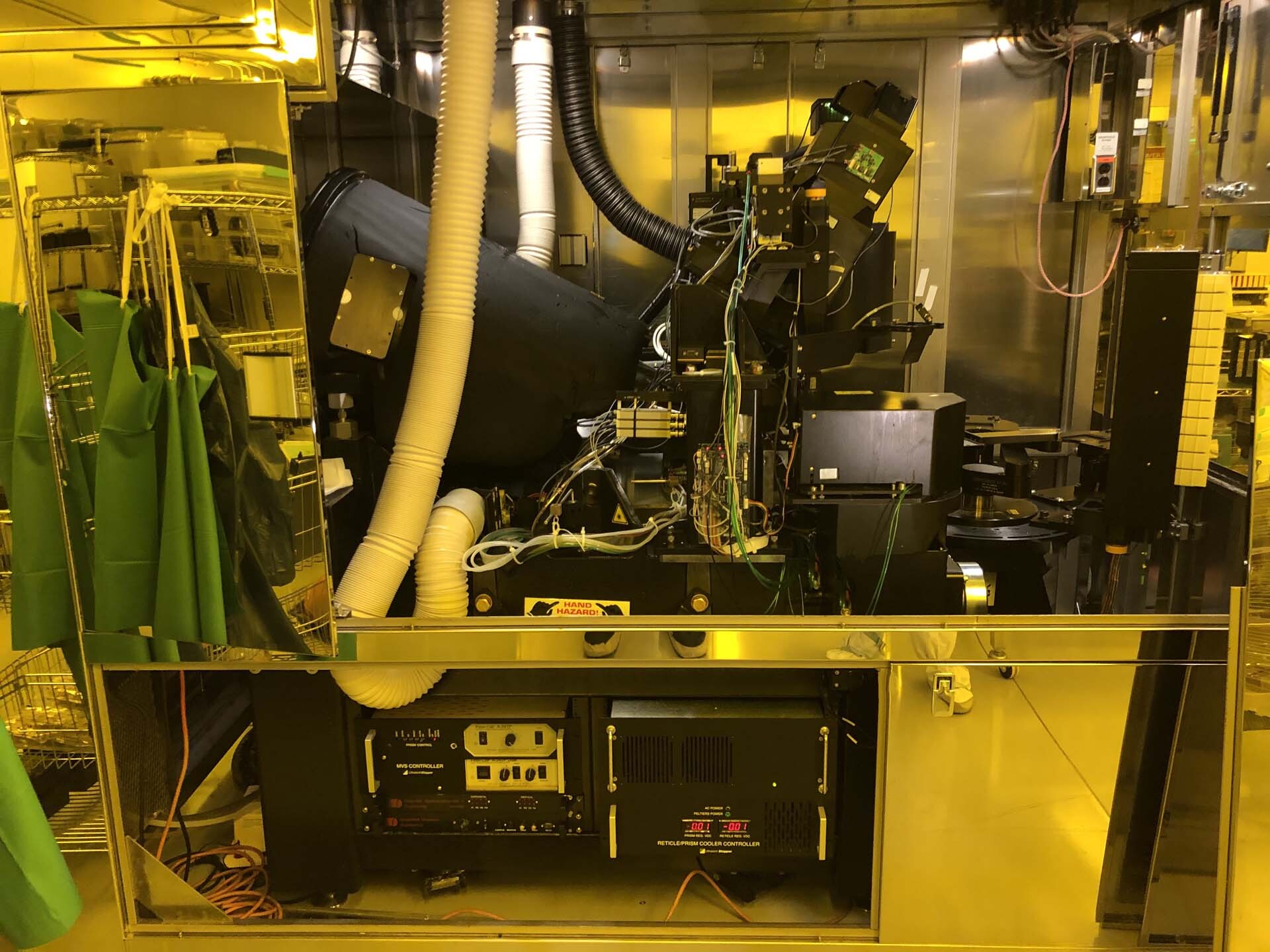

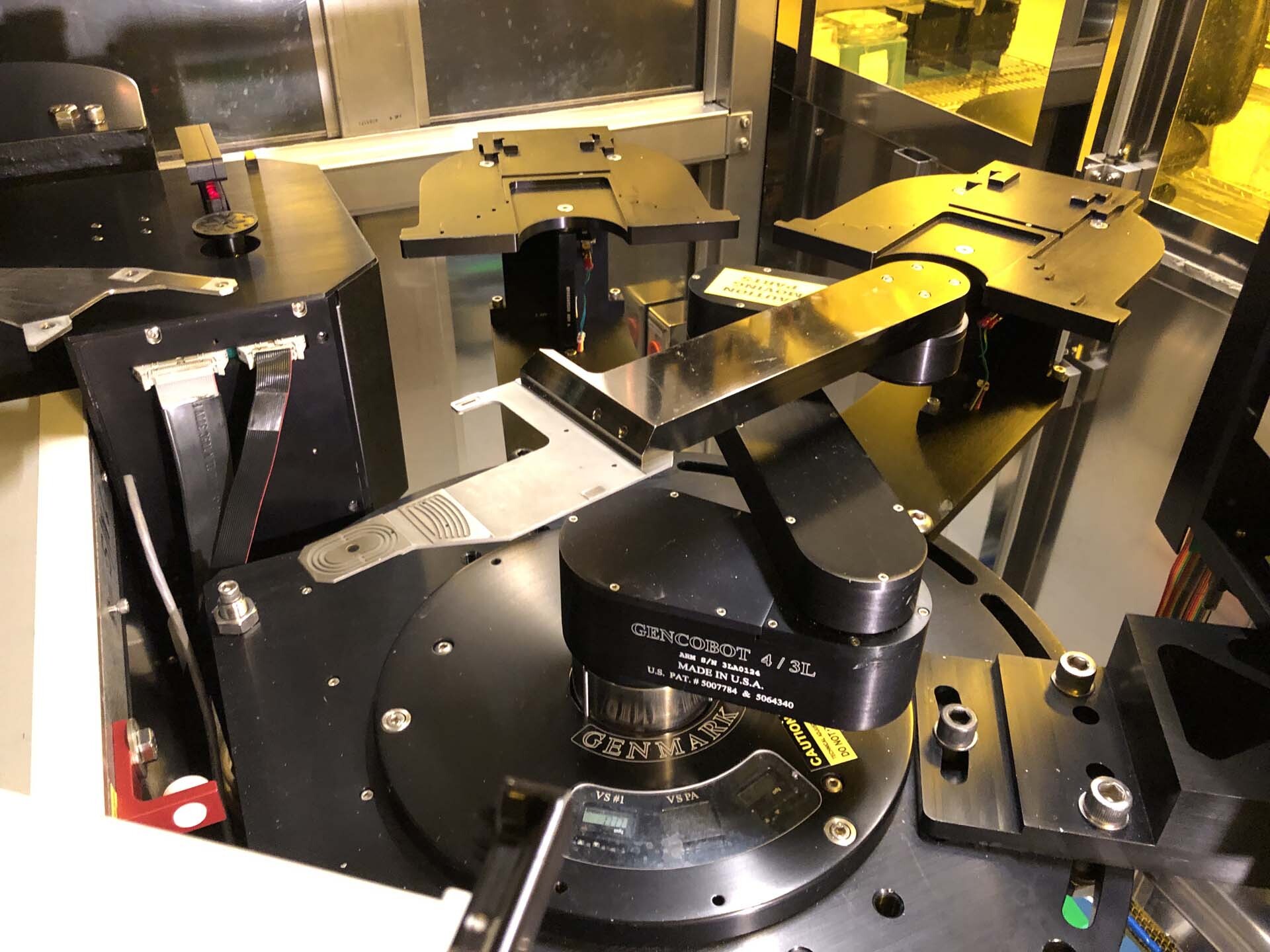

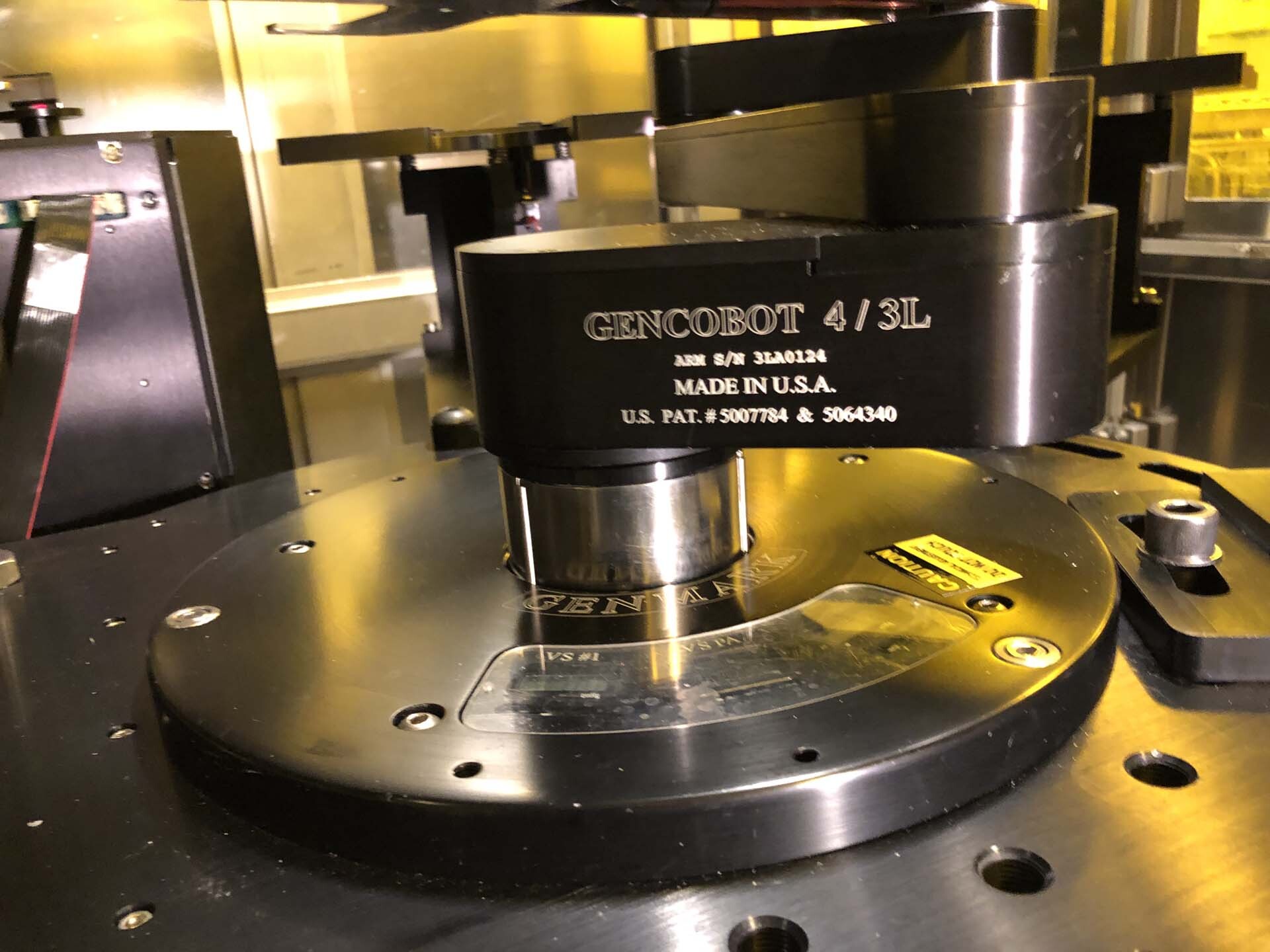

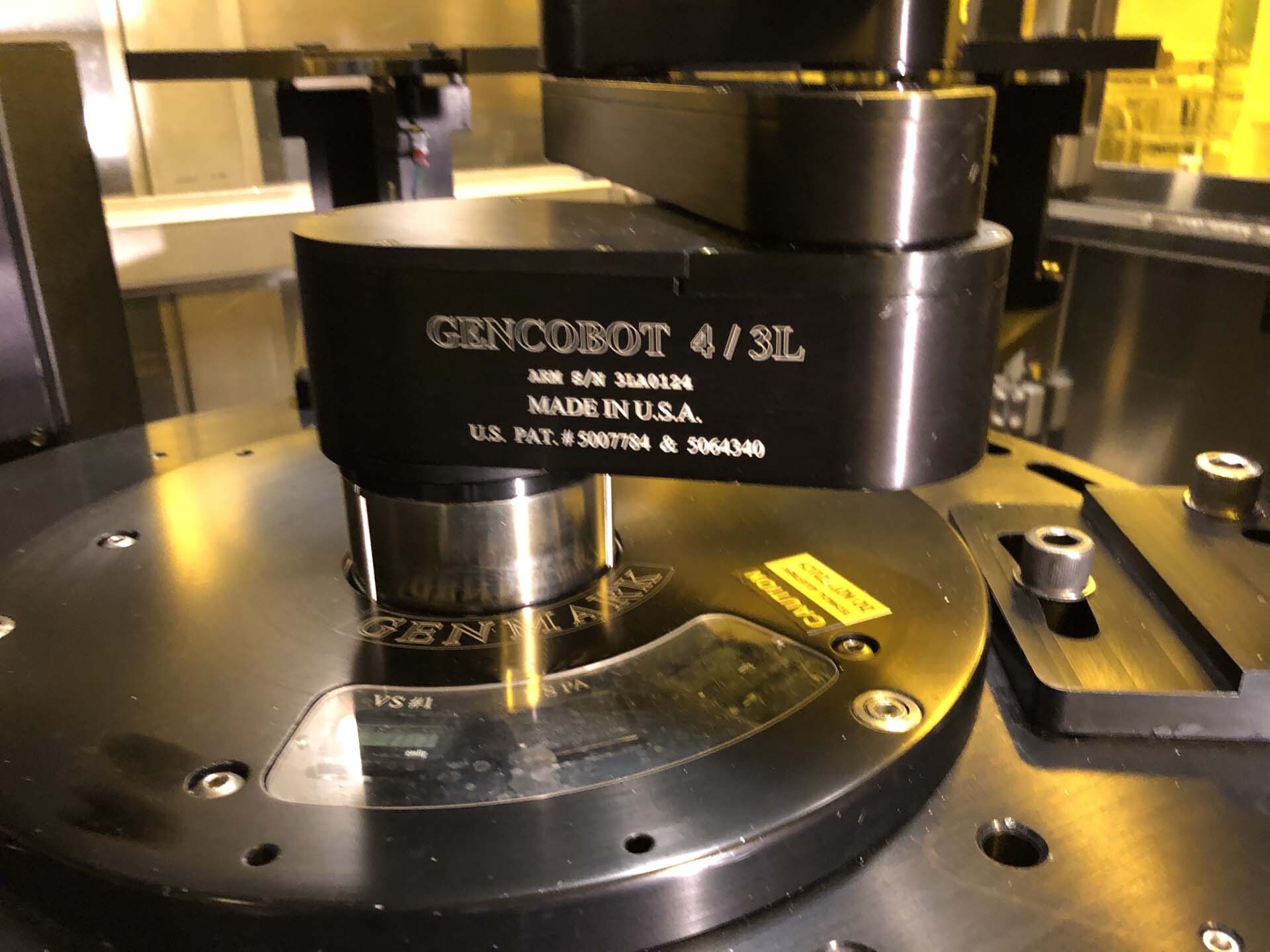

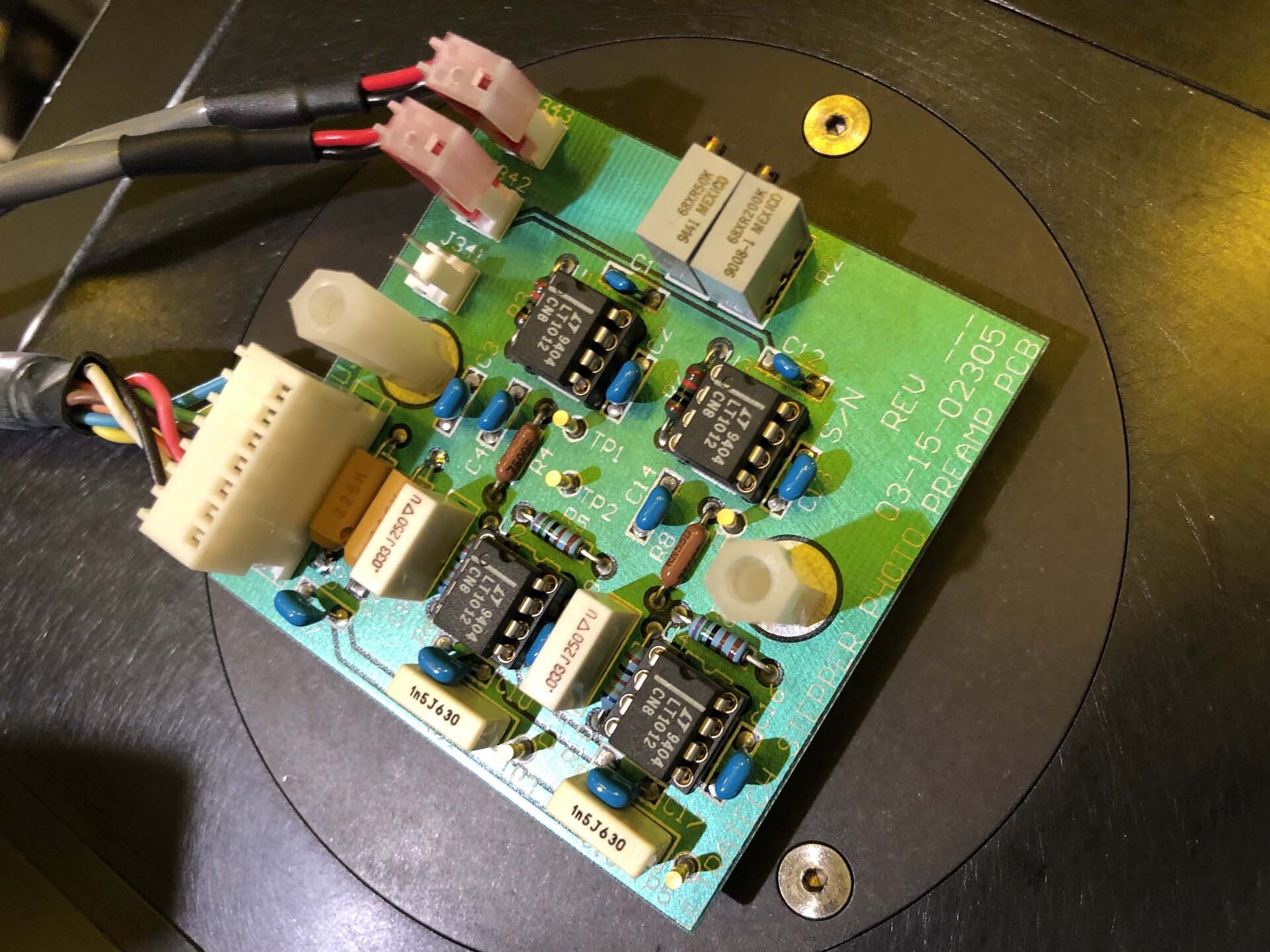

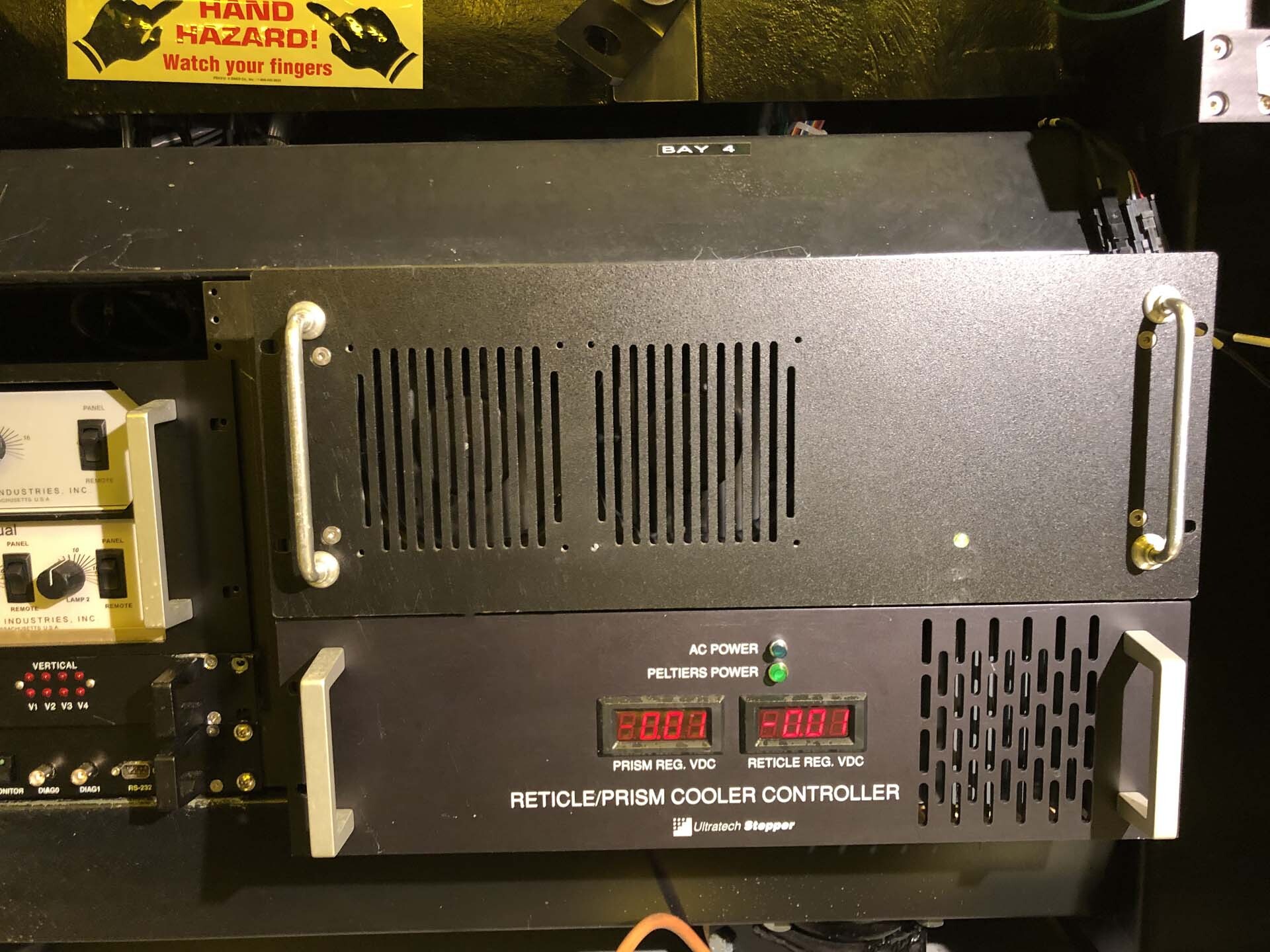

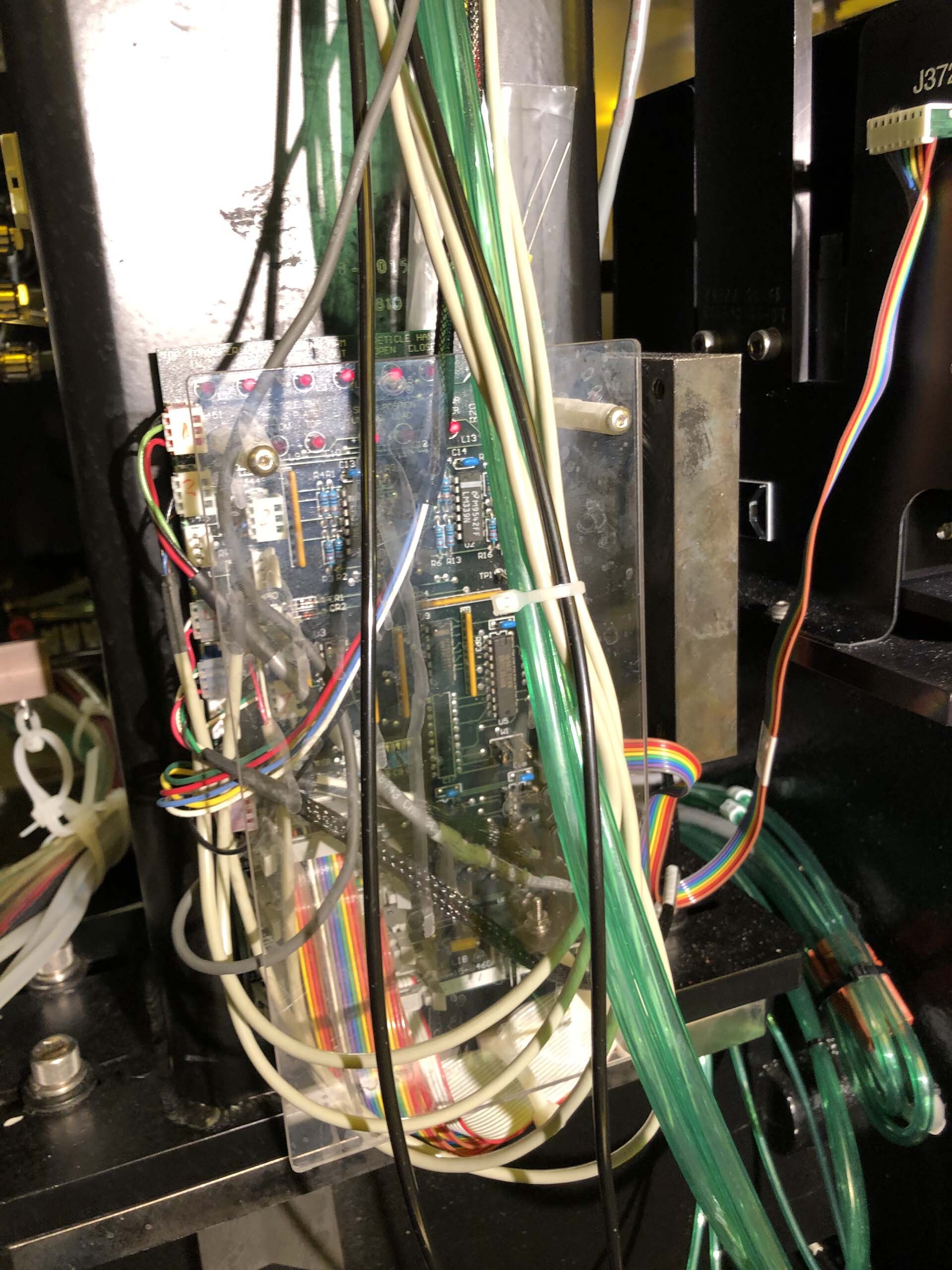

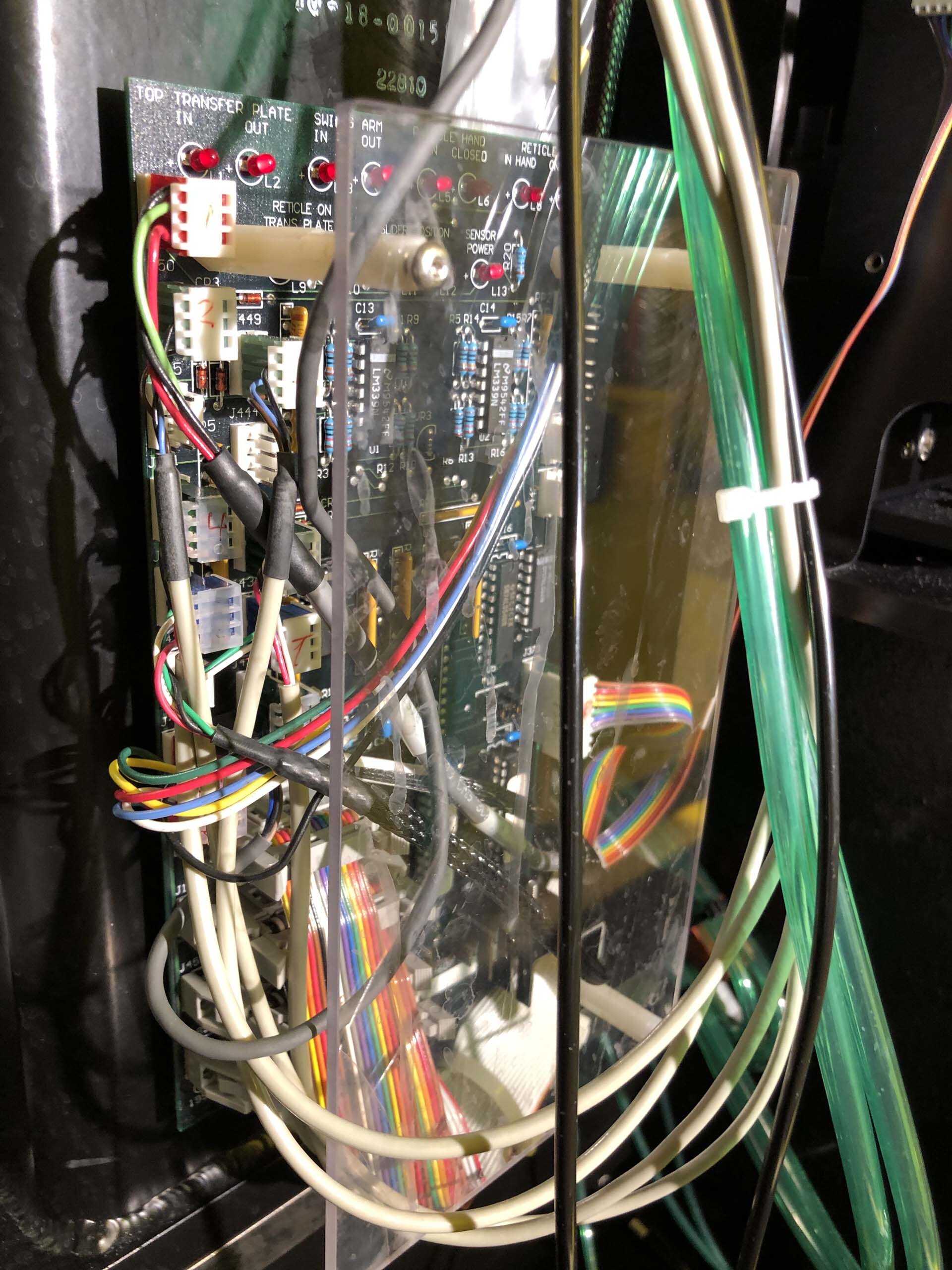

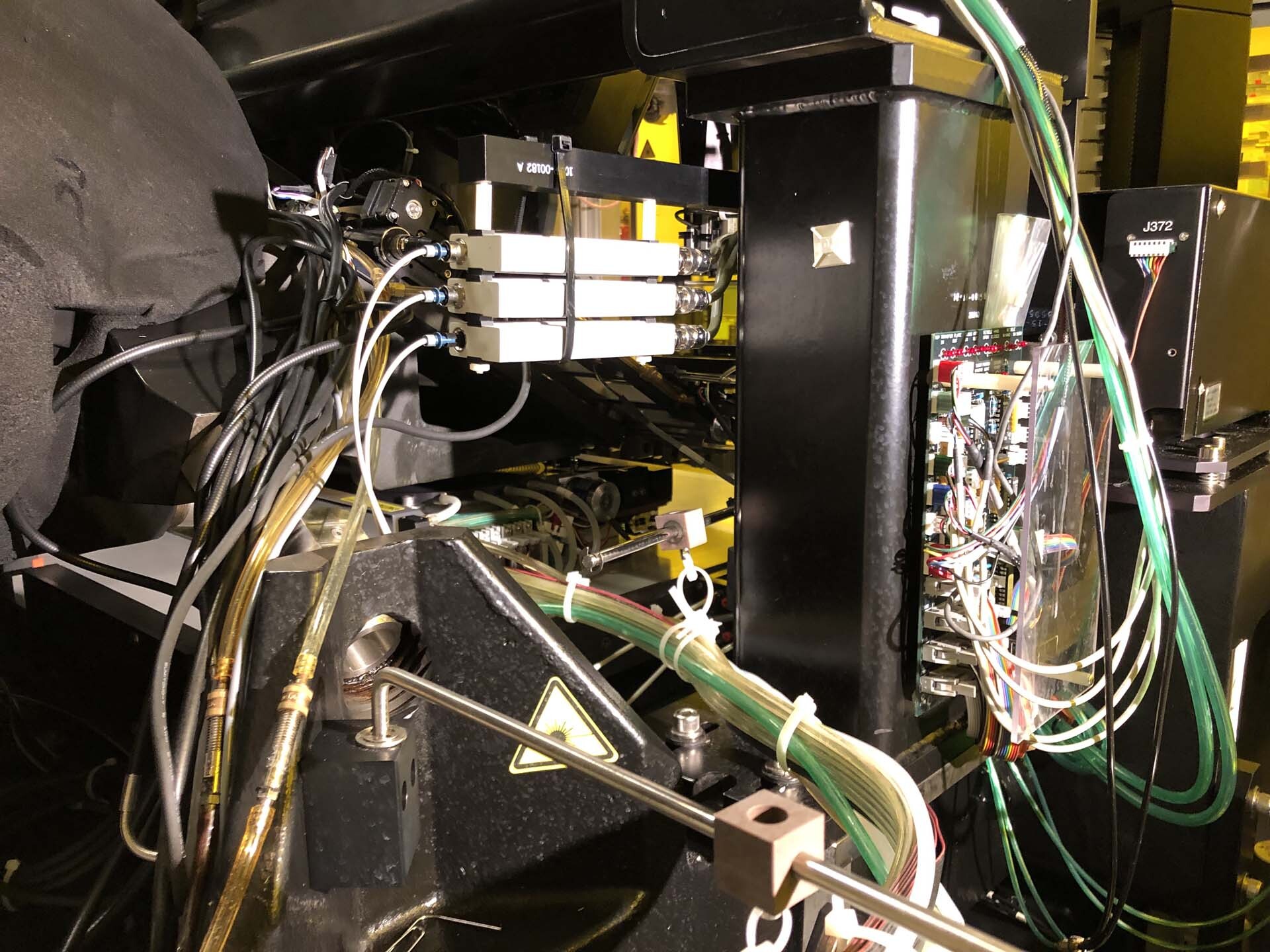

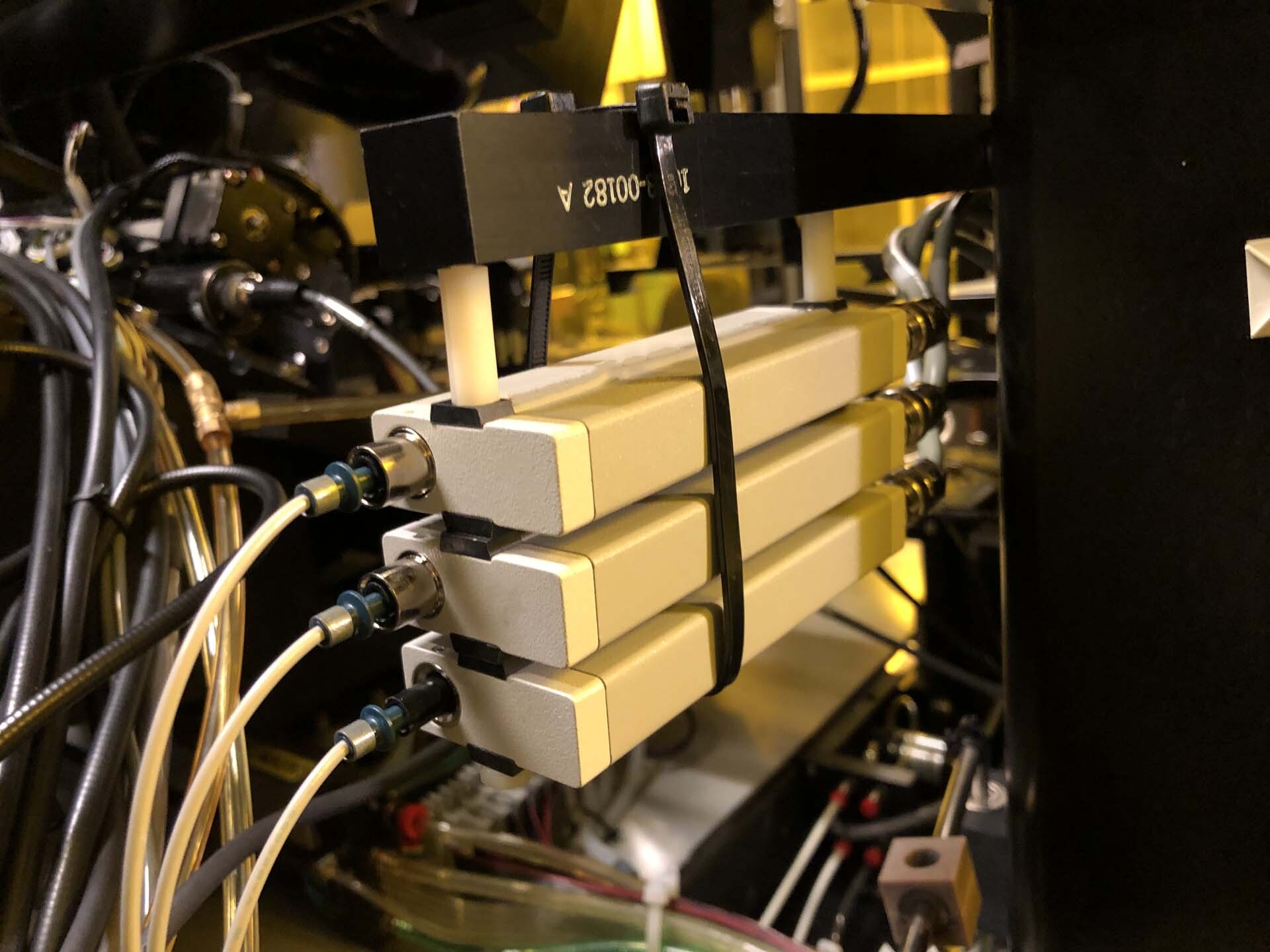

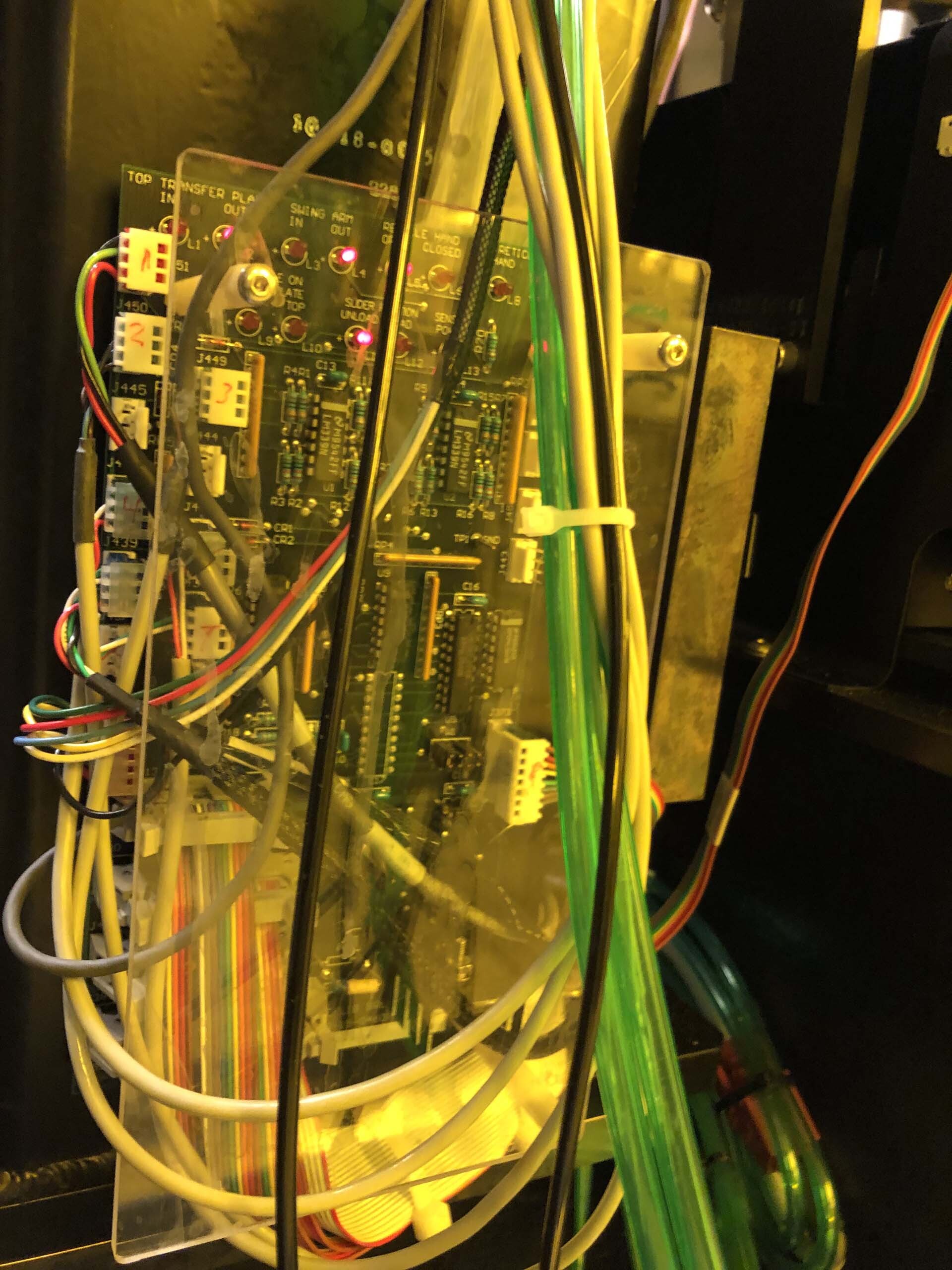

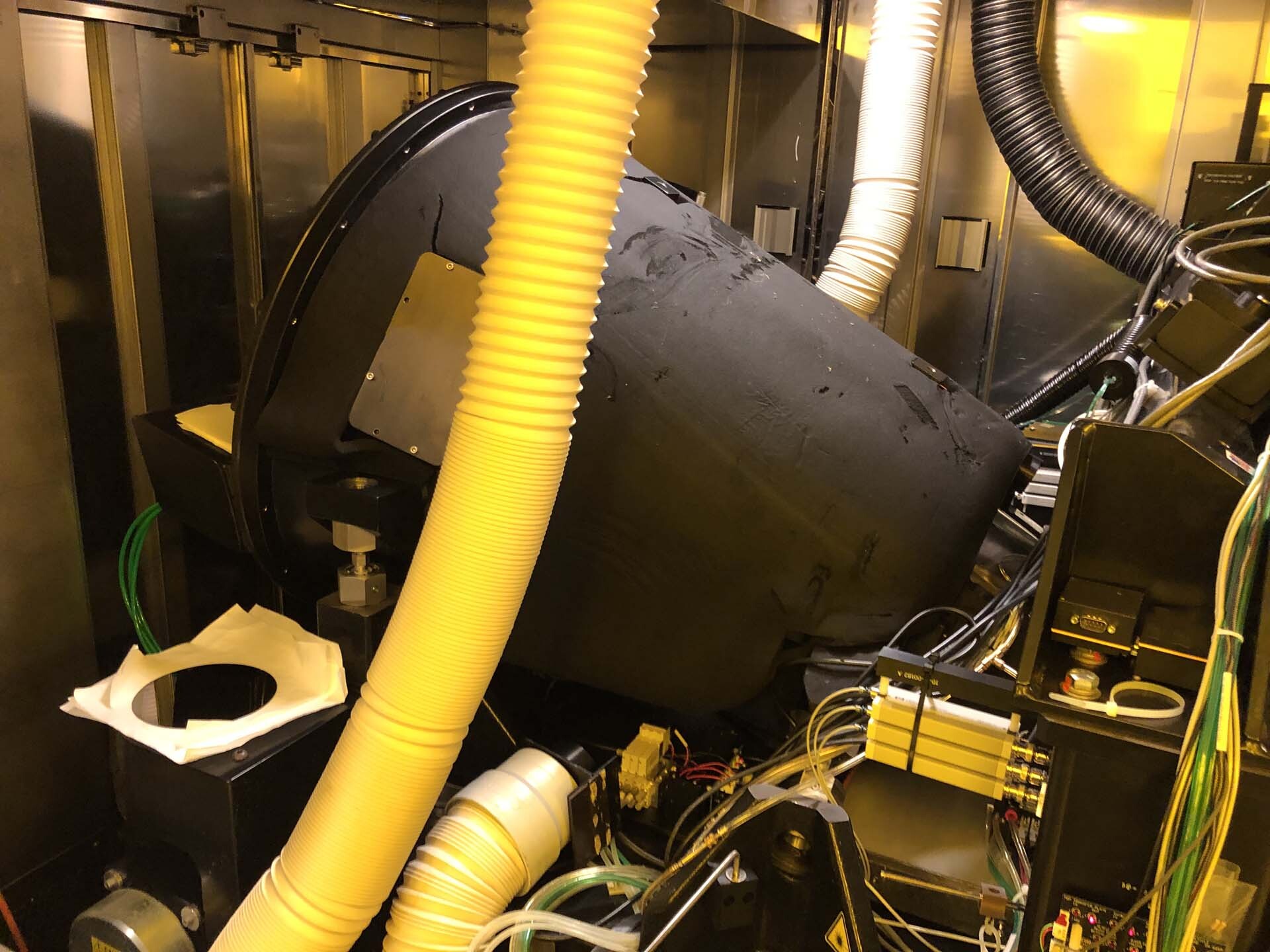

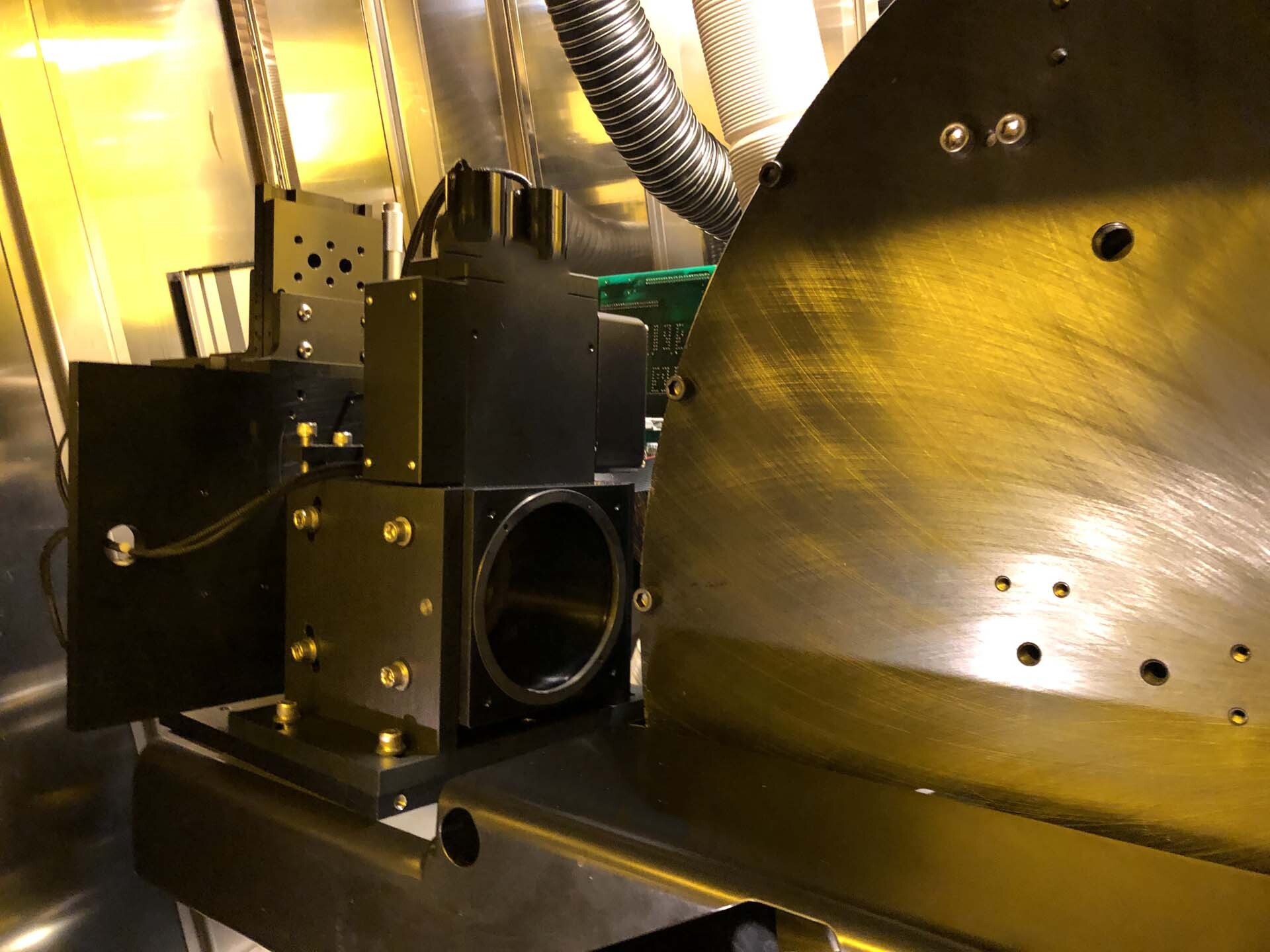

