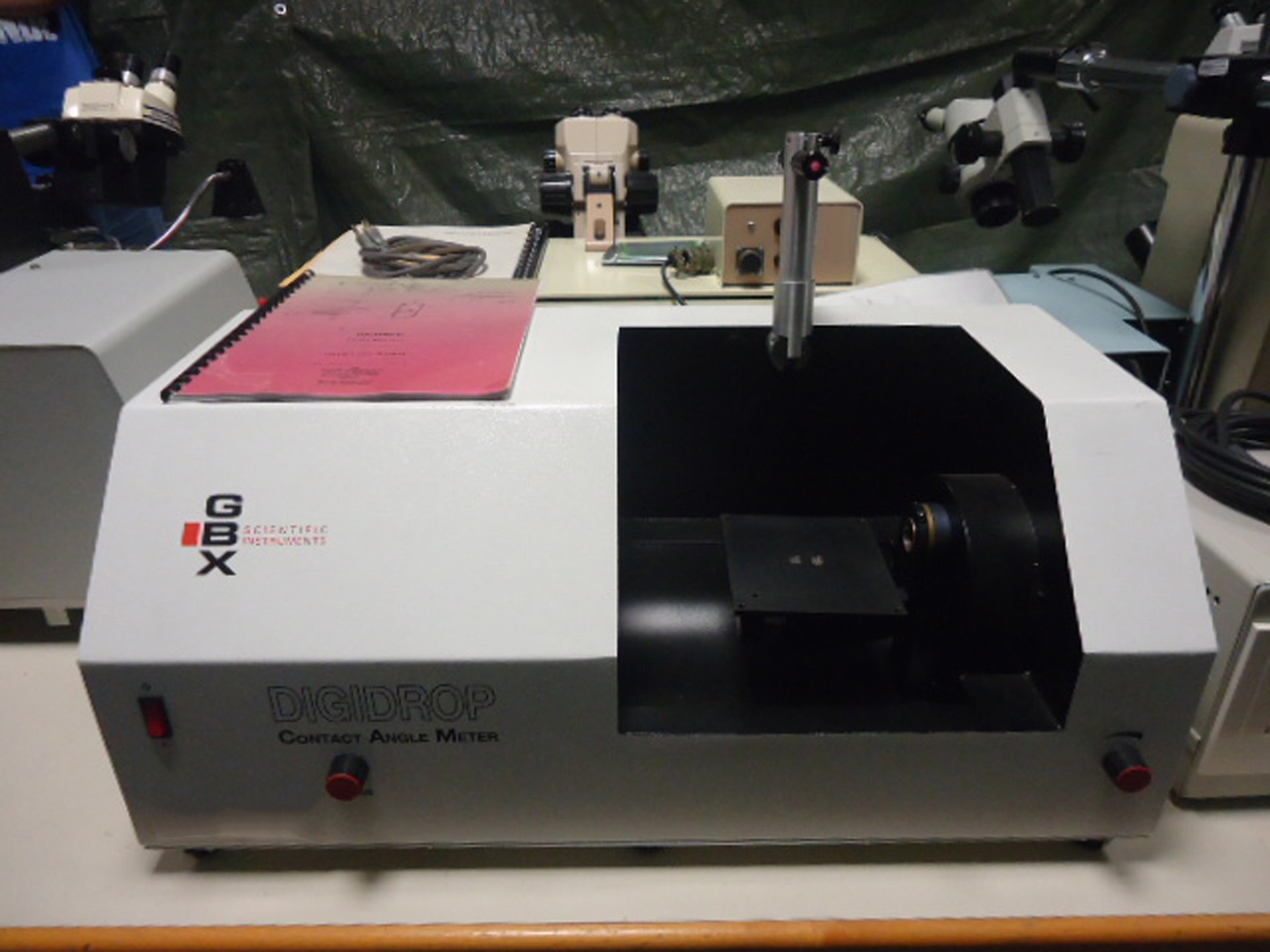

Used GBX Digidrop #9220974 for sale

URL successfully copied!

Tap to zoom

ID: 9220974

Contact angle meter

Reproducibility: 0.1°, 0.01°, 0.001°

Contact angle range: 0 - 180°

Surface energy range: 0 - 1000 mN/m

Contact angle accuracy: +/- 0.1°

Syringes type: Borosilicate glass and plastic.

GBX Digidrop is a fully automated wafer testing and metrology equipment. It has the efficient combination of individual elements to make the best use of devices, software and ergonomics for chip and wafer inspection, characterization and analysis. The system is a one-stop solution for a variety of users adopting wafer processing and testing technologies. It consists of four main components that work together and support each other: an input station, imaging and analysis platform, output station, and a computer-controlled transport unit. The input station is used to accurately locate and maneuver wafers relative to the other components of the machine. It features an adapter tool that supports a huge diversity of wafer sizes, and automated loading and unloading. The imaging and analysis platform consists of an advanced robotic arm and a high-resolution imaging sensor that allows accurate visual inspection, surface topography mapping and defect characterization of any wafer. The asset also ensures accurate metrics such as optical thickness, wafer flatness, scans over the entire surface and defect measurements. The output station, where integrated chips leave the model, includes dedicated jigs and tools in order to ensure the correct orientation of the wafer and align all the products. It also provides high-speed transfer of data, including test results, from the input station, imaging, and analysis platform. Finally, the computer-controlled routing equipment ensures transfer of the wafers between the input station, imaging and analysis platform and output station. In other words, the system can pick, transfer and place wafers to and from any station. Therefore, with a camera unit and a range of testing tools, Digidrop allows both manual and automated testing of wafers in high quantities in a production line. The result is an extremely reliable and accurate machine that offers the ultimate experience in wafer testing and metrology.

There are no reviews yet