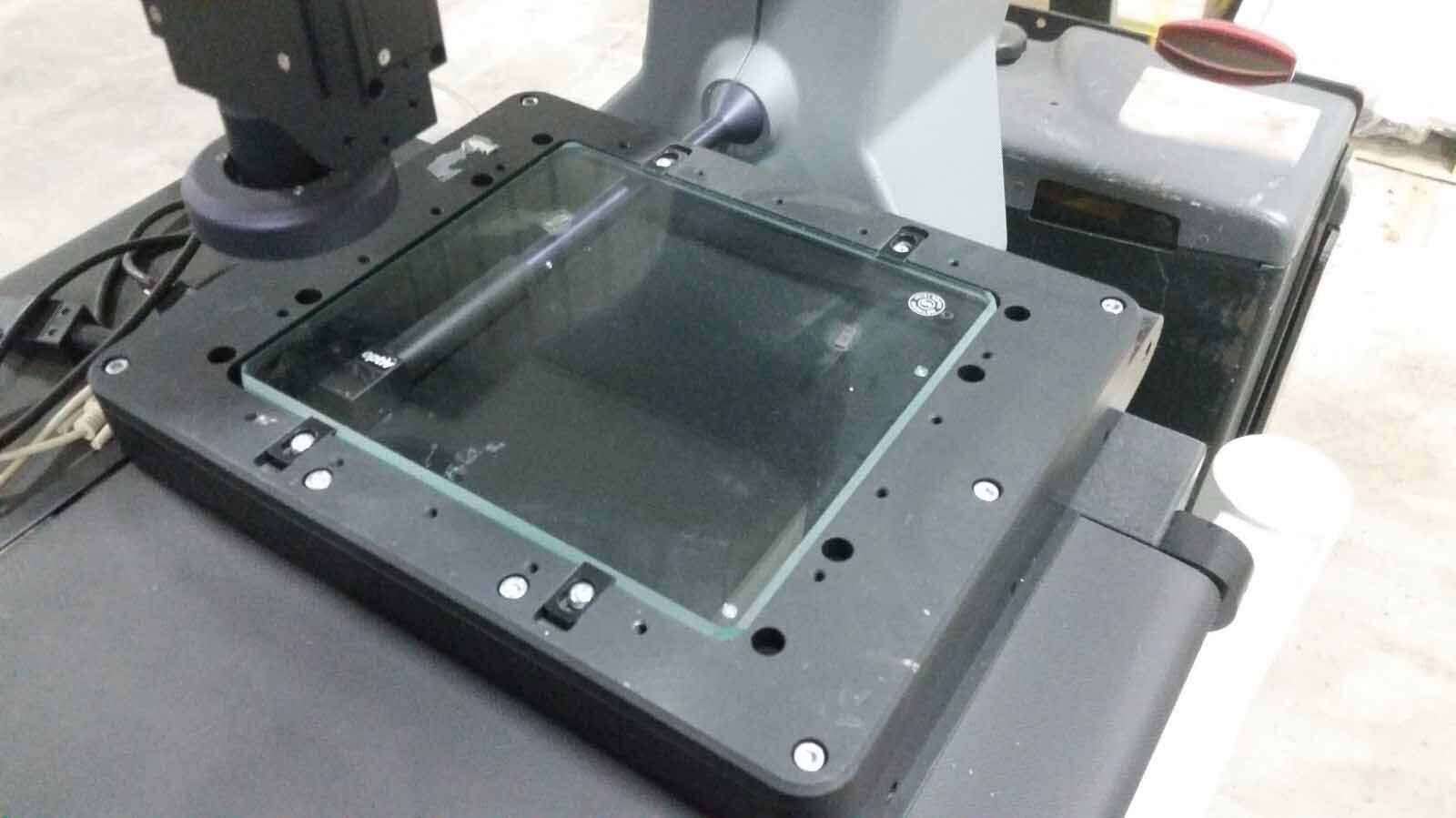

Used HEXAGON METROLOGY Optiv Performance 222 #9177179 for sale

URL successfully copied!

Tap to zoom

HEXAGON METROLOGY Optiv Performance 222 is a highly reliable and precise wafer testing and metrology equipment used in high-end semiconductor production. It enables operators to measure multiple dimensions of wafer features, with a precision of one nanometer. The system provides advanced measurement and control functions, such as non-contact automatic optical alignment techniques, precise motion control for both horizontal and vertical scanning, and multi- directional laser interferometer systems. This allows Optiv Performance 222 to accurately measure wafers in different orientations and positions in relation to the reference surface of the unit. The machine's automatic optical alignment tool uses a laser beam to adjust the alignment between the wafer and the asset stage. This ensures accurate and precise results. Additionally, the model's integrated software allows for real-time data analysis and makes it easy for operators to set up measurement protocols, resulting in faster time to market and increased efficiency. Furthermore, the equipment has an advanced circuit board which enables users to control multiple aspects of the measurement process. This includes scan speed control and scanning direction. By having a direct interface with the measurement environment, users can customize their measurement process to meet their exact requirements. In addition, HEXAGON METROLOGY Optiv Performance 222 utilizes an 8-axis sensor suite and a fieldbus communication system for precise data acquisition. This helps operators to accurately measure multiple dimensions of wafer features, as well as the individual thicknesses of a wafer substrate. Overall, Optiv Performance 222 wafer testing and metrology unit provides high precision measurements, combined with an unrivaled level of customization and control. This makes it an ideal choice for manufacturers who need reliable, accurate, and fast results.

There are no reviews yet