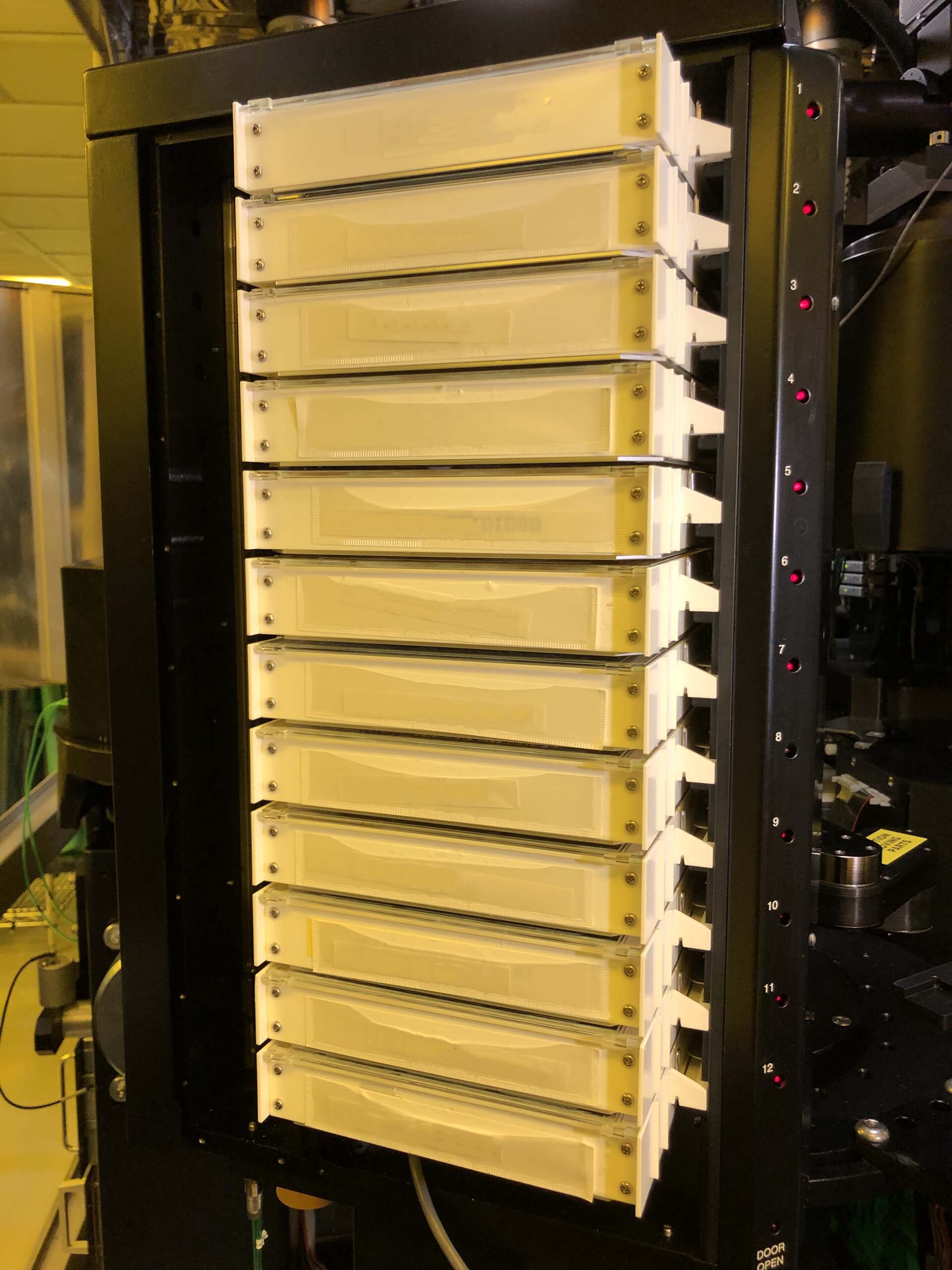

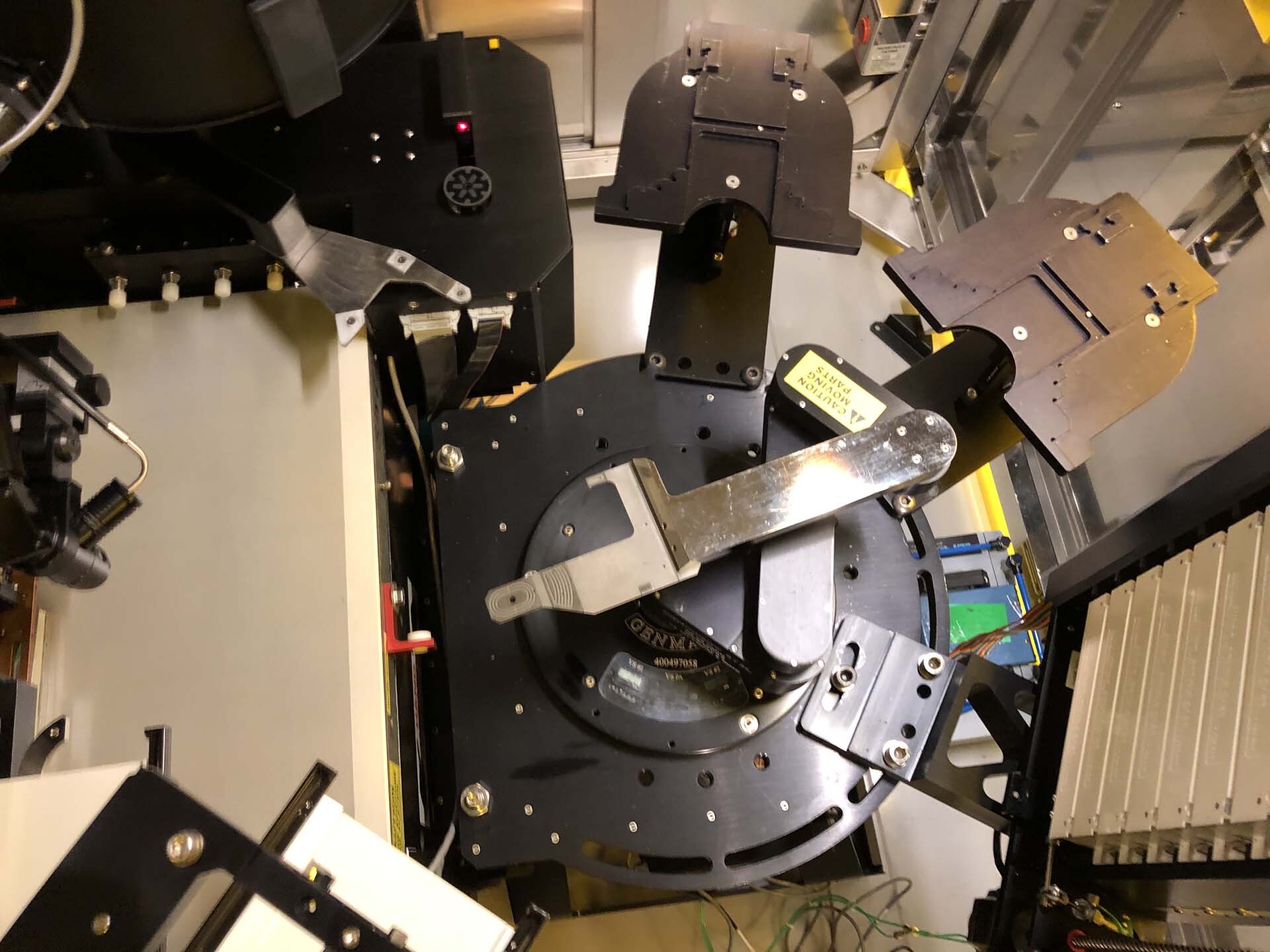

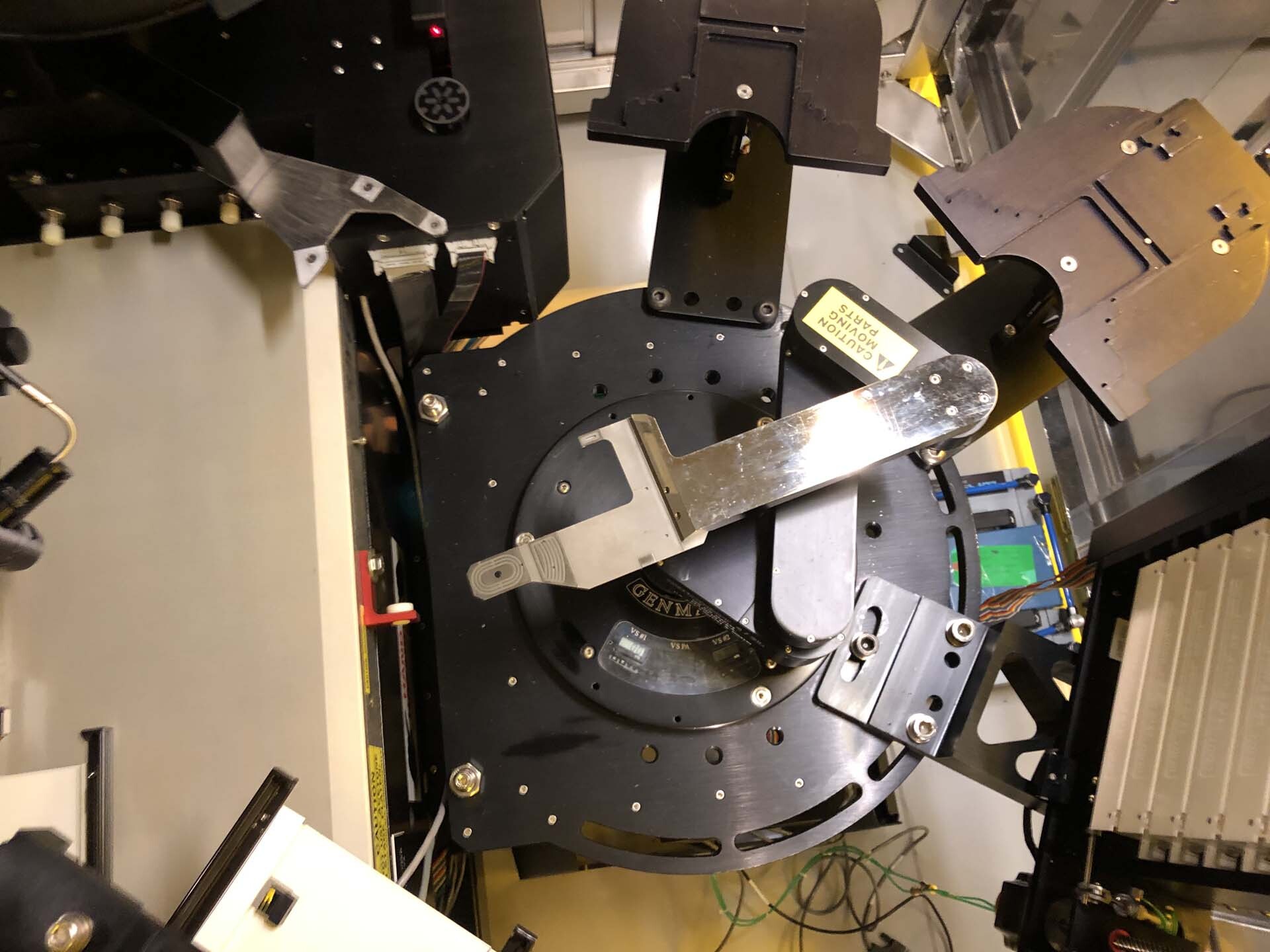

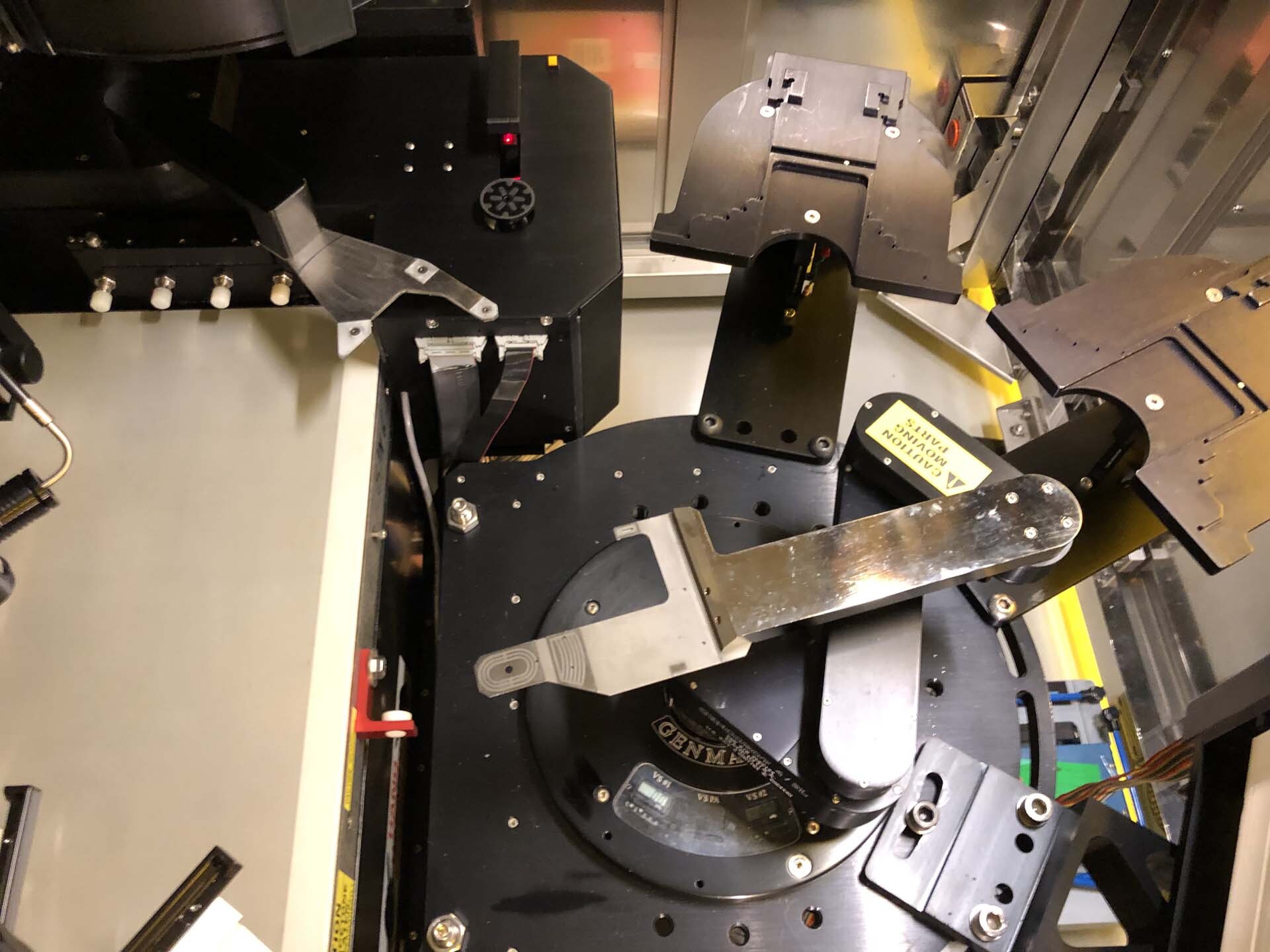

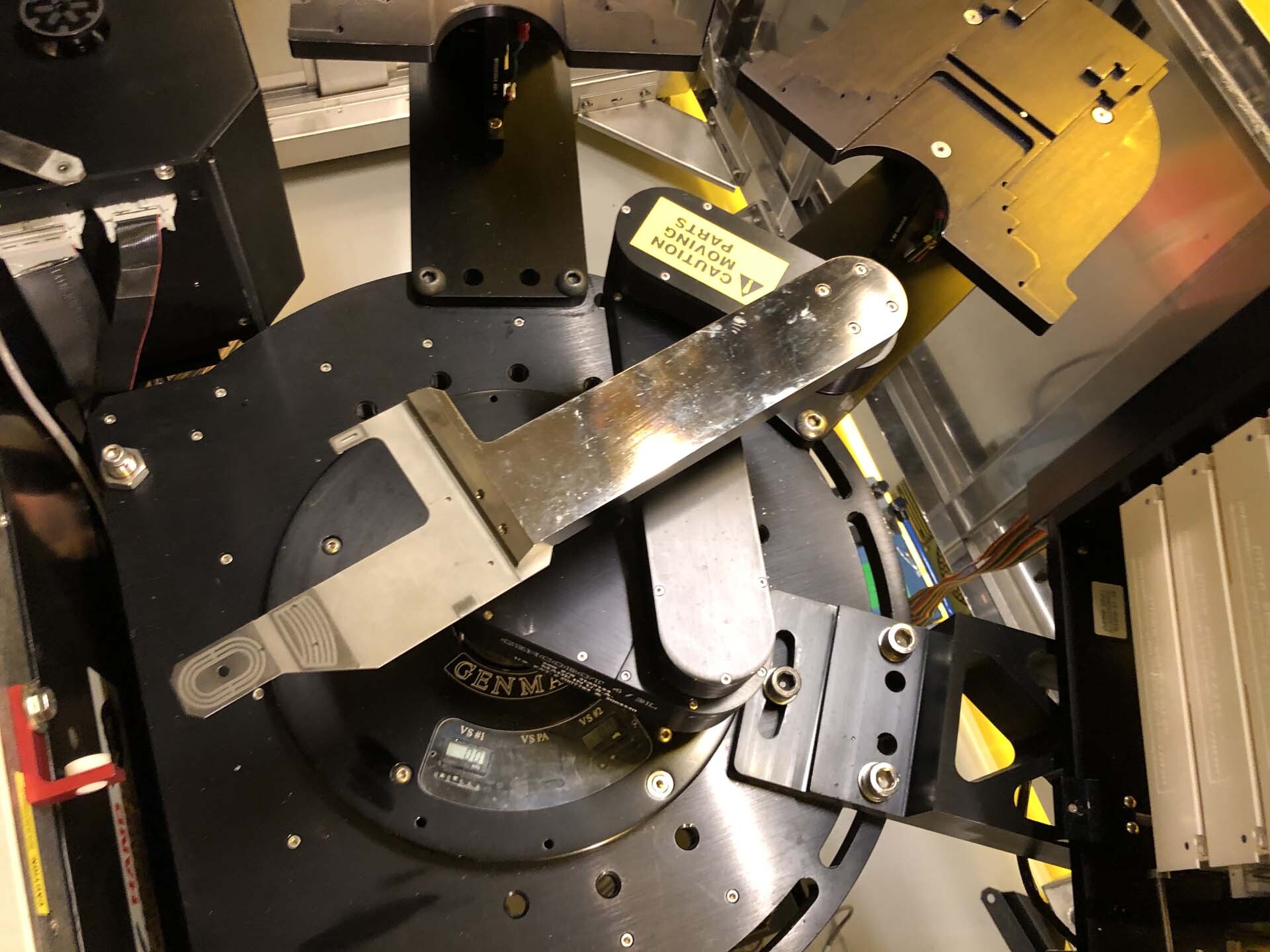

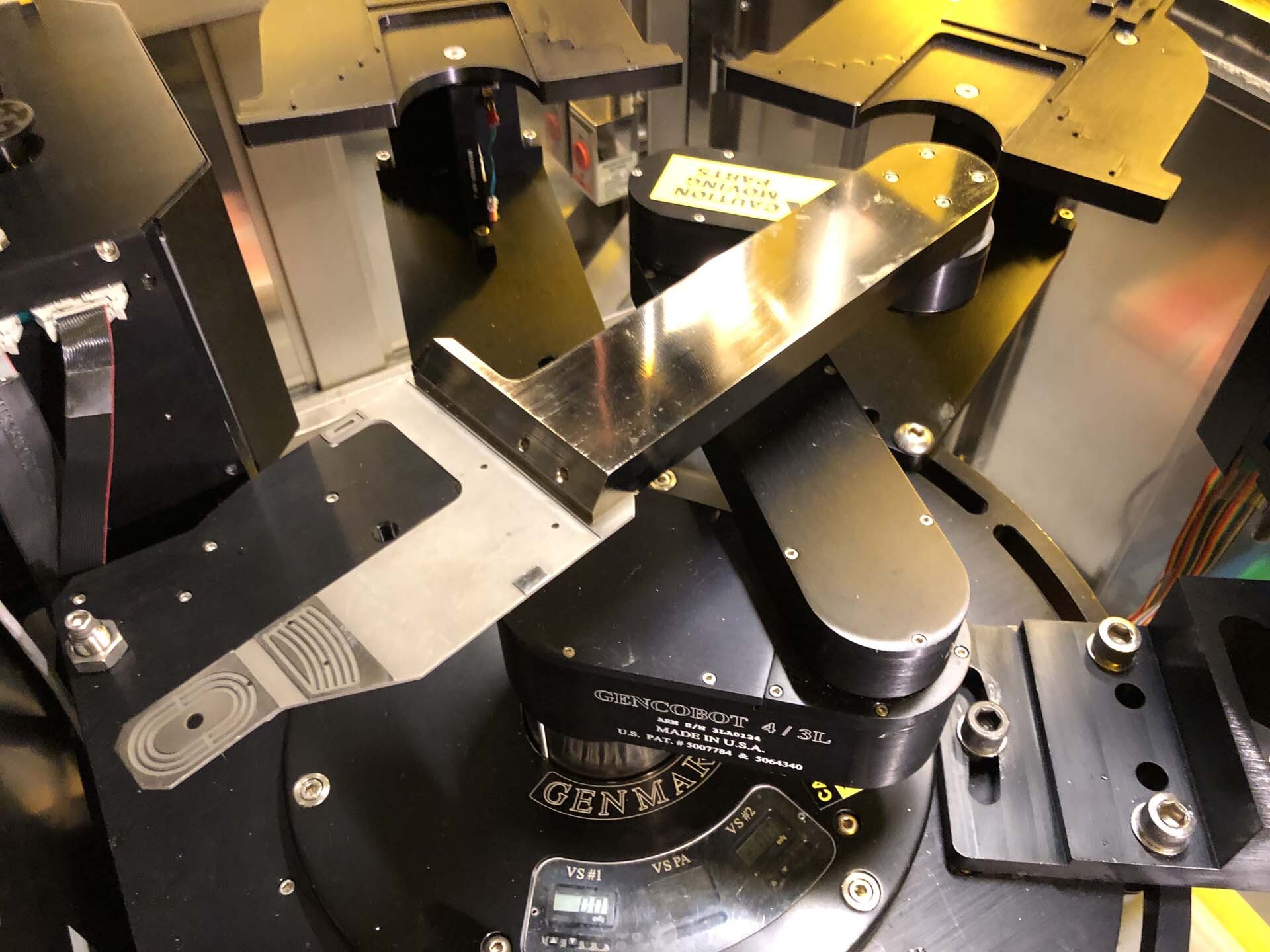

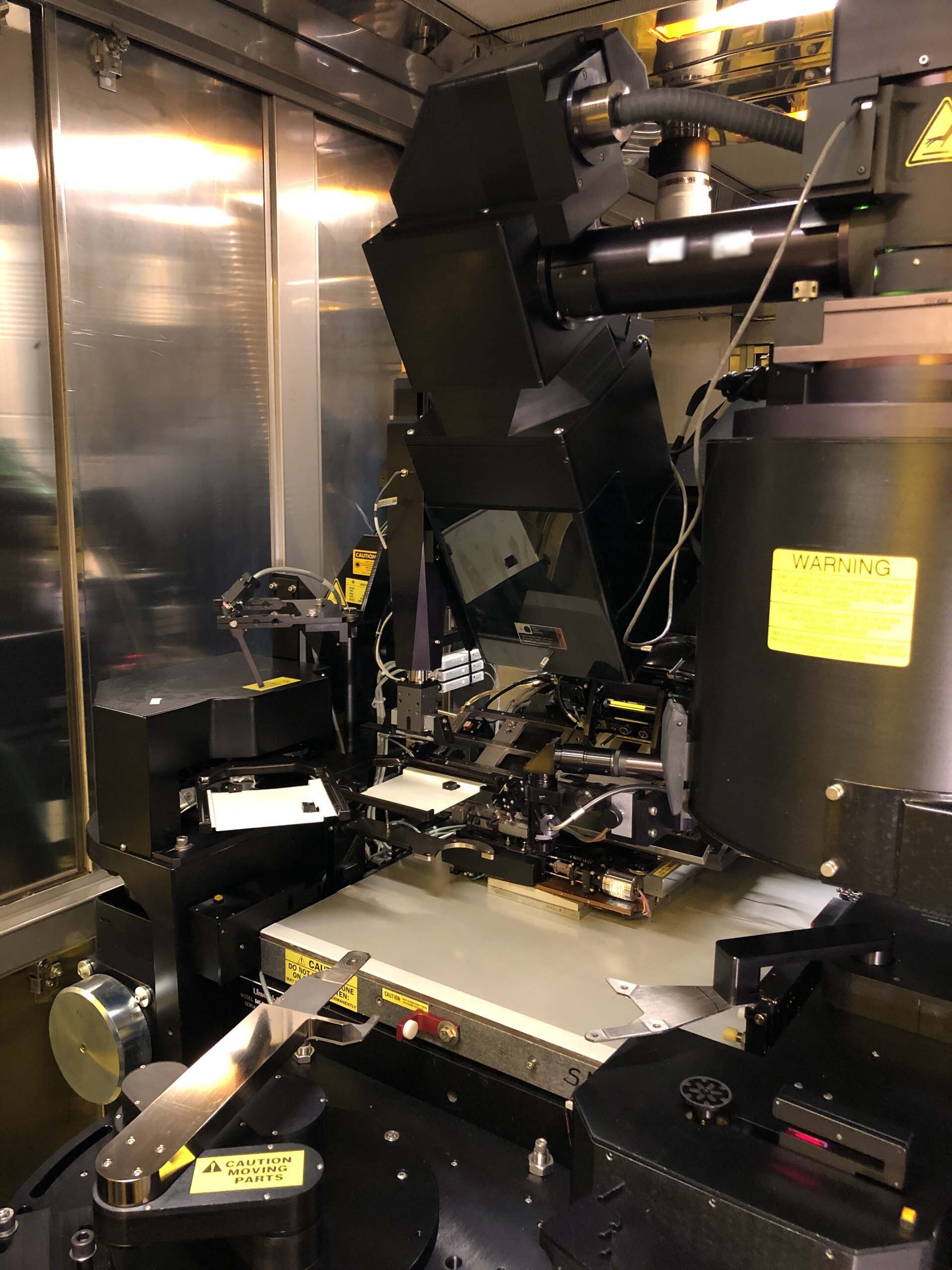

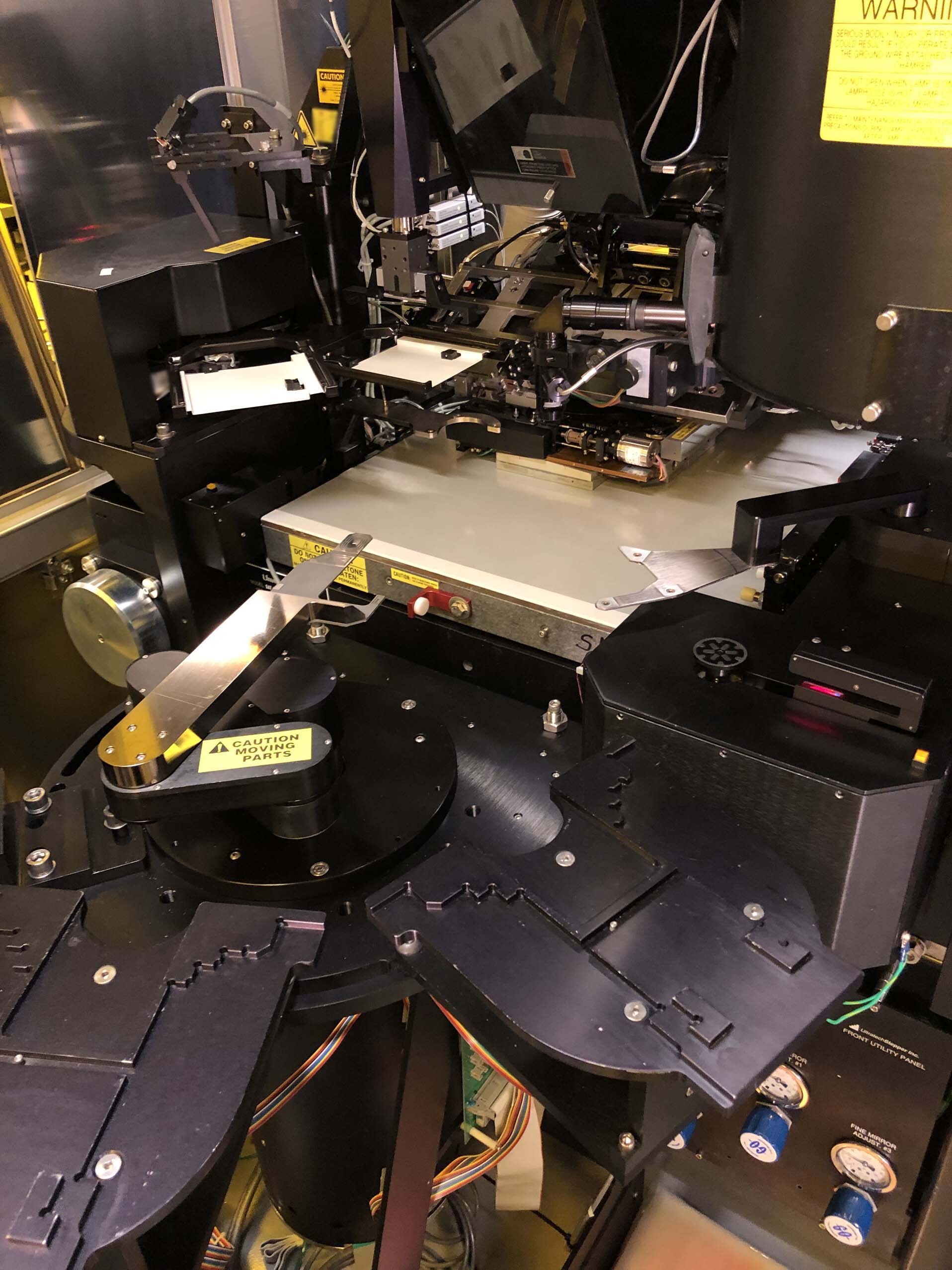

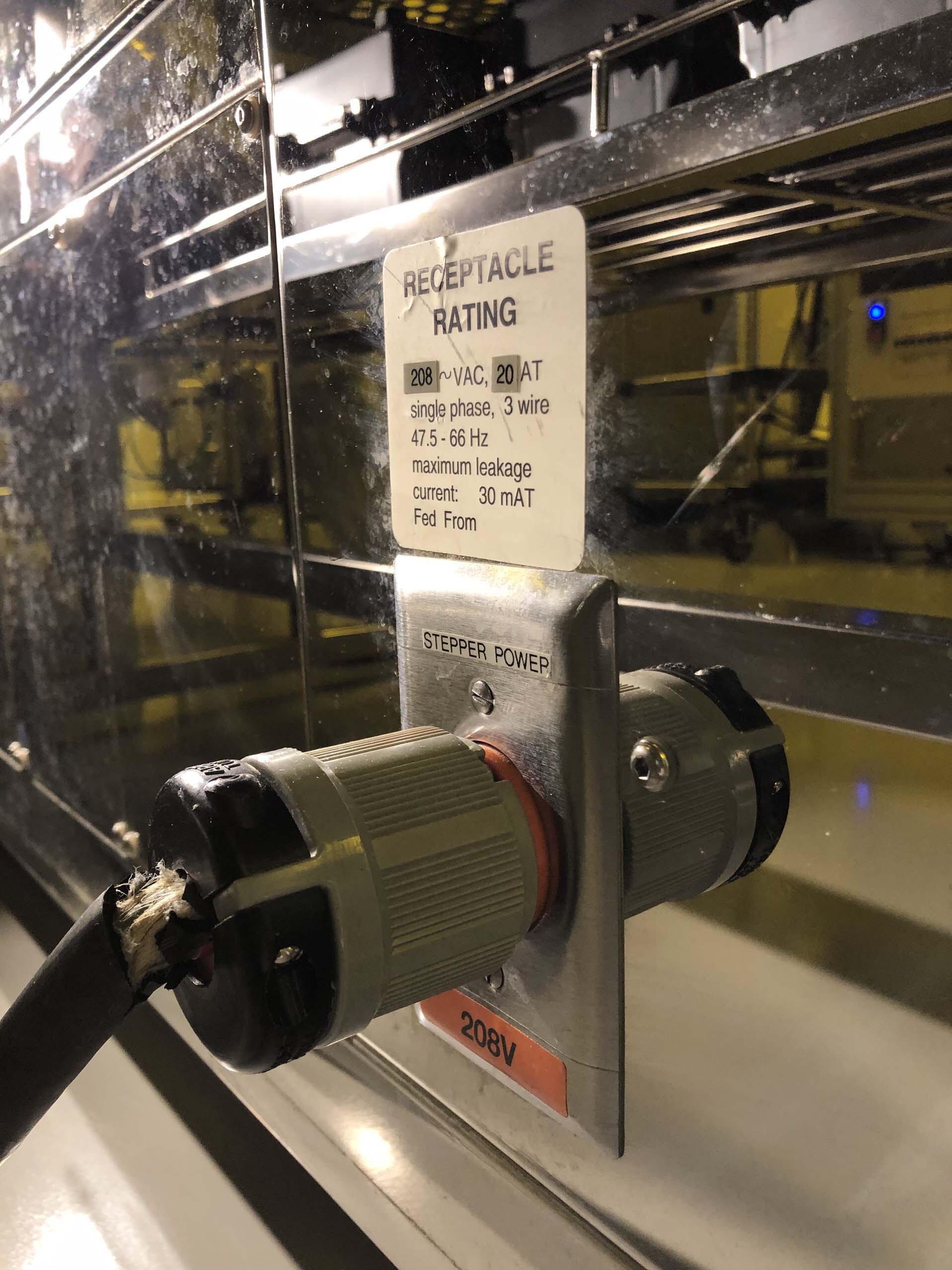

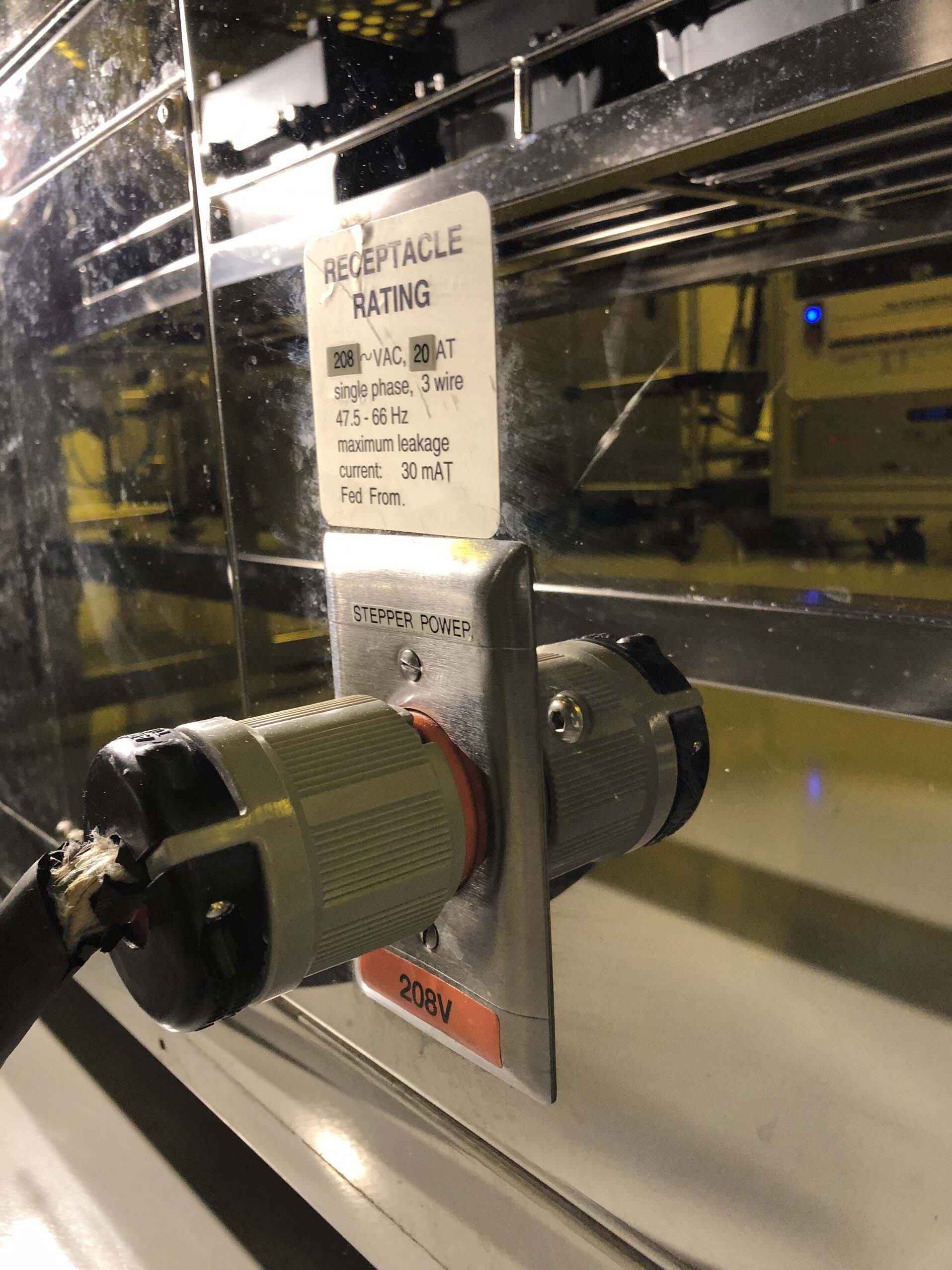

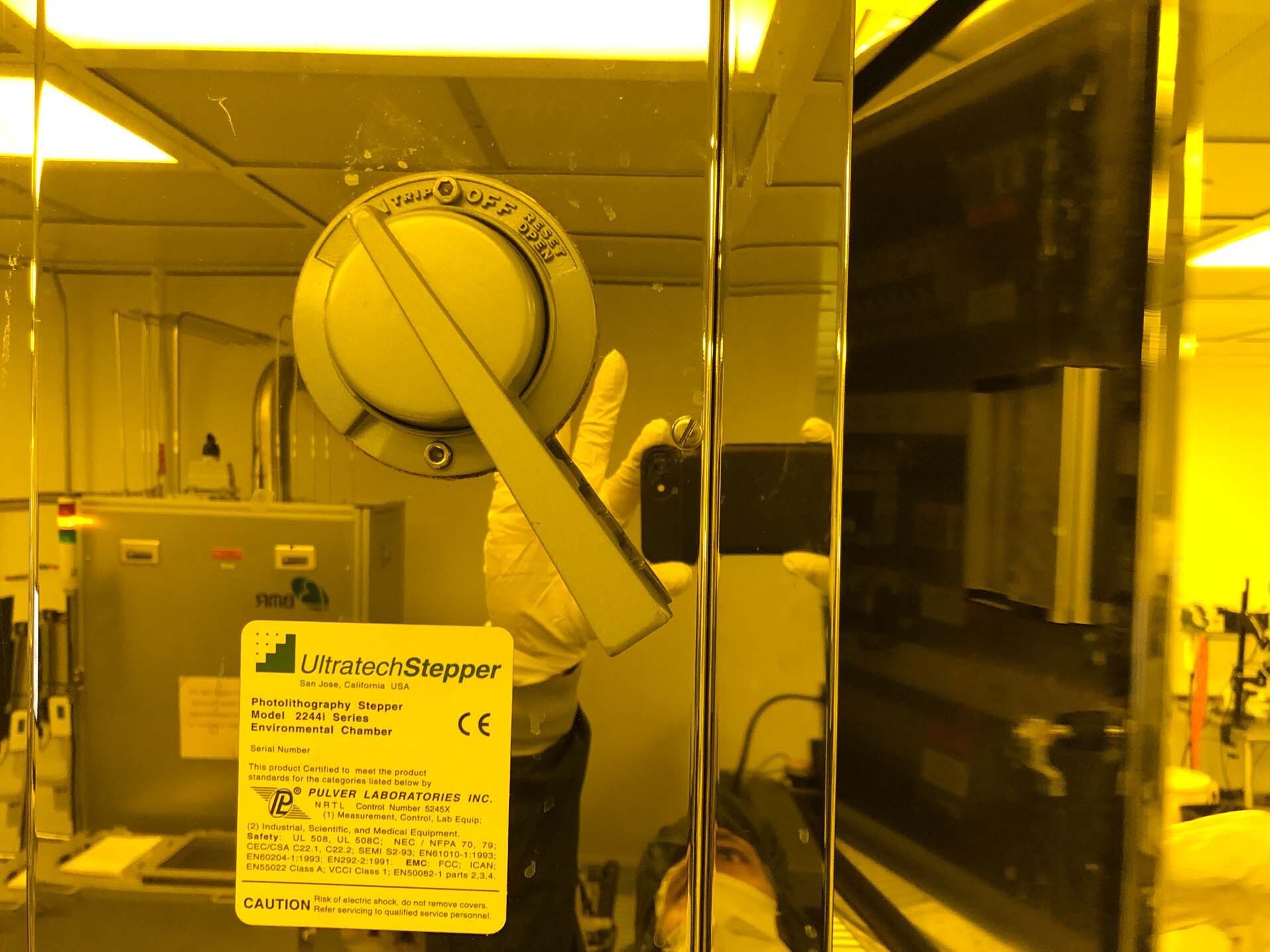

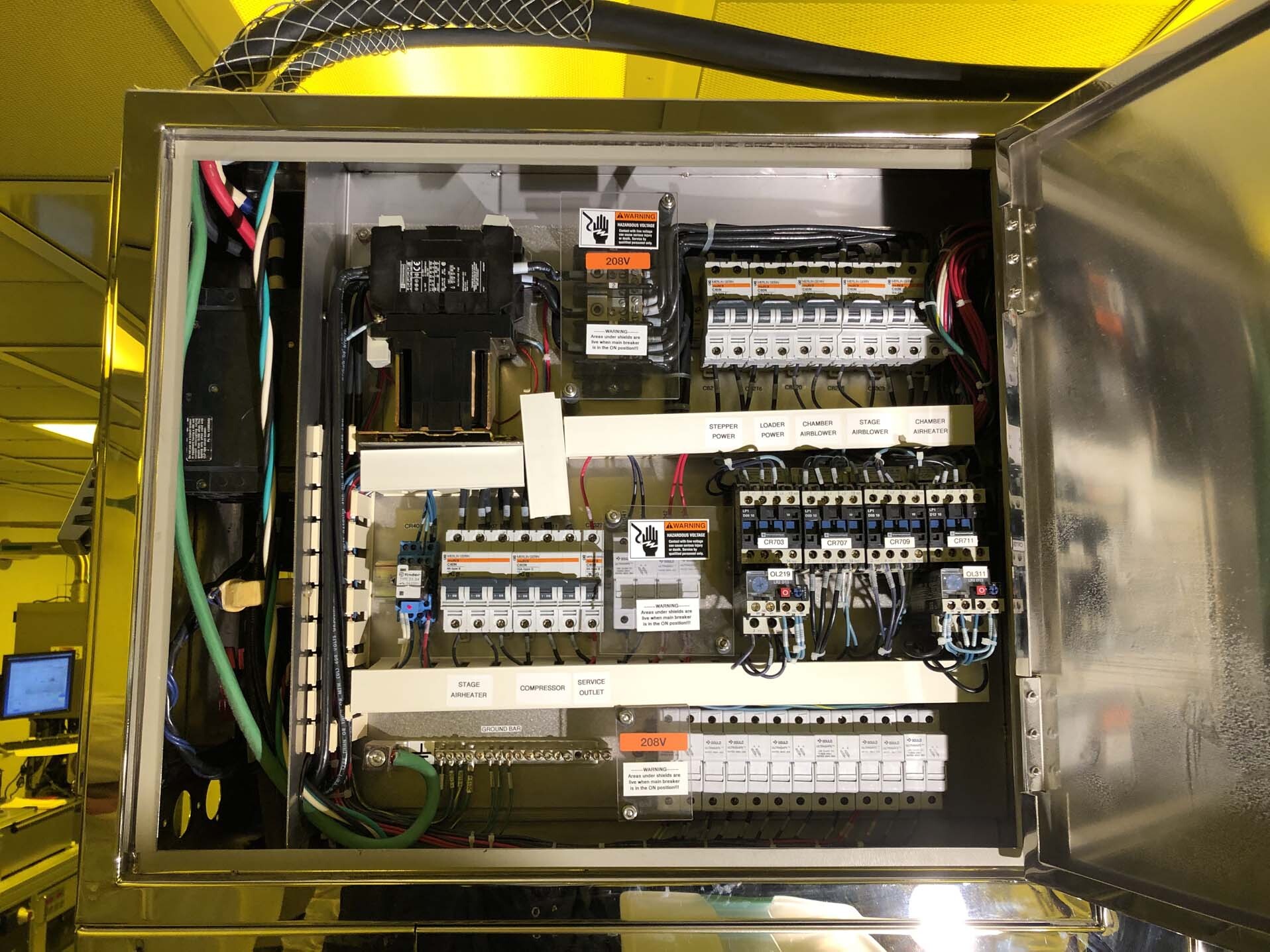

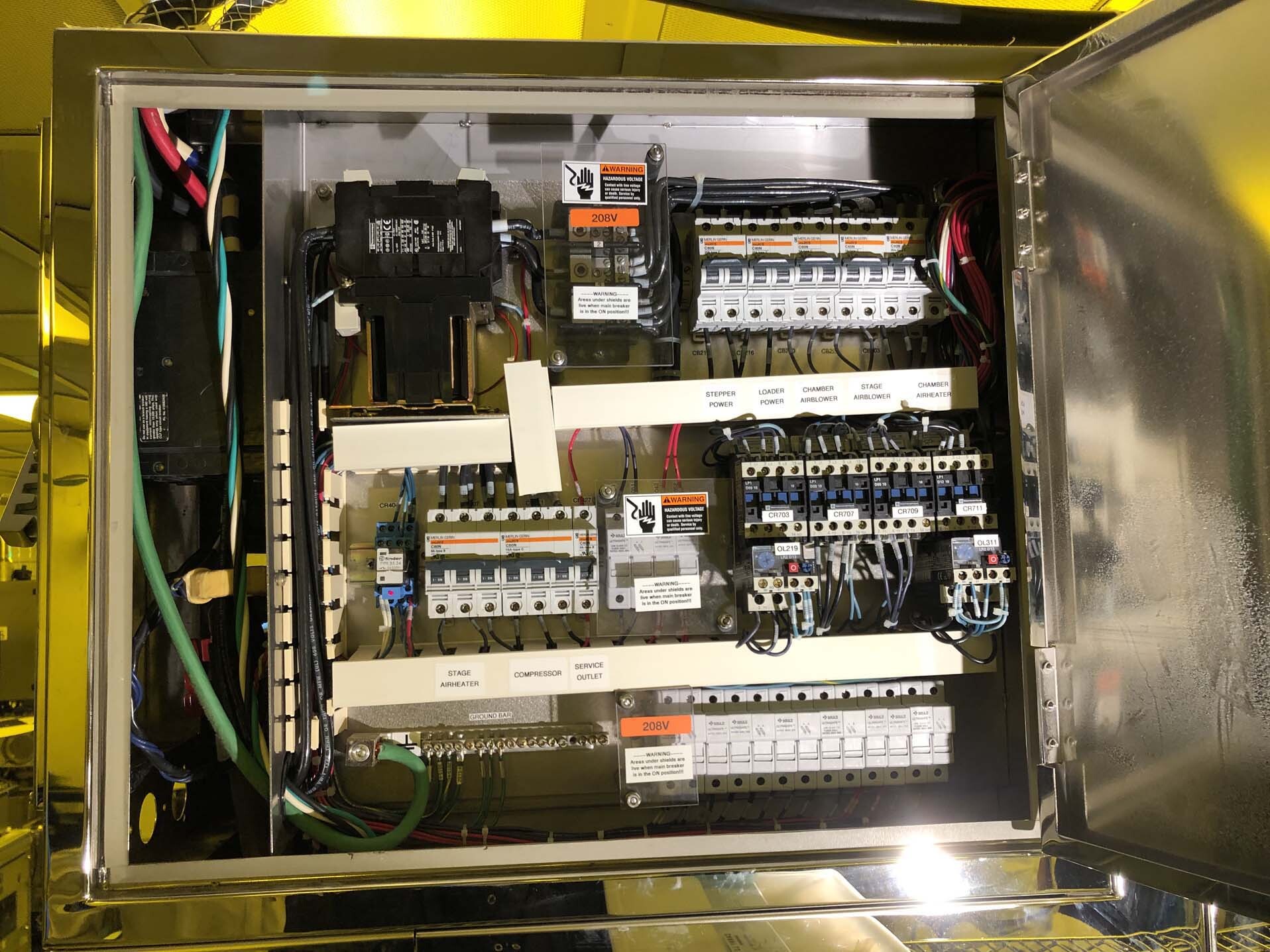

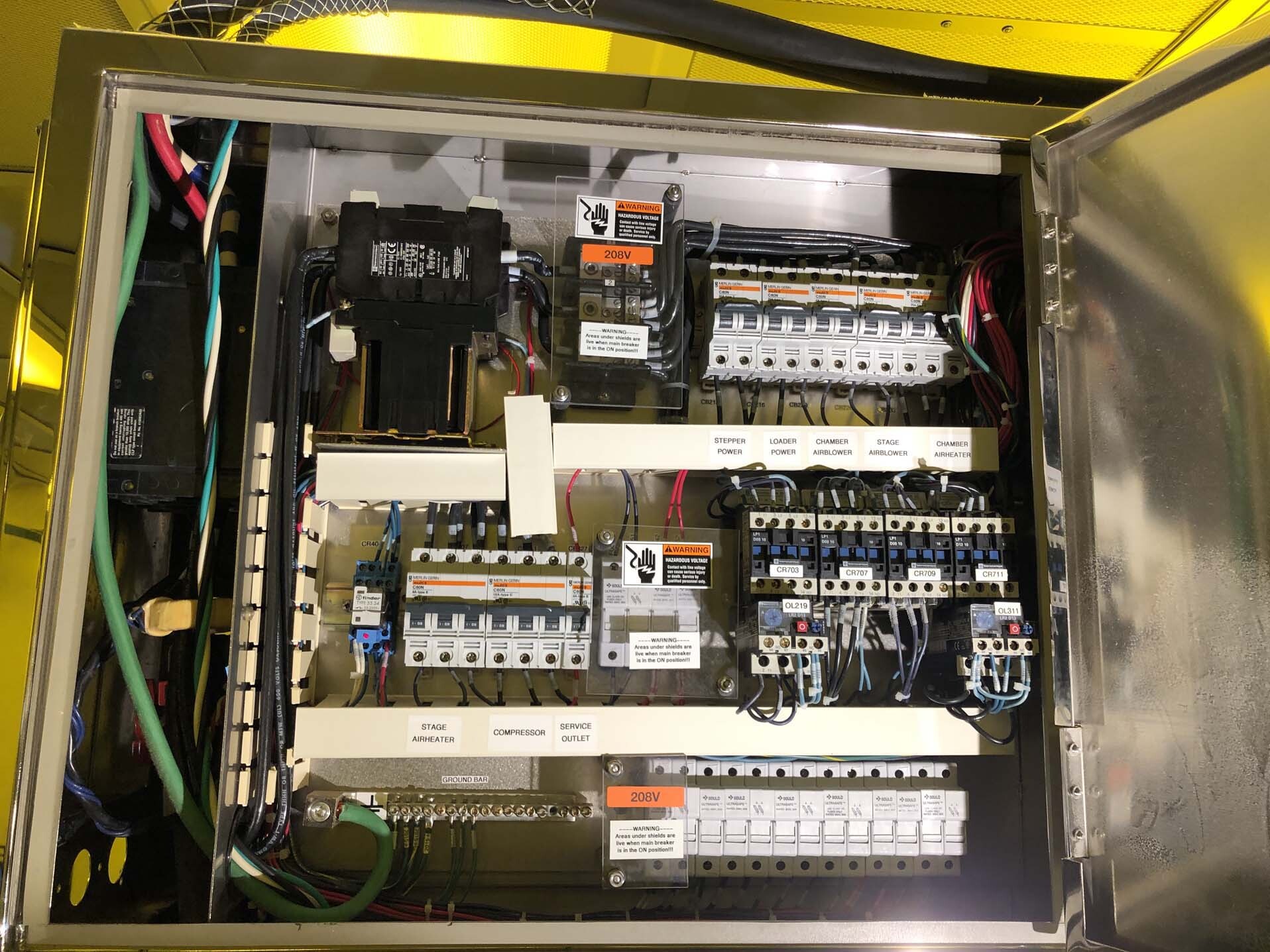

