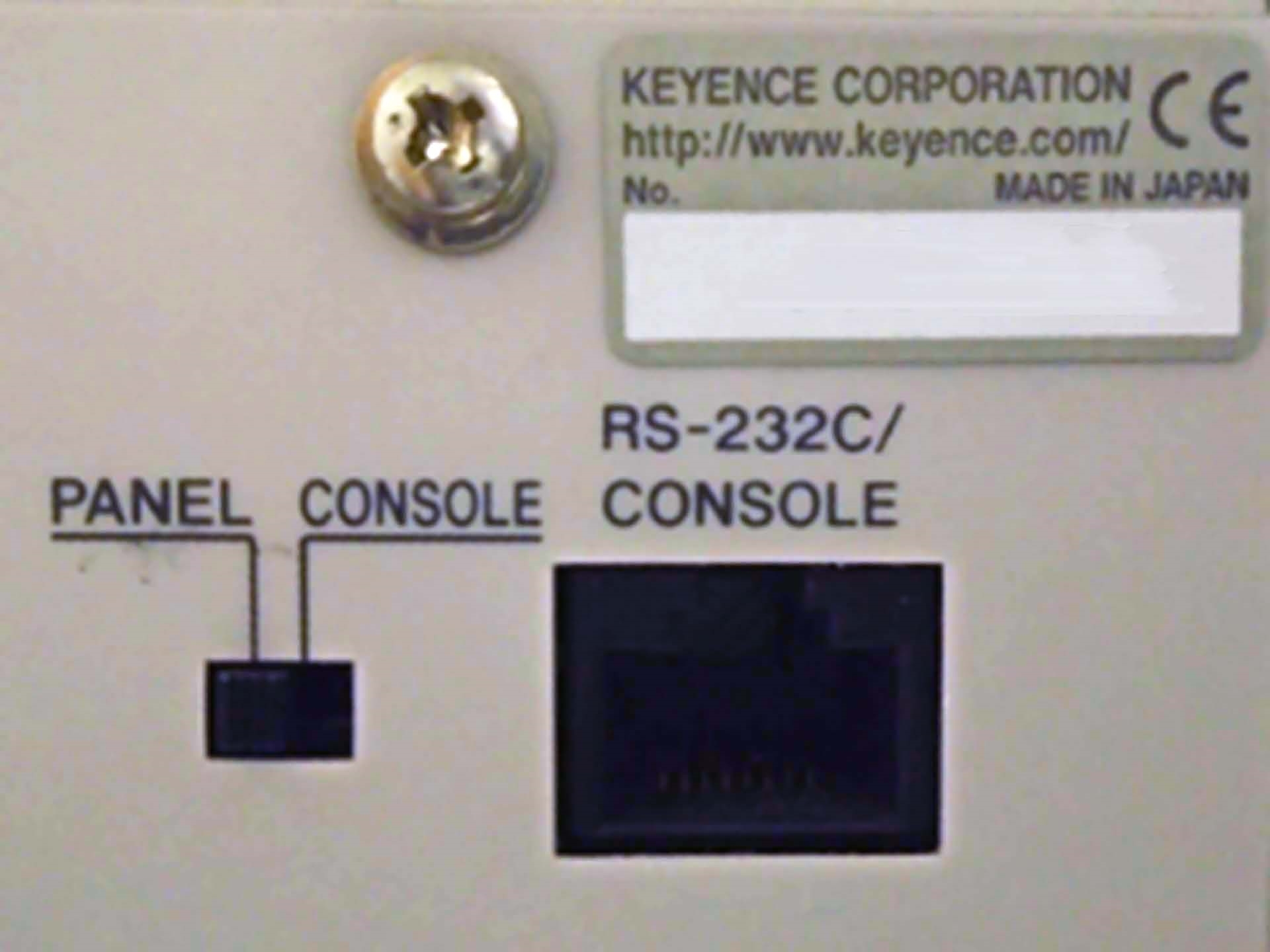

Used KEYENCE LA-2010 #9253571 for sale

URL successfully copied!

Tap to zoom

KEYENCE LA-2010 is a state-of-the-art wafer testing and metrology equipment designed for use in semiconductor manufacturing processes. It utilizes advanced technology to analyze the microscopic characteristics of a variety of wafers, such as silicon, gallium arsenide, and other semiconductors. The system features a wide range of measurements and analysis capabilities, which include nanoscale measurements, 3D imaging, defect analysis, and surface roughness testing. LA-2010 is equipped with two integrated optical systems, one with a SEM (scanning electron microscope) and the other with an interferometric microscope, enabling it to both image and analyze wafers in a variety of ways. This includes the use of SEM imaging, where a focused electron beam scans the surface of the wafer, creating images with a resolution up to 15 nanometers. With the interferometric microscope, KEYENCE LA-2010 can measure the surface topography of the wafer with an accuracy in the nanometer range. The unit's three-dimensional imaging capabilities allow it to accurately identify defects on the wafer. LA-2010 also features a wide range of analysis capabilities, such as defect and surface roughness analysis, as well as image segmentation for detecting layered defects. Using its pattern recognition technology, the machine can accurately identify patterns on the surface of the wafer. This is especially beneficial when evaluating nanoscale layers and structures. Additionally, KEYENCE LA-2010 can measure resistivity and dielectric properties of wafers, as well as generate high-precision digital elevations maps of the surface. LA-2010 is a reliable and powerful tool that can help semiconductor manufacturers ensure the highest quality of their wafers. The asset's comprehensive range of features and analysis capabilities allows for the most accurate inspection and testing of semiconductor wafers. Using KEYENCE LA-2010, manufacturers can quickly and effectively identify defects, analyze wafer characteristics, and ensure that their wafers meet quality standards and customer requirements.

There are no reviews yet