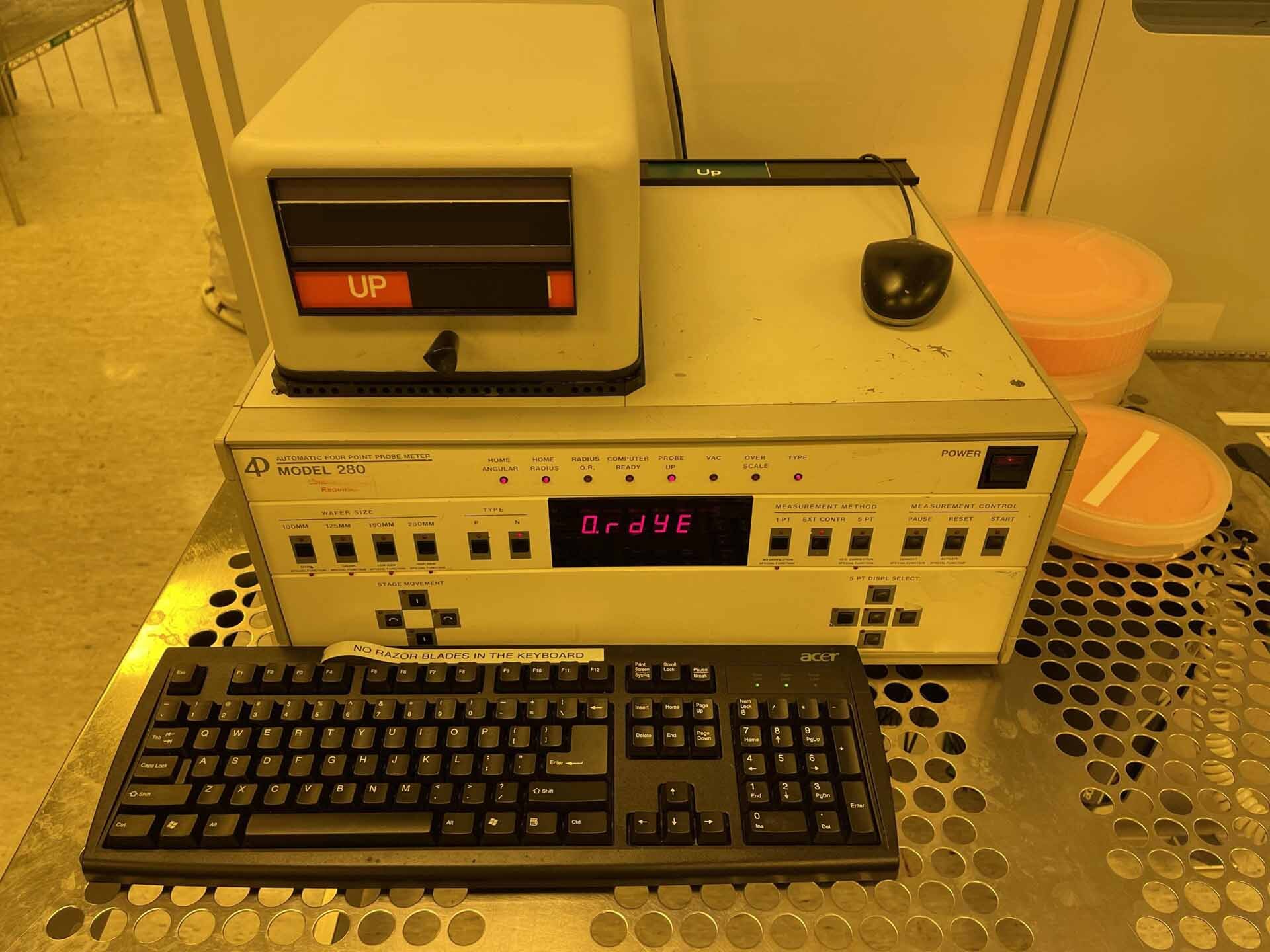

Used FOUR DIMENSIONS 280C #293622041 for sale

URL successfully copied!