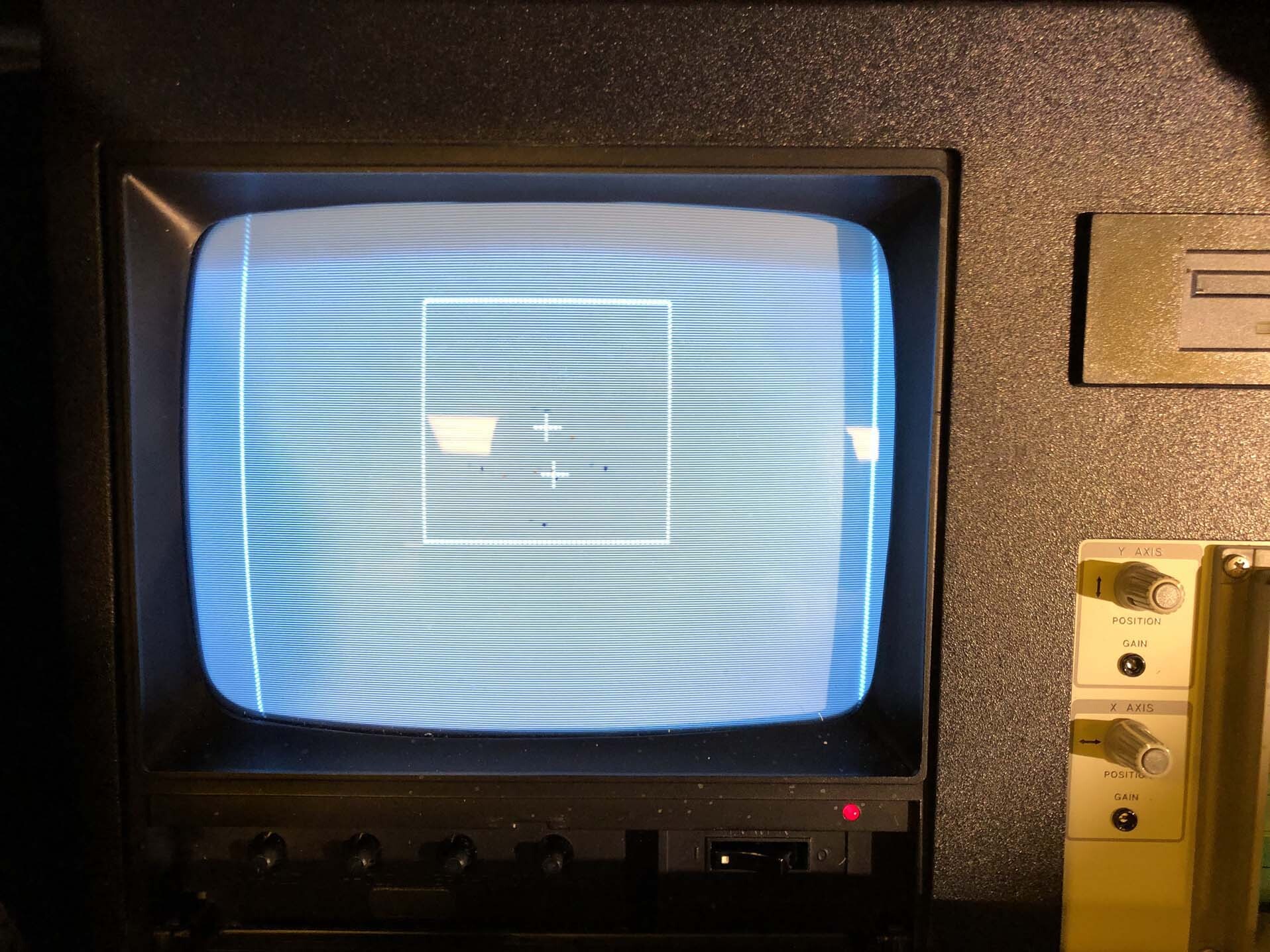

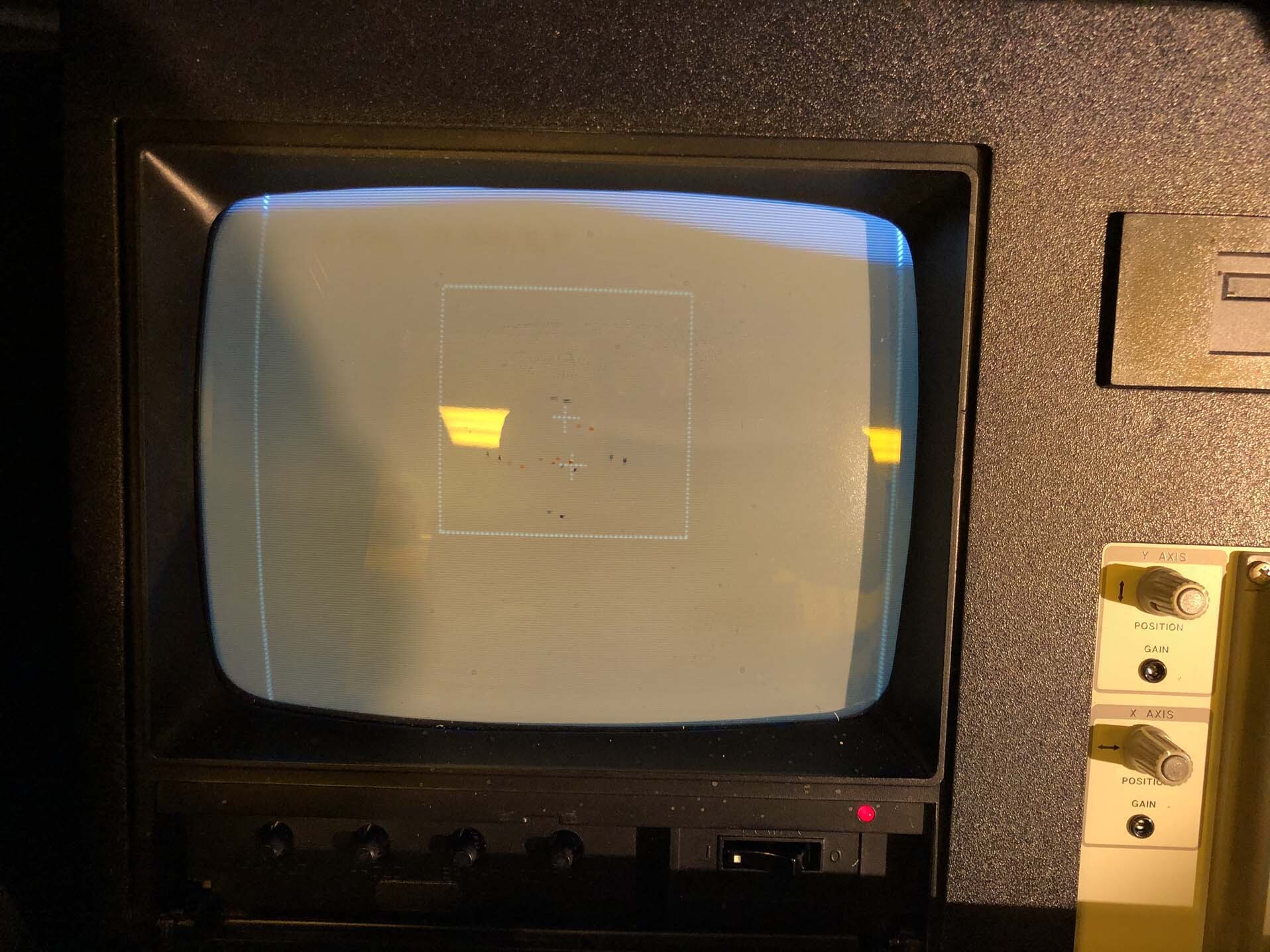

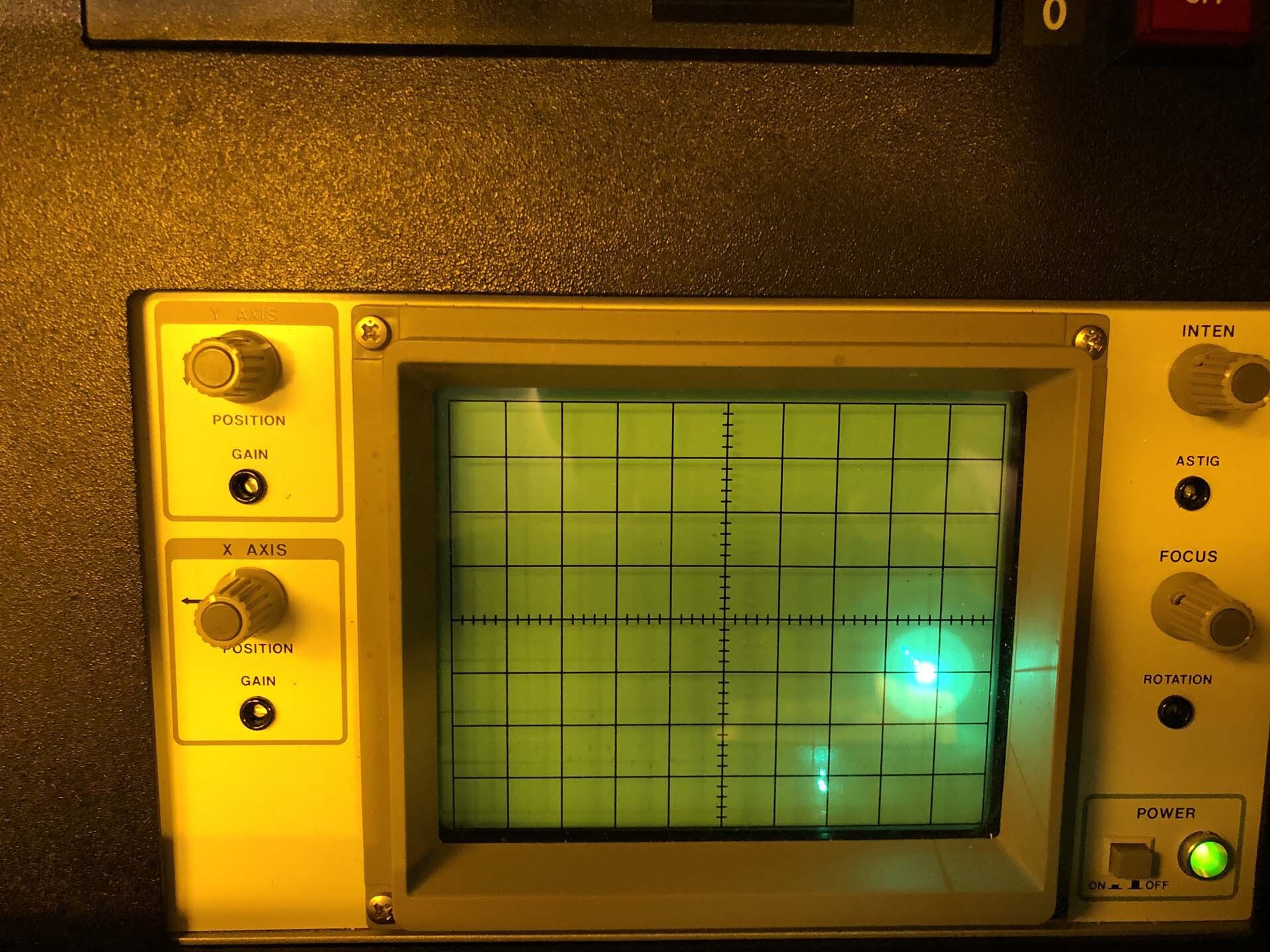

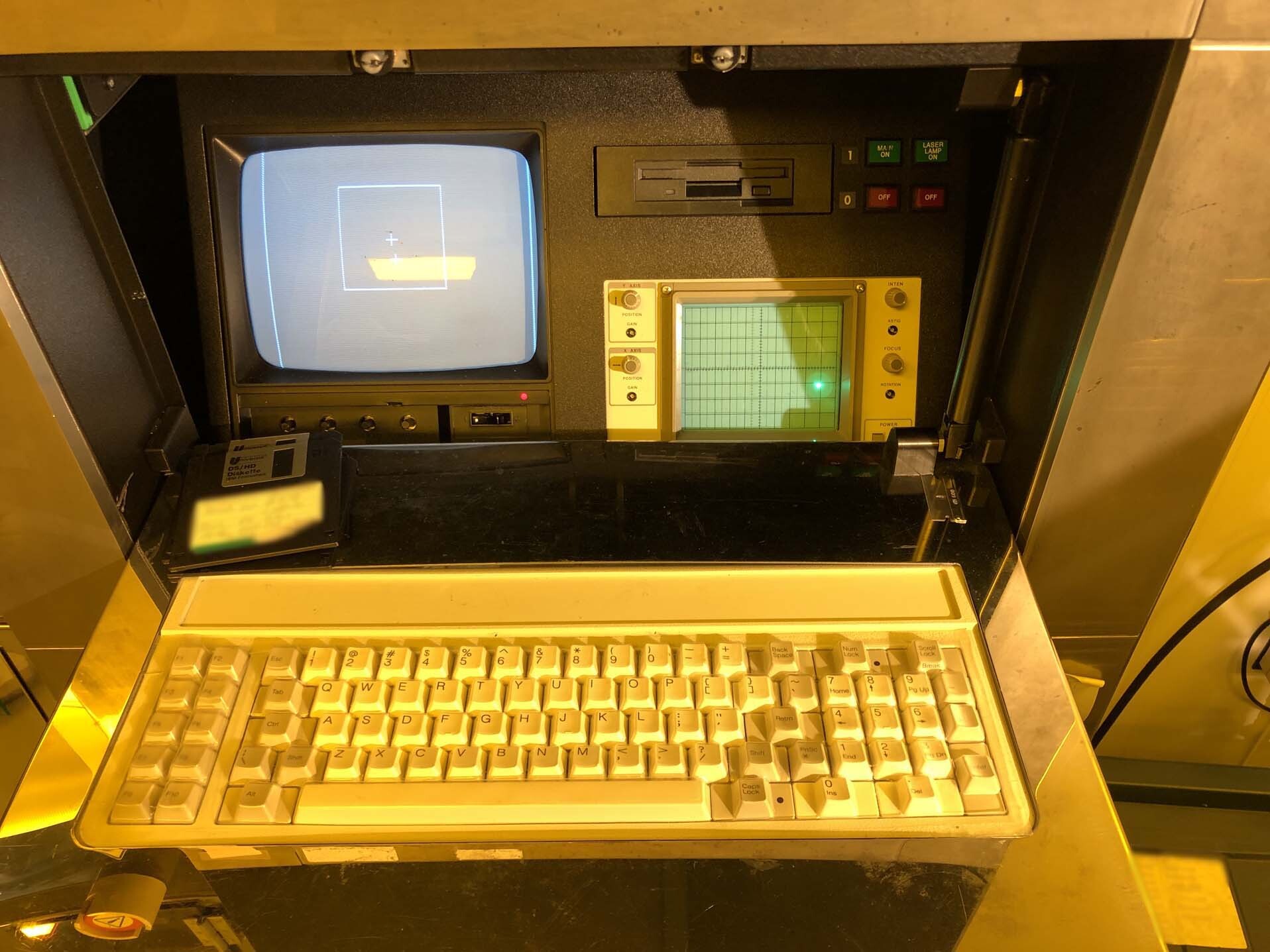

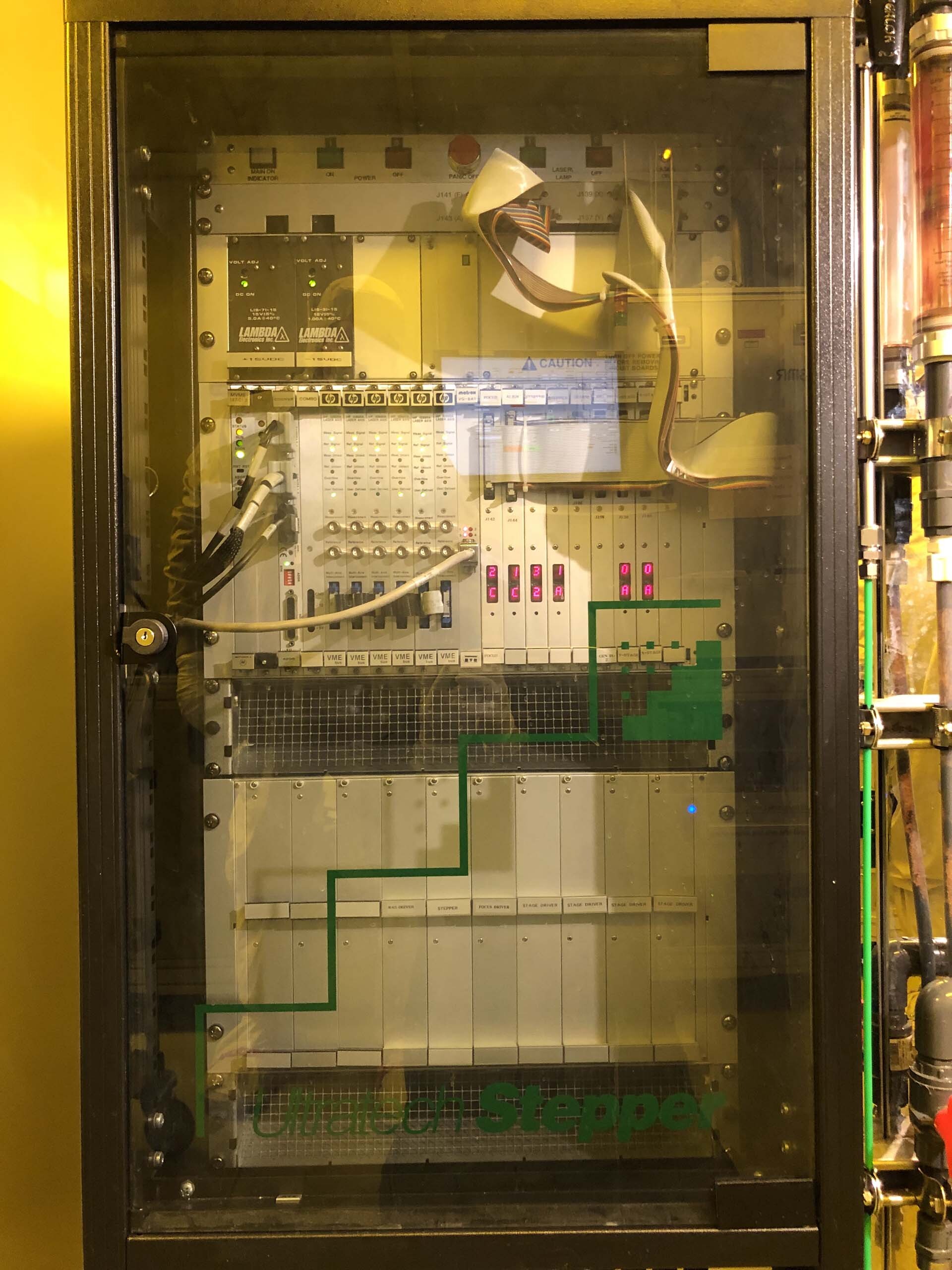

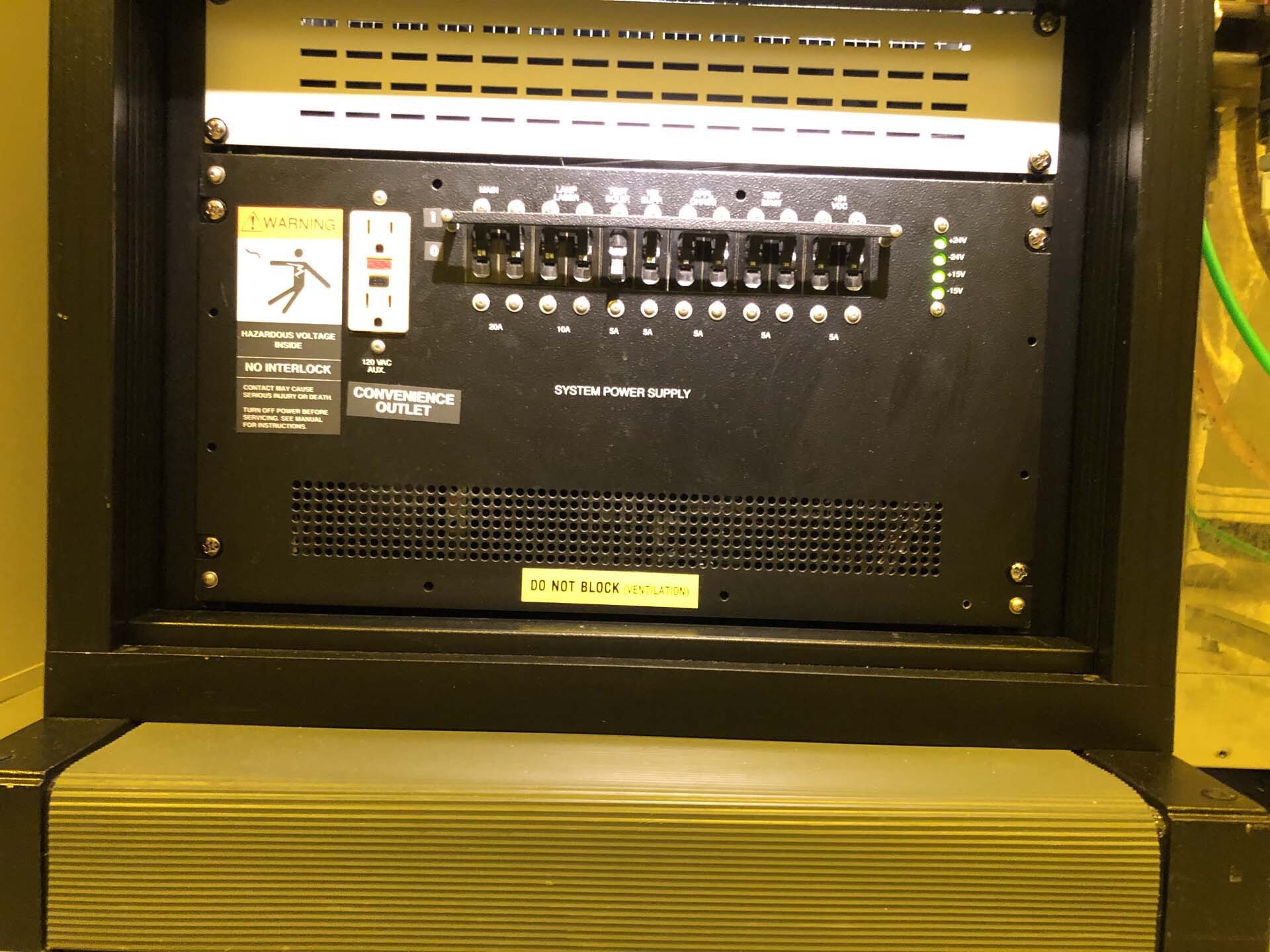

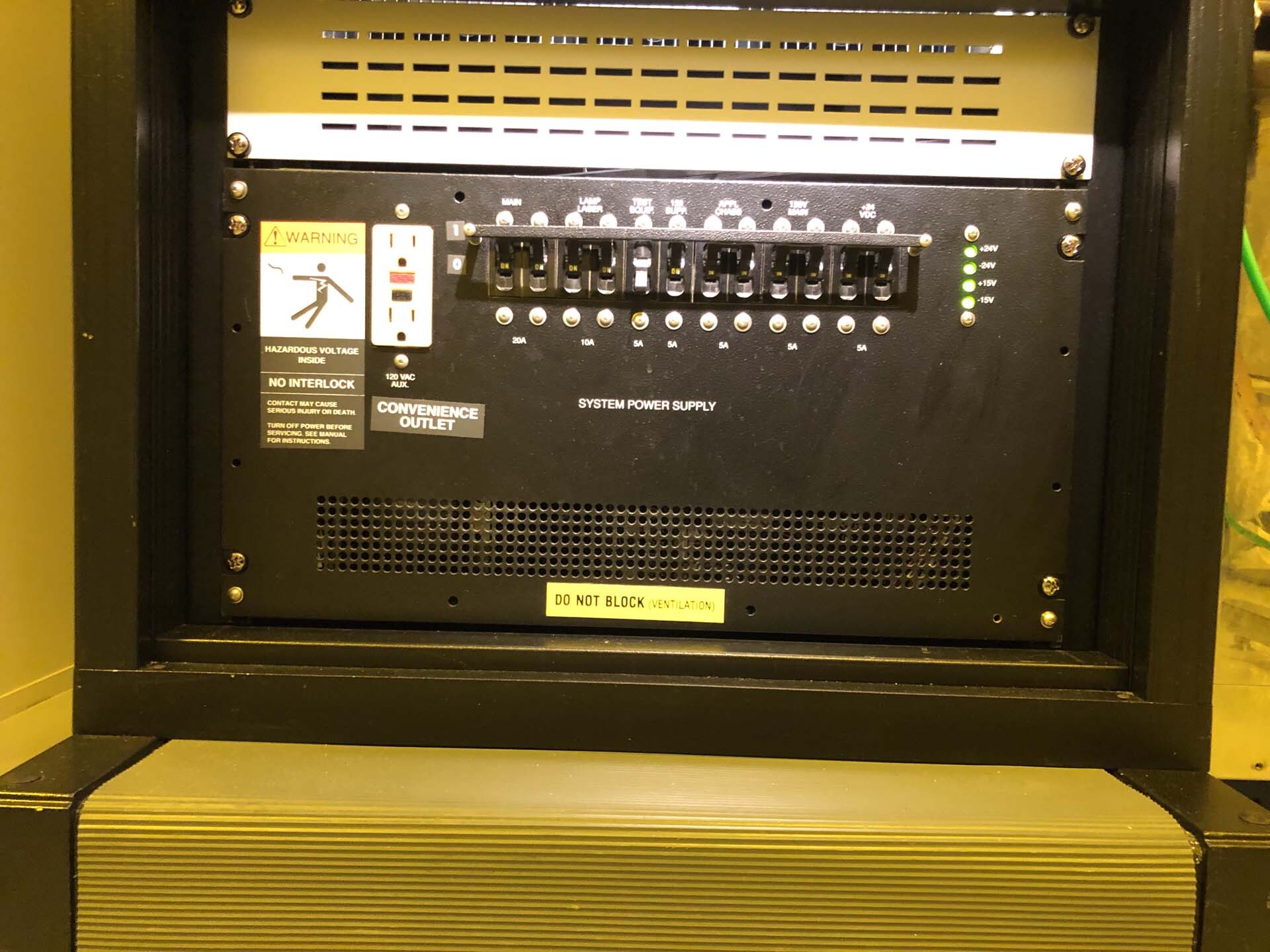

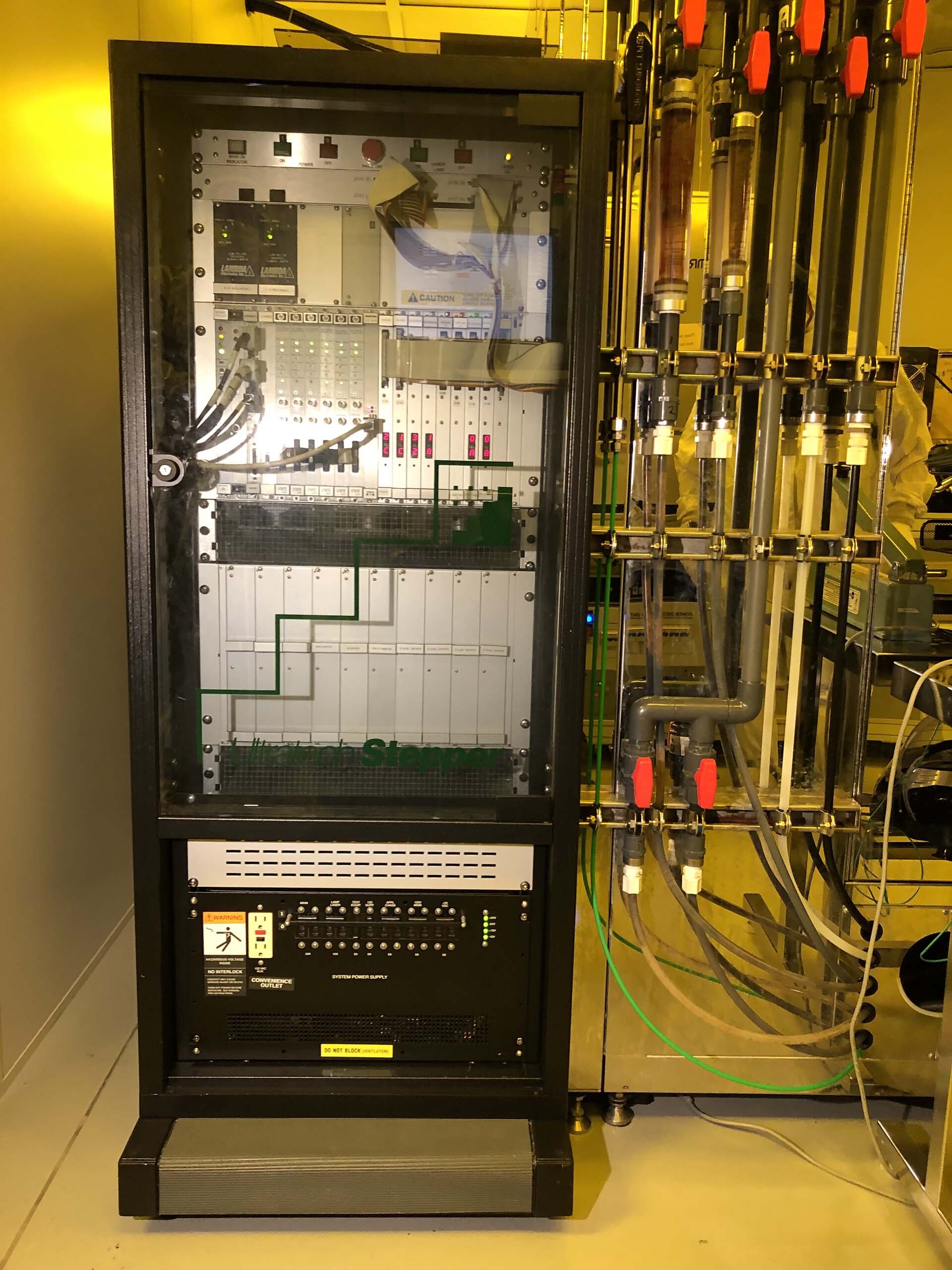

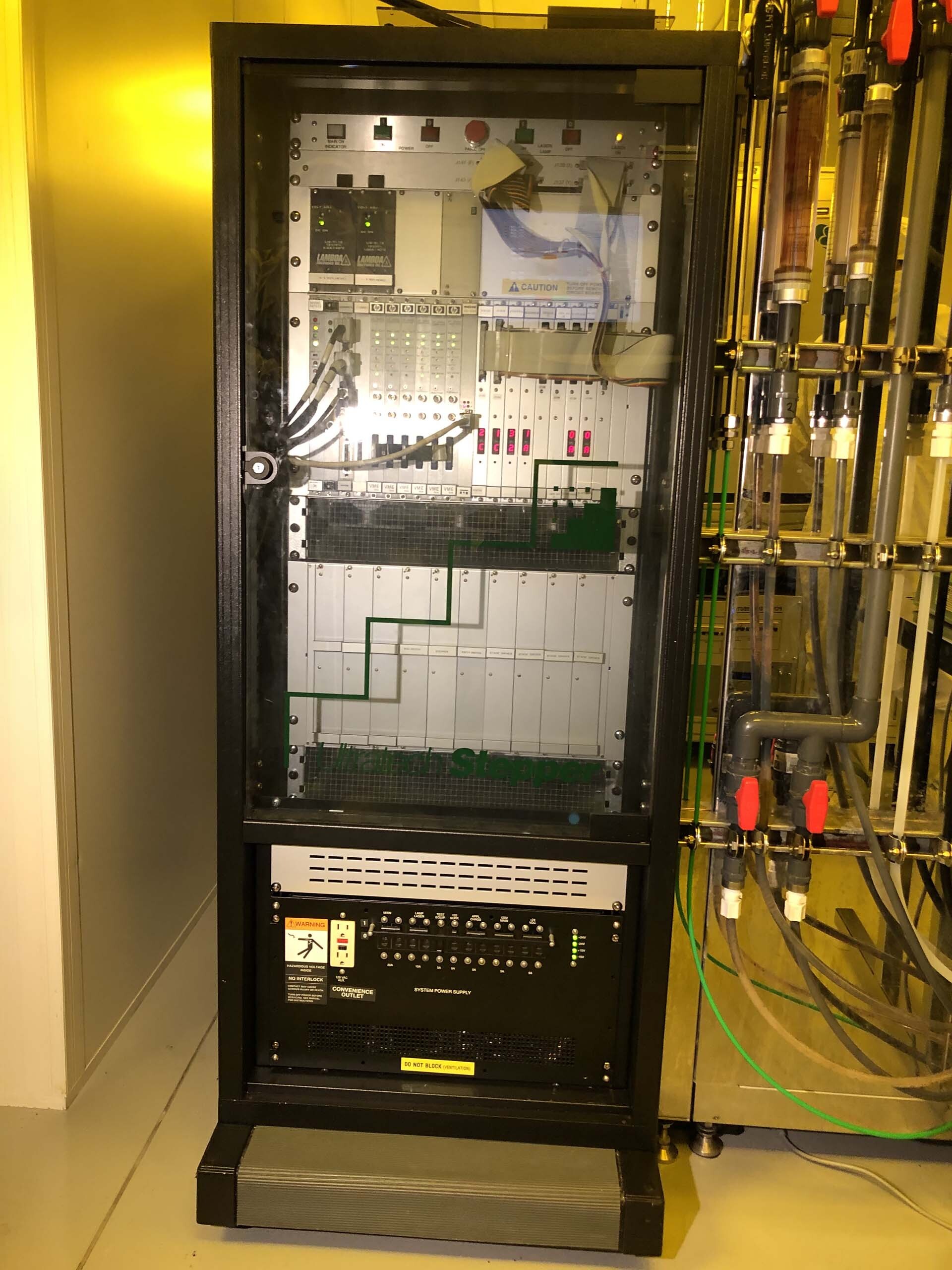

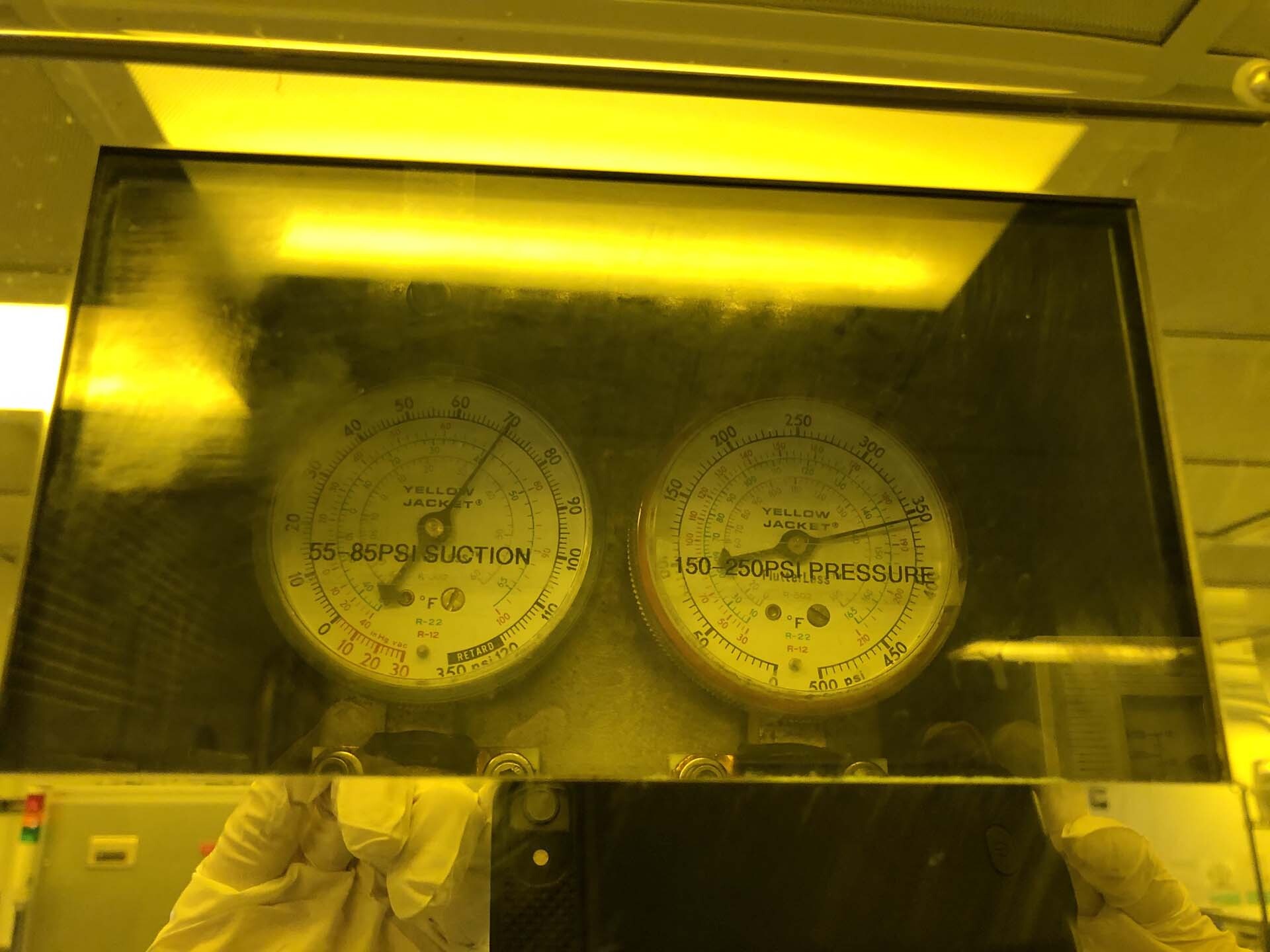

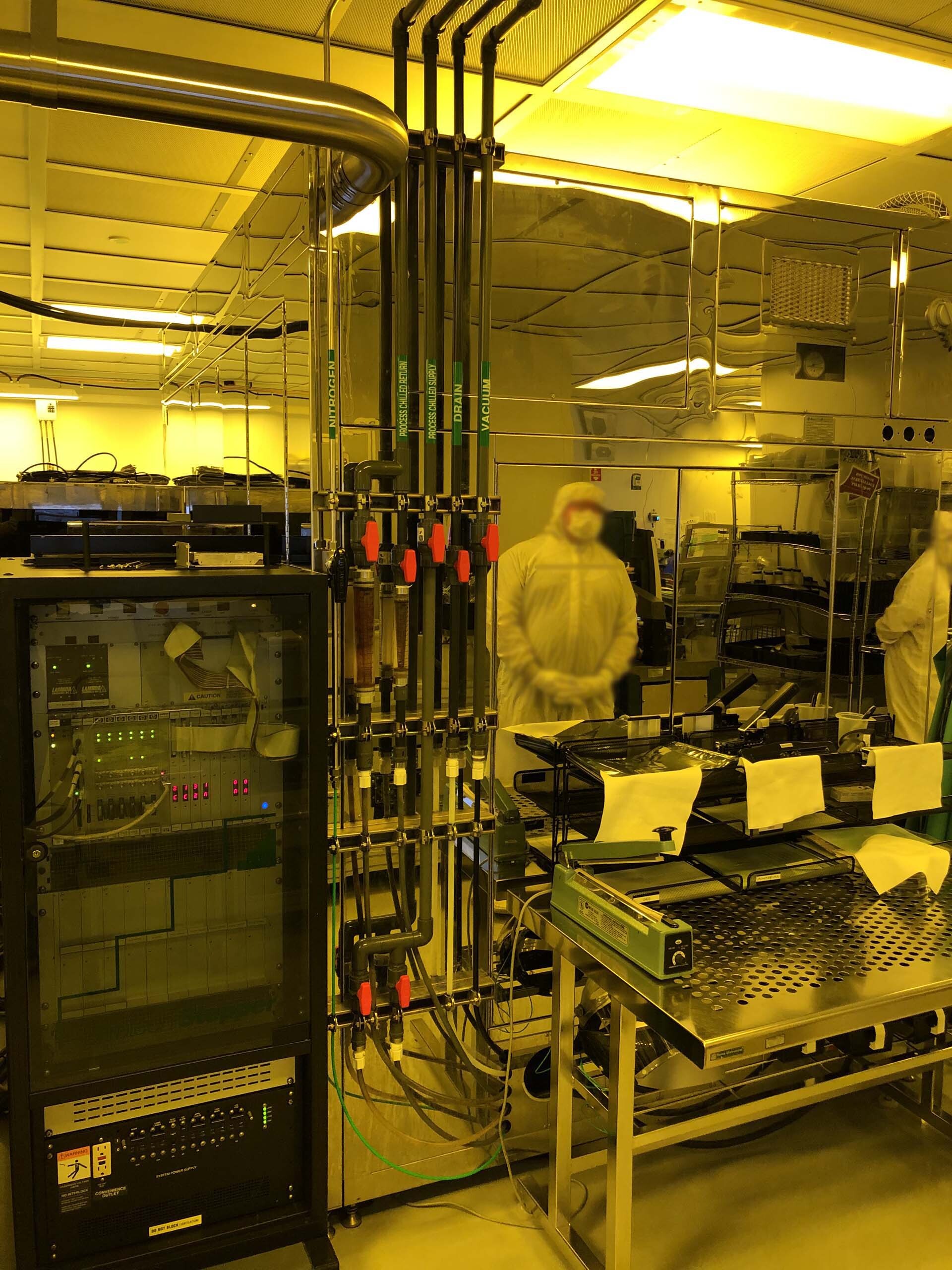

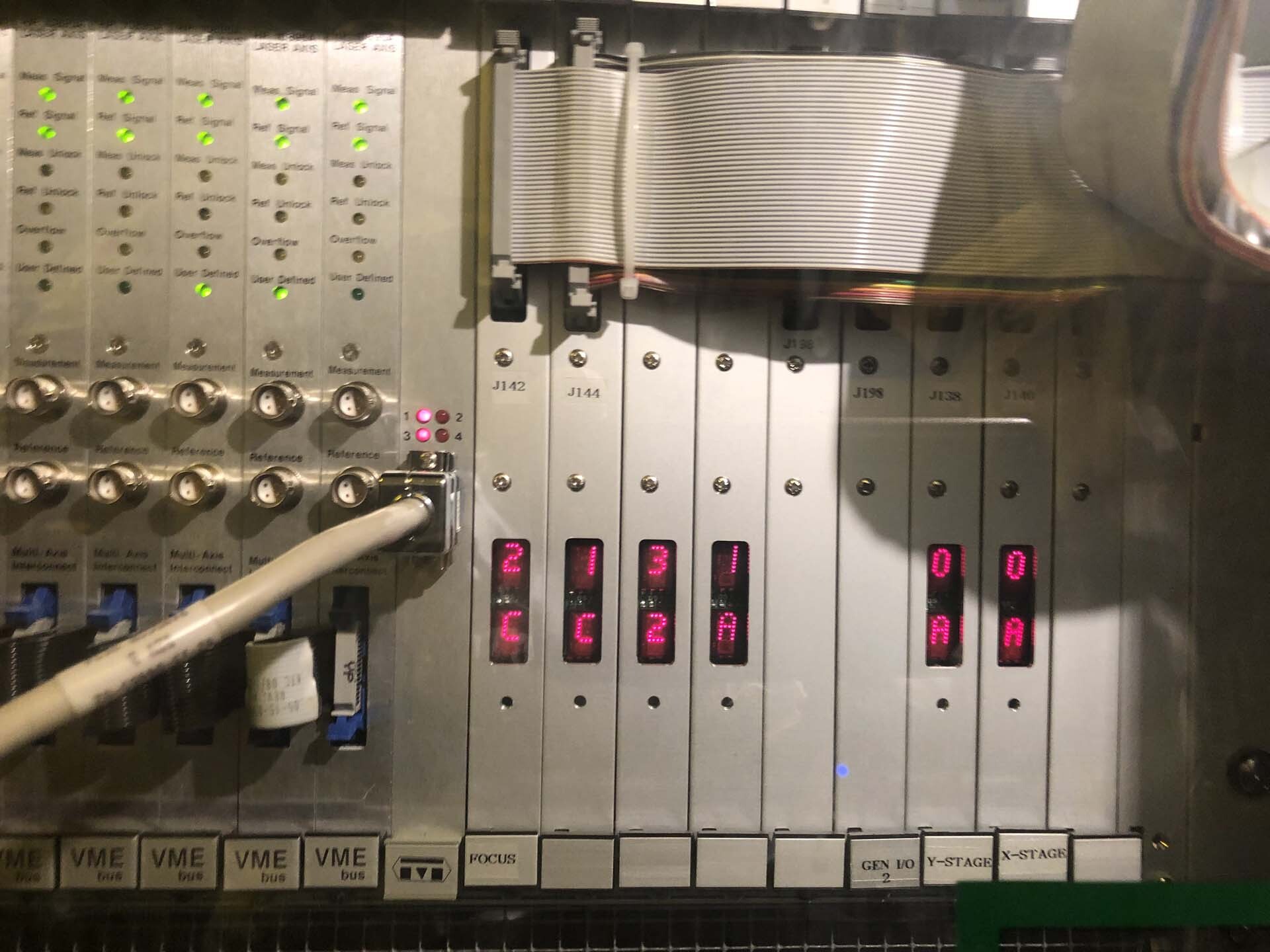

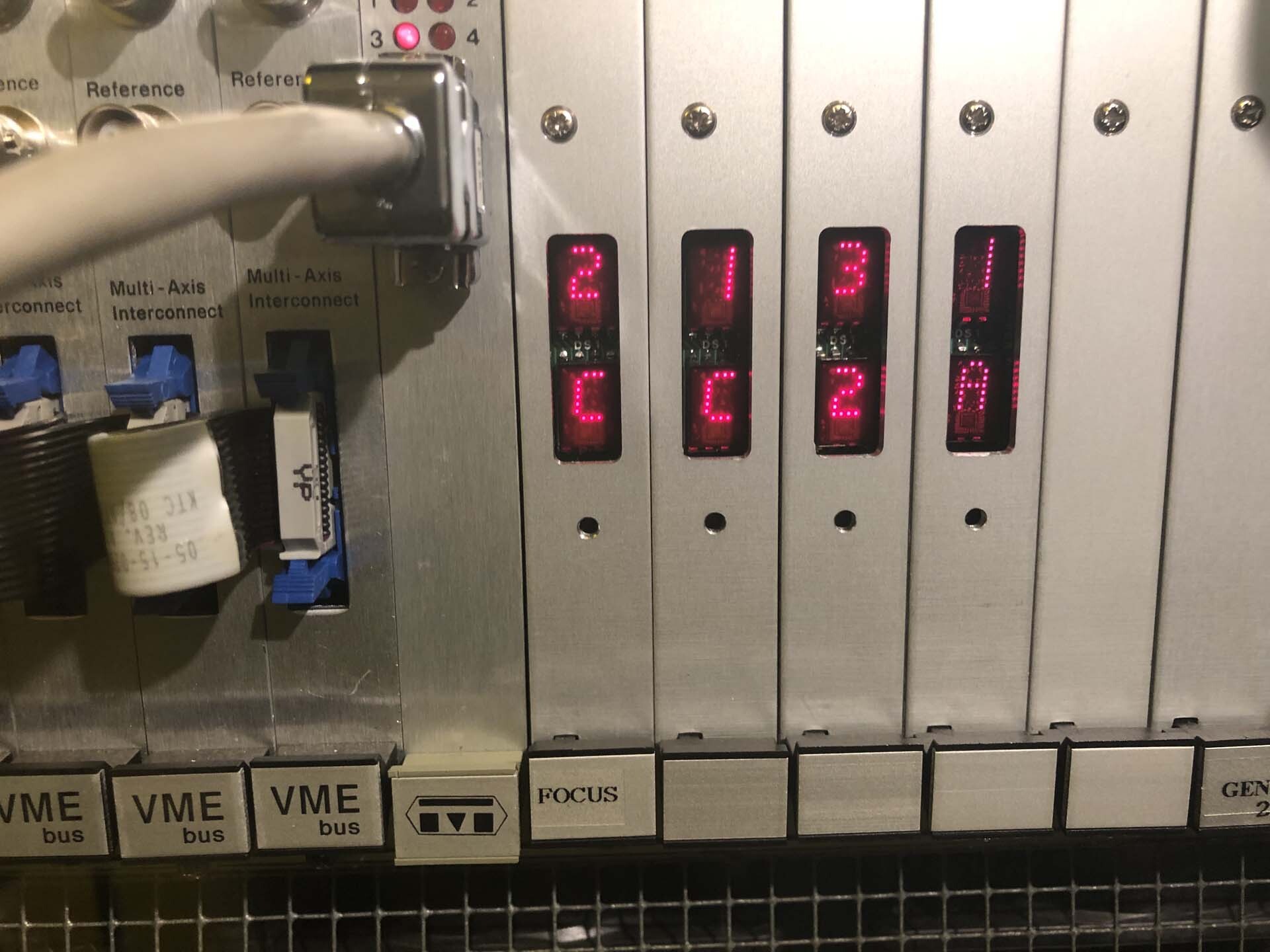

