Used ULTRATECH Unity AP300 #9128099 for sale

URL successfully copied!

Tap to zoom

ID: 9128099

Wafer Size: 12"

Vintage: 2009

Stepper, 12"

Resolution: 2 um Line / Space

Field size: 34 x 26 mm

Wave length: Ghi-line

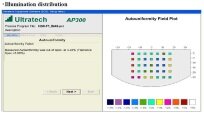

Illumination:

Strength of exposure: 2,063 mW / cm² (Ghi-line)

Exposure accuracy:

Shutter accuracy:

0.28% (250 mJ)

0.68% (2500 mJ)

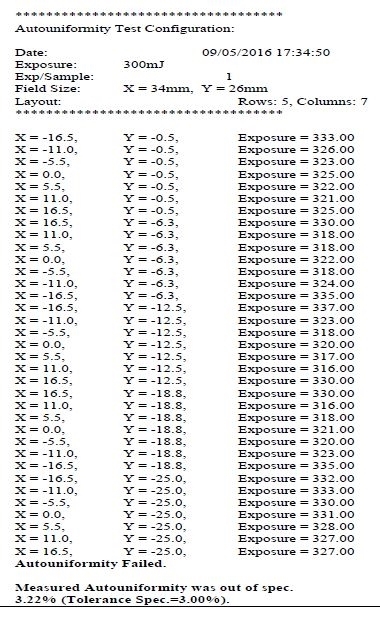

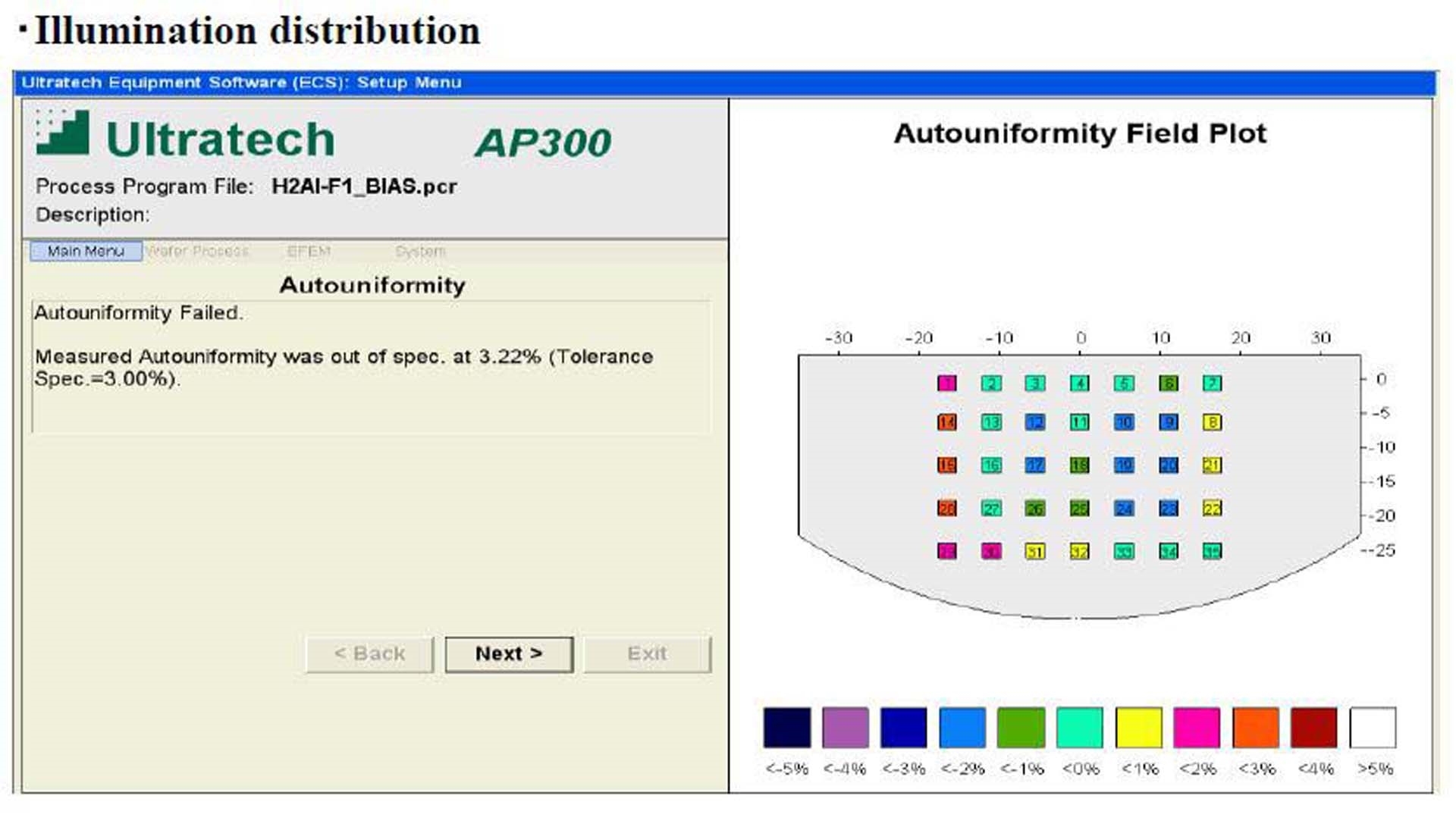

Illuminator condition: 3.22%