Tap to zoom

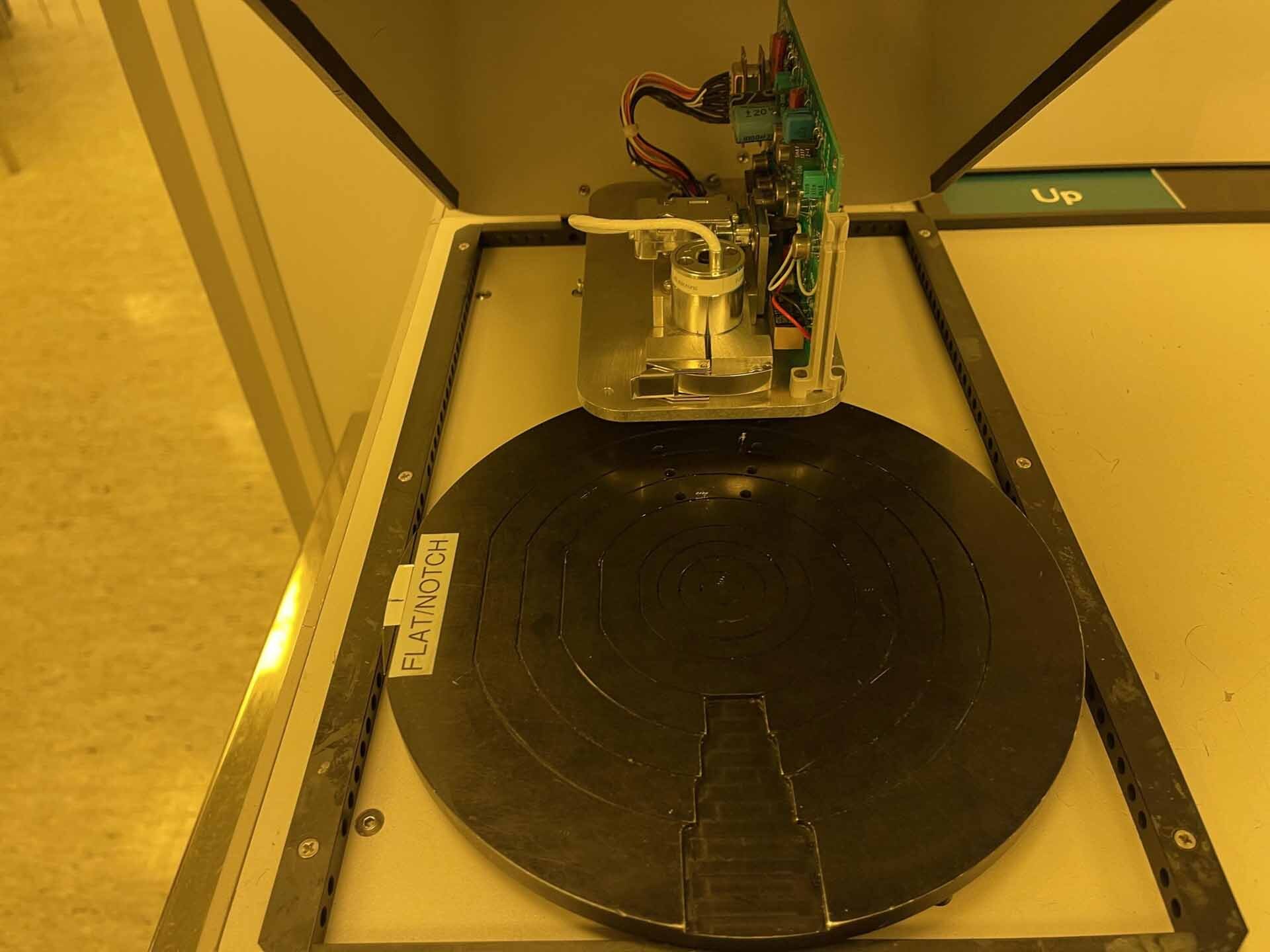

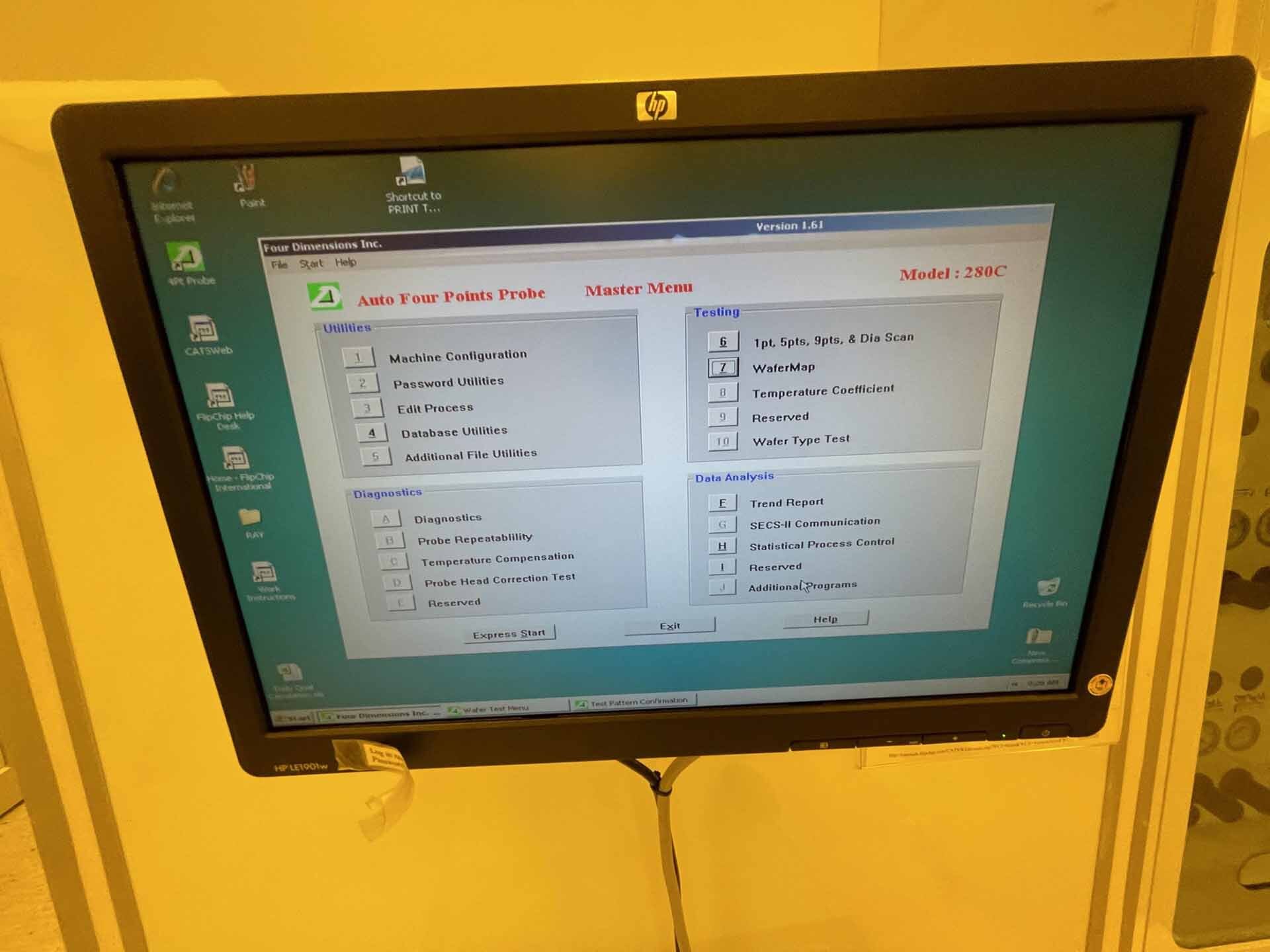

FOUR DIMENSIONS 280C Aligner Equipment is a high performance wafer testing and metrology system used to inspect, measure and analyze semiconductor devices. This automated inspection unit is designed to deliver repeatable, high accuracy performance on a wide range of semiconductor packages. The machine features an automated alignment gantry which can automatically load, align and unload wafers. The alignment gantry is capable of aligning wafers under microscope conditions which enable high accuracy measurements. The tool also comes with a comprehensive range of optical capabilities. These include visible, ultraviolet and infrared imaging as well as a wide range of contrast and brightness adjustments for enhanced wafer inspection. It also incorporates a CAD pattern overlay for increased accuracy of measurements and product testing. In addition to this, 280C includes a range of advanced metrology capabilities. These include thickness measurements, overlay and surface topography, defect analysis, critical dimension measurements, and a focal plane array for optical component alignment which are all used to ensure product quality and manufacturing repeatability. The asset also includes a high resolution camera which can capture images at up to 200X magnification. The FOUR DIMENSION FOUR DIMENSIONS 280C also features a suite of process control features such as real-time quality monitoring and process control data logging. This helps to prevent defects and deviations in the manufacturing process. Furthermore, the model also offers visual tracking and reporting of on-going production with error detection, corrective action, and quality control throughout the wafer processing. Finally, the equipment also offers remote operation capabilities and can be connected to external systems such as Enterprise Resource Planning (ERP) systems. In summary, 280C Aligner System is an advanced wafer testing and metrology unit which is designed to provide reliable and repeatable performance in the inspection, measure and analysis of semiconductor devices. It includes an alignment gantry and a suite of optical and metrology capabilities, as well as process control, tracking and reporting features for increased manufacturer quality and product accuracy.

There are no reviews yet