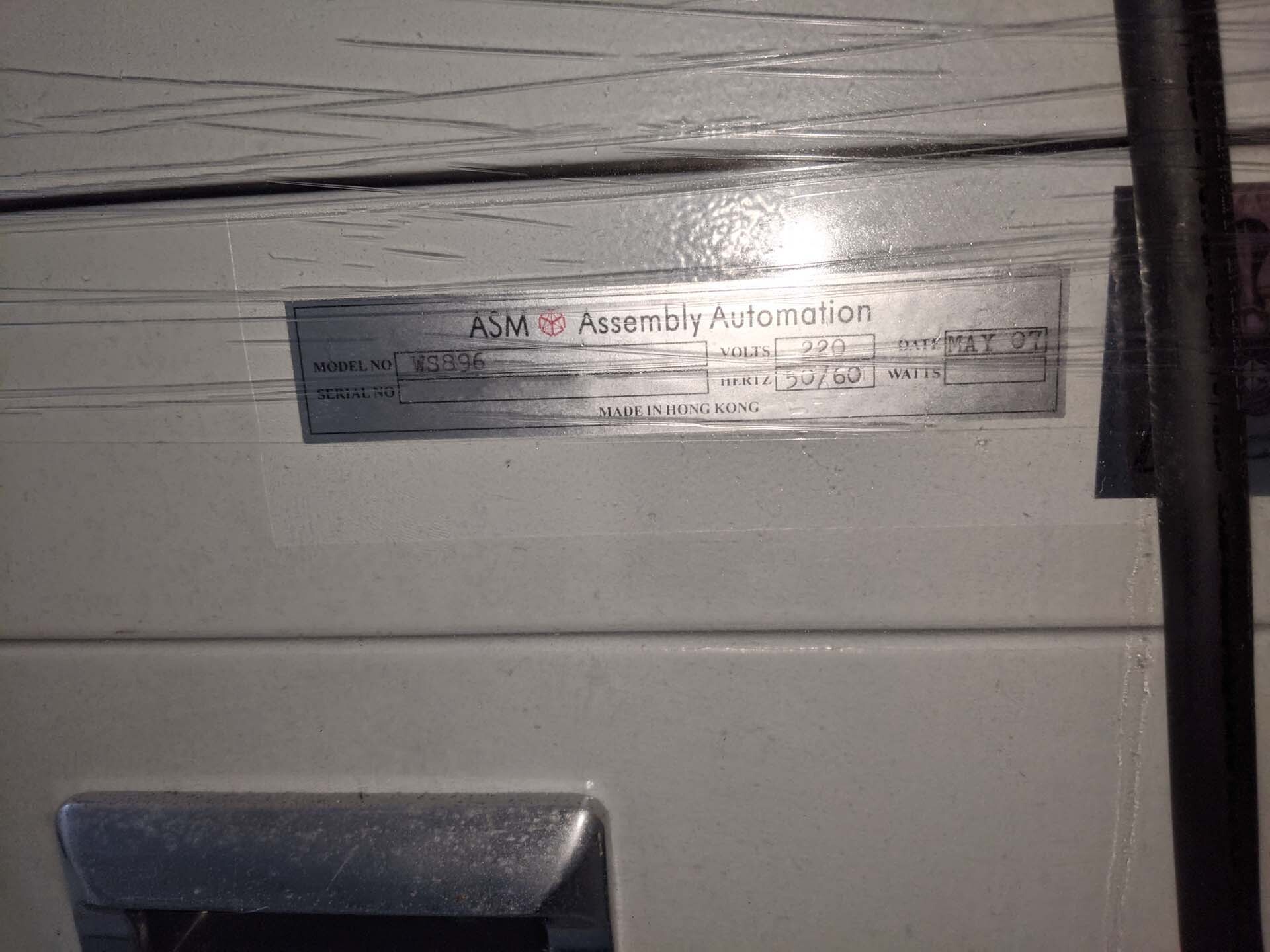

Used ASM WS 896 #9256698 for sale

URL successfully copied!

Tap to zoom

ASM WS 896 (wafer testing and metrology) equipment is an automated process environment for die testing and metrology. It enables high-volume wafer testing and monitoring of process parameters over the life of a product. The system features a unique combination of precise metrology, high-speed motion control, and proven testing methods to meet the needs of process engineers and production plants. It supports wafer testing requirements over a wide range of geometry and materials. ASM WS896 unit integrates a variety of sensors and networked instrumentation to analyze wafers and determine product quality. It can measure properties such as wafer flatness, surface roughness, grain size, topography, crack resistance, and line widths. The machine also inspects finished products for defects such as electrical shorts, variations in die composition, moisture absorption, and other irregular patterns. Flexibility is provided by advanced software, enabling customers to develop their own tests to meet their specific requirements. The tool supports both static and dynamic testing, including wafer mapping, probing, and sorting. Test results are stored and can be used for real-time process improvement. WS 896 asset is easy to operate and designed for reliable operation. It features a low part-to-part variation, low set-up time, and fast run times. The model is serviceable on-site and requires minimal maintenance. WS896 equipment is an ideal solution for high-volume wafer testing and monitoring. It offers end-to-end quality control, ensuring consistent quality throughout the production cycle. Its low cost, ease of use, and reliable operation make it an excellent choice for wafer testing and metrology.

There are no reviews yet