SSF Focus

Lens resolution: 2.0 um L/S

DOF Lens: ±7.5 um

Image plane inclination:

Wafer chuck flatness:

X: -0.0179 um/mm

Y: 0.0804 um/mm

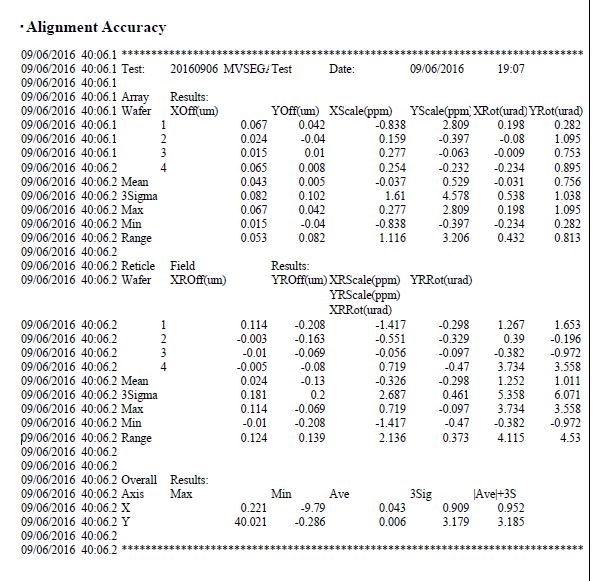

Alignment accuracy:

Overlay accuracy:

X: 0.909 um

Y: 3.179 um (3-Sigma)

Wafer place position accuracy:

X: 98.343 um

Y: 83.691 um (3-Sigma)

Reticle position test:

X: 0.480 um

Y: 0.624 um (Sigma)

TCL Test

Benchmark: 115.1 + 22 um (L: 0 um, B: -7.0 um, R: 0.8 um)

Data back up: Critical backup

2009 vintage.