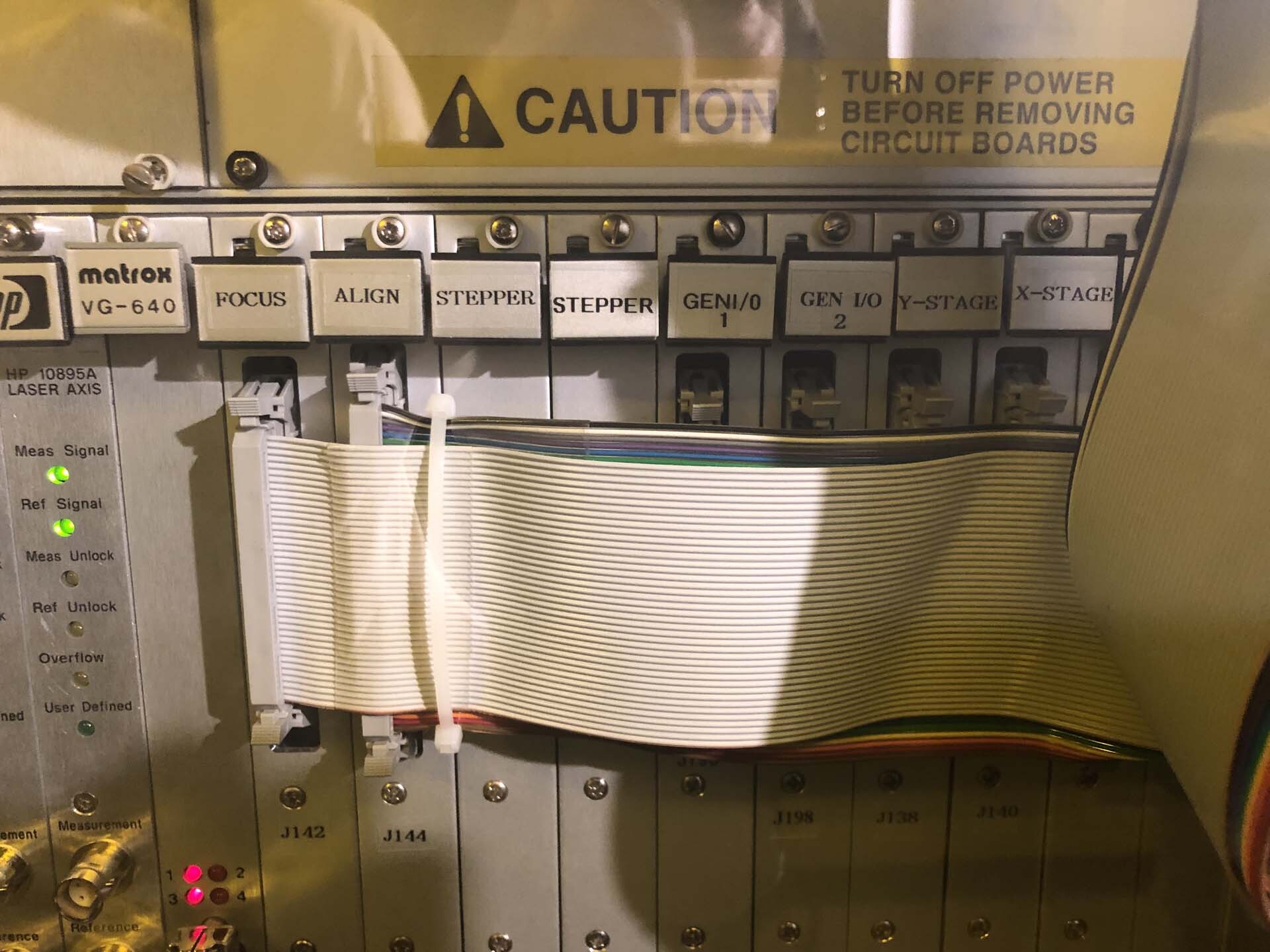

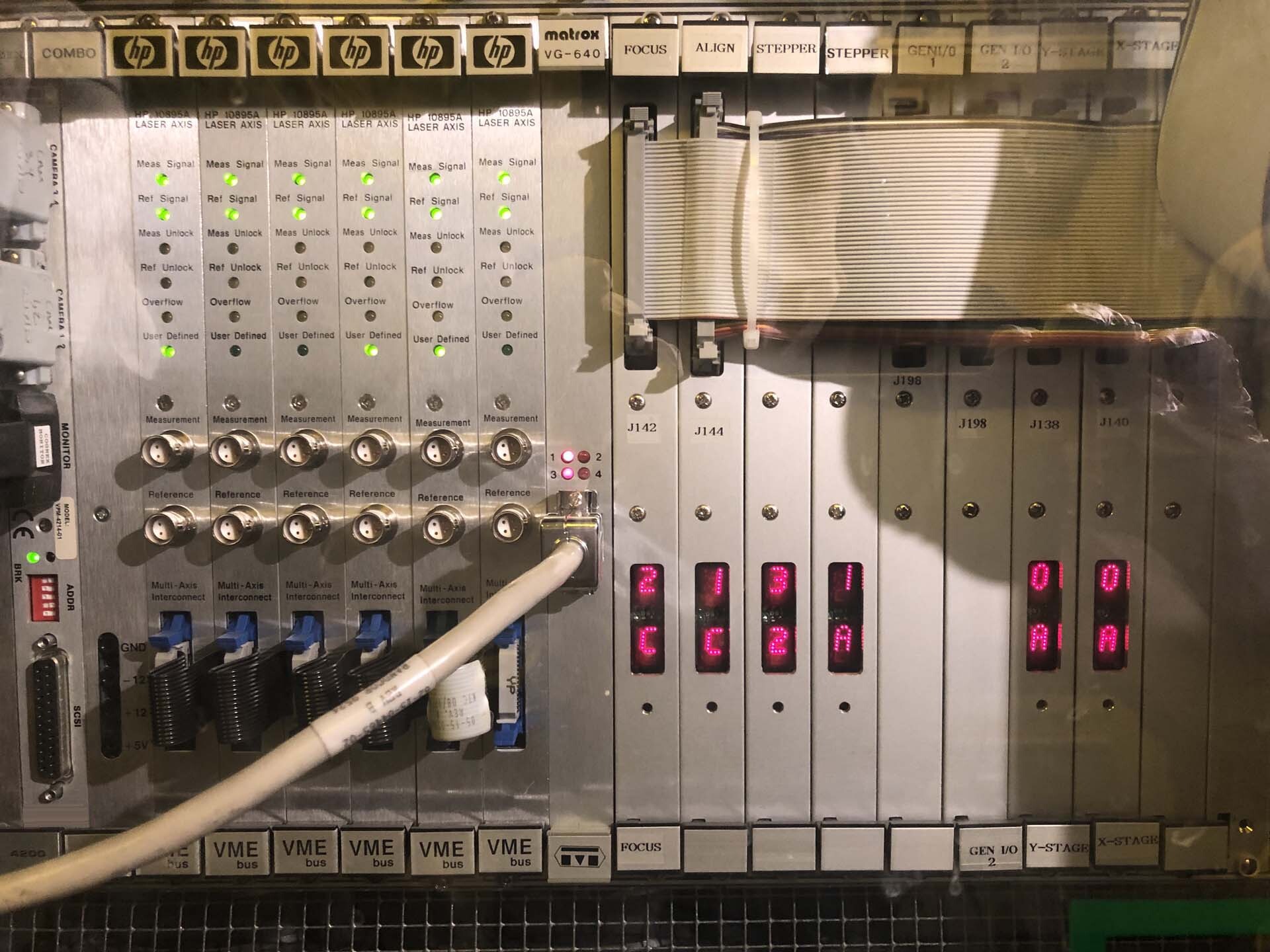

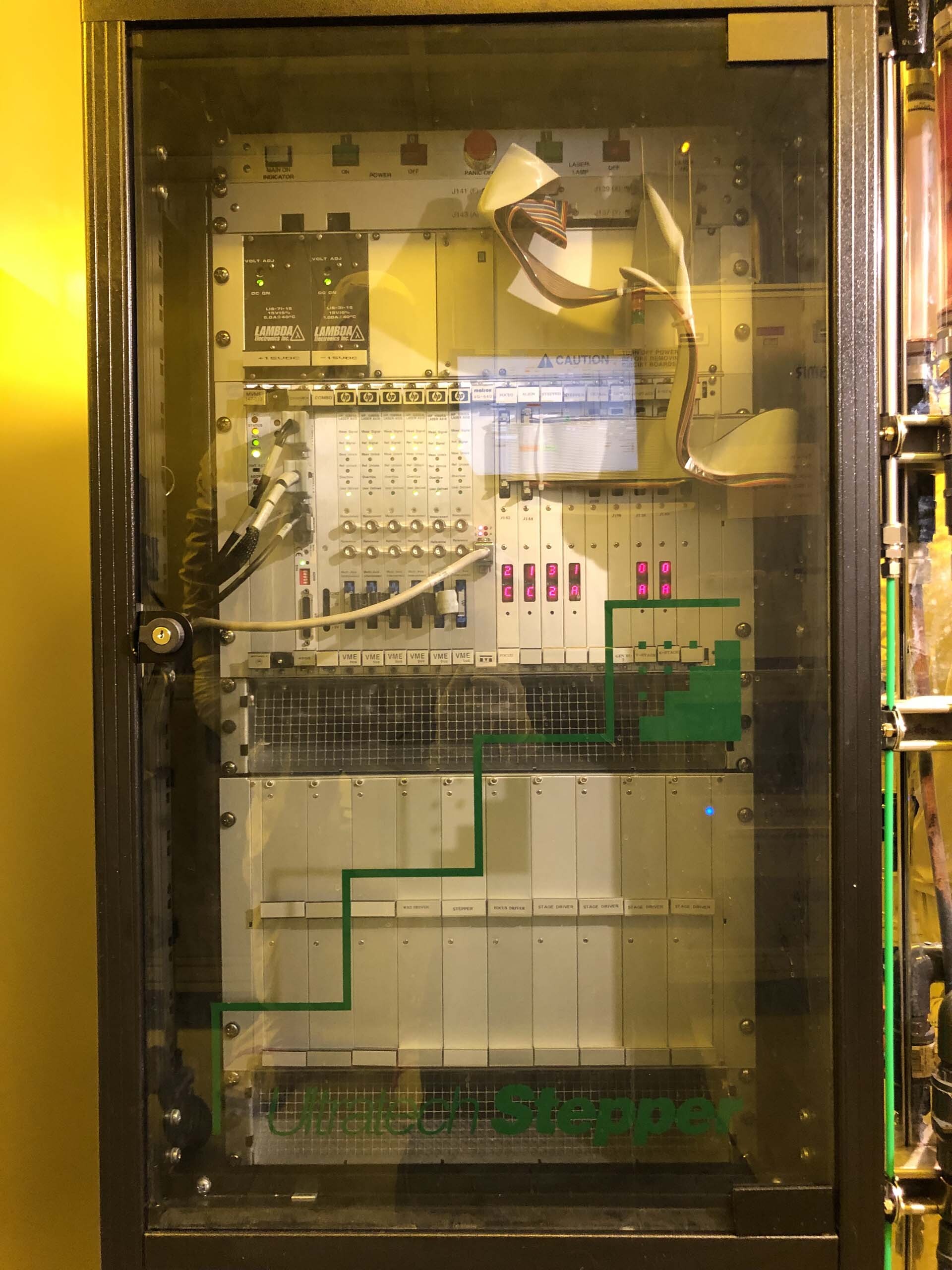

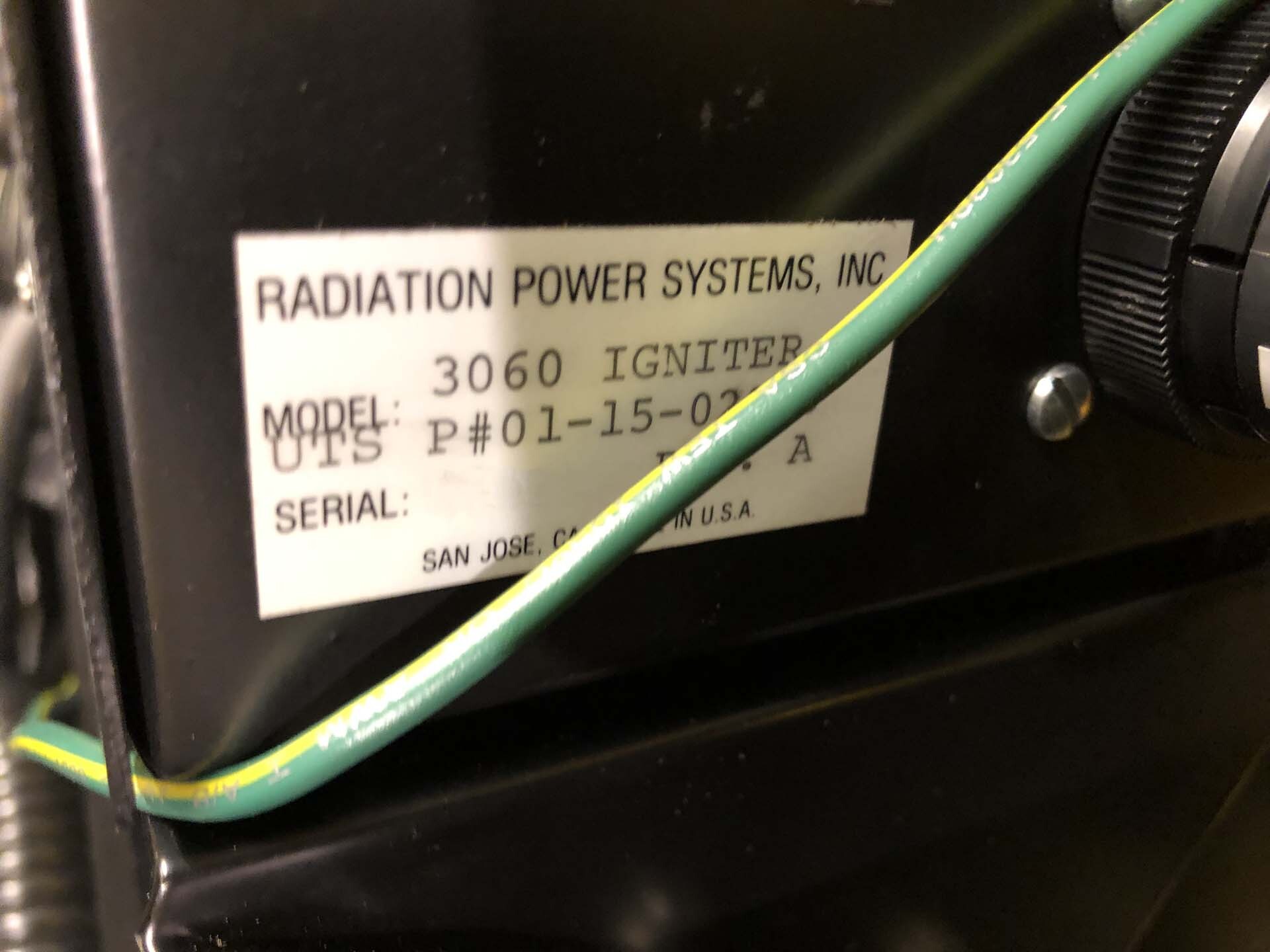

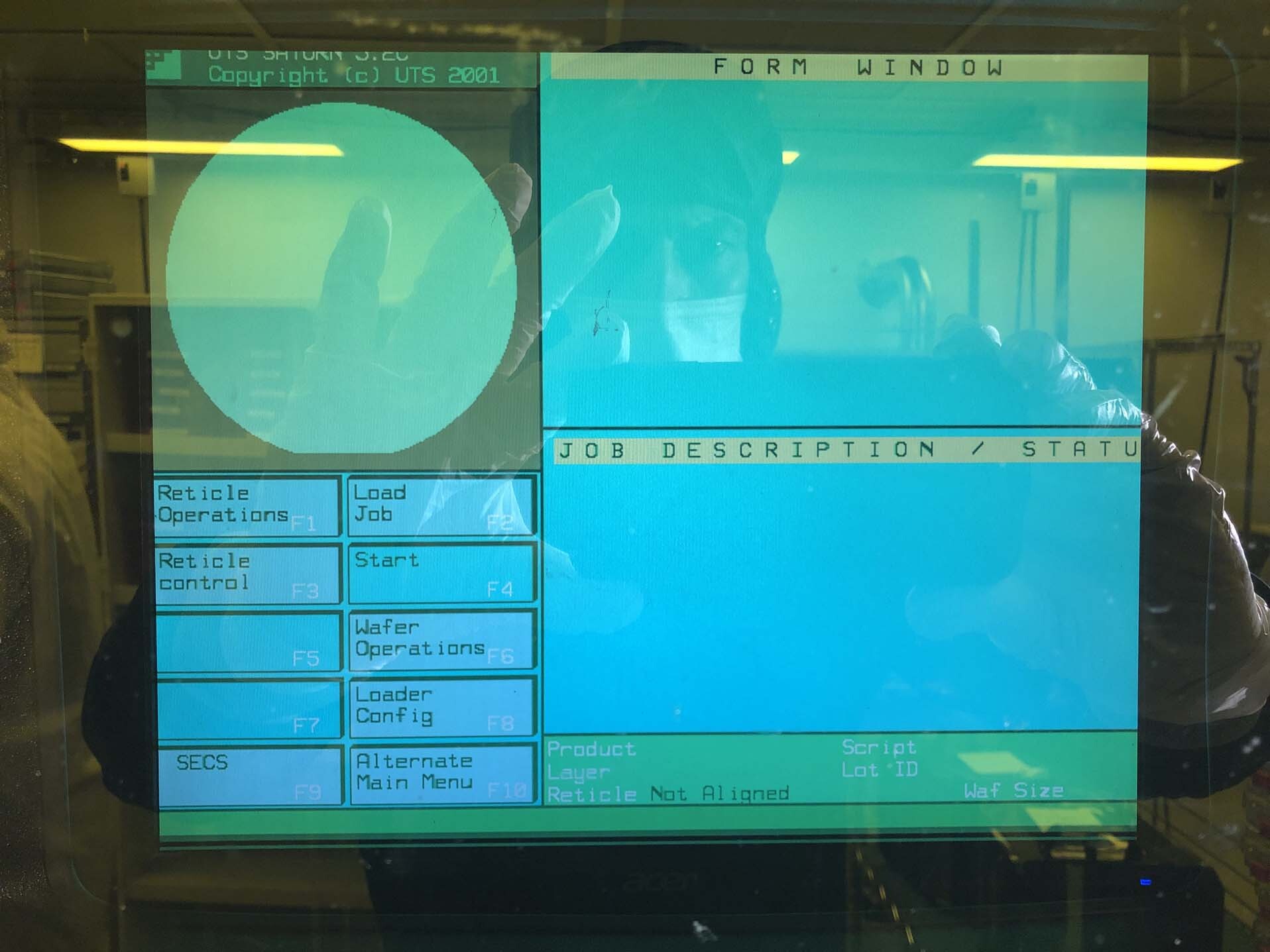

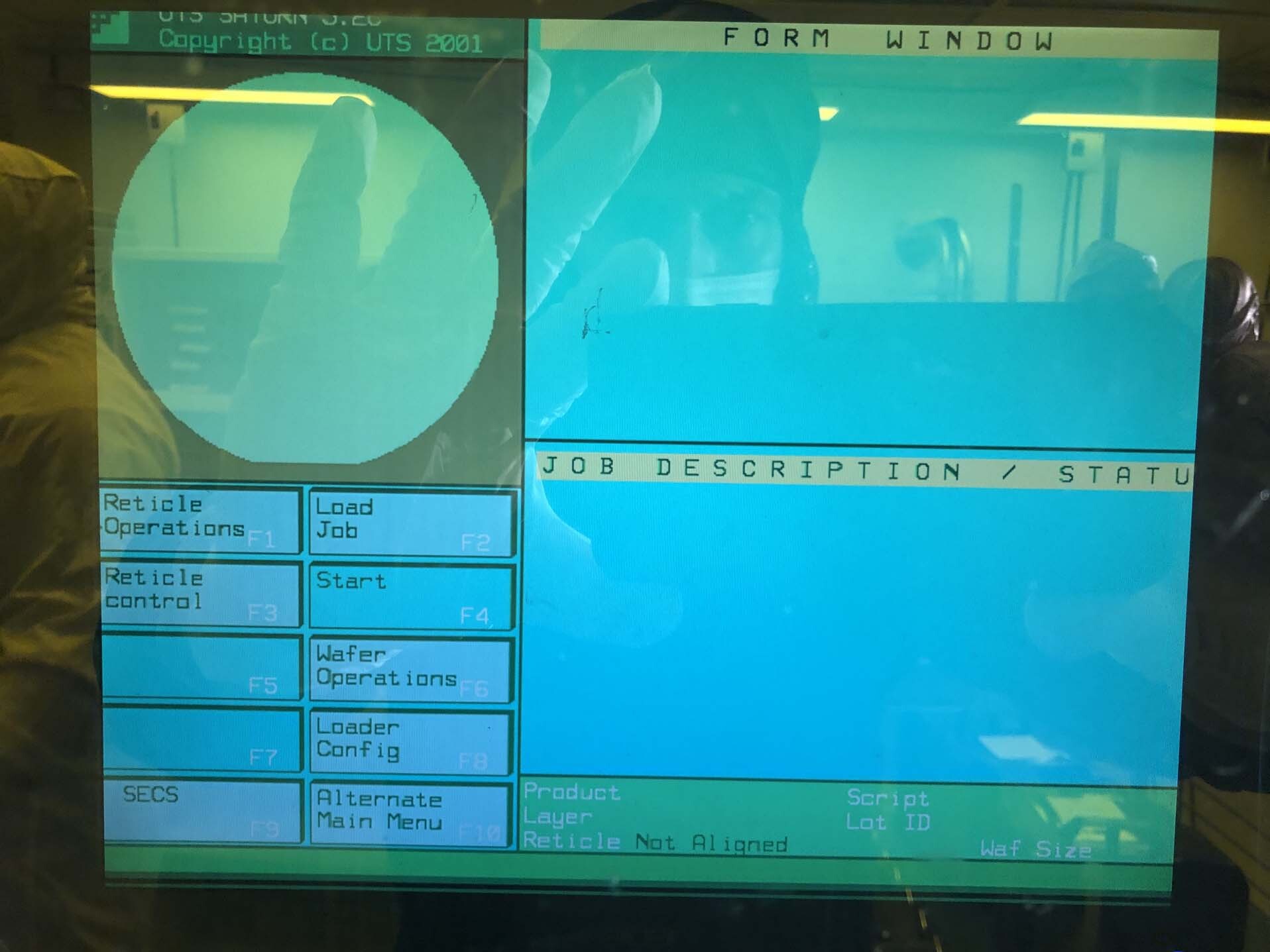

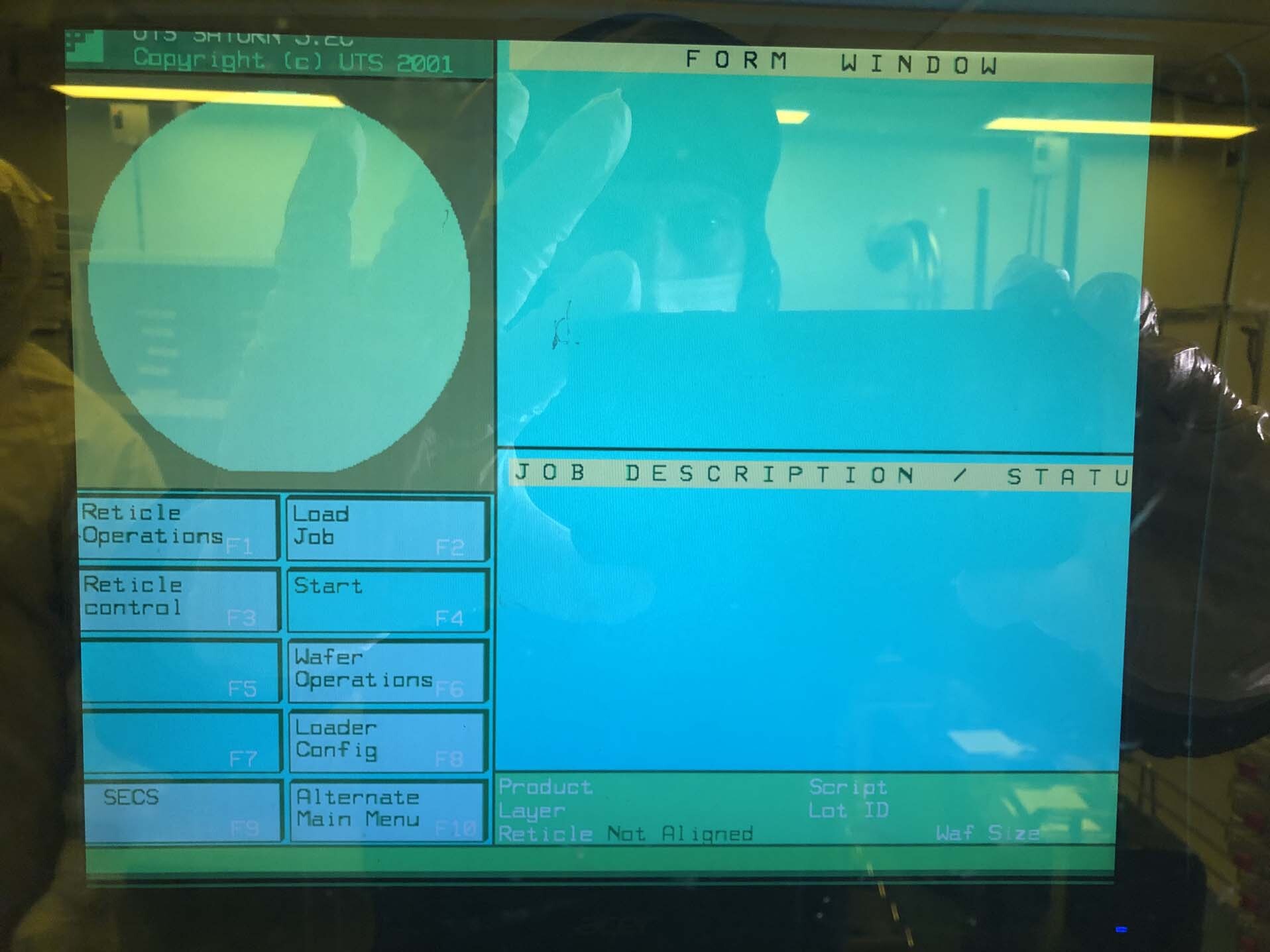

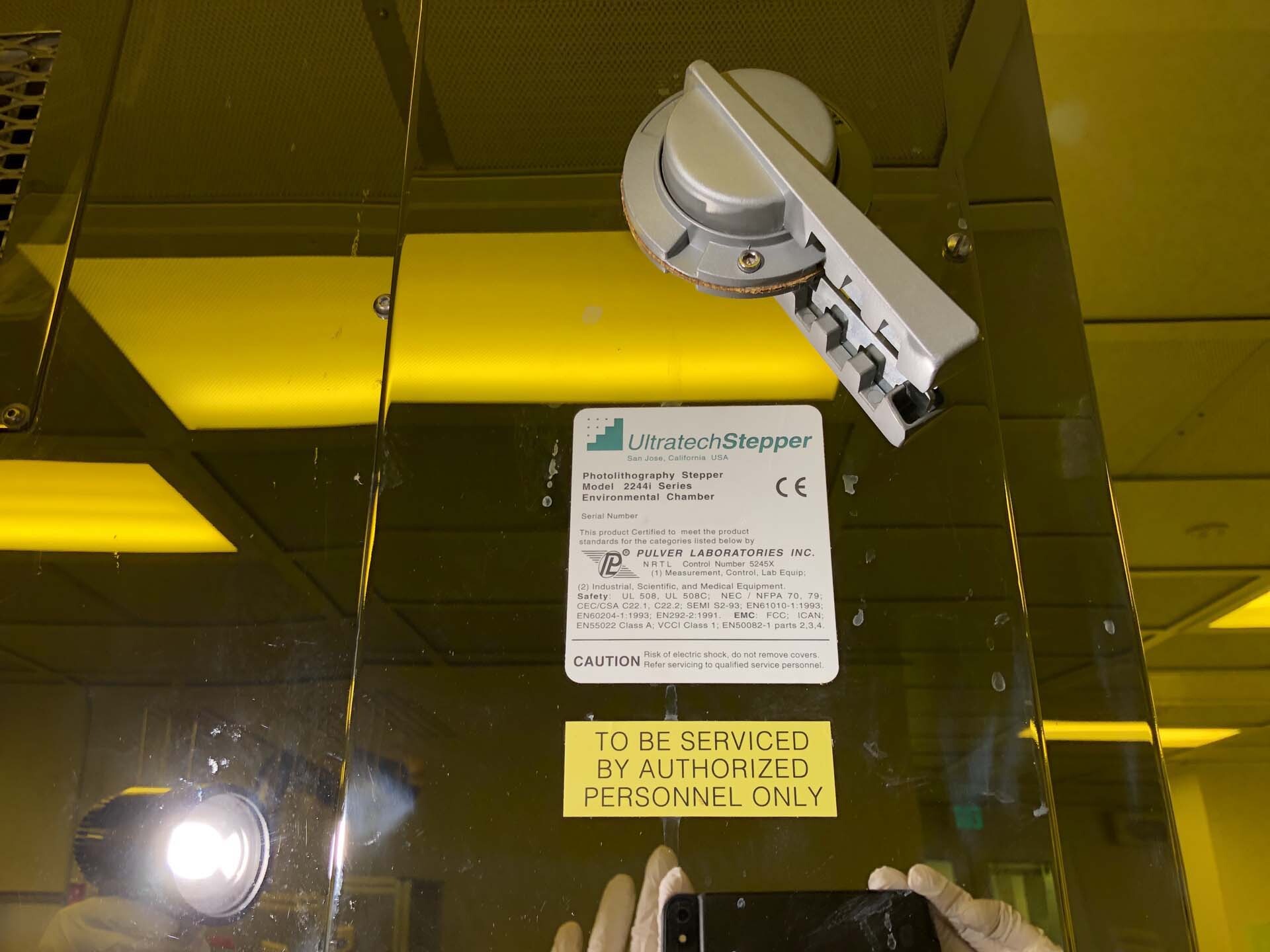

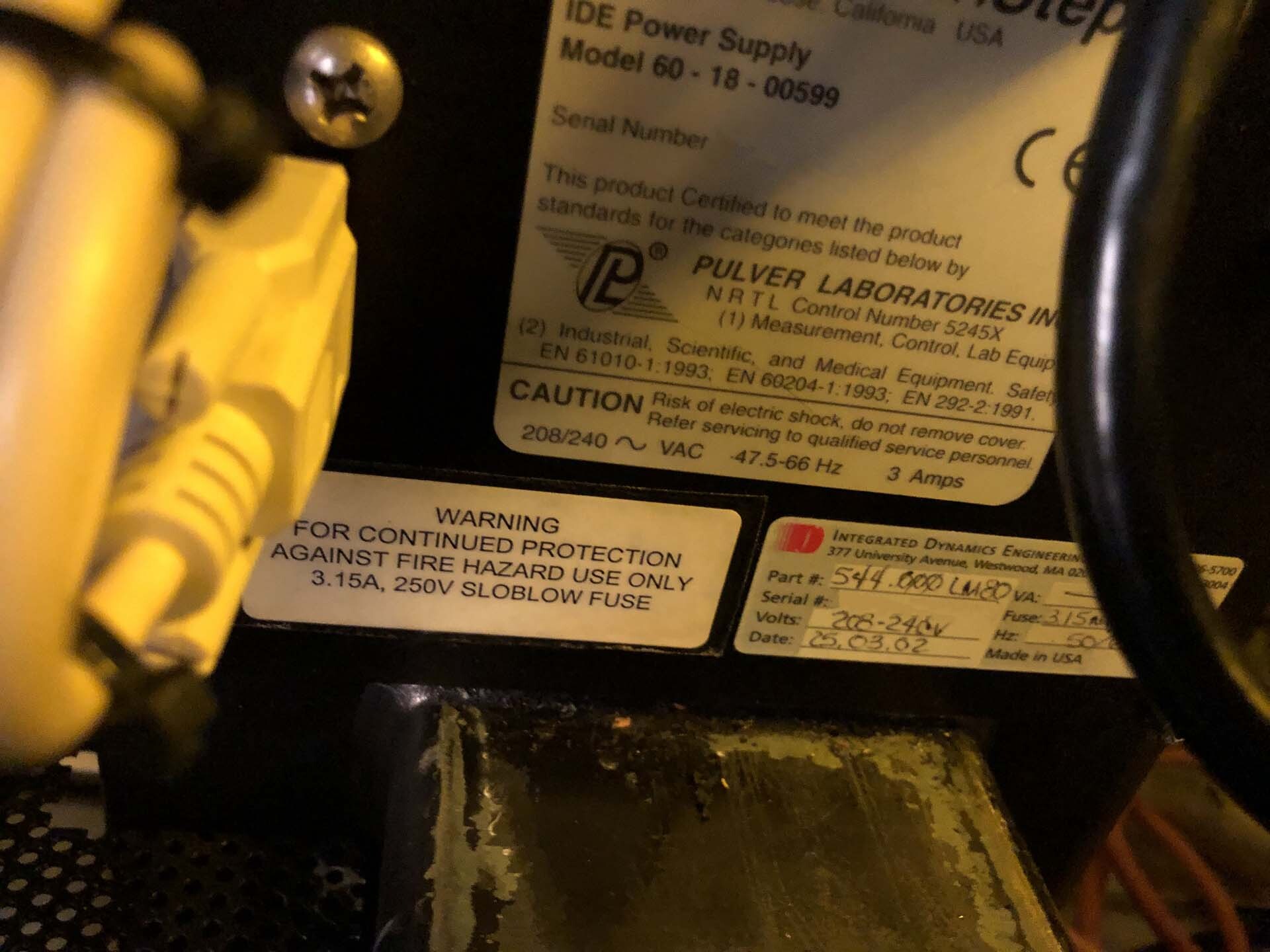

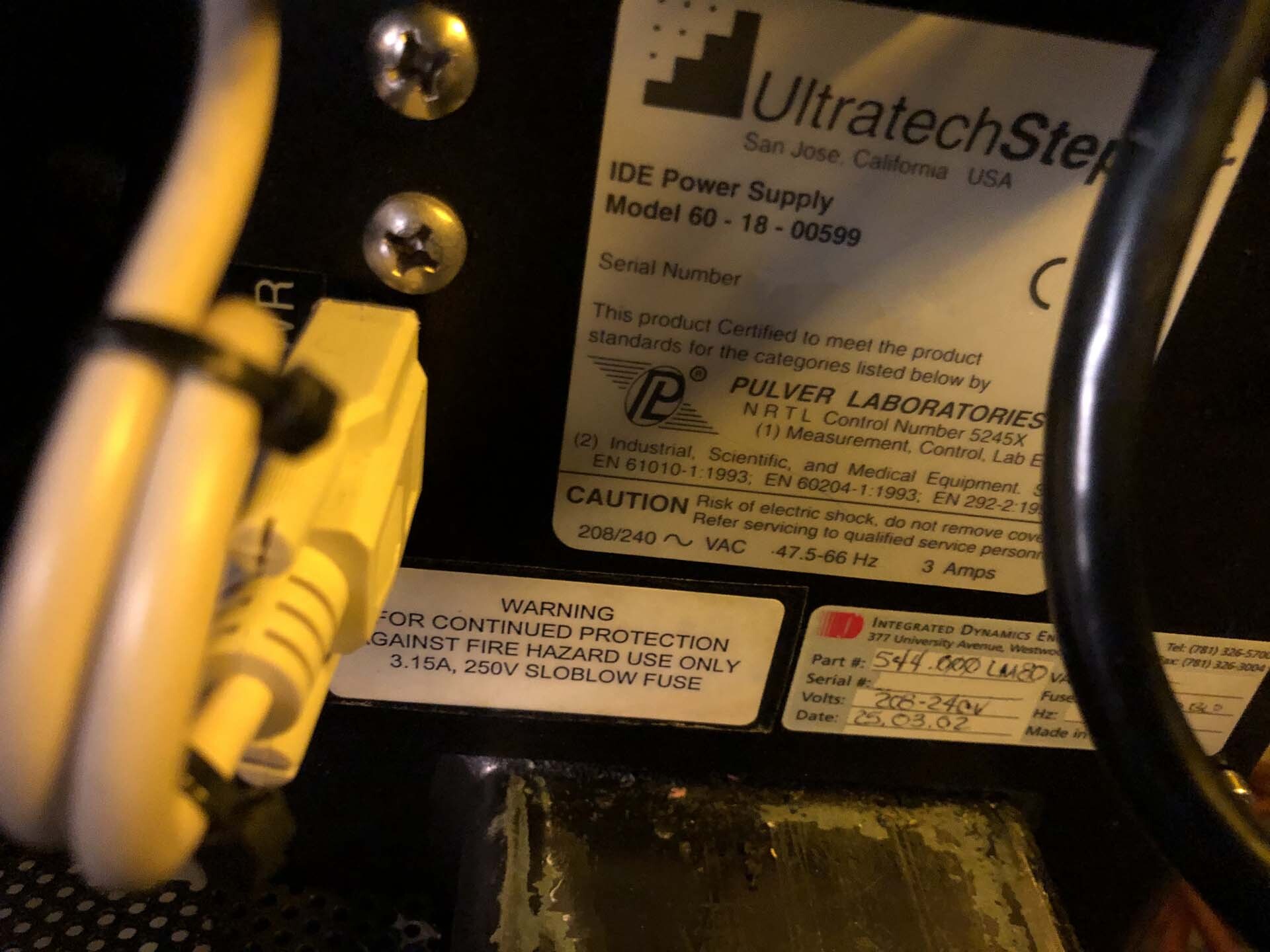

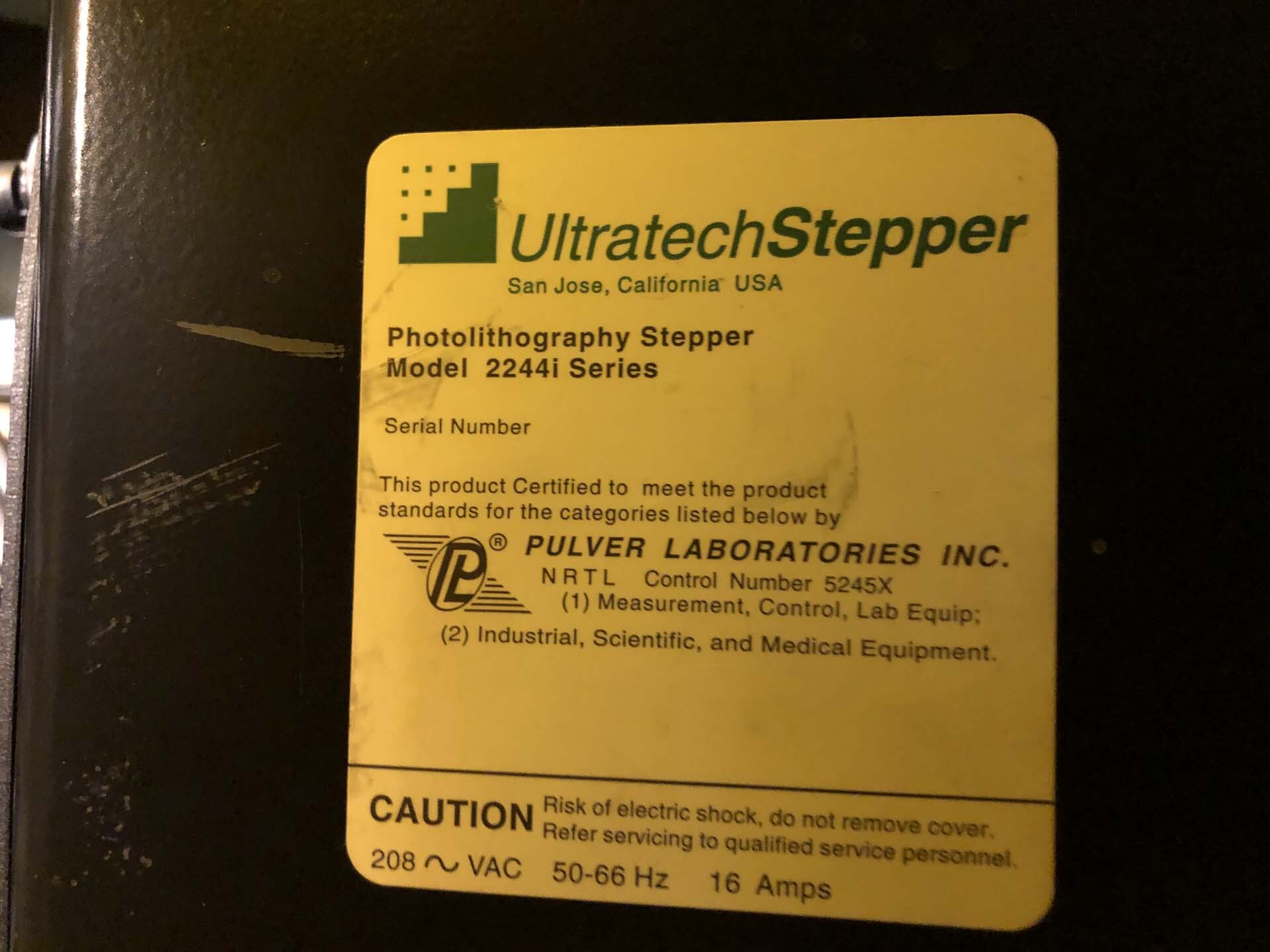

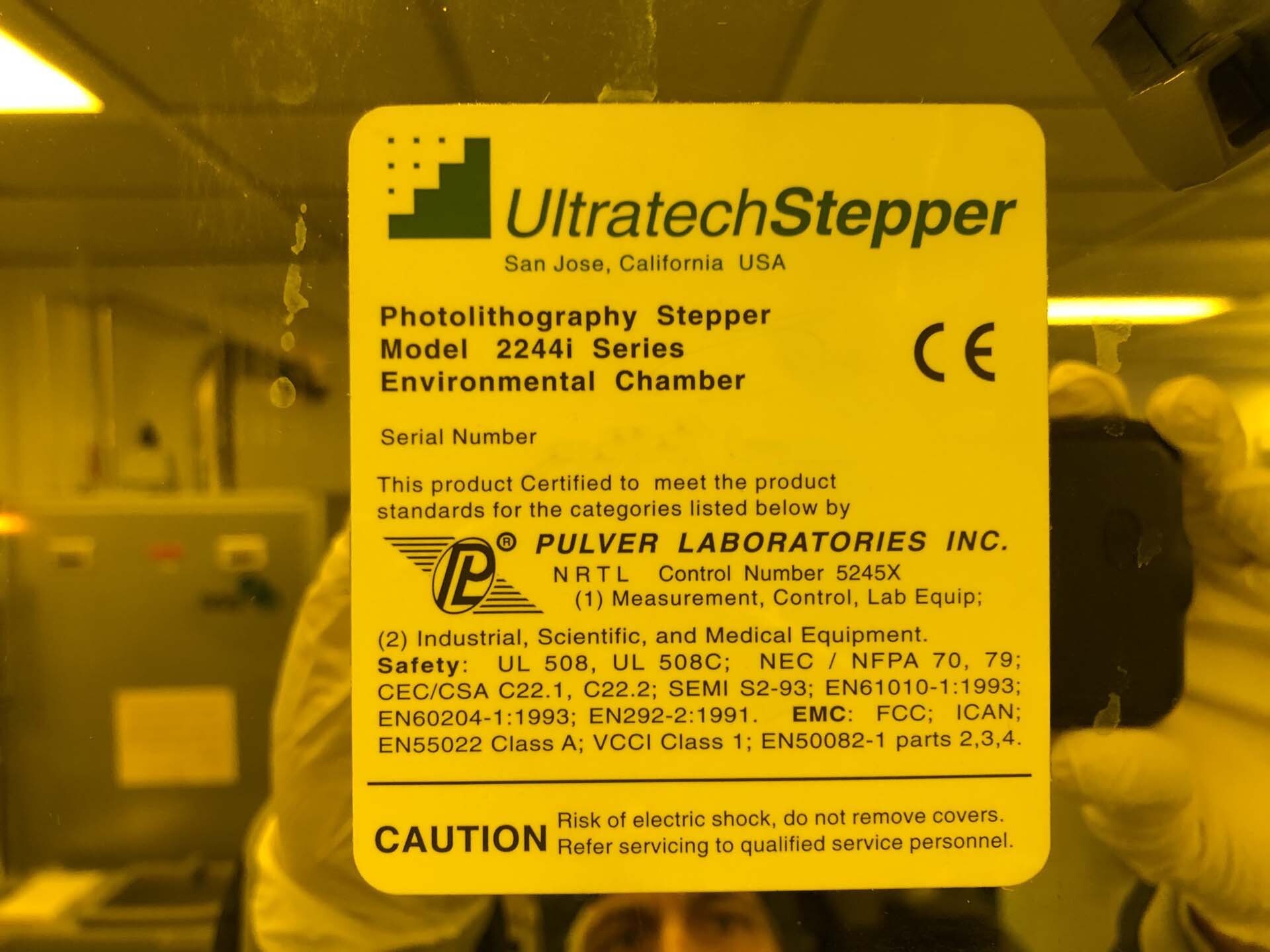

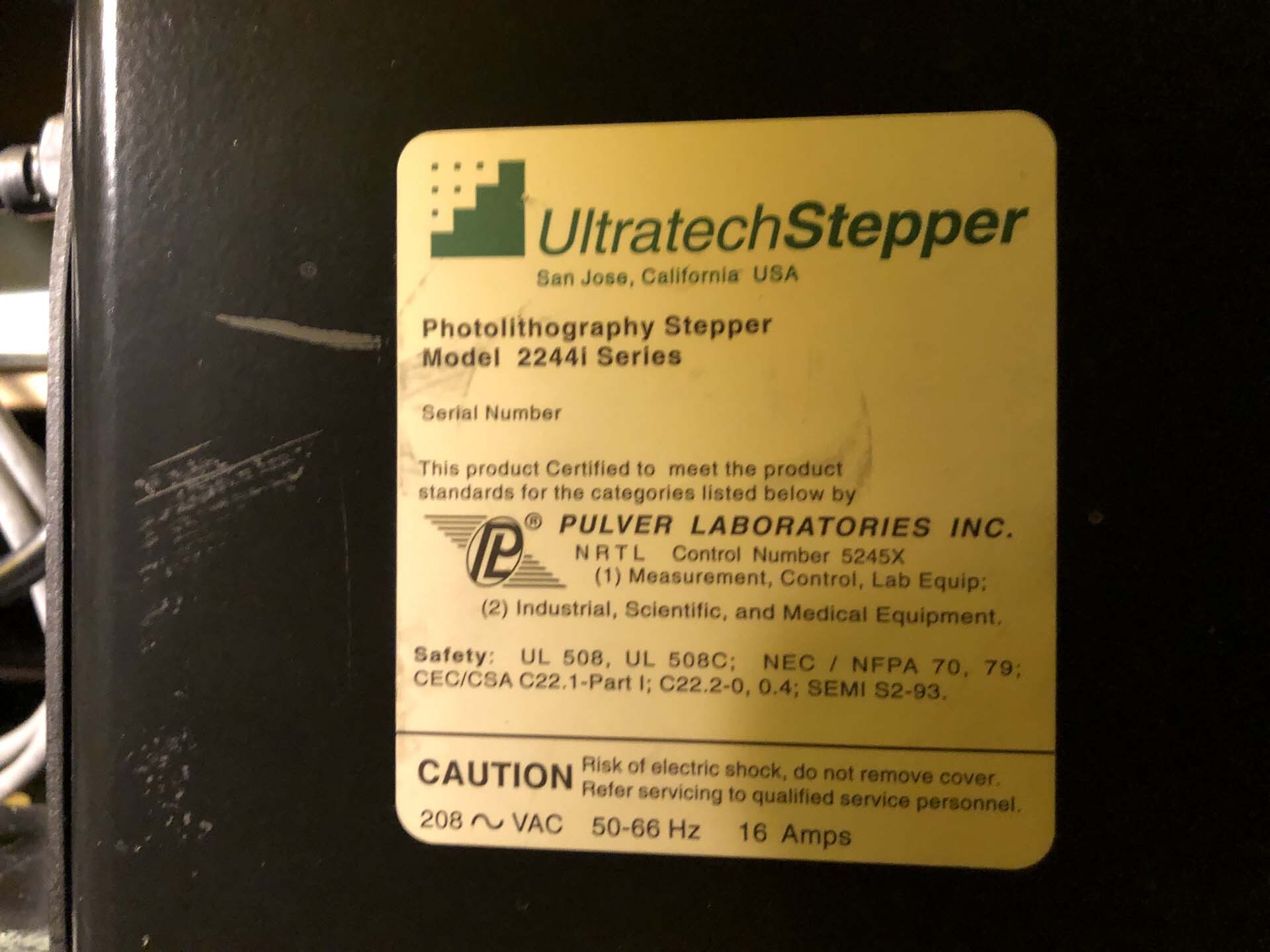

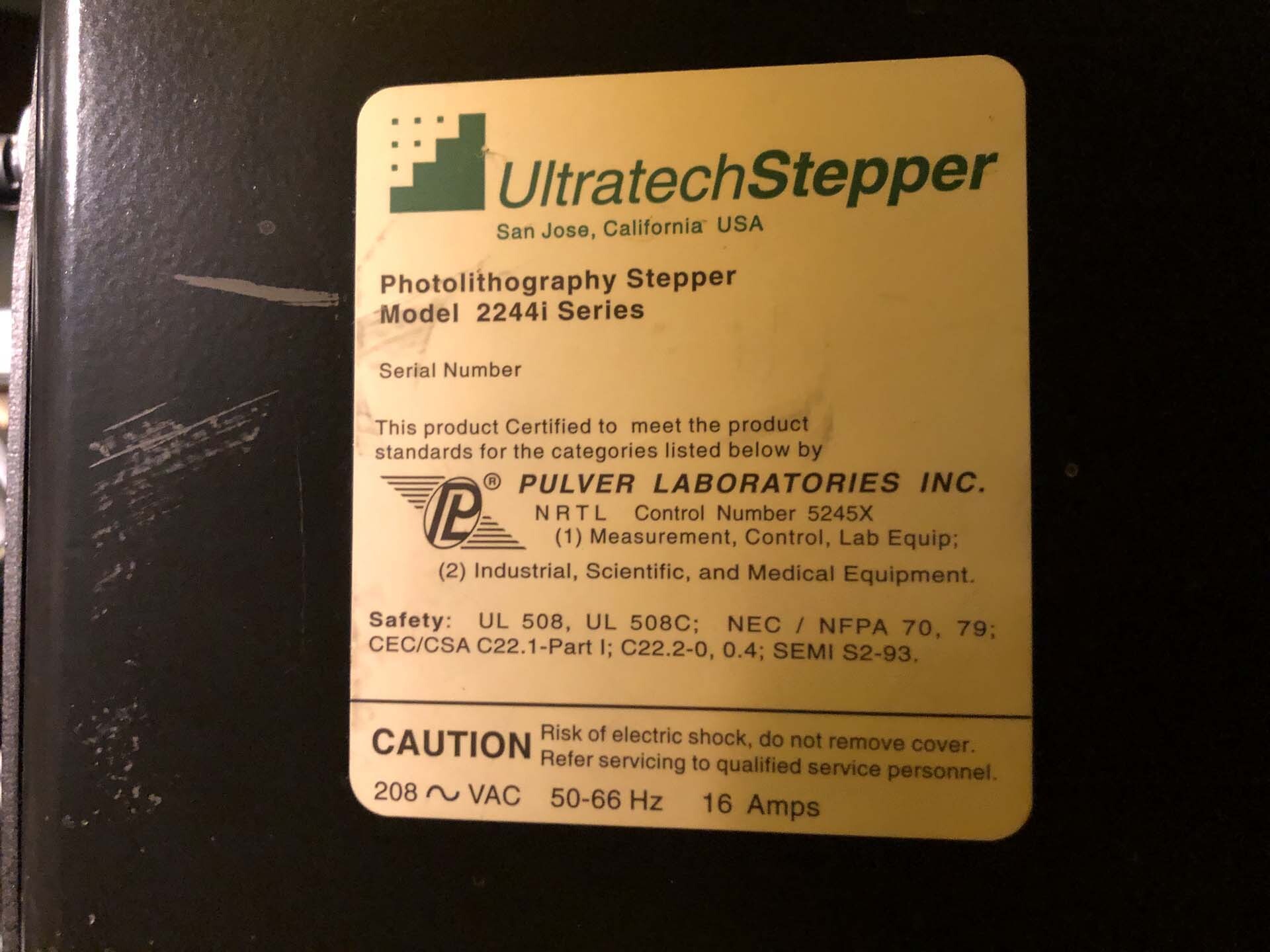

