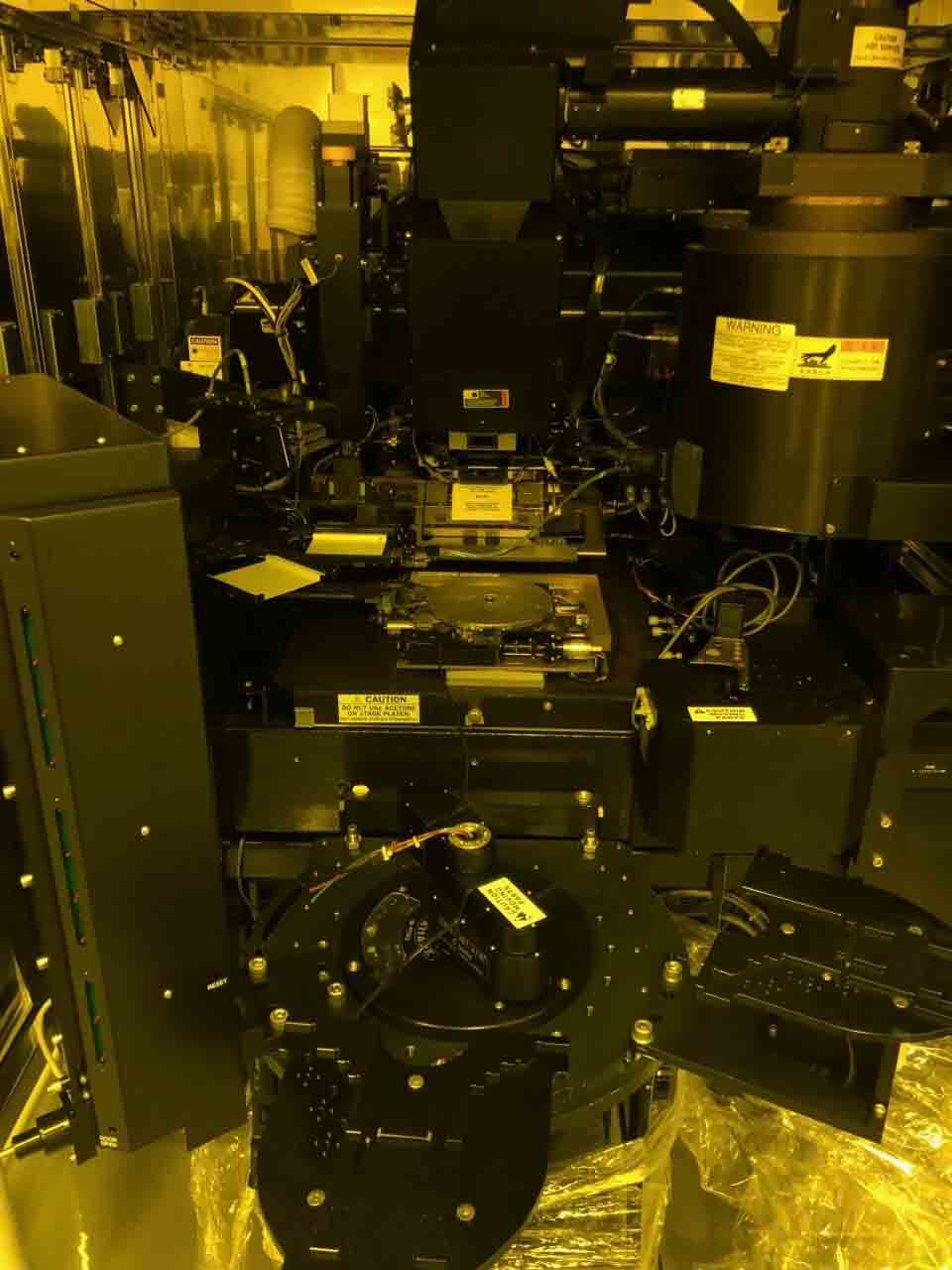

Used ULTRATECH Titan II #9207808 for sale

URL successfully copied!

Tap to zoom

ID: 9207808

Wafer Size: 4"-8"

Wafer stepper, 4"-8"