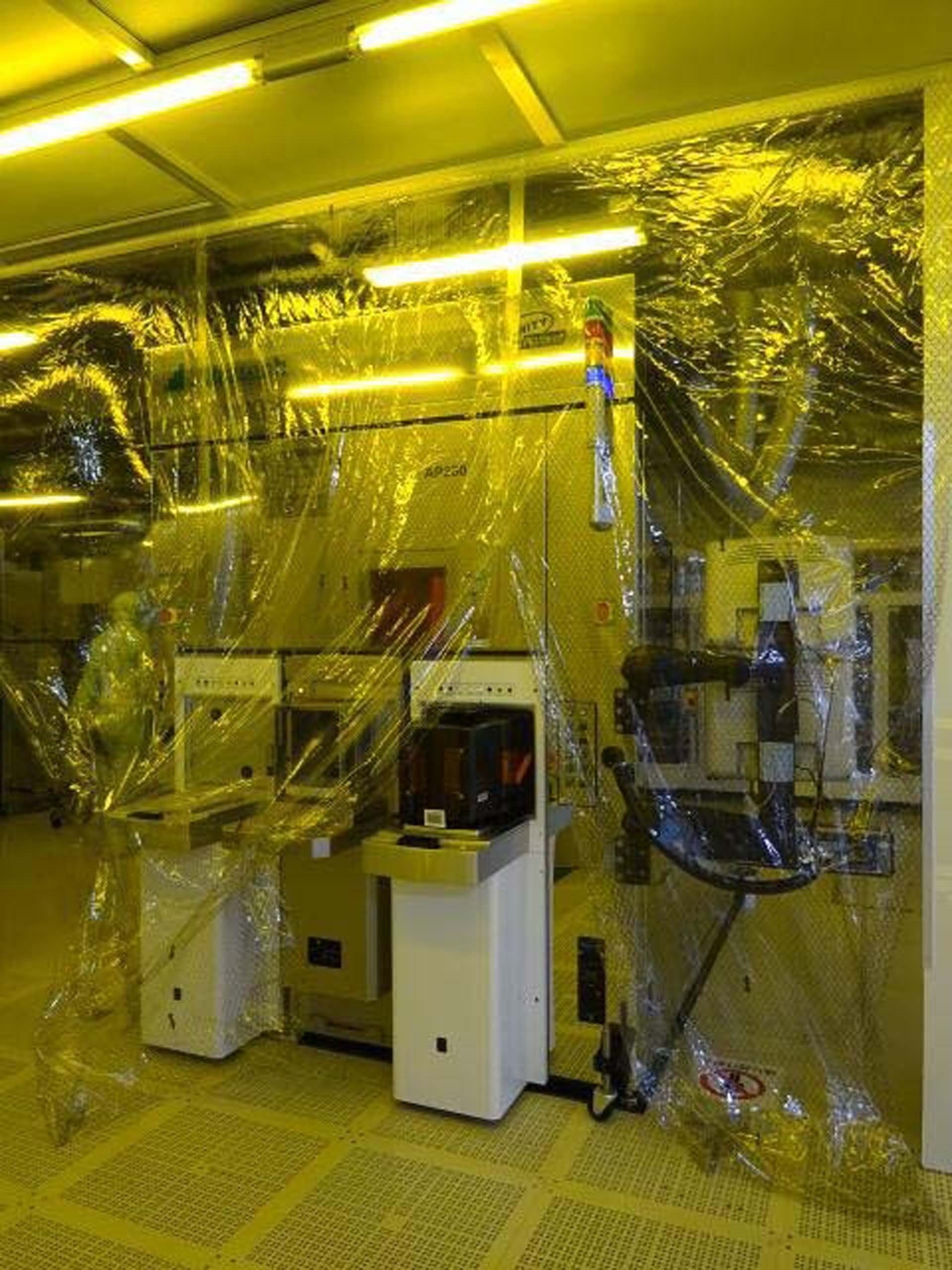

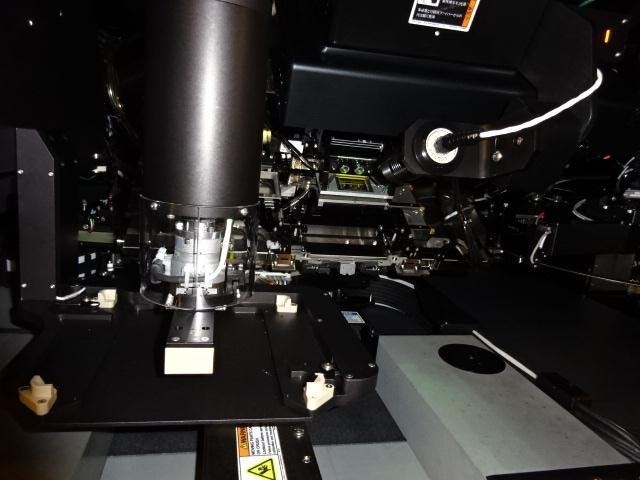

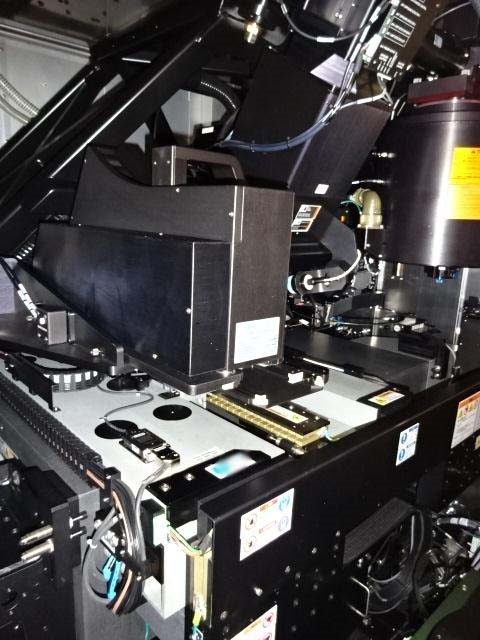

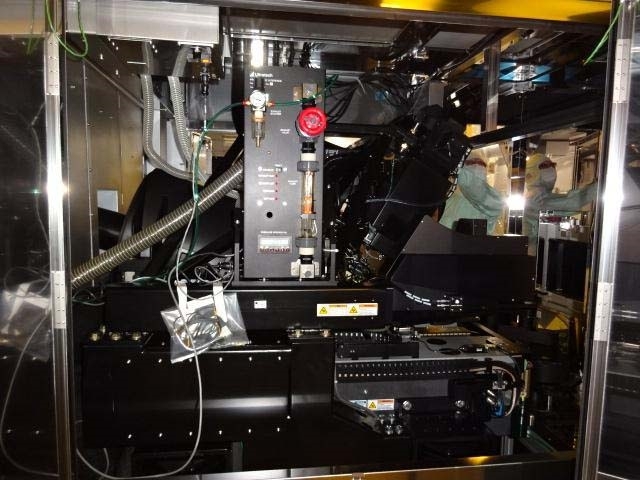

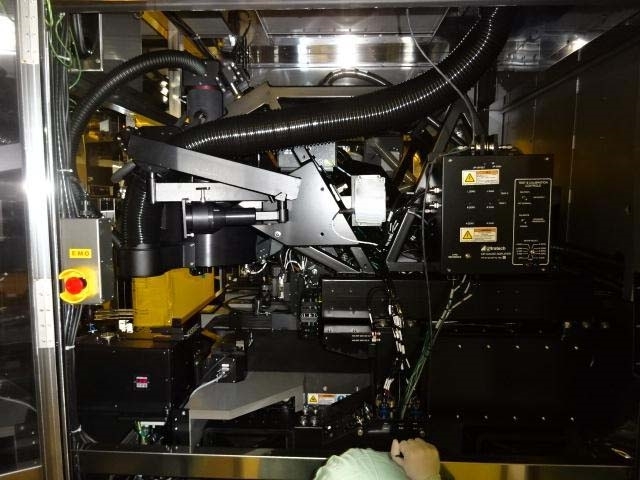

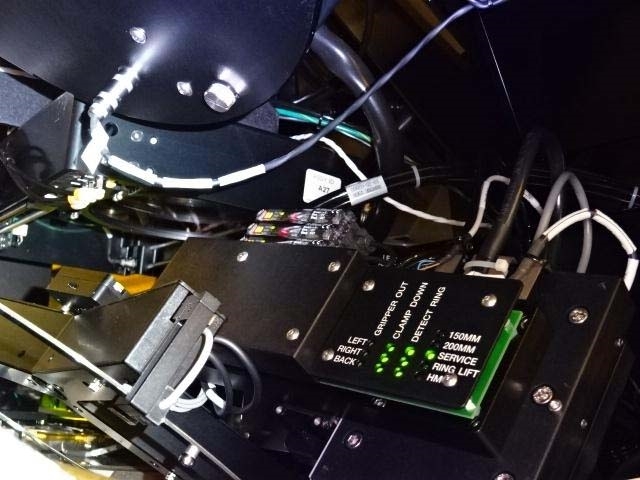

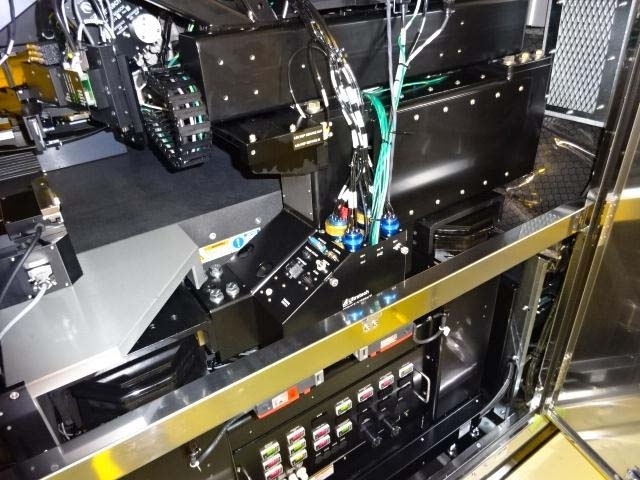

ULTRATECH Unity AP300 wafer stepper is a state-of-the-art precision lithography equipment used in the production of semiconductor wafers. The stepper features advanced optics and multi-dose capability, capable of imaging up to three wafers simultaneously. The system is designed to provide high quality imaging of both exposed and unexposed wafer surfaces. The AP300 is equipped with an Opti-Scan Robotics unit, which provides accurate and repeatable alignment and movement of the wafers within the machine. The machine is also capable of switching between two cameras, allowing the user to perform both top and bottom surface imaging. The wafer stepper is powered by a high-precision, multi-axis stage, providing air suspension and isolation of the wafer from the environment, as well as optimum motion control. The tool also features a high-end motor, with accurate and repeatable speed control, ensuring precise motion and position of the wafers during lithography. The AP300 wafer stepper utilizes a proprietary Dose Control and Exposure Asset, which provides unparalleled stability and precision in dose delivery and pattern writing speed. The model also provides advanced optical correction using calibrated uniformity masks, enabling improved image quality and more accurate lithography. The AP300 also utilizes an advanced Multi-Layer Process (MLP) equipment to monitor the wafer's progress during the step and repeat process. This helps to minimize misalignments and ensure that the correct amount of doses are applied to each die across the wafer. Finally, the AP300 is built with robust safety features, designed to ensure safe operation at all times. The stepper comes complete with a cabinet enclosure, ensuring that the system is shielded from external vibrations, dust, and EMF. The safety features also include an emergency stop button to protect the user from harm.

There are no reviews yet