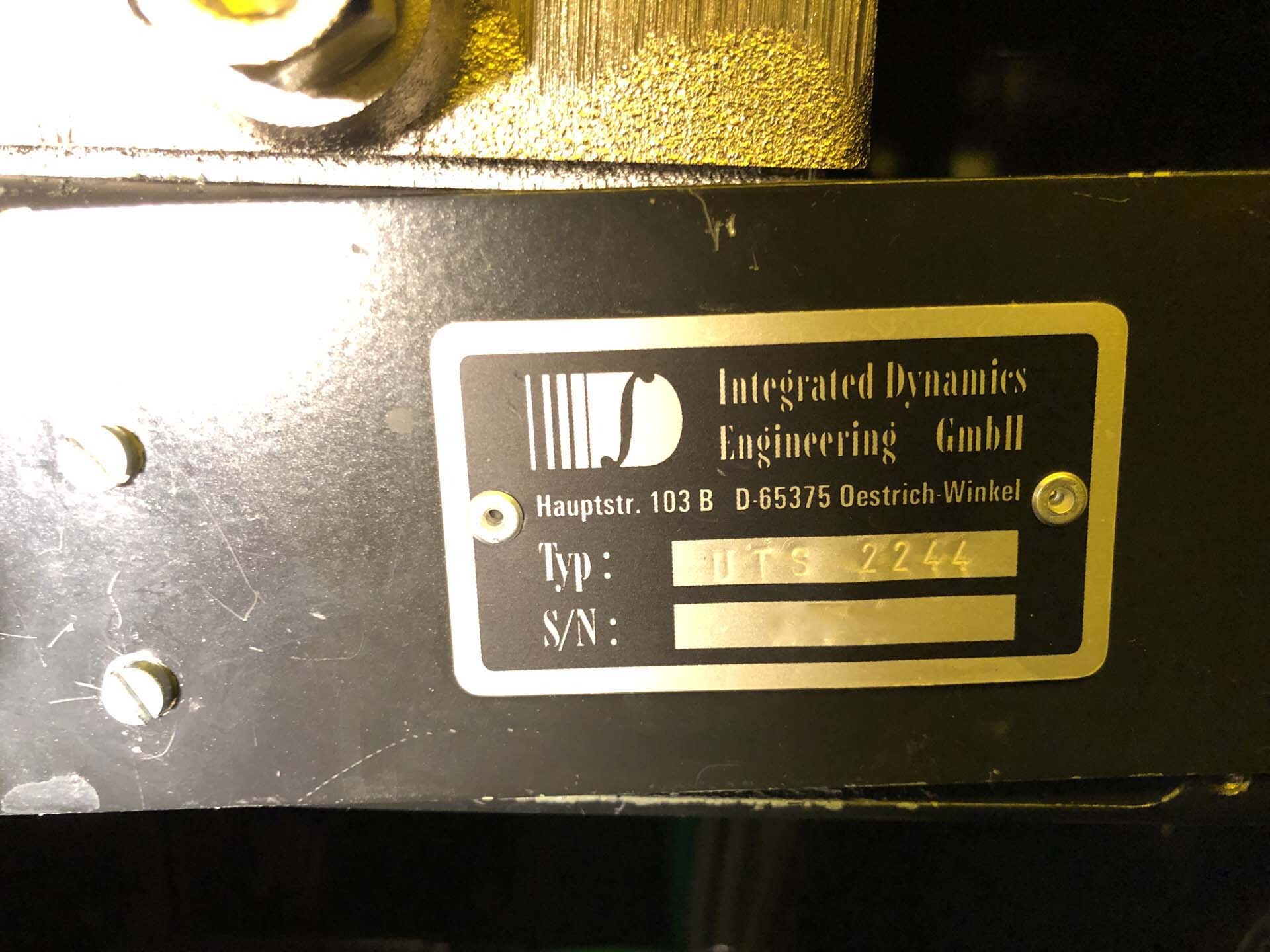

ULTRATECH Saturn III 6700 wafer stepper is a precision optical lithography machine used for manufacturing semiconductor devices. It is a 9" auto-aligning advanced stepper, with a network-based architecture and an inertial multi-axis handling system. This enables accurate, precise and repeatable placement of photomasks for high-speed production of advanced microelectronics. The 6700 Series provides exceptional throughput, with exposure times that consistently deliver a high-end yield of 0.25 microns. The built-in