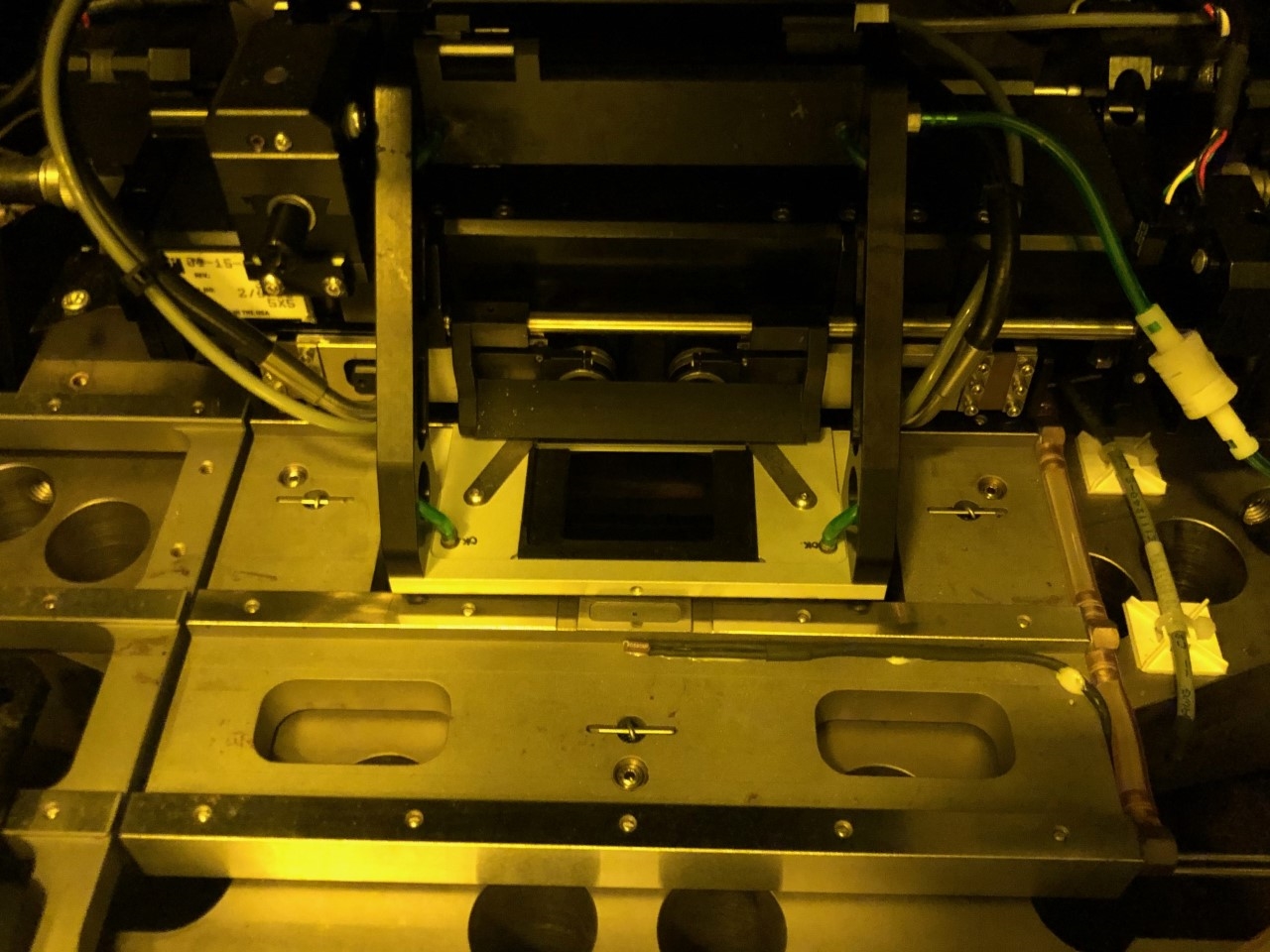

Reticle size: 5 x 5"

Reticle library: 12-Slots / Bar code reader

Projection ratio 1:1

Lens resolution: 2 um

Field size: 44 mm x 22 mm

Wavelength: GH

Substrate size: 2"-6"

Wafer handling: Cassette to cassette / Interface

(12) Reticle storages with bar code reader

Stage:

Monolithic structure

Linear motor drive

PC:

VME Bus controller

CPU 68030

Graphics monitor

Vibration control: Active air isolation

Alignment:

Global: 120 nm, 3seconds

Site by site: < 120 nm, 3seconds

Alignment spectrum: 500-650 nm

(2) Targets per field required

Imaging and lens:

Feature size: 2.0 micron

Lens distortion: 120 nm

Colinearity: 80 nm

Maximum image area: 55 mm x 18 mm

Exposure spectrum:

Broadband: 390 nm - 450 nm

Wafer plane intensity: > 1200 mW/cm²

Uniformity: 2.0%

Reticle:

Substrate type: 6" x 6" x 0.25" / 5" x 5" x 0.09" quartz

Field / Row: 2-5

Pellicle standoff: 2.0 mm

Square, 4.5":

>83 WPH (100 mJ / cm²)

65 WPH (800 mJ / cm²)

Round, 6":

>75 wph (100 mJ / cm²)

55 wph (800 mJ / cm²)

Field change time: <10 seconds

Reticle change time: <120 seconds

Alignment target: Compatible with 200 mm scribe

DOF: 6 um

Illuminator: 1000 W

Uniformity: 3%

GENMARK Wafer handler

Environmental chamber

HP / HEWLETT-PACKARD 362 Computer running HPL

CE Marked.

ULTRATECH Titan II is a fully automated multi-project wafer stepper designed to deliver high-precision, high speed lithography in a range of sizes and formats. Titan II is based on a full range of masks and features a modular design that allows users to tailor their lithography systems to the specific requirements of the application. The equipment has an integrated process chamber that is capable of handling large modules and multi-part components with ease. It offers excellent alignment accuracy and repeatability, with a feature resolution of up to 1.5 micron. ULTRATECH Titan II also has a unique, patented AutoStrobe laser interferometry system for high accuracy wafer/mask/photoresist alignment and placement. Titan II was designed for optimal throughput and ease of use. It includes a self-diagnostics unit for detecting and eliminating common causes of misfeeds and misalignments. The stepper's three-axis staging is capable of carrying the required data disks and photomasks in a repeatable and exact mode. ULTRATECH Titan II is a high-quality, powerful wafer stepper machine. It is able to lithograph components with a feature resolution of up to 1.5 microns, giving an excellent degree of accuracy and repeatability. The AutoStrobe laser interferometry tool ensures accurate alignment and placement of wafers and masks, while the asset's modular design makes it ideal for a variety of applications. Titan II is an excellent choice for a wide range of lithography needs, providing reliable, accurate and repeatable results at a very competitive price.

There are no reviews yet