precision motion control allows for fast, reliable and accurate positioning and scanning of up to 8 die simultaneously. The operator interface features a touchscreen LCD monitor and comprehensive user diagnostics. The 6700 Series is compatible with a wide range of photoresists, such as SOL-Gel, ALD, and HRG (High Resolution Glass). The 6" exposure area can handle device sizes ranging from 6" to 12", meaning a single mask set can cover multiple device sizes. The high tolerance exposure system ensures uniform exposure across a large area with a light source output of up to 3 mW/cm2 and a dose exposure of 45-200 mJ/cm2. The versatile data input from a variety of sources, including high-resolution bitmaps, vector graphics, images, and text data, is easily managed with 4MB of onboard memory and a bulk data input/output interface. Equipped with a hardened industrial air bearing, Saturn III 6700 achieves fast, repeatable multi-axis stage operation. The built-in differential drive mirror that prevents harmonic distortion helps ensure reliable operation during exposure. In addition, the 6700 Series comes with powerful exposure and focus control algorithms, compatible with all of ULTRATECH high-end lithography tools. The built-in exposure monitor ensures that exposure conditions are uniform and repeatable, while a focus monitor allows users to perform wafer-level focus controls. ULTRATECH Saturn III 6700 is ideal for producing high-end lithography repeatability, accuracy, speed and resolution on a large scale. Its combination of cost-efficiency and robust features makes it the perfect choice for achieving various advanced microelectronics projects.

There are no reviews yet